3D printed toys are transforming the way you and your family can access, customize, and enjoy playtime. With a 3D printer, you can create unique toys at home, offering endless possibilities for personalization and creativity. The wide selection of downloadable designs ranges from action figures to puzzle games, making it easy to find something for every age and interest.

You don’t need advanced skills to get started—just select a design file, print, and assemble. This simple process gives you the flexibility to try out new trends or even print replacement parts for broken toys. As 3D printing technology grows, your options for creating innovative and interactive toys will continue to expand.

Key Takeaways

- 3D printed toys offer accessible customization for at-home play.

- The process involves selecting, printing, and assembling your chosen designs.

- Growing technology means more options and innovations in the future.

What Are 3D Printed Toys?

3D printed toys are created using specialized printers that build objects layer by layer from digital designs. This process allows for a level of customization and creativity not typically found with conventional toy manufacturing.

Definition and Key Features

A 3D printed toy is an object designed to be played with, produced directly using 3D printing technology rather than traditional molding or assembly. You start with a digital model, usually made with CAD (computer-aided design) software, and send it to a 3D printer.

The printer uses materials such as plastic filament, resin, or occasionally even flexible polymers. Layers are printed in succession, fusing together to create the final shape.

Some key features include:

- Customization: Design unique toys or modify existing models to fit your preferences.

- Rapid prototyping: Print parts and figures quickly for play or testing.

- On-demand manufacturing: Create toys as needed, reducing waste and storage requirements.

- Variety: Print everything from simple puzzles to moveable action figures.

This approach has influenced how the toy industry approaches design, manufacturing, and user interaction with toys.

Benefits Over Traditional Toys

With 3D printed toys, you have the ability to create items tailored exactly to your interests or needs. The process often costs less than buying specialty items, especially for custom parts or prototypes.

There’s no need for mass production—produce only the toys you want, when you want them. You also avoid shipping delays for specific toys, since digital designs can be downloaded instantly and printed at home or in a local maker space.

Repairs and replacements are easier; if a piece breaks, you can reprint just that part instead of buying a whole new toy. This model supports educational opportunities too, as it encourages learning about design, engineering, and technology in a practical setting.

Many families and hobbyists appreciate the ability to experiment with new ideas without large upfront costs. These factors have driven significant change in the toy industry and have made 3D printers more common in educational and creative environments.

How 3D Printed Toys Are Made

Creating 3D printed toys involves digital design, material selection, and the printing process itself. These steps let you control every aspect of your toy, from the initial prototype to the final product.

Design and Prototyping Process

The process starts with creating a digital 3D model using CAD (computer-aided design) software such as Blender or Tinkercad. If design isn’t your strength, you can download pre-made toy files from online libraries or marketplaces.

After designing, you typically create a prototype by printing a first version of your toy. This lets you check for design flaws or mechanical issues before producing more copies. Many designers test function, fit, and movement at this stage.

You may need to go through several iterations, refining the digital file and reprinting until you’re satisfied. This rapid prototyping process is one of the key benefits of 3D printing for toy making.

Materials Used in 3D Printing

Most 3D printed toys are made from thermoplastics. The most common materials include:

| Material | Features | Typical Uses |

|---|---|---|

| PLA | Biodegradable, easy to print | Figurines, display toys |

| ABS | Durable, heat resistant | Moving parts, playsets |

| PETG | Flexible, food-safe | Sturdy toys, tools |

Filament is the usual form, fed into the printer where it is melted and layered to form the toy. Some toys may incorporate specialty filaments, such as glow-in-the-dark or flexible TPU, to add unique effects.

Role of 3D Printing Services

If you do not own a 3D printer, you can use a 3D printing service to produce your toys. These services allow you to upload your digital files and select your material preferences.

A 3D printing service will print the toy and ship it to you. Some platforms also provide access to libraries of downloadable toy designs and help with file preparation.

Using professional services can be helpful for complex projects or high-quality results. You can also scale up production if needed, making it a practical option for both hobbyists and small businesses.

Customization and Personalization

3D printed toys offer a wide range of ways to create unique and individualized play experiences. The flexibility provided by modern 3D printers allows you to adapt toys to specific interests, needs, or preferences.

Options for Customizing Toys

You can choose from a variety of customization options with 3D printing. Popular methods include adjusting toy size, shape, and color before printing. Many online platforms, like Toybox or specialized Etsy shops, provide interfaces where you can tweak designs or add personal touches such as names or favorite colors.

Makers often use 3D modeling software to design unique features, from movable parts to accessories that fit existing toys. If you are not comfortable with design software, pre-made templates and modular building sets are available to help. Some makers offer to customize and print toys for you, giving you results tailored to your exact specifications.

A simple table summarizing customization options:

| Customization Option | Description |

|---|---|

| Size & Scale | Choose the toy’s dimensions |

| Color & Material | Select filament colors |

| Name Personalization | Add custom text or details |

| Accessories | Design add-ons or props |

| Modular Components | Mix and match parts |

Impact on Creativity and Play

Personalization has a direct impact on how you and your children interact with toys. With control over the toy’s appearance and features, you can create characters or objects that reflect personal interests or stories, increasing engagement and attachment to the toy.

Makers use these features to foster imagination and problem-solving. Children can participate in the design process, deciding on features, colors, or even creating their own blueprints. This involvement promotes critical thinking and can introduce basic principles of engineering and design.

Having a 3D printer at home or access to one in a makerspace allows you to experiment with new designs or quickly adapt old toys. The iterative process of designing, printing, and refining a toy supports both learning and play, encouraging hands-on creativity without depending solely on mass-produced options.

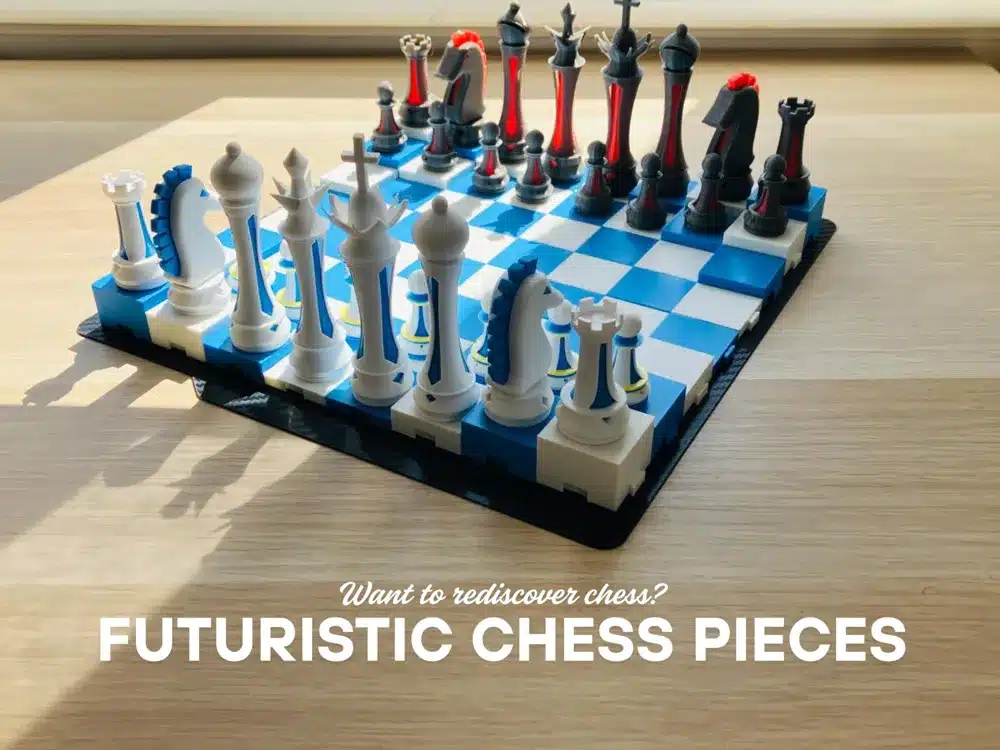

https://makerworld.com/en/models/1446065-futuristic-chess-pieces#profileId-1505839

Popular 3D Printed Toy Types and Trends

3D printing technology is changing the landscape of toys, allowing for customized designs, rapid prototyping, and new forms of creativity at home and in industry. Trends now include detailed action figures, innovative educational tools, and collaborations with well-known brands.

Action Figures and Props

Many hobbyists and collectors use 3D printing to produce action figures and props from popular franchises, movies, and games. You can find designs inspired by characters like the Terminator T-800 or create custom miniatures for your favorite tabletop campaigns.

Flexibility in materials enables you to print articulated joints and fine details. Props such as replica weapons, helmets, and cosplay accessories are common projects, giving you the opportunity to personalize designs. Fans of brands like Disney can find character models or themed items available through community repositories or licensed projects.

Internationally, designers from regions including China contribute a significant number of models, making for a diverse selection. Websites such as Printables.com and featured collections on dedicated toy printing platforms frequently showcase trending action figures, showing what is popular among enthusiasts.

Educational Toys

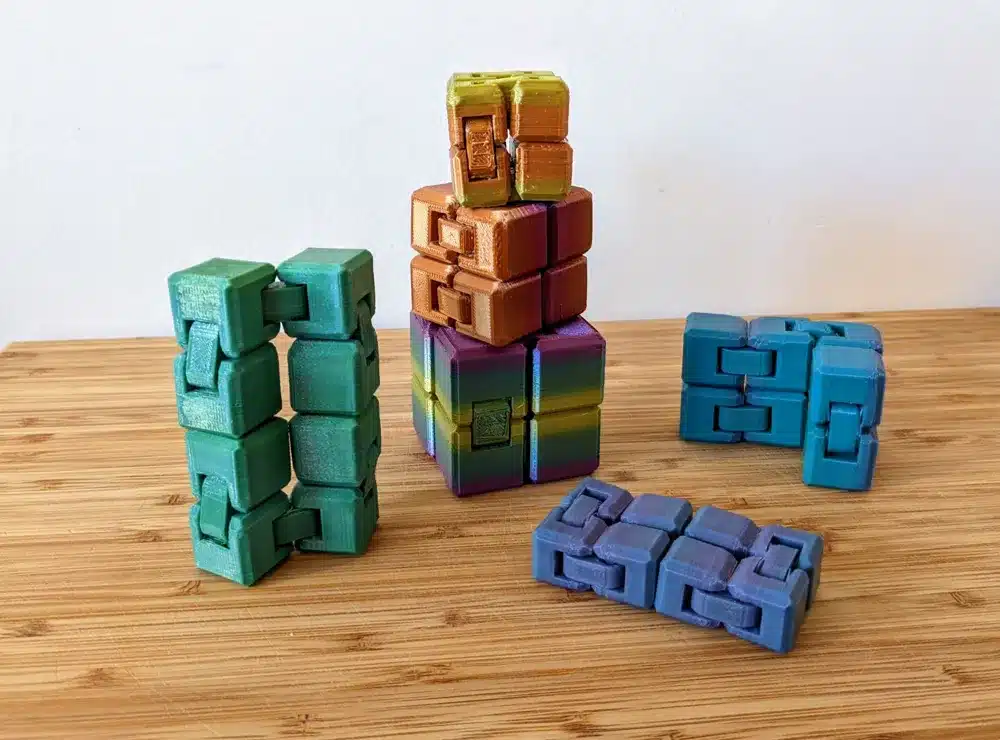

Educational toys are a leading trend in the 3D printing community due to the focus on creativity and hands-on learning. You can print puzzles, cube games, stacking toys, and mechanical models for science, engineering, or math education.

Many teachers and parents use 3D printed tools to make abstract concepts easier for children to grasp. For example, gears and simple machines can be printed and assembled to teach mechanical principles. Cube puzzles or fidget toys like clicker wheels provide interactive learning and fine motor skill development.

Customizing toys for specific age groups or learning objectives is easy. In China and elsewhere, such toys are used in classrooms and maker spaces. The rapid prototyping abilities of 3D printing allow you to iterate designs quickly based on feedback from students or children.

Collaborations with Brands

Major brands are entering the 3D printed toy market, often making official digital files available or teaming up with printing platforms. Disney, for example, has explored releasing licensed models for personal use, letting you print characters or themed playsets at home.

Toy companies such as Mega have collaborated on limited-edition digital parts or expansion sets, enhancing existing brands with new accessories. This approach makes it possible for you to personalize or expand collections more easily.

Collaborations are not limited by geography; global companies work with designers from various countries, including China, to reach wider markets. Partnerships have also encouraged the development of higher-quality, branded designs that maintain uniform standards regardless of where you print.

Future of 3D Printed Toys

3D printing is influencing how toys are designed and experienced, not only creating new possibilities for customization but also changing who can manufacture and sell toys. Emerging technologies are set to affect both how children interact with toys and how the global market operates.

Integration with AR Technology

The merging of 3D printed toys with augmented reality (AR) is turning physical objects into interactive learning tools. When you pair printed toys with AR apps, children can unlock digital content like animations, stories, and educational games using smartphones or tablets.

Manufacturers are starting to embed visual markers or QR codes directly into 3D printed toys. This lets devices recognize and enhance these toys instantly.

This approach allows for updates and new experiences without physically replacing the toy. For example, a dinosaur model could come alive with facts and sound effects through an app, offering extra value for both education and entertainment.

AR integration is expanding the utility of simple, plastic models. It provides richer experiences while keeping the physical design straightforward and cost effective.

https://makerworld.com/en/models/1440271-mario-piranha-plant#profileId-1498987

Influence on the Global Toy Market

3D printing is shifting traditional toy manufacturing by enabling rapid prototyping and localized production. In China, one of the world’s largest toy producers, companies are adopting 3D printing to shorten development cycles and respond faster to market changes.

This technology enables small businesses and individuals to create and sell toys with minimal up-front investment. You can personalize toys for unique markets or individual tastes, which traditionally required large-scale manufacturing.

As digital files for toys can be shared globally, established companies may face new competition from independent designers worldwide. Localized production can also reduce shipping needs, impacting pricing and supply chains across regions.

These changes may disrupt established brands and lower barriers for entering the industry, leading to a more diverse and competitive global toy market.

- 0shares

- Facebook0

- Pinterest0

- Twitter0

- Reddit0