Have you ever looked at a perfectly 3D printed object and thought, “Wow, this is amazing!” only to then wonder about its environmental footprint? You’re not alone. As makers, creators, and innovators, we’re constantly pushing the boundaries of what’s possible with additive manufacturing. But as the world grapples with climate change and resource scarcity, a new imperative has emerged: sustainability. This isn’t just a buzzword; it’s a call to action. The good news? Getting started with eco-friendly 3D printing is not only possible but also incredibly rewarding. It allows us to merge our passion for creation with a deep commitment to planetary well-being.

This journey into sustainable innovation isn’t about giving up the magic of 3D printing. Instead, it’s about making smarter choices, exploring new materials, and optimizing our processes to reduce waste, conserve energy, and build a greener future, one layer at a time. Whether you’re a seasoned pro or just dipping your toes into the world of 3D printing, there are tangible steps you can take right now to make your passion more planet-friendly. Let’s dive in and discover how we can transform our workshops into hubs of sustainable creativity!

The Environmental Imperative: Why Go Green with 3D Printing?

Before we jump into the “how,” let’s quickly touch on the “why.” Traditional manufacturing processes are notoriously resource-intensive. Think about it: massive factories, long supply chains, significant energy consumption, and often, a lot of material waste. While 3D printing, by its very nature, is a more efficient “additive” process (meaning it builds up rather than carves down), it’s not inherently perfectly green. The materials we choose, the energy we consume, and how we handle waste all play a huge role.

However, 3D printing holds immense potential to be a far more sustainable alternative. Unlike subtractive manufacturing, where material is cut away from a larger block (generating significant scrap), 3D printing only uses the material it needs. This drastically reduces material waste. Furthermore, the ability to produce items locally and on-demand minimizes transportation emissions and the need for vast storage warehouses. Imagine a world where spare parts are printed when needed, not manufactured in batches of thousands and shipped across continents. That’s the promise of green 3D printing.

By embracing eco-friendly 3D printing, we’re not just making our hobbies or businesses more responsible; we’re actively contributing to a circular economy. This means designing products for longevity, ease of repair, and eventual recycling, ensuring resources are used and reused as much as possible. It’s about building a better future, one layer at a time.

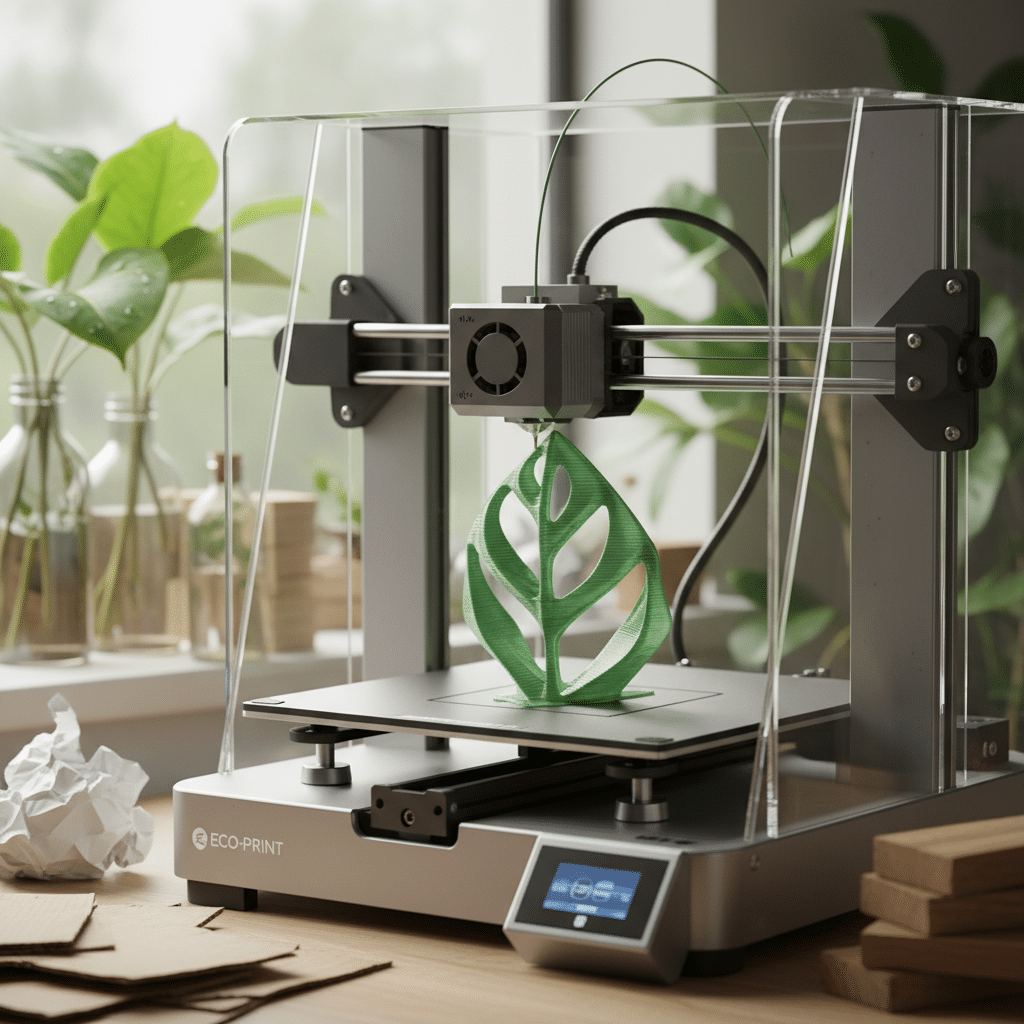

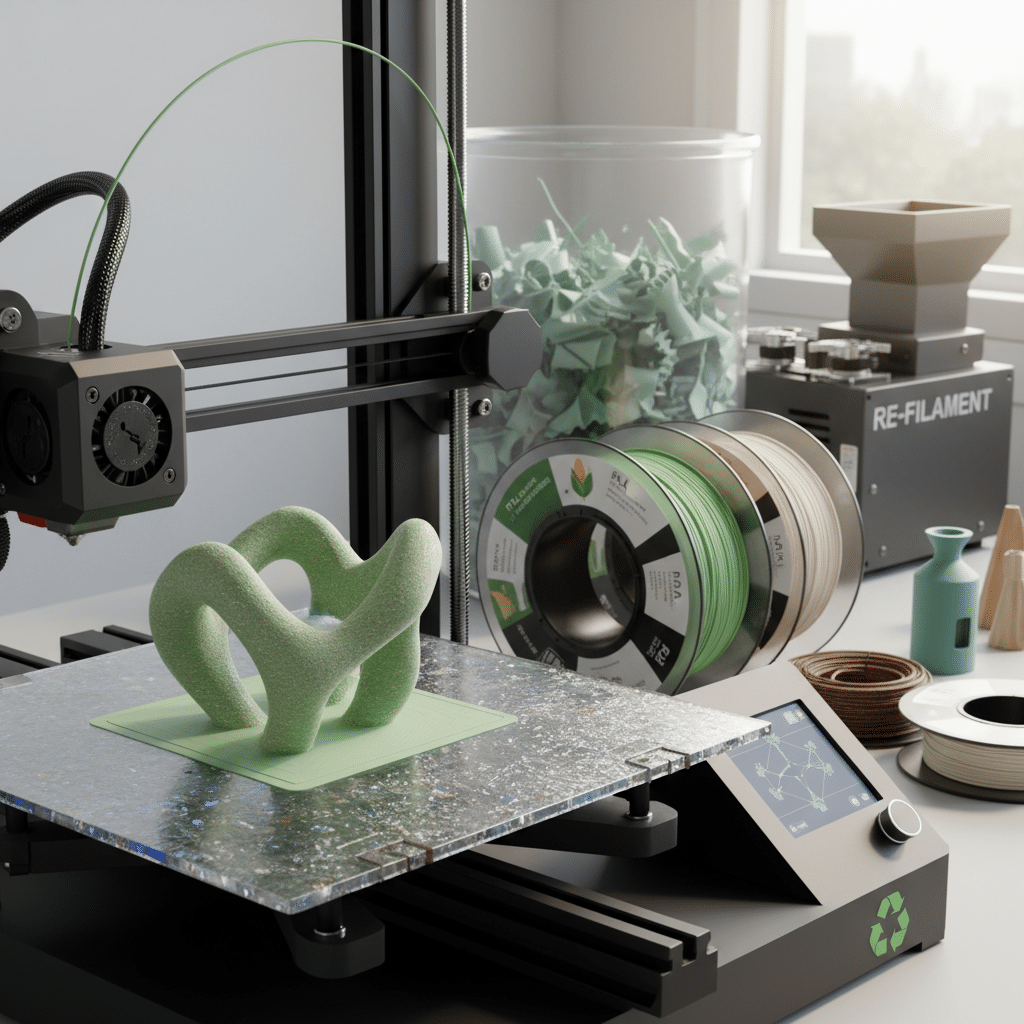

The Heart of Sustainable 3D Printing: Eco-Friendly Filaments

When most people think about eco-friendly 3D printing, the first thing that comes to mind is materials. And for good reason! Your choice of filament is arguably the biggest factor in the environmental impact of your prints. Thankfully, the market for sustainable filaments has exploded in recent years, offering exciting alternatives to traditional, petroleum-based plastics like ABS.

#### Recycled Filaments: Giving Plastic a Second Life

One of the most straightforward ways to be more eco-conscious is by using recycled filaments. These are made from post-consumer or post-industrial plastic waste that’s been collected, processed, and extruded into new filament. It’s a fantastic example of the circular economy in action, diverting plastic from landfills and giving it new purpose.

- rPLA (Recycled PLA): PLA (Polylactic Acid) is already considered more eco-friendly than many plastics because it’s derived from renewable resources like corn starch. Recycled PLA takes this a step further by using discarded PLA prints or manufacturing waste as its base. It prints similarly to virgin PLA, making it an easy switch for most makers.

- rPETG (Recycled PETG): PETG is known for its strength and durability. Recycled PETG often comes from plastic bottles and packaging. Using rPETG reduces the demand for new plastic production, offering a robust and sustainable material option for functional parts.

- Other Recycled Options: You can find rABS, rNylon, and even specialized recycled materials like those made from discarded car dashboards or marine plastics. Each one helps close the loop on plastic waste.

#### Bio-Based Filaments: From Plants to Prints

Beyond recycled plastics, bio-based filaments are making huge strides. These materials are derived from renewable biomass sources, often making them biodegradable or compostable under specific industrial conditions.

- PLA (Polylactic Acid): As mentioned, PLA is the most common bio-based filament. It’s made from fermented plant starch, usually corn, sugarcane, or tapioca. It’s easy to print, has a low warping tendency, and offers a wide range of colors. While it biodegrades much faster than traditional plastics, it typically requires industrial composting facilities, not just your backyard compost bin. Still, it’s a significant improvement over petroleum-derived options.

- PHA (Polyhydroxyalkanoate): PHA is a newer bioplastic derived from bacterial fermentation of organic matter. What makes PHA exciting is its potential for true home compostability, although availability and printability can still be challenging compared to PLA.

- Bio-TPU: This flexible filament is made from bio-based polyols, offering an elastic and durable material derived from renewable resources, perfect for parts requiring flexibility.

#### Composite Filaments: Natural Aesthetics and Reduced Plastic Content

Composite filaments blend traditional plastics (often PLA) with natural fibers or powders. These not only reduce the overall plastic content but also offer unique aesthetic and tactile properties, mimicking natural materials.

- Wood-Filled Filaments: These combine PLA with wood fibers, giving prints the look, feel, and even smell of real wood. You can sand, stain, and paint them just like wood, making them fantastic for decorative items, architectural models, or artistic pieces. Just remember, they can be a bit more abrasive on nozzles!

- Cork, Coffee, Bamboo, Hemp: Similar to wood, these filaments incorporate ground cork, spent coffee grounds, bamboo dust, or hemp fibers into a PLA base. Each offers distinct textures and appearances, allowing for incredibly unique and sustainable creations.

- Stone and Ceramic Composites: While less about being “eco-friendly” in the sense of biodegradability, these often use mineral powders mixed with polymer to achieve a stone-like finish. They can be great for artistic or architectural applications.

#### Water-Soluble Support Materials: Cleaner Disposal

Finally, let’s not forget about support materials. Many complex prints require supports, and disposing of these can add to waste. Water-soluble support materials like PVA or BVOH offer a cleaner solution. Instead of peeling off and discarding plastic scraps, you simply dissolve them in water, leaving behind only your finished print and a relatively harmless liquid solution (though proper disposal of the solution is still important – check local regulations).

By carefully selecting your filaments, you’re making a huge stride towards a more sustainable 3D printing practice. It’s an easy win that has a direct impact. Want to get inspired by things you can print? Check out these stuff to 3D print to kickstart your creative journey with sustainable materials!

Optimizing Your 3D Printing Process for Sustainability

Choosing the right materials is crucial, but eco-friendly 3D printing goes beyond just filament. The way you operate your printer and design your models can significantly impact your environmental footprint. Think of it as holistic sustainability for your workshop.

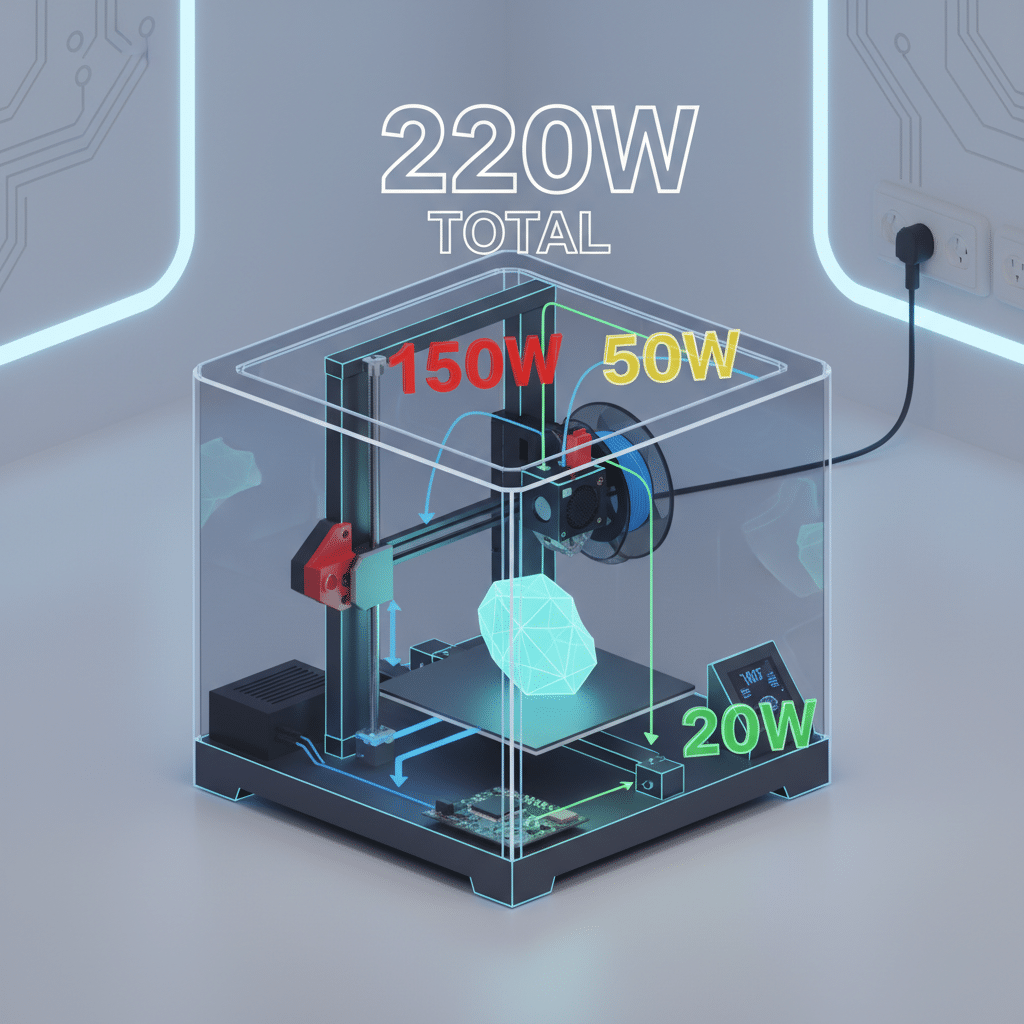

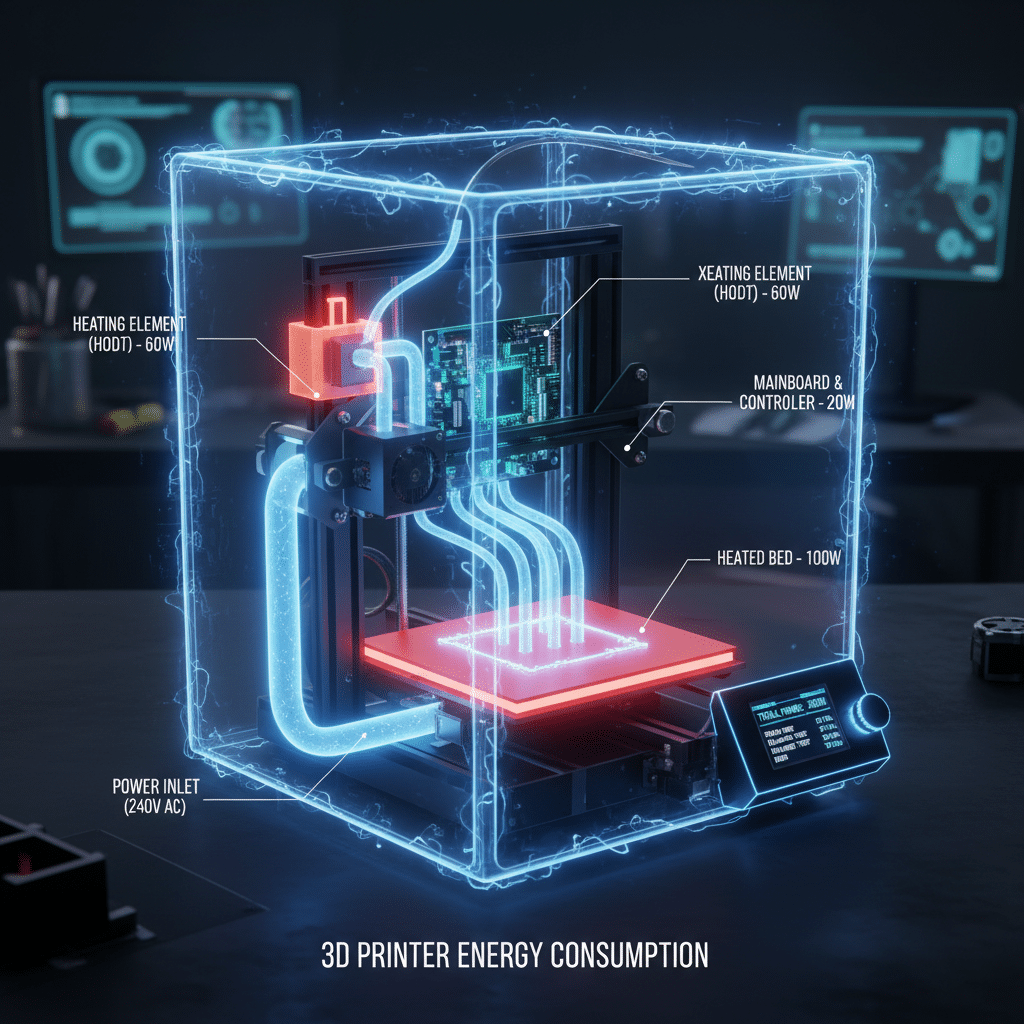

#### Energy Efficiency: Powering Your Prints Responsibly

3D printers, especially when running for long hours, consume electricity. Being mindful of your energy usage can lead to significant savings, both for your wallet and the planet.

- Printer Choice: When buying a new printer, consider its energy consumption. Some newer models are designed with energy-saving features. Look for printers with good insulation, efficient heating elements, and smart power management.

- Print Settings Optimization:

Heated Bed & Nozzle Temperature: Experiment to find the lowest possible temperatures that still yield good adhesion and print quality. Lowering these by even a few degrees can save energy over a long print. Standby Modes: Utilize any standby or sleep modes your printer might have. Turn Off When Not In Use:* This might seem obvious, but many makers leave their printers on between prints. Get into the habit of powering down when your printer isn’t actively working.

- Renewable Energy Integration: For the truly committed, consider powering your workshop with renewable energy sources. This could involve installing solar panels on your roof or purchasing electricity from a green energy provider. Large-scale solar panels are increasingly shaping greener designs, not just for homes but for businesses too. Learn more about how industrial solar panels are shaping greener design.

- Smart Plugs: Use smart plugs to monitor your printer’s energy consumption and schedule power-offs. This helps you understand your usage patterns and ensure your printer isn’t drawing phantom power when idle.

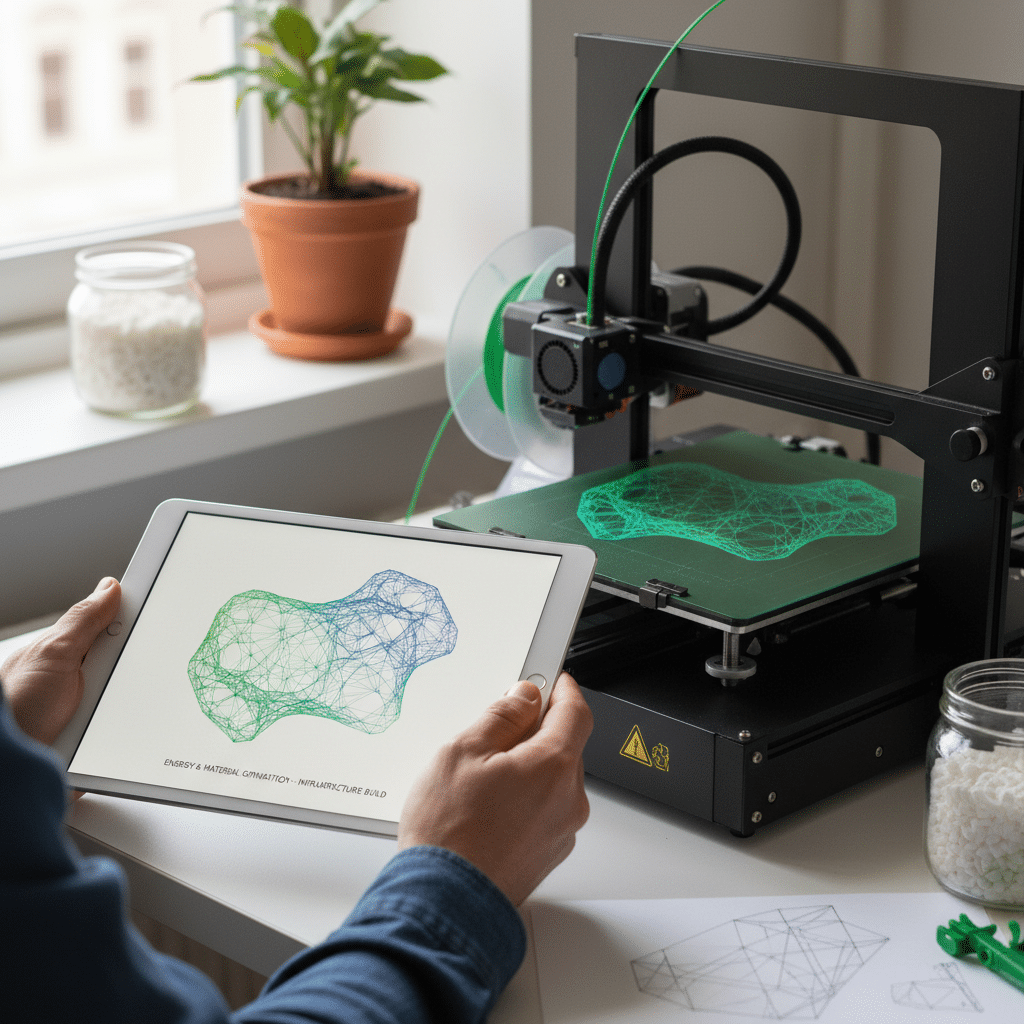

#### Design for Sustainability: The Blueprint for a Greener Future

The design phase is where a lot of eco-friendly decisions can be made. Thinking sustainably from the start can minimize material usage and extend a product’s life cycle.

- Minimize Material: Can your design be hollowed out? Can infill be reduced without compromising strength? Use generative design tools if available, which can optimize structures for minimal material while maintaining strength.

- Modular Design: Design objects with interchangeable or replaceable parts. If one component breaks, you only need to print a new part, not a whole new item. This drastically extends the life of the product.

- Repairability: Create designs that are easy to disassemble and repair. Avoid permanent adhesives or inaccessible components.

- End-of-Life Considerations: Think about what happens to your print when it’s no longer useful. Can it be easily recycled (if made from a recyclable filament)? Can it be composted (if it’s a true bioplastic)? Design for easy separation of different materials.

- Functional Over Decorative: Prioritize creating useful, long-lasting items over purely decorative ones that might quickly end up in the trash. When designing for things like 3D printed cosplay props, consider how durable and reusable the components can be, or if they can be easily recycled after use.

#### Waste Management: Closing the Loop in Your Workshop

Even with the best intentions, 3D printing generates some waste. Failed prints, support structures, and filament scraps are inevitable. The goal is to manage this waste responsibly.

- Filament Recycling Services: Some companies and local initiatives offer services to collect 3D printing waste (especially PLA) and recycle it into new filament. Look for these programs in your area.

- At-Home Recycling: While not as common for hobbyists, some advanced makers invest in filament extruders that allow them to turn their plastic scraps into new filament. This is the ultimate closed-loop system for your workshop.

- Proper Disposal: For materials that can’t be recycled locally, ensure they are disposed of according to local waste management guidelines. Don’t assume everything goes into your curbside recycling bin.

- Reduce First: The best way to manage waste is to prevent it in the first place. Calibrate your printer regularly, optimize settings, and use adhesion aids to minimize failed prints.

#### Local Production & On-Demand Manufacturing: Cutting Down on Carbon

One of the inherent advantages of 3D printing is its ability to facilitate local, on-demand production.

- Reduced Transportation: Producing goods close to the point of consumption drastically cuts down on emissions from shipping and logistics. This is a huge win for the environment compared to products manufactured halfway across the globe.

- No Overproduction: With 3D printing, you can print exactly what’s needed, when it’s needed. This eliminates the waste associated with mass production, where large batches of items might go unsold or become obsolete.

- Customization and Repair: The ability to print custom parts or replacements on demand reduces the need to discard entire items because a small part failed or was unavailable. This ethos aligns with the broader push towards eco-friendly home renovations and sustainable living.

Innovations and the Future of Green 3D Printing

The field of eco-friendly 3D printing is constantly evolving, with researchers and innovators pushing the boundaries of what’s possible. The future looks incredibly exciting, promising even more sustainable solutions.

#### Advanced Recycled Materials and Ocean Plastics

Expect to see a greater variety and higher quality of recycled filaments. Efforts are underway to refine the recycling process to produce filaments with properties comparable to virgin materials. A particularly impactful area is the use of ocean-bound plastics. Imagine printing a functional part or a beautiful piece of art from plastic waste recovered from our seas! Companies are already developing technologies to turn this challenging waste stream into viable 3D printing materials.

#### Bioprinting and Truly Biodegradable Bioplastics

Beyond PLA, research into next-generation bioplastics is intense. Scientists are exploring materials that can genuinely biodegrade in various environments, including home compost or even natural settings, without requiring industrial facilities. The goal is to develop materials that fully integrate into natural cycles. Furthermore, bioprinting, using living cells and biomaterials, holds immense potential for medical applications, tissue engineering, and even creating synthetic foods, all with a reduced environmental footprint compared to traditional methods.

#### Circular Economy Models: Cradle-to-Cradle Design

The philosophy of the circular economy is gaining traction, and 3D printing is a perfect fit. We’re moving towards a “cradle-to-cradle” approach where products are designed from the outset to be fully recycled or composted at the end of their life, feeding back into the production cycle. This includes initiatives like filament take-back programs, where manufacturers accept used prints or scraps to turn them back into new filament. This evolution in material thinking echoes the broader shift in design and manufacturing, including the evolution of modern home materials towards more sustainable options.

#### Large-Scale Applications: Building a Greener World

Eco-friendly 3D printing isn’t just for small desktop projects. Its potential for large-scale applications is immense:

- Sustainable Construction: Imagine printing entire houses or building components using locally sourced, recycled, or bio-based materials like earth, clay, or concrete derived from waste products. This could revolutionize construction, reducing waste, energy, and costs.

- Automotive and Aerospace: Lightweight, custom-printed parts from recycled composites can significantly improve fuel efficiency in vehicles and aircraft.

- Fashion and Product Design: Designing bespoke items or clothing using recycled or bio-based filaments could lead to a more sustainable fashion industry, reducing textile waste and overproduction.

These innovations show that eco-friendly 3D printing is not just a niche interest but a foundational shift with the power to reshape industries and contribute significantly to a more sustainable planet.

Real-World Impact: Case Studies of Eco-Friendly 3D Printing in Action

It’s one thing to talk about potential; it’s another to see eco-friendly 3D printing making a tangible difference. Here are a few examples that highlight its real-world impact across various sectors.

- Medical Devices and Prosthetics: Consider the case of 3D printed prosthetics. Traditionally, these are expensive and often take a long time to produce. With 3D printing, custom prosthetics can be made on demand, tailored precisely to the individual. Using recycled or bio-based filaments for non-implantable parts not only reduces cost but also environmental impact, making life-changing devices more accessible and sustainable. Organizations worldwide leverage this technology to provide affordable limbs to those in need.

- Sustainable Product Design: Many small businesses and individual designers are now exclusively using eco-friendly filaments. From stylish planters made with wood-filled PLA to durable phone cases made from recycled PETG, creators are demonstrating that sustainability doesn’t mean compromising on aesthetics or functionality. This trend extends to packaging as well, with companies using 3D printing to create custom, reusable, or biodegradable packaging solutions.

- Architecture and Construction Prototypes: Architects frequently use 3D printing for models and prototypes. By opting for recycled PLA or other sustainable materials, they can visualize designs without generating excessive waste. Some ambitious projects are even exploring 3D printing entire structures using recycled aggregates or bio-concrete, showing a path towards truly green construction.

- Educational Tools and Art: Schools and universities are adopting eco-friendly filaments for their 3D printing labs. This not only teaches students valuable skills but also instills environmental awareness from a young age. Artists are also embracing these materials, creating beautiful sculptures and installations that carry an inherent message of sustainability, using everything from recycled bottle caps to coffee grounds in their prints.

These examples underscore that sustainable 3D printing is not just a theoretical concept. It’s happening now, driven by innovative individuals and organizations committed to making a difference.

Challenges and Considerations

While the future of eco-friendly 3D printing is bright, it’s important to acknowledge that there are still some hurdles to overcome. Being aware of these challenges helps us make informed decisions and contribute to solutions.

- Cost of Sustainable Filaments: Generally, recycled and advanced bio-based filaments can be more expensive than their virgin plastic counterparts. This is often due to smaller production scales, specialized processing, and the costs associated with collecting and sorting waste materials. However, as demand grows and technologies improve, these costs are likely to decrease.

- Printability and Material Properties: Some sustainable filaments can be more challenging to print with, requiring specific settings, higher temperatures, or slower speeds. Their mechanical properties (strength, flexibility, heat resistance) might also differ from traditional plastics, which can be a consideration for functional parts. Researching and experimenting with different brands and types is key.

- Infrastructure for Recycling 3D Print Waste: While some local initiatives exist, a widespread, standardized infrastructure for collecting and recycling 3D printing waste (especially multi-material failed prints) is still lacking in many regions. This can make it difficult for individual makers to truly close the loop on their waste. Advocacy and participation in local programs are important.

- Greenwashing: As “eco-friendly” becomes a powerful marketing term, it’s crucial to be wary of greenwashing. Some products might claim to be sustainable without truly delivering. Always look for certifications, transparency in sourcing, and clear explanations of a product’s environmental benefits and limitations (e.g., “biodegradable” often means “industrially compostable,” not “will break down in your garden”). Do your homework!

Understanding these challenges doesn’t diminish the value of eco-friendly 3D printing; instead, it empowers us to address them collectively and work towards more robust and accessible solutions.

Getting Started: A Practical Guide for Makers

Feeling inspired to make your 3D printing more sustainable? Fantastic! Here’s a practical roadmap to help you get started, no matter your current skill level.

1. Educate Yourself: The first step is always learning. Read articles, watch videos, and join online communities focused on sustainable 3D printing. Understanding the materials and processes is key. 2. Start with PLA (if you haven’t already): If you’re currently using ABS or other petroleum-based plastics, switching to standard PLA is an easy first step. It’s widely available, easy to print, and bio-based. 3. Experiment with Recycled Filaments: Once comfortable with PLA, try a spool of rPLA or rPETG. Many brands offer high-quality recycled options that print just like their virgin counterparts. This is one of the most impactful switches you can make. 4. Optimize Your Settings: Dive into your slicer software. Experiment with lower print temperatures (nozzle and bed), reduce infill where appropriate, and ensure your retraction settings are dialed in to minimize stringing and waste. 5. Design with Sustainability in Mind: Before you hit print, ask yourself: Can this design use less material? Can it be modular? Can it be easily repaired or recycled? Even small design tweaks can make a big difference. 6. Manage Your Waste Proactively: Keep a separate bin for your failed prints and filament scraps. Research local recycling options or look for national filament recycling programs. If nothing exists, consider reaching out to other makers to explore collective solutions. 7. Monitor Energy Usage: Use a smart plug to track your printer’s energy consumption. This awareness can help you identify opportunities to reduce power usage, like turning off the printer between jobs or optimizing print times. 8. Join the Community: Connect with other makers who are passionate about sustainable 3D printing. Share tips, learn from their experiences, and collaborate on initiatives. The collective power of the maker community is immense.

Remember, every step, no matter how small, contributes to a larger goal. You don’t have to overhaul your entire setup overnight. Start with one change, then build on that success.

Conclusion

Eco-friendly 3D printing isn’t just a trend; it’s the responsible evolution of an incredible technology. By consciously choosing sustainable filaments, optimizing our printing processes for energy efficiency, and designing with the planet in mind, we can transform our passion into a powerful force for good. From reducing material waste and energy consumption to fostering a circular economy, the opportunities for sustainable innovation are boundless.

The journey starts with a single step, perhaps a new spool of rPLA or a commitment to turn off your printer when it’s idle. Every conscious choice you make contributes to a greener future. So, makers, let’s embrace this challenge with creativity and purpose. Let’s print not just amazing objects, but also a better, more sustainable world for everyone. Get started today, and let your innovations inspire others to join the green revolution in 3D printing!

Why should I consider eco-friendly 3D printing?

Eco-friendly 3D printing helps reduce environmental impact by minimizing waste, conserving energy, and promoting sustainable materials, contributing to a healthier planet.

What are some sustainable materials I can use in 3D printing?

You can use recycled filaments like rPLA and rPETG, bio-based filaments such as PLA, PHA, and Bio-TPU, as well as composite filaments made with natural fibers like wood, cork, bamboo, or hemp.

How can I make my 3D printing process more sustainable?

You can improve sustainability by choosing energy-efficient printers, optimizing print settings to reduce energy usage, designing for minimal material, managing waste responsibly, and powering your workshop with renewable energy.

What are water-soluble support materials and how do they help sustainability?

Water-soluble support materials like PVA and BVOH can be dissolved in water, making support removal cleaner and reducing waste, which makes the overall printing process more environmentally friendly.

What are some major challenges in adopting eco-friendly 3D printing?

Challenges include higher costs of sustainable filaments, printability issues, lack of recycling infrastructure, and the risk of greenwashing, so it’s important to research and choose genuinely eco-friendly options.

- 30shares

- Facebook0

- Pinterest30

- Twitter0

- Reddit0