3D printing opens up endless possibilities for creating functional items and personalized accessories that solve everyday problems. Whether you’re new to 3D printing or looking to expand your project repertoire, the right ideas can transform your printer into a tool for both practical solutions and creative expression.

This collection of 15 carefully selected 3D printing projects will help you discover versatile designs that enhance your daily life while developing your printing skills. From workspace organization tools to custom decorative pieces, each project offers unique value whether you’re printing for personal use, gifts, or simply exploring what’s possible with modern 3D printing technology.

1) Custom phone stands

Custom phone stands represent one of the most practical 3D printing projects for beginners and experienced makers alike. You can design stands that perfectly match your specific phone model and personal preferences.

These stands offer complete customization for your exact needs. You can adjust the angle, height, and stability based on how you use your device most often.

The design process allows you to incorporate features like cable management slots or adjustable viewing angles. You can create stands optimized for video calls, media consumption, or hands-free operation.

Your custom phone stand can match your desk aesthetic or personal style perfectly. Choose materials and colors that complement your workspace or home environment.

The printing process typically requires minimal material and short print times. Most phone stands can be completed within a few hours using basic PLA filament.

You can experiment with different designs and iterate quickly. If the first version doesn’t meet your needs, you can modify the design and print an improved version.

These projects help you learn fundamental 3D design principles while creating something immediately useful. The combination of practicality and customization makes phone stands an ideal starting project for any 3D printing enthusiast.

https://makerworld.com/en/models/717070-phone-stand?from=search#profileId-647981

2) Modular desk organizers

Modular desk organizers represent one of the most practical applications for your 3D printer. These customizable storage systems let you create compartments that fit your exact workspace needs.

You can design organizers with specific slots for pens, paper clips, USB drives, and other office essentials. The modular nature means you can print individual components and arrange them however works best for your desk layout.

Popular designs include stackable drawer systems and interlocking compartments. You can start with a basic configuration and add more modules as your organizational needs change.

The customization options are extensive. You can adjust compartment sizes, add dividers, or create specialized slots for specific items like phones or cables.

Many free designs are available online, including systems like OrganiZen which offers fully customizable modular components. These open-source projects provide excellent starting points for your own modifications.

Your 3D printed organizers can match your desk aesthetic perfectly. Choose colors and finishes that complement your workspace while providing the exact storage solutions you need.

The scalable nature of these projects makes them ideal for both small home offices and larger work environments.

https://makerworld.com/en/models/144270-modular-mario-desk-organizer?from=search#profileId-156852

3) Personalized keychains

Personalized keychains represent one of the most practical and accessible 3D printing projects you can tackle. They require minimal material and print time while offering maximum customization potential.

You can create name keychains featuring custom text in various fonts and styles. These make excellent gifts for friends, family members, or coworkers who appreciate unique accessories.

Character-themed keychains from movies, TV shows, and video games allow you to showcase your interests. Popular designs include logos, symbols, and miniature figures that reflect your personal passions.

The printing process is straightforward and beginner-friendly. Most keychain designs print in 30-60 minutes using standard PLA filament, making them perfect test prints for new users.

You can experiment with different materials to achieve specific looks. Clear PETG creates transparent effects, while flexible TPU produces soft, squeezable keychains that won’t crack under pressure.

Adding functional elements enhances their utility. Consider incorporating bottle openers, LED light holders, or small tool attachments to create multi-purpose accessories.

The compact size means you can print multiple designs simultaneously. This efficiency makes personalized keychains ideal for small business ventures or bulk gift production.

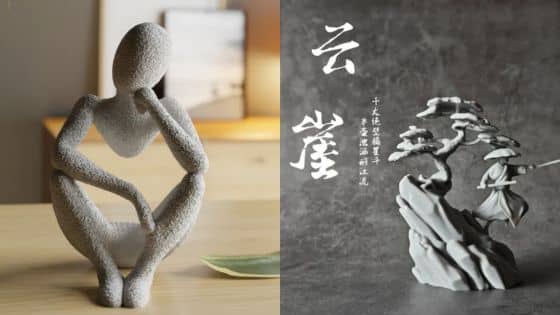

4) Decorative planters

3D printed planters transform ordinary plant containers into personalized decor pieces. You can design planters that match your home’s aesthetic while providing proper growing conditions for your plants.

The customization options are extensive with 3D printing. You can create planters in unique shapes, sizes, and patterns that traditional manufacturing cannot easily produce.

These planters work perfectly for indoor gardens, windowsills, or outdoor spaces. You can scale designs up for large plants or down for small succulents and herbs.

Modern 3D printing allows you to incorporate functional features like drainage systems and water reservoirs. You can also add decorative elements such as geometric patterns, textured surfaces, or artistic designs.

For outdoor use, consider printing with ASA filament since it resists UV damage and weather exposure. Indoor planters can use standard PLA filament for most applications.

The variety of available designs is substantial. You can find thousands of free STL files online or create your own custom designs to match specific plants or spaces.

3D printed planters combine functionality with artistic expression. They offer an affordable way to create unique garden containers while exploring your creativity through design and customization.

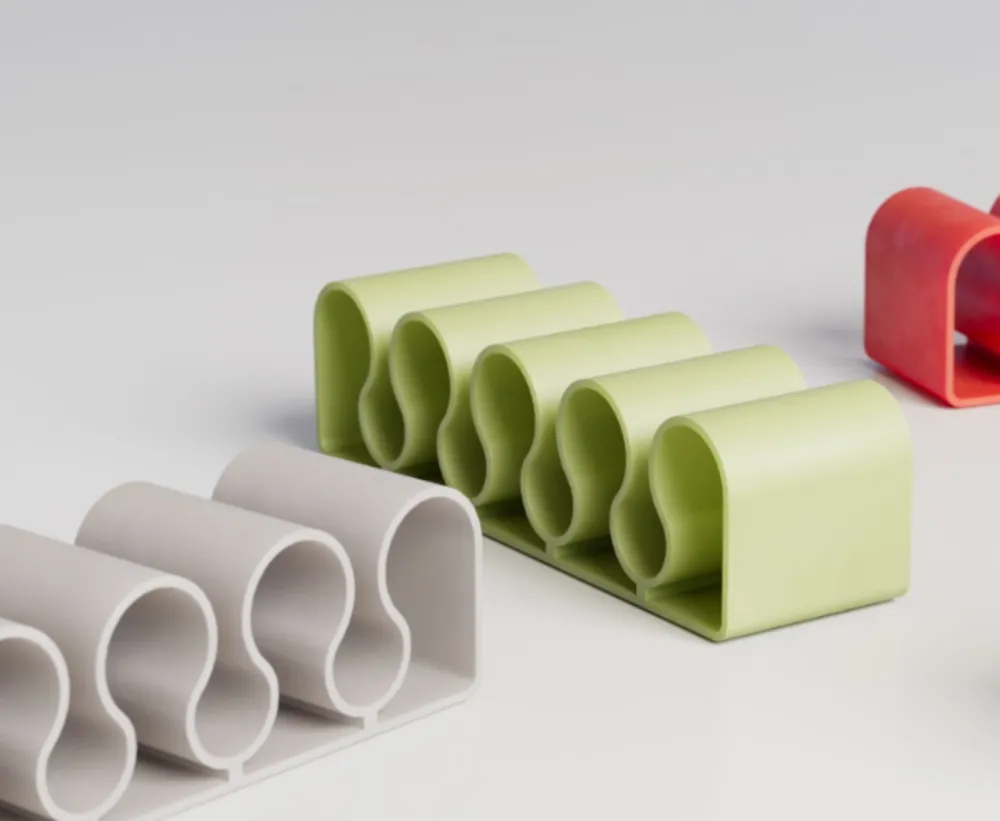

5) Functional cable holders

Cable management becomes simple with 3D printed holders. You can design custom solutions that fit your exact workspace needs and device configurations.

These organizers snap into place on desks, walls, or computer cases. They keep charging cables, USB cords, and power adapters organized and easily accessible.

You can print holders with multiple slots for different cable types. Desktop versions work well for keeping frequently used cables within reach while you work.

Wall-mounted designs help route cables behind monitors or along baseboards. They prevent tangling and reduce clutter around your electronics setup.

The printing process is straightforward for beginners. Cable holders typically use basic geometric shapes that don’t require complex supports or intricate details.

Material choice affects durability and flexibility. PLA works for basic desktop organizers, while PETG or ABS provide better strength for wall-mounted versions that hold heavier cables.

You can customize dimensions to match your specific cables and mounting locations. This flexibility makes 3D printing ideal for cable management compared to store-bought options.

These functional prints solve real organizational problems while helping you learn fundamental 3D printing skills through simple, practical projects.

https://makerworld.com/en/models/486404-simple-cable-holders?from=search#profileId-399136

6) Ergonomic pen holders

Ergonomic pen holders address hand strain and grip difficulties through thoughtful 3D printed design. These holders provide enhanced stability and comfort for extended writing sessions.

You can create adaptive grips that accommodate conditions like arthritis, carpal tunnel, or partial paralysis. The ergonomic handle reduces hand fatigue while improving writing control.

3D printing excels at producing these holders because of their complex angles and curves. Traditional manufacturing would struggle with the intricate geometry required for proper ergonomics.

Your printer can create the entire holder as one solid piece, ensuring structural integrity. This single-piece construction eliminates weak joints that might break under regular use.

The designs feature wider grips that distribute pressure across your hand. This reduces stress on specific pressure points that cause discomfort during writing.

You can customize the holder size to match your specific hand dimensions. Print different versions until you find the perfect fit for your grip style.

These holders work with standard pens and pencils without modification. Simply insert your writing instrument and experience improved comfort immediately.

The printing process remains straightforward regardless of your 3D printing experience level. Most ergonomic pen holder files print successfully with basic settings.

7) Adjustable headphone stands

Adjustable headphone stands represent one of the most practical 3D printing projects you can tackle. These stands offer customizable height settings to accommodate different headphone sizes and personal preferences.

You can design stands with multiple height levels using only 3D printed components. Most adjustable designs feature three to five different height positions, making them versatile for various headphone types.

The beauty of 3D printing your own adjustable stand lies in customization. You can modify the design to fit your specific workspace dimensions and aesthetic preferences.

Many adjustable headphone stand files are designed to fit standard printer build volumes. You won’t need a large-format 3D printer to create these functional accessories.

These stands help organize your workspace while keeping expensive headphones safe and easily accessible. The adjustable feature means one stand can serve multiple users or different headphone models.

You can find numerous free STL files online for adjustable headphone stands. Popular designs include sliding mechanisms, removable posts, and modular components that stack to create different heights.

The printing process typically requires minimal support material, making these projects beginner-friendly and material-efficient.

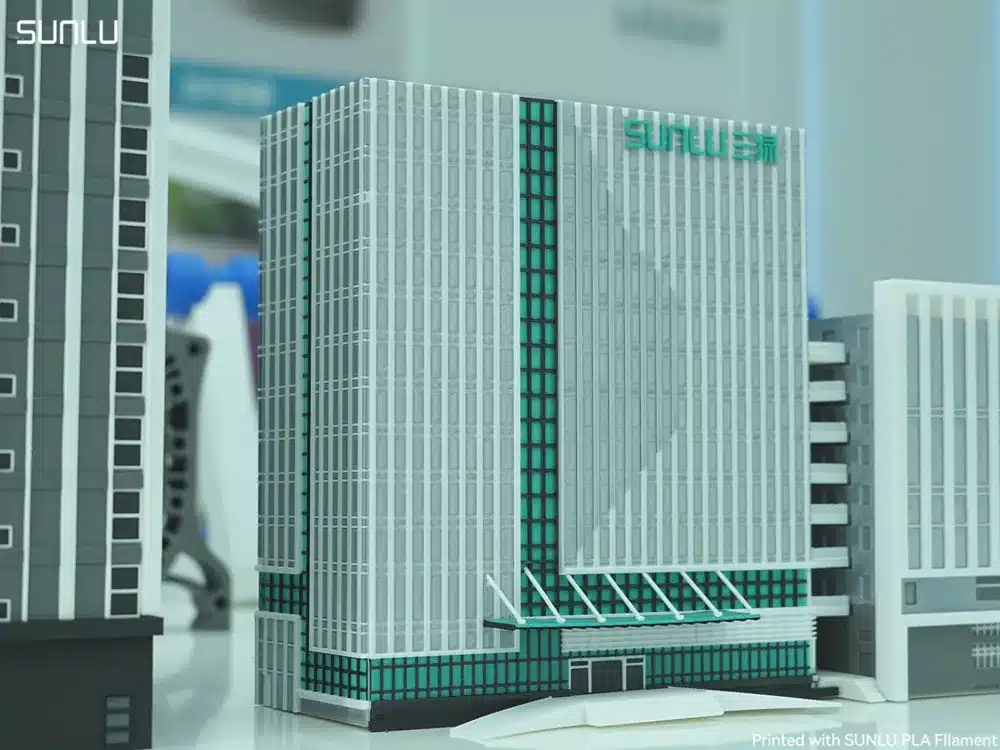

8) Miniature architectural models

3D printing has revolutionized how architects create building models. You can now produce detailed miniatures with precision that traditional hand-crafting methods struggle to match.

The layered construction method allows accurate placement of building materials within each layer. This creates incredibly detailed facades, interior structures, and complex geometric designs.

You can print famous landmarks like the Eiffel Tower or Hogwarts Castle. Medieval castles, modern city blocks, and historical buildings are all possible projects for your printer.

Architectural models serve multiple purposes beyond decoration. Architects use them to present ideas to clients and test design concepts before construction begins.

Educational institutions benefit greatly from 3D printed architectural models. Students can examine building structures up close and understand construction principles through hands-on interaction.

The accessibility factor is significant too. Visually impaired individuals can explore architectural designs through touch when models are printed in physical form.

You’ll find thousands of free STL files online for architectural miniatures. Popular platforms offer everything from simple houses to complex urban developments ready for printing.

Material costs remain low compared to traditional model-making supplies. A single spool of filament can produce multiple detailed building models.

9) Puzzle toys

3D printing opens up endless possibilities for creating engaging puzzle toys. You can print classic brain teasers like Rubik’s cubes, cryptex puzzles, and maze cubes right from your desktop printer.

These printable puzzles offer excellent cognitive benefits for both children and adults. They challenge problem-solving skills while providing hours of entertainment.

Popular 3D printed puzzle designs include articulated dragons that move in complex ways, interlocking geometric shapes, and customizable puzzle cubes. You can find thousands of STL files online featuring different difficulty levels.

The beauty of 3D printed puzzles lies in their customization potential. You can adjust sizes, colors, and complexity levels to match the intended user’s skill level.

PLA filament works best for puzzle toys since it’s non-toxic and produces smooth, precise parts that fit together properly. The material’s durability ensures your puzzles will withstand repeated handling.

Many puzzle designs print without supports, making them beginner-friendly projects. You can create everything from simple sliding puzzles to complex mechanical brain teasers that challenge even experienced puzzle solvers.

These printed puzzles make excellent gifts and educational tools for developing spatial reasoning skills.

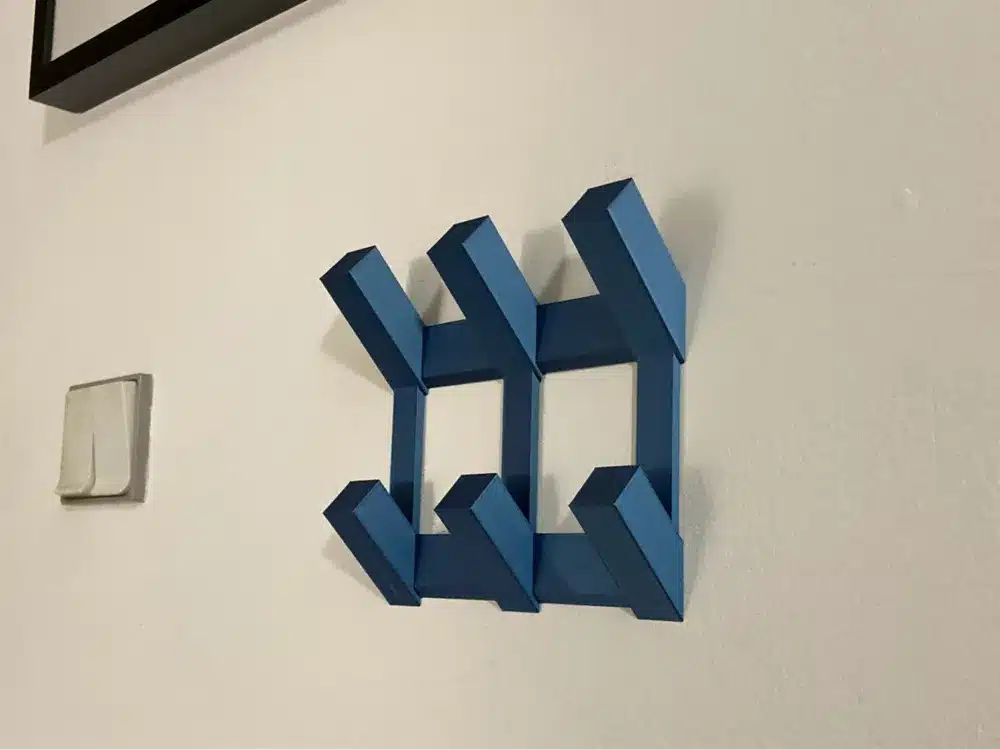

10) Wall-mounted coat hooks

Wall-mounted coat hooks are practical 3D printing projects that solve everyday organization problems. You can create custom hooks that match your home’s decor and specific storage needs.

These hooks typically feature concealed mounting systems that hide screws for a cleaner appearance. Many designs include reinforcing ribs through the center for added strength and durability.

You can print modular coat hook systems that allow you to add or remove hooks as needed. The modular approach lets you customize the number of hooks and their spacing based on your wall space.

Steampunk-style coat hooks offer decorative alternatives to basic designs. You can explore various aesthetic themes while maintaining functionality for heavy coats and bags.

Most coat hook designs work well with standard PLA filament. The compact size means quick print times and minimal material usage for each hook.

Your printed hooks should accommodate different garment types, from lightweight jackets to heavy winter coats. Consider the hook depth and curve when selecting or modifying designs.

Wall-mounted coat hooks prove especially useful in entryways, mudrooms, and children’s rooms where organization matters most.

11) Reusable coffee cup lids

You can reduce waste by 3D printing reusable coffee cup lids that replace disposable ones. These functional prints work with standard takeout cups from most coffee shops.

Custom-designed lids offer better sealing than generic options. You can create lids that fit perfectly on specific cup sizes like 8oz, 12oz, and 16oz containers.

Many printable designs include improved features like spill-resistant openings and comfortable drinking surfaces. Some models double as coasters when not in use.

You’ll find thousands of free STL files online for different lid styles. Popular designs include twist-on lids, snap-fit versions, and models with built-in stoppers to prevent spills.

Food-safe filaments like PETG or PLA work best for these prints. You should wash printed lids thoroughly before first use and regularly clean them like any reusable drinkware.

The printing process typically takes 1-3 hours depending on lid complexity. Most designs require minimal support material and print reliably on entry-level 3D printers.

Creating multiple lids in different colors helps you organize drinks for family members or keep extras available when others are being washed.

https://makerworld.com/en/models/1205186-can-lid?from=search#profileId-1218895

12) Innovative headphone cable wraps

Tangled headphone cables create frustration and reduce equipment lifespan. 3D printing offers customizable solutions for cable management that you can tailor to your specific needs.

You can design cable wraps to fit different cord diameters by scaling existing models. Most designs work for standard 3mm cables, but studio monitor headphones require larger wraps for their bulkier cords.

Simple wrap designs feature hollow cores to reduce print time and material usage. These basic models provide effective cable management without complex features.

More sophisticated designs incorporate hinged mechanisms inspired by classic audio equipment. These wraps allow cables to wind around the hinge before snapping securely into place, preventing unwinding.

You can create wraps for various headphone types, from lightweight earbuds to professional studio monitors. Each design addresses specific cable lengths and thicknesses.

The printing process is straightforward and requires minimal filament. Most cable wraps print quickly due to their compact size and efficient designs.

These functional prints solve everyday problems while demonstrating practical 3D printing applications. You can modify existing designs or create custom solutions based on your headphone collection’s specific requirements.

13) Custom cookie cutters

Creating your own cookie cutters with a 3D printer opens up endless design possibilities for your baking projects. You can craft unique shapes that match any theme or occasion.

The process is surprisingly straightforward. You design the cutter digitally or download existing STL files from various online communities.

Standard materials like PLA plastic work perfectly for cookie cutters. They’re food-safe and easy to print with most home 3D printers.

You can create seasonal shapes for holidays, personalized designs with names or initials, or replicas of favorite characters. Complex geometric patterns that would be impossible to find in stores become achievable.

The cutting edge should be thin enough to slice through dough cleanly but thick enough to maintain structural integrity. Most designs include a comfortable grip area above the cutting surface.

Thousands of free cookie cutter files are available online. You can also modify existing designs or create completely original shapes using basic 3D modeling software.

Custom cookie cutters make excellent gifts and conversation starters. They transform ordinary baking into a creative outlet that reflects your personal style and interests.

https://makerworld.com/en/models/990319-pikachu-cookie-cutter?from=search#profileId-965746

14) Unique jewelry pieces

3D printing transforms jewelry creation by enabling intricate designs impossible with traditional methods. You can craft custom rings, necklaces, bracelets, and earrings with complex geometries and personalized details.

The technology allows you to experiment with various materials. Plastics and resins offer affordable prototyping options, while metals like silver, gold, and bronze create premium finished pieces.

You gain complete design freedom with 3D printed jewelry. Create fully articulated bracelets, detailed pendants with moving parts, or rings with impossible interlocking structures that cannot be manufactured conventionally.

The precision of modern 3D printers makes them ideal for small jewelry components. You can achieve fine details and smooth surfaces that rival traditional jewelry-making techniques.

Custom jewelry becomes accessible through 3D printing. Design pieces that perfectly fit your measurements or create personalized gifts with names, dates, or meaningful symbols embedded in the design.

You can iterate quickly on jewelry designs. Print prototypes in inexpensive materials to test fit and appearance before committing to precious metals for final production.

15) Desk nameplates

Desk nameplates are practical 3D printing projects that add personalization to your workspace. You can create custom designs that reflect your professional identity or personal style.

The beauty of 3D printed nameplates lies in their customization options. You control the font, size, colors, and overall design to match your preferences perfectly.

Most nameplate designs use simple geometric shapes and raised text. This makes them ideal beginner projects that don’t require advanced 3D modeling skills.

You can find thousands of free STL files online for desk nameplates. Many platforms offer modular systems where you print individual letters and arrange them as needed.

Consider printing nameplates for colleagues or as gifts. They work well in offices, classrooms, or home workspaces where you want to establish ownership of your area.

The printing process typically takes 1-3 hours depending on size and complexity. Standard PLA filament works well, though you might choose premium materials for professional settings.

Some designs include holders for business cards or small accessories. Others feature stands that elevate the nameplate for better visibility on crowded desks.

https://makerworld.com/en/models/1081189-supreme-desk-name-plate?from=search#profileId-1072954

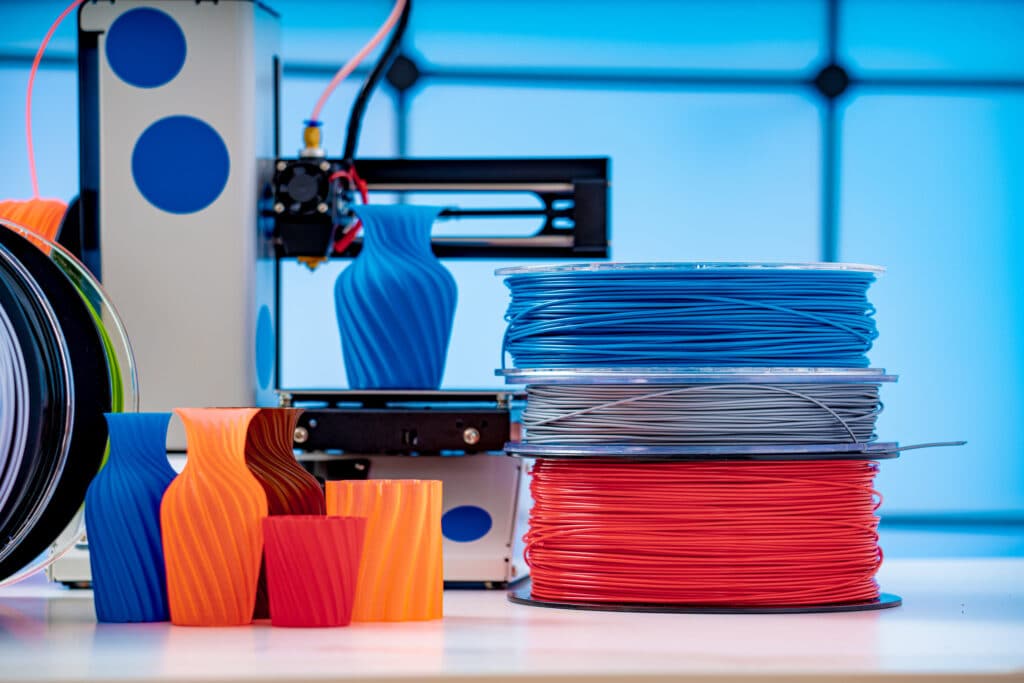

Choosing the Right 3D Printing Materials

The filament you select directly impacts your print’s strength, flexibility, and ease of printing. Traditional plastics like PLA and ABS remain popular choices, while specialty materials offer unique properties for specific applications.

PLA vs. ABS: Pros and Cons

PLA (Polylactic Acid) offers the easiest printing experience for beginners. It prints at lower temperatures (190-220°C) and requires no heated bed.

PLA produces minimal warping and emits a sweet, corn-like odor during printing. The material creates detailed prints with smooth surface finishes.

However, PLA becomes brittle over time and softens at 60°C. This limits its use for functional parts exposed to heat or stress.

ABS (Acrylonitrile Butadiene Styrene) provides superior durability and heat resistance up to 80°C. It maintains flexibility and impact resistance better than PLA.

ABS requires higher printing temperatures (220-250°C) and a heated bed at 80-100°C. The material tends to warp without proper enclosure and ventilation.

| Property | PLA | ABS |

|---|---|---|

| Print Temperature | 190-220°C | 220-250°C |

| Bed Temperature | Not required | 80-100°C |

| Durability | Low | High |

| Ease of Use | Excellent | Moderate |

Flexible and Specialty Filaments

TPU (Thermoplastic Polyurethane) creates rubber-like prints with excellent flexibility. It works well for phone cases, gaskets, and wearable items.

TPU requires slower print speeds (20-30mm/s) and direct drive extruders for best results. The material stretches without breaking and returns to its original shape.

PETG combines PLA’s ease of printing with ABS’s durability. It offers chemical resistance and crystal-clear transparency when printed correctly.

Wood-filled filaments contain real wood particles mixed with PLA base material. These create prints that smell like wood and can be sanded, stained, or painted.

Carbon fiber filaments add strength and stiffness to prints while reducing weight. They require hardened steel nozzles due to the abrasive carbon particles.

Metal-filled filaments like copper or steel create heavy, realistic-looking parts that can be polished to a metallic finish.

Design Tips for Creative 3D Printing

Successful 3D printing requires careful model optimization and proper file preparation. The right techniques prevent print failures and ensure your creative designs translate perfectly from digital concept to physical object.

Optimizing Models for Print Success

Wall thickness determines print strength and success rates. Maintain minimum wall thickness of 0.8mm for most desktop printers. Walls thinner than 0.4mm often fail to print properly.

Support structures become necessary for overhangs exceeding 45 degrees. Design models to minimize support requirements by orienting parts strategically. Consider splitting complex models into separate pieces that print without supports.

Bridge distances should stay under 50mm for reliable printing. Longer bridges tend to sag or fail completely. Break long spans with intermediate support points in your design.

Layer adhesion improves when you avoid sharp transitions between thick and thin sections. Gradual thickness changes prevent stress concentrations that cause layer separation.

File Preparation and Slicing Best Practices

STL resolution affects both file size and print quality. Use 0.1mm tolerance for detailed models and 0.3mm for basic shapes. Higher resolution creates unnecessarily large files without quality improvements.

Slicing parameters require adjustment based on your specific printer and material. Set layer heights between 0.1-0.3mm for standard prints. Use 20-30% infill for most projects.

Print orientation impacts surface quality and support requirements. Position your model’s best surface facing up. Rotate parts to minimize overhangs and maximize stability during printing.

First layer settings determine overall print success. Increase first layer height to 150-200% of normal layer height. Reduce print speed to 50% for the initial layers.

FAQ

What materials are best suited for creating durable and functional 3D prints?

PLA is easy to print and good for decorative items, while ABS is more durable and heat-resistant. For flexible or rubber-like parts, TPU is ideal, and specialty filaments like PETG, wood-filled, or metal-filled can add unique properties.

How do I start designing my own phone stand with a 3D printer?

You can start by designing a stand that fits your specific phone model, adjusting features like angle, height, and stability, and incorporating cable management or viewing features to customize it for your needs.

What are some practical 3D printing project ideas for everyday use?

Practical 3D printing projects include custom phone stands, modular desk organizers, personalized keychains, decorative planters, and functional cable holders, all designed to solve common daily problems.

What are some tips for preparing my 3D print files for the best results?

Use appropriate STL resolution (0.1mm for detail), adjust slicing parameters like layer height and infill, choose optimal print orientation, and set the first layer and support settings carefully to achieve a high-quality print.

- 20shares

- Facebook0

- Pinterest20

- Twitter0

- Reddit0