3D printing has revolutionized the way we create and customize everyday objects, offering endless possibilities for both practical and decorative items. From organizational tools to mind-blowing artistic creations, the 3D printing community continues to develop innovative designs that showcase the technology’s impressive capabilities.

You can transform your home and workspace with these cool 3D prints that combine functionality with creative design. These printable models don’t just look impressive—they solve real problems and enhance your daily life. Whether you’re new to 3D printing or looking for your next project, these inspiring ideas demonstrate why this technology has become an essential tool for makers and hobbyists alike.

1) Articulated Robot Model

Articulated robot models are some of the most impressive and functional 3D prints you can create. These designs feature movable joints that allow for realistic motion without requiring assembly with separate parts.

You can find thousands of articulated robot designs online ready for printing. Popular repositories like Printables.com and Yeggi host extensive collections of robot models specifically designed for 3D printers.

The beauty of these prints is in their engineering. Each joint is printed in place, allowing you to simply remove the completed model from your print bed and start posing it immediately.

Articulated robots range from simple desk toys to complex, detailed replicas of popular characters. Some models even incorporate electronic components, allowing for remote control functionality.

For a more advanced project, consider a BB8 droid. Detailed instructions exist for creating a remote-controlled version entirely with 3D printed parts. This type of project combines the artistic aspects of 3D printing with practical robotics.

When selecting an articulated robot model, look for designs with positive reviews confirming that the joints move smoothly after printing. Print settings matter significantly for these models, as layer height and infill can affect joint mobility.

https://makerworld.com/en/models/79673-tars-interstellar-print-in-place?from=search#profileId-518461

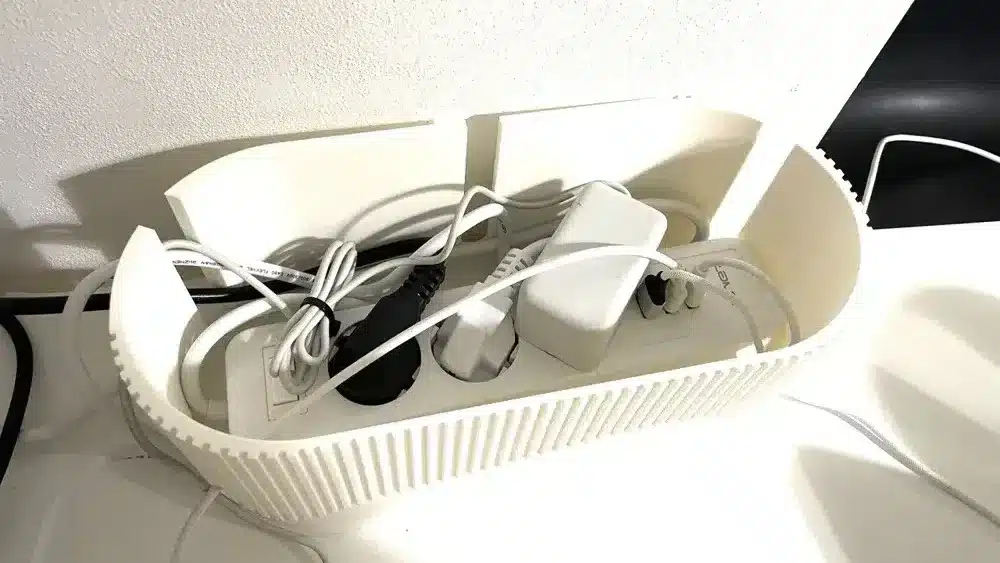

2) Cable Management Box

A cable management box is an excellent 3D printing project that helps eliminate the unsightly tangle of cables behind your desk or entertainment center. These boxes contain power strips and excess cord length, keeping your space neat and organized.

You can find numerous cable management box designs on popular 3D printing websites. Many options are customizable to fit your specific power strip dimensions and cable requirements.

The beauty of 3D printing your own cable management solution is the ability to create exactly what you need. You can design or modify existing models to include specific openings for different cable types or add ventilation features if needed.

These boxes typically feature a lid to completely hide the cables and a few strategic openings to route cords where needed. Some designs include internal dividers to keep different cables separated and organized.

By printing your own cable management box, you can choose colors that match your decor or make it a statement piece with bright, contrasting filament. The practical nature of this print makes it both functional and aesthetically pleasing.

https://makerworld.com/en/models/254677-cable-management-box?from=search#profileId-271032

3) Minimalist Wall Clock

A functional mechanical wall clock is a perfect addition to your 3D printing project list. These timepieces combine aesthetics with engineering, creating both a decorative and practical item for your home.

You can find many designs online that offer reliable performance despite being made from plastic components. Some 3D printed clocks can achieve impressive accuracy, with variations of only 1-2 minutes per week.

The runtime for these clocks varies by design. Some models can run for more than 24 hours on a full wind, while more sophisticated designs might offer up to 8 days of operation before needing to be rewound.

Weight-driven clock mechanisms tend to be more reliable when 3D printed. These classic style designs harness gravity to power the movement, reducing the complexity of the printing process.

Creating your own clock allows for customization to match your interior design preferences. You can opt for minimalist styles that enhance modern spaces without overwhelming them with unnecessary details.

When selecting a design, look for models with positive user reviews confirming their functionality. Many enthusiasts report their 3D printed clocks continuing to run perfectly even after months of operation.

https://makerworld.com/en/models/1323499-wall-clock?from=search#profileId-1360174

4) Slippers with Custom Fit

3D printed slippers are revolutionizing personal footwear with custom-fit options that traditional manufacturing can’t match. You can now create slippers perfectly molded to your unique foot shape, providing comfort that mass-produced options simply cannot deliver.

The technology allows for adjustable sizing without needing different molds, making them particularly suitable for people with non-standard foot sizes. Many designs feature breathable structures and are fully washable, which is especially beneficial if you have sweaty feet.

You can customize not just the fit but also the design and color of your slippers. Some options include plush lining for extra comfort during colder seasons, combining the precision of 3D printing with cozy materials.

Services like Cobbl3D Footwear now make this technology accessible to anyone with a 3D printer. If you don’t own a printer, companies offer custom slipper printing services based on your specifications.

The production freedom of 3D printing allows for lightweight yet durable designs that can be tailored to your specific needs. You can even incorporate personal artwork or logos into your slippers, creating truly unique footwear that reflects your style.

https://makerworld.com/en/models/242527-crocs-voronoi?from=search#profileId-383818

5) Phone Lantern

Ever wished your phone’s harsh flashlight could provide a warmer, more diffused light? The Phone Lantern is a practical 3D print that transforms your smartphone’s bright flashlight into a cozy, ambient light source.

This clever design works by creating a housing that your phone sits in, with the flashlight pointing inward. The lantern’s walls diffuse the light, creating a softer glow that’s perfect for camping, power outages, or setting a relaxing mood.

The Phone Lantern became increasingly popular in early 2025, appearing on “50 Cool Things to 3D Print for May 2025” lists. It’s both functional and attractive, often featuring decorative patterns that cast interesting shadows.

You can find various STL models online, including one by Supervince that’s free to download. Most designs are straightforward to print with minimal supports required.

The practical benefits are significant. You can use your existing phone rather than carrying a separate lantern device. This makes it ideal for emergency kits or travel where space is limited.

Print times typically range from 2-5 hours depending on the complexity of the design and your printer settings.

https://makerworld.com/en/models/585249-phone-lantern?from=search#profileId-506456

6) Headphone Stand

A headphone stand is one of the most practical 3D prints you can make for your desk setup. It keeps your headphones easily accessible while preventing them from taking up valuable workspace or getting damaged.

Many 3D printing enthusiasts have created headphone stand designs that range from minimalist to elaborate. Some designs are inspired by popular brands like Focal, known for their clean aesthetic.

You can find thousands of headphone stand models on sites like Yeggi, where new designs are uploaded daily from creators worldwide. These designs vary in complexity, with some requiring just a few hours to print.

The beauty of 3D printing your own headphone stand is customization. You can choose one that matches your desk’s color scheme or even modify existing designs to fit your specific headphone model.

Printing a headphone stand is also relatively straightforward, making it an ideal project for beginners. Most designs use minimal filament and don’t require complex support structures.

https://makerworld.com/en/models/536200-headphone-stand?from=search#profileId-453121

7) Coffee Filter Holder

Coffee filter holders are practical 3D printing projects that combine functionality with customization. Many designs are available online, from simple containers to more elaborate decorative pieces.

Mountain-styled coffee filter holders add a touch of nature to your kitchen while keeping your filters organized. These designs often feature mountain silhouettes along the sides, bringing an outdoorsy aesthetic to a practical item.

Collapsible filter holders are particularly innovative for those with limited space. These lightweight designs (around 30g) can be folded down for travel or storage, making them perfect for camping trips or small kitchens.

Some models include lids to keep your filters dust-free between uses. This additional protection helps maintain the quality of your coffee by preventing contamination.

You can find options specifically designed for pourover coffee setups, supporting your preferred brewing method. These holders are typically created to fit standard filter sizes while adding convenience to your coffee routine.

Many designs on platforms like Etsy offer customization through laser engraving, allowing you to personalize your filter holder. With multiple patterns and colors available, you can find one that matches your kitchen decor.

8) Custom Battery Case

A custom 3D printed battery case is a practical solution for organizing and storing your batteries. These cases can be designed to fit specific battery types like AA, AAA, or other cylindrical batteries.

You can find customizable battery case models online that allow you to adjust the number and type of batteries they hold. This flexibility ensures you get exactly what you need for your storage requirements.

Some designs feature wave or FIFO (First In, First Out) patterns that make it easy to access your batteries while keeping them organized. This system helps you use older batteries first, preventing waste.

For travelers, a compact battery case prevents batteries from rolling around in your bag or accidentally discharging if they touch metal objects. You can even find stacking designs that maximize space efficiency.

Battery cases can also include features like labels to distinguish between charged and uncharged batteries. Some designs incorporate foam padding for added protection.

With a 3D printer, you can create custom battery holders for specialty batteries or unique configurations that might not be commercially available. This makes 3D printed battery cases both practical and personalized.

https://makerworld.com/en/models/444029-big-battery-case?from=search#profileId-350229

Choosing the Right Materials for 3D Printing

Material selection dramatically affects your 3D printing outcomes, from durability and aesthetics to functionality and print success rate. Different materials offer unique properties that make them suitable for specific applications.

Common Filament Types and Their Properties

PLA (Polylactic Acid) is the most beginner-friendly option, requiring lower printing temperatures (180-220°C) and no heated bed. It’s biodegradable, comes in countless colors, but has limited heat resistance.

ABS offers greater durability and heat resistance (up to 105°C) but requires higher printing temperatures (220-250°C) and a heated bed. It produces fumes during printing, so good ventilation is necessary.

PETG combines PLA’s ease of printing with better durability. It’s food-safe, water-resistant, and less prone to warping than ABS, making it excellent for functional parts.

TPU (Thermoplastic Polyurethane) provides flexibility and elasticity, perfect for items needing bendable properties. Print slowly with this material to avoid extrusion issues.

Nylon offers exceptional strength and durability but is hygroscopic (absorbs moisture) and requires high temperatures (240-260°C).

How Material Choice Impacts Print Quality

Print temperature significantly affects layer adhesion and surface finish. Each material has an optimal temperature range—too low causes weak bonding, while too high leads to stringing and blobs.

Bed adhesion varies by material type. PLA works well on blue tape or glass, while ABS needs higher bed temperatures (100-110°C) and often benefits from an enclosure to prevent warping.

Layer height selection should consider material properties. Flexible filaments like TPU print better with thicker layers (0.2-0.3mm), while detailed models in PLA can utilize finer layers (0.1mm).

Cooling requirements differ dramatically between materials. PLA benefits from maximum cooling, whereas ABS needs minimal cooling to prevent layer cracking and separation.

Storage conditions affect print quality too. Keep moisture-sensitive filaments like Nylon and PETG in airtight containers with desiccant to maintain optimal printing properties.

Tips for Designing Unique 3D Models

Creating distinctive 3D models requires understanding both design principles and the technical limitations of 3D printing technology. Successful designs balance creativity with practical considerations to ensure printability and functionality.

Best Practices for Beginner Designers

Start with simple designs and gradually increase complexity as you gain experience. When designing, maintain minimum element sizes appropriate for your printer’s capabilities to avoid failed prints.

Consider the orientation of your model during printing. Proper orientation minimizes the need for support structures and improves surface quality.

Design parts that fit together in only one way to eliminate misalignment issues during assembly. This approach saves time and frustration when putting complex models together.

Avoid steep overhangs exceeding 45 degrees when possible. If overhangs are necessary, incorporate proper support structures into your design or ensure your slicing software can generate appropriate supports.

Test critical components separately before printing a complete model. This practice helps identify potential problems early and saves material.

Optimizing Designs for Strength and Functionality

Incorporate fillets and rounded edges rather than sharp corners to reduce stress concentrations. This simple change significantly increases the structural integrity of your prints.

Consider the layer orientation relative to stress directions. Printed objects are typically weaker along the Z-axis (between layers), so design accordingly.

Add reinforcing features like ribs or gussets to areas that require additional strength without significantly increasing material use. Strategic reinforcement is more efficient than increasing overall thickness.

Use appropriate infill patterns and densities based on your model’s purpose. Functional parts may require higher infill percentages than decorative items.

Think about post-processing requirements during the design phase. Leave space for sanding, drilling, or adding hardware if your finished piece requires these modifications.

Test functional features through prototyping. Creating small test pieces of moving parts or connections ensures your final print will work as intended.

- 17shares

- Facebook0

- Pinterest17

- Twitter0

- Reddit0