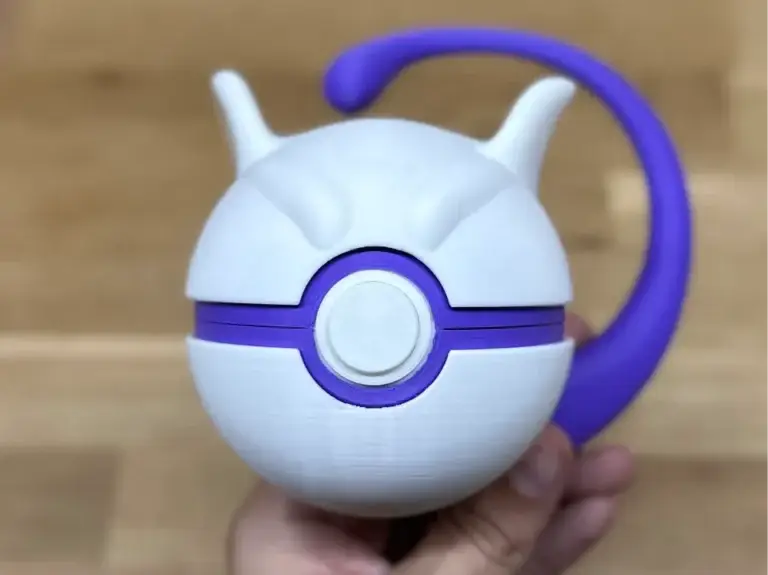

3D printing has become an exciting way for people to create toys at home, opening up new opportunities for customization and creativity. With a 3D printer, anyone can design and produce unique toys that are both affordable and fun for all ages. Families, hobbyists, and collectors are increasingly using this technology to make playtime more engaging.

These toy ideas show how accessible and versatile 3D printing has become. By exploring top suggestions, readers can discover new projects that suit different interests and skill levels.

1) Spinning Tops with Orbital Bases

Spinning tops with orbital bases have become a popular choice for 3D printing toy enthusiasts. These tops emphasize creative design by shifting their weight distribution toward the outer edge. This arrangement takes advantage of centrifugal force, resulting in easier spinning and longer-lasting rotations.

The orbital base style is not just aesthetically unique, but it also improves performance during play. Tops with this design are often stable and can keep spinning on various flat surfaces. The spinning action and the visible movement around the center make these toys visually engaging.

Many designs are available for download, ranging from simple single-piece to multi-part models. Some versions include extras such as launchers or holes for inserting strings, making them more interactive for users. These features provide opportunities to experiment with different launching methods for optimal spin.

Due to their simple shape and minimal material usage, spinning tops with orbital bases are quick to print and assemble. They serve as accessible and fun projects for both beginners and experienced 3D printing users

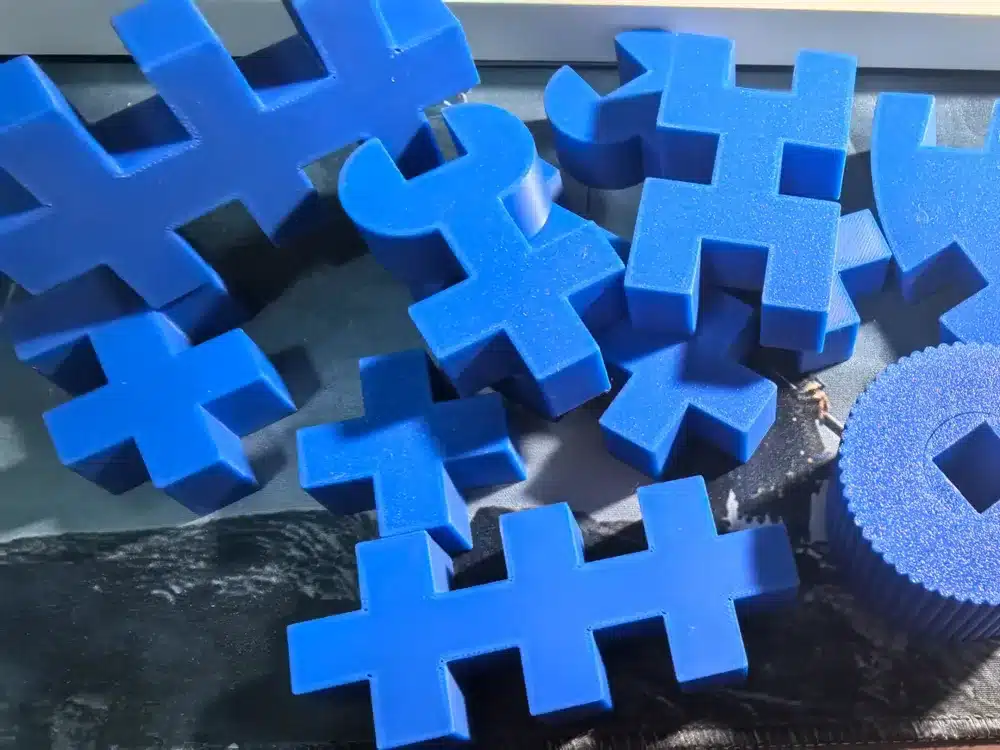

2) Customizable Puzzle Cubes

Customizable puzzle cubes are a popular 3D printing toy option for people of all ages. These cubes often feature multiple interlocking pieces that require assembly in a specific sequence, providing a satisfying challenge for users.

Unlike standard jigsaw puzzles, puzzle cubes utilize three-dimensional geometry. Users can select from various designs, including classic interlocking cubes and sliding piece variants. Many designs allow for customization of piece shapes, colors, or even sizes.

Some models include as few as eight pieces, while others can be much more complex. This flexibility makes puzzle cubes suitable both for beginners and those seeking a greater challenge.

They are practical for teaching spatial reasoning and problem-solving skills. PLA is commonly chosen for printing puzzle cubes due to its safety and ease of use, as noted in recent discussions within the 3D printing community.

Printing and assembling these cubes can also be a collaborative activity for families or groups. Puzzle cubes are widely available as STL files online, giving users plenty of choices to match their skill and interest levels.

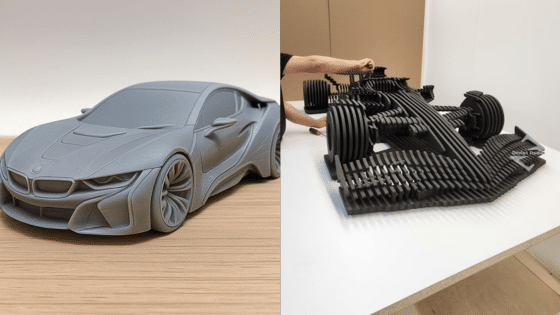

3) Interlocking Building Blocks

Interlocking building blocks are a favorite project among 3D printing enthusiasts. These blocks are designed to fit together securely, allowing users to build stable structures in a wide variety of shapes and sizes.

Many models are inspired by popular construction toys but feature unique connector styles, such as pegs or clips, that offer new assembly techniques. Some 3D-printed designs, like PrintABlok, even allow for connections in all six directions, making them versatile for creative projects.

Printing these blocks at home provides the freedom to customize shapes, colors, and sizes. It also lets users print replacement or special pieces as needed, which is useful when building large or complex creations.

Interlocking blocks printed with a 3D printer are useful for educational purposes, as children can explore concepts in geometry and engineering while having fun. There is a wide availability of free and paid designs, so those interested can easily find files to start printing.

4) Articulated Robot Figures

Articulated robot figures are popular choices among 3D printing enthusiasts. These toys feature moving joints, allowing them to pose in multiple positions. Their design often mimics mechanical or humanoid robots, making them appealing for both play and display.

The printing process usually involves separate parts for the limbs, head, and torso. Once printed, these parts can be assembled using snap fits or small hardware to create movable joints. This modular approach adds an extra layer of engagement, as users put the figure together themselves.

Many designs focus on durability and smooth articulation. Some incorporate detailed features, like gears or armor panels, to enhance visual appeal. They come in various sizes, from small pocket-sized toys to larger models better suited for shelves.

Articulated robot figures can be customized in color or style depending on the filament used. They are suitable for children interested in robotics as well as adult hobbyists. The final result is a poseable robot toy that encourages creativity and hands-on exploration.

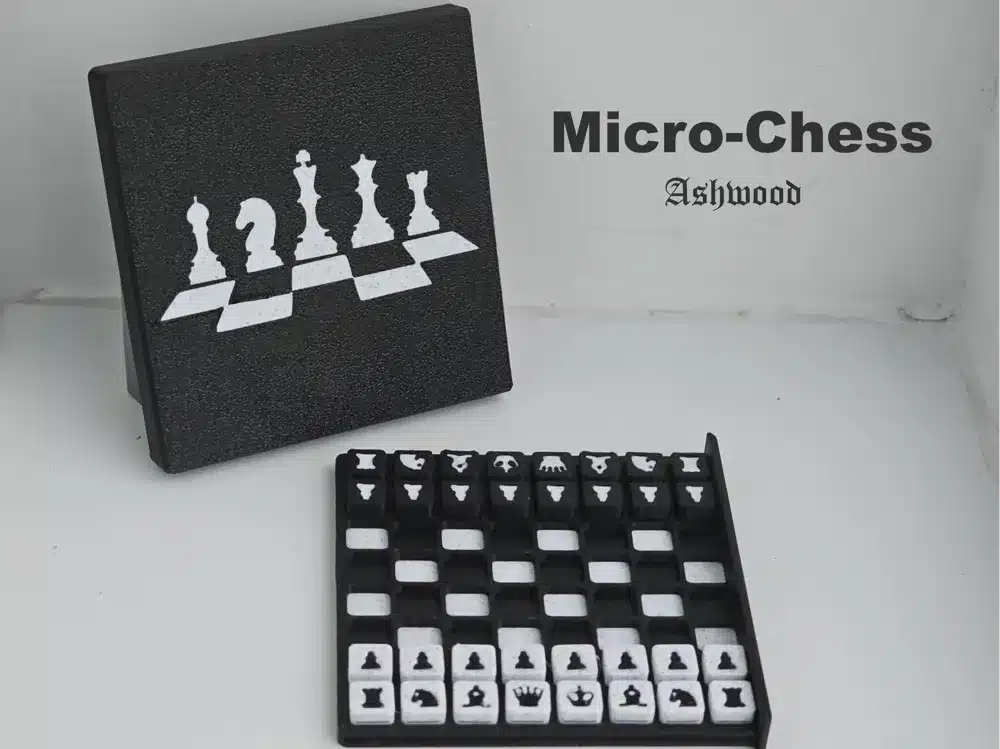

5) Miniature Chess Sets

Miniature chess sets are a popular project for 3D printing enthusiasts. These sets can be made compact enough for travel or display, making them both practical and decorative.

A wide variety of chess piece designs are available, ranging from classic styles to themed sets. Users can choose or modify designs to fit their personal preferences.

Many designers also offer 3D models for printable boards. This means users can create a complete, portable chess set, entirely from their 3D printer.

Miniature chess pieces require attention to detail for successful printing. This provides a manageable challenge for both beginners and experienced makers.

The versatility of 3D printing allows for unique customizations, such as changing the size, style, or materials used for each piece. Some people even design sets to scale for dollhouses or dioramas.

Chess sets created this way can be used for regular play, gifts, or collecting. Most sets are designed to be easy to assemble, and many files are freely available for download.

https://makerworld.com/en/models/741274-micro-travel-chess-set?from=search#profileId-673692

6) Wind-up Mechanical Cars

Wind-up mechanical cars are a popular 3D printing toy. These miniature vehicles operate using a simple spring mechanism that is wound up by hand. When released, the stored energy turns the gears and makes the car move forward.

Many designs are available for download online, suited for a range of printing skills. Some feature a 16:1 gear ratio, offering a straightforward example of mechanical movement. These projects can be adjusted for speed and distance by tweaking the internal gears and spring tension.

Wind-up cars are typically printed in several parts that snap or slot together. Some models include print-in-place features, where the car is printed as a single piece with moving parts already assembled. This reduces the need for post-print assembly and small hardware.

Printing wind-up cars is a practical way to learn about gears, springs, and basic mechanics. They are also child-friendly and can be enjoyed at home or in educational settings. The simplicity of their design makes them accessible even for those new to 3D printing.

7) Animal-Shaped Keychains

Animal-shaped keychains are popular 3D printing projects that appeal to a range of ages. They are small, making them quick and inexpensive to produce on most desktop printers.

There is a wide variety of animal designs available, from simple outlines to more detailed models. Some popular choices include foxes, cats, monkeys, penguins, lions, and elephants. Many of these designs require little or no support, which helps save on material and post-processing time.

These keychains are often used as gifts, backpack accessories, or party favors. Users can personalize them by resizing or adding names and initials. Animal-themed keychains work well as small print tests when calibrating a 3D printer.

Designers frequently share free STL files for animal keychains online. This makes it easy for beginners or experienced users to find and print new designs without starting from scratch. The compact size and straightforward shapes help ensure reliable prints, even on entry-level machines.

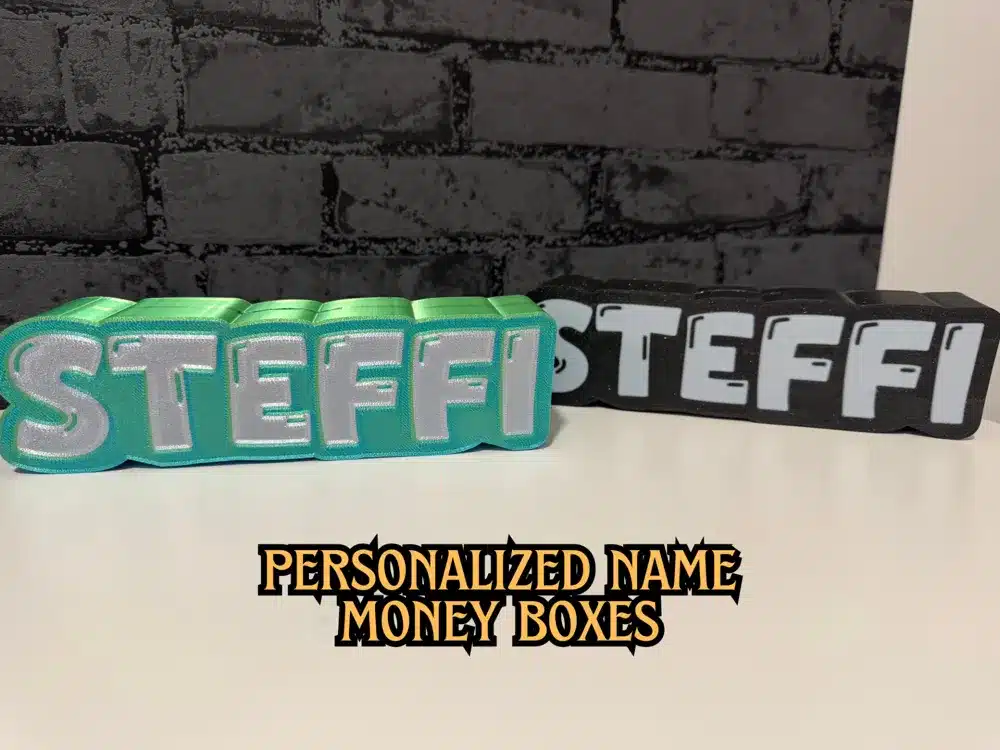

8) Personalized Name Badges

Personalized name badges are a practical and fun idea for 3D printing enthusiasts. They can be designed with custom names, titles, or shapes, making them suitable for events, workplaces, or children’s parties.

Many online platforms offer downloadable STL files or name tag generators to help users create badges that reflect their own style. The ability to print in various colors and materials allows for further customization.

3D printed name badges are usually lightweight and durable. Attachments like safety pins or magnetic backings can be added after printing to make them easy to wear.

Printing personalized badges is also a useful project for those new to 3D design and printing. It allows users to practice simple modeling and labeling skills while producing a tangible and usable product.

Design Considerations for 3D Printed Toys

Safe, durable, and suitable toy design requires careful selection of materials, age-focused features, and flexible customization options. Each of these factors directly affects the toy’s safety, user enjoyment, and creative appeal.

Material Safety and Durability

Material selection determines both the toy’s longevity and user safety. PLA filament is often preferred because it is non-toxic and biodegradable, making it suitable for children’s toys. ABS is more durable but can release fumes during printing and may require extra ventilation.

Durability is equally important, especially for toys that face frequent handling or rough play. Thicker wall thicknesses and reinforced structures help prevent breakage. Avoid designs with thin, fragile components for anything intended for children under 10.

The table below outlines common materials:

| Material | Safety | Durability | Common Use |

|---|---|---|---|

| PLA | Non-toxic | Moderate | Kids’ toys |

| ABS | Toxic fumes | High | Collectibles, adult use |

| PETG | Food-safe | High | Moving parts, tougher pieces |

Toys should also avoid sharp edges or loose parts that could pose a choking hazard.

Age Appropriateness

The target age group should shape every part of a toy’s design. For infants and toddlers, choose simple shapes with large dimensions and avoid any detachable small parts. Toys for older children can have more intricate mechanisms or small pieces, but all moving parts should be securely enclosed.

The following points are critical for age appropriateness:

- Small Parts: Avoid for children under 3.

- Mechanical Features: Use only for ages 6+ with clear safety instructions.

- Decorative Elements: Painted or coated finishes should be non-toxic even if not meant for mouthing.

Designers can refer to established safety guidelines such as ASTM F963 or EN71 to inform decisions.

Customization Options

3D printing enables high levels of customization, allowing toys to be adapted for personal preferences or special needs. Modular designs can let users swap components, and custom names or colors can be added easily before printing.

Customizable toys are not just more engaging; they can also be adjusted for left-handed or differently-abled users. Design files can include variant options, for example, wheels that click in or animal figures with interchangeable heads.

Simple customization ideas include:

- Custom Engravings: Names, birthdays

- Color Variations: Print in multiple colors or add accents post-print

- Modular Parts: Swappable limbs or accessories

A clear labeling system for users to select features ensures the process is accessible, even for beginners.

Tips for 3D Printing Toy Prototypes

Successful toy prototypes depend on careful print settings and detailed post-processing. Quality, safety, and durability improve significantly when the right steps are followed.

Optimizing Print Settings

Selecting the correct filament is essential. PLA is often recommended for toy printing because it is non-toxic and user-friendly. A layer height of 0.1–0.2 mm offers a good balance between detail and print speed.

Infill percentage affects strength—20–40% works well for most toys. More infill means stronger toys but uses more filament and time. Print temperature should match the filament, usually around 200°C for PLA.

Supports must be enabled for overhangs to avoid drooping. Printing at a slower speed (40–60 mm/s) raises accuracy, especially for parts with tight tolerances. Printing multiple prototypes may require slight tweaks in each run.

Finishing Techniques

Post-processing can improve toy appearance and safety. First, remove any supports and sand rough edges with fine-grit sandpaper. Smoothing seams reduces the chance of scratches or sharp corners.

For a glossy surface, use a polishing compound or apply a food-safe clear coat. Painting can add color, but ensure paints are non-toxic if toys are for children. For moving parts, consider lightly lubricating joints with food-grade mineral oil.

Assembly of multi-part toys should use non-toxic adhesives if required. Always check for loose pieces to prevent choking hazards, especially with toys for younger children.

Recommended Tools:

| Step | Tool/Material |

|---|---|

| Support Removal | Needle-nose pliers |

| Smoothing | Fine-grit sandpaper (400–800) |

| Polishing | Plastic polish, soft cloth |

| Painting | Non-toxic acrylic paints |

Testing each finished prototype for durability and safety is recommended before use or distribution.

- 2shares

- Facebook0

- Pinterest2

- Twitter0

- Reddit0