Modern industrial spaces combine practicality with smart design to meet today’s business needs. They focus on efficiency, flexibility, and the use of new technology to improve operations. These spaces are no longer just simple warehouses or factories but are built to support modern workflows and safety.

These areas often include open layouts, durable materials, and energy-saving features. This makes them adaptable for various industries and helps companies save time and resources. The shift in design also reflects a stronger focus on worker comfort and environmental impact.

Key Takeaways

- Modern industrial spaces are designed for efficiency and flexibility.

- New technology and smart design improve workplace operations.

- Sustainability and safety are important in these spaces.

Defining Modern Industrial Spaces

Modern industrial spaces combine functionality with updated design and technology. They focus on efficiency, flexibility, and adapting to current business needs.

Core Characteristics

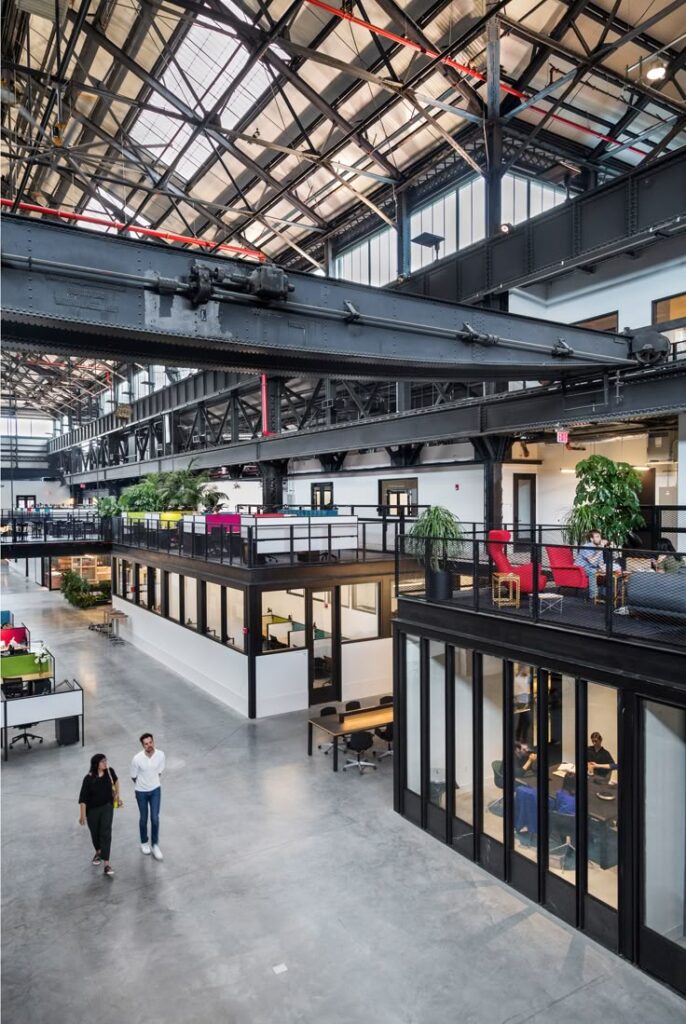

Modern industrial spaces use open floor plans to maximize usable area. High ceilings and large doors support heavy machinery and easy movement of goods. Durable materials like concrete and steel are standard for safety and longevity.

Energy efficiency is common, with LED lighting and smart HVAC systems reducing costs. These spaces often have advanced electrical setups to handle modern equipment. Accessibility for trucks and employee parking is also important for smooth operations.

Historical Evolution

Industrial spaces once centered on manufacturing with fixed, machine-heavy layouts. Over time, the shift moved toward warehousing and distribution due to e-commerce growth. This change required more adaptable buildings with fast loading docks and technology integration.

Older factories had limited technology; now, automation and robotics impact design significantly. Buildings also evolved to meet stricter safety and environmental rules. The focus moved from just production to supporting a broad range of industrial activities.

Key Components

A few parts define modern industrial buildings:

- Loading docks: Designed for quick loading/unloading.

- Clear height: Usually 24-36 feet for stacking and equipment.

- Floor load capacity: Strong floors to hold heavy machines and inventory.

- Office space: Often built inside or adjacent for management.

- Technology: WI-FI, security cameras, and climate control systems.

These components make the space ready for current industrial demands. Flexibility to adapt layout is essential.

Market Trends

Growing e-commerce drives demand for distribution centers near cities. Sustainability is a growing focus, with solar panels and green building certifications becoming common.

Companies want spaces with easy upgrades for new technology. Multi-tenant buildings are increasingly popular, offering smaller spaces with shared amenities.

Rental rates fluctuate by region but tend to rise near transport hubs. Flexibility and location remain top factors in leasing decisions.

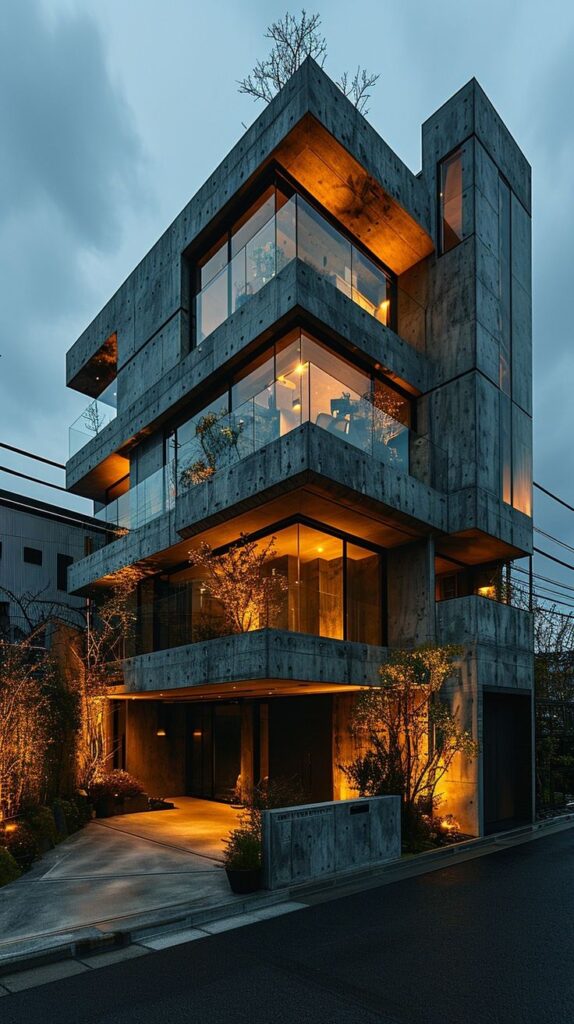

The growing use of mezzanine floors for industry shows how industrial spaces are being adapted to maximize vertical space while maintaining efficiency and flexibility in modern urban environments.

Architectural Design Principles

Modern industrial spaces focus on creating efficient, flexible, and durable environments. Design choices prioritize spacious layouts, natural materials, and energy-saving solutions.

Open Floor Plans

Open floor plans remove unnecessary walls to maximize usable space. This allows better movement of people and equipment. It also improves communication and collaboration in work environments.

Large, unobstructed areas support various activities, from manufacturing to storage. High ceilings and wide spans are common, enabling easy installation of heavy machinery and tools. This design reduces construction costs by limiting internal partitions.

Open layouts also improve lighting and ventilation. Natural light can reach deeper inside the space, reducing the need for artificial lighting during the day. Overall, open floor plans help make industrial spaces more adaptable and efficient.

Use of Raw Materials

Raw materials like exposed concrete, steel, and brick are common in modern industrial designs. They provide strength and toughness needed for heavy-duty use. These materials often remain visible to highlight the building’s structure.

Steel beams and columns support large open spaces. Concrete floors withstand high traffic and heavy loads. Brick walls add texture and durability without extra finishing.

Using raw materials lowers maintenance costs since they are less prone to damage. They also create an aesthetic that is both industrial and minimal. This choice reflects function over decoration, focusing on performance and practicality.

Sustainable Features

Sustainability is a key focus in industrial design. Buildings use energy-efficient lighting, such as LEDs, to reduce power consumption. Solar panels are often installed to generate renewable energy on-site.

Water-saving systems collect rainwater for reuse. Insulation materials help keep temperatures steady, cutting heating and cooling expenses. Ventilation systems improve air quality while reducing energy needs.

Sustainable design also considers materials with low environmental impact. Recycled steel and reclaimed wood are common choices. These features lower operating costs and lessen the environmental footprint of industrial spaces.

Innovative Technologies in Modern Industrial Spaces

Modern industrial spaces use new technologies to improve work efficiency, safety, and energy use. These spaces focus on smart controls, advanced machines, and better energy management to meet today’s industrial demands. Key developments involve digital systems, automation tools, and green energy solutions.

Smart Building Systems

Smart building systems use sensors and software to control lighting, heating, ventilation, and security automatically. These systems collect real-time data to optimize energy use and maintain ideal working conditions. For example, motion sensors turn off lights in empty areas, cutting energy waste.

They often include centralized dashboards, allowing managers to monitor and adjust systems remotely. This reduces downtime and lowers maintenance costs. Smart HVAC controls also improve air quality by adjusting to occupancy levels and indoor pollution.

Automation and Robotics

Automation replaces repetitive tasks with machines that work faster and with fewer errors. Robots handle tasks like packing, welding, and material transport. This boosts productivity and reduces workplace injuries by limiting human exposure to hazardous jobs.

Robotic systems integrate with computer networks for real-time tracking and adaptive control. Collaborative robots, or “cobots,” work alongside humans, supporting tasks instead of replacing workers entirely. This mix improves workflow flexibility and efficiency.

Energy Efficiency Solutions

Energy efficiency depends on better equipment and smarter management. Industrial spaces use LED lighting, variable-speed motors, and solar panels to reduce power use. Buildings also use energy monitoring systems to track consumption down to specific machines.

Advanced insulation materials and reflective roofing reduce heating and cooling needs. Implementing energy storage, like batteries, helps manage supply during peak and off-peak hours. These measures lower costs and support environmental goals.

Functionality and Space Utilization

Modern industrial spaces focus on making the most of every square foot. These spaces are designed to support different work styles, store materials efficiently, and connect tasks in smooth workflows. Each part of the space is planned to improve productivity and safety.

Flexible Work Environments

Flexible work environments in industrial settings allow for quick changes to the layout. This adaptability helps meet the needs of different projects or teams without costly renovations. Movable walls, modular furniture, and multi-use zones are common tools used to create these spaces.

Employees can shift from assembly lines to quality control or packaging areas with ease. This flexibility supports varying production volumes and different types of manufacturing processes. It also makes it easier to introduce new technology or machinery as the business grows.

Storage Optimization

Storage optimization is critical in industrial spaces to reduce clutter and improve efficiency. Shelving systems are often designed vertically to use height, freeing up floor space. Pallet racks, bins, and automated storage units create organized systems that save time.

Labeling and clear pathways are key elements so workers can find materials quickly. This reduces downtime and helps maintain safety standards. Using software for inventory management often supports physical storage systems, improving accuracy and speed.

Workflow Integration

Workflow integration ties together different parts of the production process. Industrial spaces are arranged so materials, tools, and finished goods move smoothly from one step to the next. This reduces unnecessary walking or handling.

Clear zones for receiving, assembly, inspection, and shipping are arranged logically. Technology such as conveyor belts and digital tracking supports this flow. Well-integrated workflows minimize bottlenecks and improve overall output.

Interior Design Elements

Modern industrial spaces often feature a mix of raw materials, functional items, and restrained color palettes. Attention is given to how light, furniture, and color work together to create a balanced, practical environment.

Industrial Lighting

Industrial lighting uses fixtures made from metals like steel or iron, often with exposed bulbs. Pendant lights and metal cage lamps are common, providing direct and focused illumination. This kind of lighting highlights the raw, industrial textures within the space.

Lighting placement is important. It usually emphasizes work areas or architectural features, such as brick walls or steel beams. Natural light is paired with artificial light to keep the space bright but not harsh.

Furniture Selection

Furniture in industrial spaces typically blends metal and wood, combining sturdy materials with simple designs. Pieces are often functional with clean lines, minimal ornamentation, and a rough or unfinished look.

Popular options include metal-framed tables, reclaimed wood desks, and leather chairs. Furniture must be durable and easy to maintain, fitting the practical vibe of industrial interiors. Comfort and utility are prioritized over elaborate design.

Color Schemes

Color palettes in industrial design focus on neutrals and earth tones. Shades like grey, black, white, and brown dominate, creating a calm, muted backdrop.

Accent colors come from natural materials or small pops of paint, such as dark green or navy blue. Walls are often left bare or painted in simple colors, allowing textures and materials to stand out rather than bright paint.

Sustainability Practices

Modern industrial spaces focus on reducing environmental impact by using eco-friendly materials and cutting down on waste. These methods help save money and promote healthier work environments.

Green Building Materials

Using green building materials means choosing products that have a low environmental footprint. These materials often come from renewable resources or recycled content. Examples include bamboo flooring, recycled steel, and low-VOC (volatile organic compound) paints.

Green materials improve energy efficiency. For instance, insulated panels reduce heating and cooling costs. They also help maintain better air quality inside buildings by limiting harmful chemicals.

Many industrial spaces install solar panels and use energy-efficient lighting like LEDs. These choices reduce reliance on nonrenewable energy and lower utility bills. Builders often look for certifications like LEED to ensure the materials meet specific environmental standards.

Waste Reduction Strategies

Waste reduction in industrial spaces involves minimizing what goes to landfills. Companies adopt recycling programs for metal, plastic, and paper waste. Sorting materials directly on-site makes recycling easier and more effective.

Some industries use reusable containers instead of single-use packaging. This practice cuts down on plastic waste and saves money in the long term.

Manufacturers also invest in waste prevention by redesigning processes to use fewer raw materials or generate less scrap. Tracking waste helps find problem areas and improve efficiency.

A simple list of common strategies includes:

- On-site recycling stations

- Reusable packaging

- Process redesign to minimize scrap

- Regular waste audits

These steps lower waste volume and support a circular economy in industrial settings.

Safety and Compliance Considerations

Industrial spaces must meet specific rules and systems to keep workers safe and ensure legal use. This includes following laws, installing fire protection, and designing for easy access in emergencies.

Regulatory Standards

Industrial buildings must follow national and local safety laws. These rules cover things like machinery safety, worker protection, and building structure. Compliance is checked through inspections and reports.

Agencies such as OSHA in the U.S. require regular safety training and hazard controls. Failure to comply can lead to fines or shutdowns. It’s important to update policies as standards change.

Documentation is critical. Maintaining clear records of safety audits, equipment checks, and employee training shows ongoing compliance. This helps avoid legal problems and keeps workers safe.

Fire Protection Systems

Modern industrial spaces need advanced fire systems. These include smoke detectors, sprinkler systems, and fire alarms. Automatic sprinklers help control or stop fires quickly.

Fire exits and clear evacuation routes are essential. Signs must be visible, and emergency lighting should work during power failures. Staff need training on fire response procedures.

Fireproof materials in walls and ceilings can slow fire spread. Regular testing and maintenance of fire equipment prevent malfunctions. A detailed fire safety plan helps manage emergencies effectively.

Accessibility Design

Industrial spaces must be accessible to all workers, including those with disabilities. This means ramps, wide doorways, and clear paths are needed.

Accessible restrooms and break areas should meet legal standards. Emergency exits must allow easy access for everyone. Planning routes free of obstacles is crucial.

Design also covers emergency communication. Visual alarms and accessible emergency phones ensure all workers can get help if needed. Proper design decreases risk during evacuations.

Applications of Modern Industrial Spaces

Modern industrial spaces are used in many ways today. They serve businesses, housing, and city projects. Each use focuses on making the best of large, open areas combined with updated design and technology.

Commercial Uses

Many companies pick modern industrial spaces for offices, studios, and warehouses. These spaces offer high ceilings and large floors, which work well for storage and team work areas.

Retailers also use them for showrooms and shops, benefiting from open layouts that are easy to customize. Tech startups and creative firms like design studios often choose these spaces to encourage collaboration.

The strong, durable materials in these buildings reduce maintenance costs. Their industrial character can give brands a unique, professional look. This mix of aesthetic and practical value makes these spaces popular in competitive markets.

Residential Conversions

Old factories and warehouses are often turned into apartments or lofts. These conversions keep features like exposed brick and metal beams, which appeal to people who want unique living spaces.

The large windows and open floor plans let in a lot of light. They allow owners to design flexible layouts that suit many living styles.

These homes usually attract young professionals and creatives. They offer something different from traditional housing, often located near city centers where older industry once thrived. The mix of history and modern living draws many buyers and renters.

Urban Redevelopment

Cities use modern industrial buildings to revitalize neighborhoods. Empty industrial zones are turned into mixed-use areas with offices, homes, and shops. This helps bring more people and business to parts of the city that were once run down.

Using old buildings reduces the need for new construction and cuts waste. This approach supports sustainability goals and preserves historical value.

These projects often include parks and public spaces to improve quality of life. They create places where residents can work, live, and play in close proximity. This urban mix is key to modern city planning.

Future Trends in Modern Industrial Spaces

Industrial spaces are evolving to meet new needs and technologies. The focus is on making buildings more useful over time and connecting them with urban systems for better efficiency.

Adaptive Reuse

Adaptive reuse is the practice of transforming old industrial buildings for new purposes instead of demolishing them. This approach saves costs and reduces environmental impact by reusing existing structures.

Many old factories and warehouses are being turned into offices, retail spaces, or residential units. The main challenge is upgrading the buildings to meet modern safety and energy standards without losing their original character.

This trend supports sustainability goals and preserves cultural history. It also helps cities manage space better by using what they already have rather than building new structures from scratch.

Integration with Smart Cities

Modern industrial spaces are increasingly linked with smart city technologies. This means using sensors, data analytics, and automation to improve operations and reduce waste.

Examples include real-time monitoring of energy use, automated inventory management, and connected logistics systems. These tools help reduce costs and improve productivity.

Integration with smart cities also enhances safety through better environmental tracking and automated alerts. Industrial areas become part of a larger network designed to optimize resource use and support urban growth.

- 3shares

- Facebook0

- Pinterest0

- Twitter3

- Reddit0