3D printing has revolutionized various industries by offering innovative solutions for design, production, and customization. This article presents ten creative ideas that demonstrate the diverse applications of 3D printing technology. From practical tools to artistic creations, these concepts highlight the potential for 3D printing to enhance functionality and creativity.

The integration of 3D printing into daily life encourages experimentation and personal expression. Readers will discover how these ideas can inspire them to explore the possibilities within this evolving field.

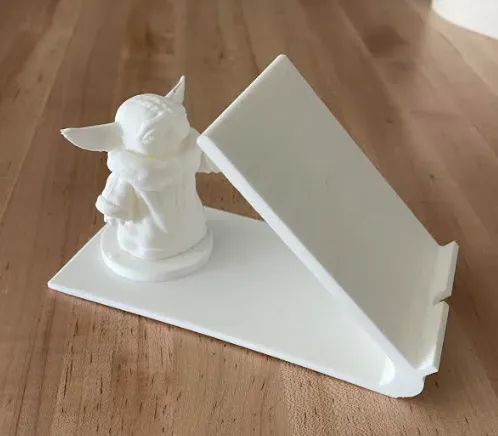

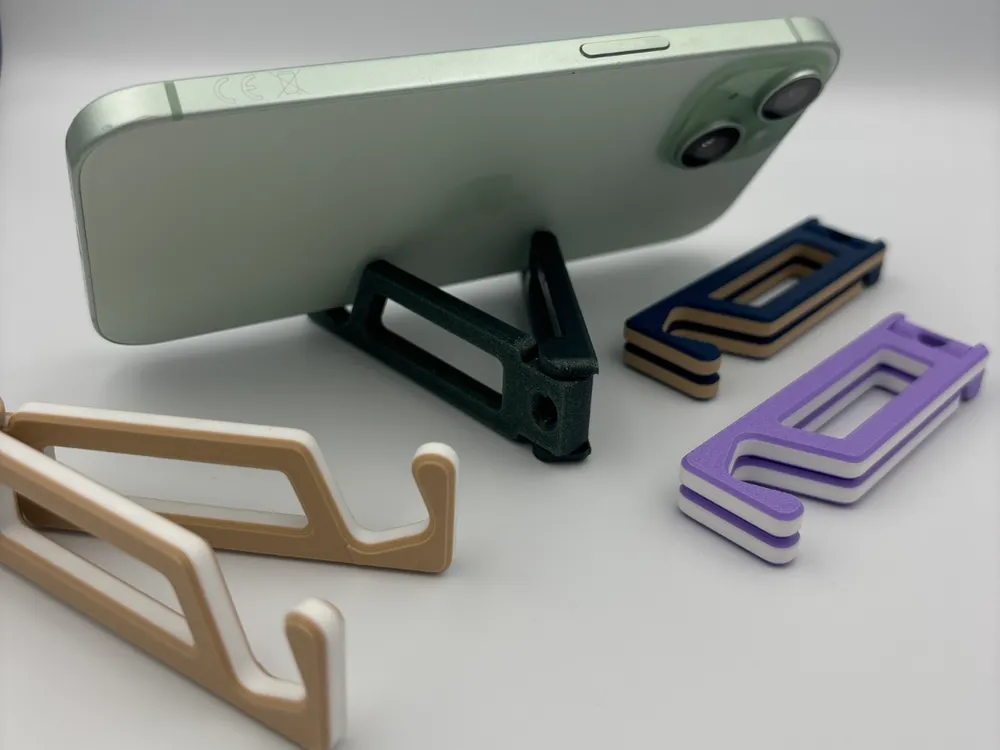

Custom Phone Stand

A custom phone stand is a practical project for 3D printing enthusiasts. It serves to hold smartphones at an optimal angle for viewing and accessibility.

Designing a phone stand can be an opportunity for creativity. Individuals can tailor the dimensions, style, and features to fit specific devices or personal preferences. This customization ensures the stand meets ergonomic needs.

Materials like PLA or ABS are commonly used in 3D printing. These materials provide strength and durability, making the stand suitable for daily use.

Additionally, adding features like cable management or adjustable angles enhances functionality. This makes the phone stand not only unique but also more useful in various settings.

Custom phone stands are versatile. They can be designed for desks, kitchens, or nightstands, catering to diverse lifestyles. The ability to personalize the design also makes it an appealing gift option.

2. Personalized Keychains

Personalized keychains represent a practical and creative use of 3D printing technology. They can be customized with names, initials, or special symbols, making each piece unique.

This customization allows individuals to express their personality. A keychain can also serve as a memorable gift for friends or family. The process is simple, involving design software to create a personalized model, which can then be printed.

The materials used for 3D printing keychains vary. Common choices include plastic, metal, and resin. Each material offers different strengths and finishes, allowing for various aesthetic outcomes.

Additionally, incorporating features like photo engravings or meaningful quotes can enhance personalization. This functionality makes keychains not just decorative items, but also keepsakes.

3D printed keychains can be manufactured quickly and affordably. This accessibility opens up opportunities for small businesses or hobbyists to create unique designs for niche markets.

Desk Organizer

A desk organizer is a practical solution for maintaining an orderly workspace. It can be customized to fit specific needs, making it an appealing project for 3D printing enthusiasts.

These organizers can hold pens, notepads, sticky notes, and other office supplies. They help maximize desk space and improve efficiency by providing easy access to essential items. Diverse designs can reflect personal style and preferences, from minimalistic to elaborate structures.

3D printing allows for unique shapes and configurations. Individuals can create sections for specific tools, making organization more effective. The materials used can also be tailored to the user’s preferences, whether they favor plastic, wood filaments, or other composites.

Creating a desk organizer can be a fun and rewarding project. It combines creativity with functionality and helps develop skills in 3D modeling and printing. This customizable approach ensures that the final product perfectly suits the user’s work habits and aesthetic.

4. Miniature Planters

Miniature planters are a popular choice for 3D printing enthusiasts. They serve as unique decorative elements for homes and offices. These small pots can accommodate a variety of plants, including succulents and air plants.

Creating miniature planters allows for creativity in design. Different shapes, colors, and textures can be incorporated to match any aesthetic. Custom designs can include features such as drainage holes or intricate patterns.

3D printing enables the production of planters that might be difficult to find in stores. It also allows individuals to produce unique gifts or party favors. Miniature planters can be personalized with names or dates, adding a special touch.

The process of 3D printing planters is straightforward. It typically involves selecting a suitable filament like PLA or PETG. After printing, they can be painted or left in their natural state, depending on personal preference.

Miniature planters offer versatility and charm. They can enhance any small space, brightening up desks or windowsills. This makes them an appealing option for both seasoned and beginner 3D printing enthusiasts.

5. Jewelry Organizer

A jewelry organizer made with 3D printing can provide a customized solution for storing accessories. Designers can create compartments tailored to specific items, such as rings, necklaces, and earrings. This ensures that everything remains untangled and easily accessible.

Users can choose different styles and sizes according to their preferences. Some may prefer a wall-mounted organizer, while others might opt for a small desktop version. The flexibility of 3D printing allows for intricate designs that incorporate personal aesthetics.

Materials used in 3D printing can vary from durable plastics to eco-friendly options. This variety lets individuals select an organizer that aligns with their values and decor.

By utilizing 3D printing, one can also create unique designs that reflect personal taste. Customization options extend to colors, shapes, and even engraved names or initials.

Such organizers not only serve a functional purpose but also enhance the aesthetic of a space. They can be practical gifts or a personal DIY project. The result is a neat, organized, and visually appealing way to store jewelry.

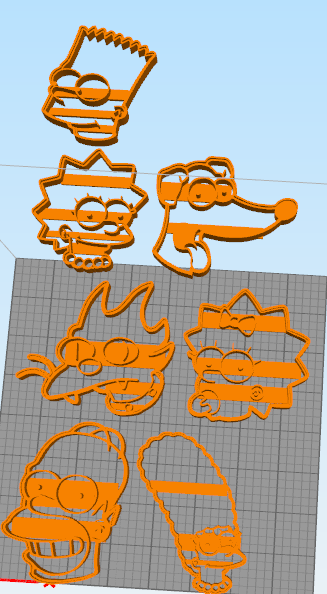

6. Cookie Cutters

3D printing cookie cutters offers a personalized touch to baking. They can be designed in various shapes and sizes, fitting specific themes or occasions.

Creating custom cookie cutters is accessible through various design software. Users can modify existing templates or design unique shapes that reflect personal interests or holiday themes.

Choosing the right material is essential. Food-safe plastics are available, ensuring that cookie cutters are safe to use with dough.

Printing time is usually short, making this an efficient project. After printing, it is advisable to clean the cutters thoroughly before use.

3D printed cookie cutters also allow for easy replication. This can be convenient for large events or parties where many cookies are needed.

Overall, 3D printing cookie cutters is an enjoyable way to enhance baking experiences while adding a creative element to cookies.

7. Desk Name Plate

A desk name plate serves as a professional identification tool in any workspace. It can include a person’s name, title, and even a company logo, providing clarity in an office setting.

Designing a custom name plate using 3D printing allows for unique shapes and styles. Individuals can choose materials, colors, and finishes that align with personal or corporate branding.

With a 3D printer, creating a desk name plate is a straightforward process. One can use design software to create the template and then print it in a single batch, ensuring consistent quality.

These name plates also make great gifts for new employees or for recognition purposes. They add a personal touch to any desk and can be designed to fit any aesthetic.

8. Wall Art

3D printing offers unique opportunities for creating custom wall art. Artists can design intricate patterns and shapes that would be difficult to achieve through traditional methods.

Personalized pieces allow for expression of individuality. They can complement any decor style, from modern to eclectic.

Materials such asPLA orPETG are commonly used for 3D printed wall art. These materials provide durability and a variety of colors.

Hanging installations, sculptures, or even frames can transform a blank wall into a focal point. Many designs can be made with interlocking pieces for added depth and interest.

3D printed wall art can also be functional. Items like shelving or decorative hooks blend practicality with aesthetics.

The process encourages creativity. Artists can experiment with textures, layers, and patterns, pushing the boundaries of artistic design.

9. Headphone Stand

A 3D printed headphone stand offers a practical solution for organizing headphones while adding a personal touch to a workspace. The stand can be designed to fit various headphone shapes and sizes.

Customization is a key advantage. Users can choose colors, styles, and dimensions that match their aesthetic. Many designs incorporate features like cable management to keep cords untangled.

Creating a headphone stand is also a straightforward project for those new to 3D printing. Available templates can be adjusted using CAD software to meet specific needs. This versatility makes the headphone stand a popular choice for hobbyists.

The process of 3D printing such an accessory is generally quick and efficient. Most standard printers can handle the common materials used, such as PLA or ABS. Once printed, the stand can be painted or finished for added durability.

With the ability to create a unique and functional item, a 3D printed headphone stand is a perfect addition for any audio enthusiast.

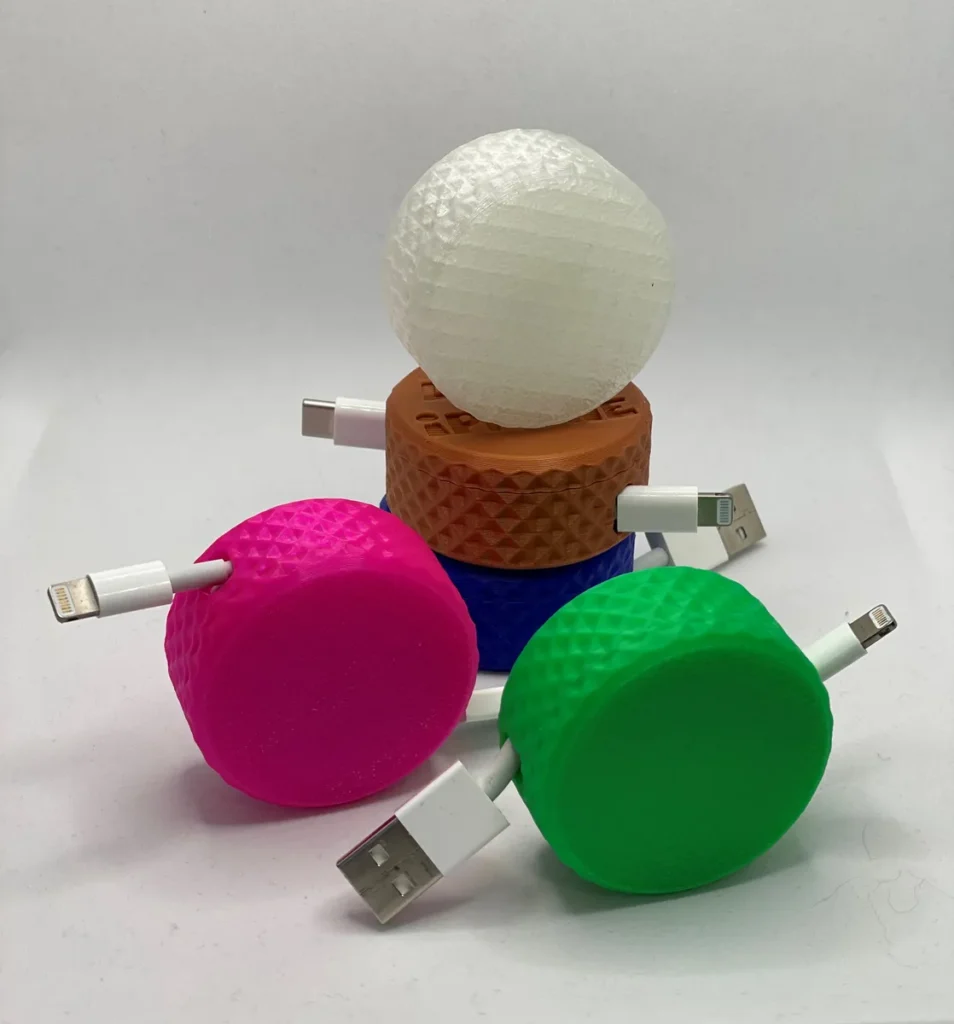

10. Cable Holders

Cable holders are practical 3D printing projects that help organize cables in both home and office settings. They prevent tangling and create a neat appearance around desks and entertainment centers.

These holders can be designed in various shapes and sizes to accommodate different cable types, such as USB and HDMI. Customizable designs allow users to match their aesthetic preferences or color schemes.

3D printing cable holders can reduce clutter and improve efficiency. They are particularly useful for those who work with multiple devices or have a complex setup requiring various cables.

Materials like PLA or ABS are commonly used for these projects, providing durability and strength. The ease of printing allows for rapid prototyping and testing of different designs, making adjustments simple.

Cable holders not only serve a functional purpose but can also enhance the overall look of spaces. With creativity, they can feature personalized designs, logos, or even themed styles to reflect individual tastes.

Understanding 3D Printing

3D printing is a revolutionary technology transforming various industries. It allows users to create three-dimensional objects layer by layer using digital models. Key aspects of 3D printing include its basic principles, types of printers available, and the materials used in the process.

Basics of 3D Printing

The fundamental principle of 3D printing is additive manufacturing. This process involves the layering of material to build an object from a digital file. The digital model can be created through Computer-Aided Design (CAD) software or obtained from a 3D scanner.

A 3D printer reads the digital file and lays down material according to the specified dimensions. It can create complex shapes that traditional manufacturing methods often cannot.

Common applications of 3D printing include prototyping, custom products, and components in various fields such as healthcare, automotive, and aerospace. The technology offers flexibility and efficiency, enabling rapid iterations and modifications during design.

Types of 3D Printers

Several types of 3D printers are available, each suited for different applications and materials.

Fused Deposition Modeling (FDM): This is the most common type, where thermoplastic filament is melted and extruded layer by layer. FDM printers are affordable and user-friendly.

Stereolithography (SLA): This method utilizes a UV light source to cure liquid resin into solid parts. SLA printers produce high-resolution prints with excellent detail.

Selective Laser Sintering (SLS): SLS printers use a laser to fuse powdered material into solid structures. They can handle a variety of materials, including metals and polymers.

Each printer type has its strengths, with FDM being widely used for hobbyist projects and SLA and SLS offering advanced options for professional applications.

Materials Used in 3D Printing

The materials used in 3D printing significantly impact the properties of the final product. Common materials include:

PLA (Polylactic Acid): A biodegradable thermoplastic, easy to print, and available in various colors. Ideal for beginners.

ABS (Acrylonitrile Butadiene Styrene): Known for its strength and durability, frequently used in industrial applications.

Resins: Used in SLA printing, resins can create highly detailed models and are popular in jewelry and dental industries.

Nylon: Strong and flexible, suitable for functional parts. It’s often used in SLS printing.

Understanding these materials enables users to select the most appropriate one for their projects, affecting durability, flexibility, and aesthetic qualities.

Designing for 3D Printing

Creating effective designs for 3D printing involves understanding specific principles of design, utilizing appropriate software, and ensuring compatibility of file formats. These factors significantly influence the success of a 3D printed object.

Basic Design Principles

Designing for 3D printing requires consideration of material properties and the limits of printing technology. Key principles include:

- Support Structures: Consider if the design needs support materials during printing. Overhangs generally require supports.

- Wall Thickness: Maintain sufficient thickness to ensure structural integrity without wasting material. Typically, a minimum of 1-2 mm is advisable.

- Fillet Corners: Rounded edges are smoother to print and reduce stress concentration, which can lead to failures.

- Orientation: Print orientation affects strength and appearance. Reorient parts to optimize finished quality and structural strength.

By integrating these principles, one can create more effective and reliable 3D printed items.

3D Modeling Software

Choosing the right 3D modeling software is crucial for creating successful designs. Popular programs include:

- TinkerCAD: User-friendly and great for beginners. It offers a straightforward interface and essential features.

- Fusion 360: More advanced with parametric design capabilities. Ideal for professional and complex projects.

- Blender: Best for artistic designs and organic shapes. It may have a steeper learning curve.

Each software has unique strengths, so selecting one should align with specific project requirements.

File Formats and Compatibility

File formats play a vital role in the 3D printing process. Common formats include:

- STL (Stereolithography): Widely used, compatible with most slicers. It captures geometry but lacks color data.

- OBJ: Supports color and texture information, suitable for high-detail projects.

- AMF (Additive Manufacturing File): A newer alternative that supports color, texture, and multiple materials.

Ensuring compatibility between design software and 3D printers is crucial. This minimizes file errors and enhances the print’s success rate.

Post-Processing in 3D Printing

Post-processing is essential for enhancing the quality and appearance of 3D printed objects. This stage often involves cleaning, finishing, and applying coatings to achieve the desired final product.

Cleaning and Finishing Printed Objects

After printing, objects typically have residual support materials, filament strings, or surface imperfections. Cleaning these items is critical for aesthetics and functionality. Techniques vary depending on the material used.

Common cleaning methods include:

- Manual removal: Using tools like tweezers or scissors to trim excess material.

- Solvent baths: Submerging prints in solvents to dissolve support materials.

- Ultrasonic cleaners: Efficient for removing fine particles, especially from intricate designs.

Finishing techniques such as sanding, polishing, or applying heat can significantly improve surface quality. Sanding down rough edges or using a heat gun to smooth out layer lines enhances the final product’s appearance.

Painting and Coating Techniques

Adding color and protection to 3D prints often requires specific techniques. Painting can be done using various types of paints compatible with the print material, such as acrylic or spray paint.

Key steps to consider:

- Priming: Applying a primer helps paint adhere better and provides a smoother base.

- Layering: Using multiple thin layers of paint ensures even coverage and prevents drips.

- Sealing: A clear coat adds durability and protects against scratches or UV damage.

Coating techniques may include applying resin for a glossy finish or using specialized coatings for improved heat resistance or waterproofing. Understanding the material properties and desired outcome will assist in choosing the right approach.

Aesthetic Things to 3D Print

In the realm of 3D printing, creating aesthetic things to 3D print offers an excellent opportunity to combine artistry with technology. These items serve not only functional purposes but also enhance the visual appeal of any space. From decorative ornaments to stylish accessories, the possibilities are vast and inspiring.

Artistic Vases and Planters

Design unique vases and planters that feature intricate patterns or minimalist styles. These aesthetic things to 3D print can elevate the ambiance of a room, adding a touch of elegance and personality. Customizable in various sizes and shapes, they allow for personal expression while showcasing craftsmanship.

Elegant Jewelry and Accessories

Create bespoke jewelry pieces such as earrings, pendants, or bracelets with detailed designs. These aesthetic things to 3D print enable personalization with different textures, motifs, and finishes. They serve as distinctive fashion statements that reflect individual style.

Decorative Wall Art

Produce intricate wall hangings or geometric sculptures that act as focal points in interior decor. These aesthetic things to 3D print can be tailored to match specific themes or color schemes, transforming blank walls into captivating art displays.

Stylish Desk Accessories

Design sleek desk organizers, pen holders, or paperweights that combine functionality with visual appeal. Such aesthetic things to 3D print contribute to a sophisticated workspace environment while expressing artistic sensibilities.

Customized Home Decor Items

Create personalized picture frames, candle holders, or figurines that add charm and character to living spaces. These aesthetic things to 3D print can be customized in terms of design, color, and size, making each piece uniquely suited to its environment.

Engaging in the creation of aesthetic things to 3D print allows enthusiasts and artists alike to explore their creativity while producing visually stunning items that enhance everyday life.

- 1.7Kshares

- Facebook0

- Pinterest1.7K

- Twitter0

- Reddit0