3D printing has rapidly become an accessible tool for creativity, problem-solving, and innovation at home and in professional settings. Whether you’re looking to make something practical, decorative, or unique, this technology offers a wide range of possibilities.

By exploring creative 3D printing ideas, you can discover new ways to solve everyday problems, enhance your hobbies, or even start small projects of your own. This article introduces a selection of inspiring 3D printing ideas to help you make the most of your printer and expand your skills.

1) Custom phone stands

If you need a simple and practical project, designing a custom phone stand is a reliable choice. You can create stands that fit your device and suit your preferences, whether you want something minimal or a stand with features like adjustable angles.

Many 3D printable phone stand designs are freely available online. Some are foldable, compact, or sized to fit in your wallet. Printing your own can be more economical than buying one in a store.

You have the flexibility to choose materials, sizes, and add unique features. Customizing your stand with patterns, initials, or extra supports is straightforward with basic design tools.

3D printed stands are useful for watching videos, making video calls, or keeping your workspace organized. You can also experiment with ergonomic or clever designs to improve stability and comfort while using your device.

2) Modular desk organizers

If you want a tidy workspace, modular desk organizers are an excellent 3D printing project. You can print stackable trays, drawer units, and customizable storage boxes to fit the specific items you use every day.

These organizers can hold pens, sticky notes, USB drives, or cables—whatever you need at your desk. Their modular design means you can expand or rearrange sections as your needs change.

Many designs are available online that allow you to snap together or stack different compartments. You don’t need tools or adhesives, just print and assemble the pieces.

Choose from minimalistic styles for a clean look or more complex layouts for greater storage. Using 3D printing, you can also match the color and size of your organizer to your workspace for a truly personalized solution.

Having everything organized and within reach streamlines your daily routine. Printing your own modular organizer is a practical way to use your 3D printer and keep clutter under control.

https://makerworld.com/en/models/1397248-modular-desk-organiser?from=search#profileId-1448466

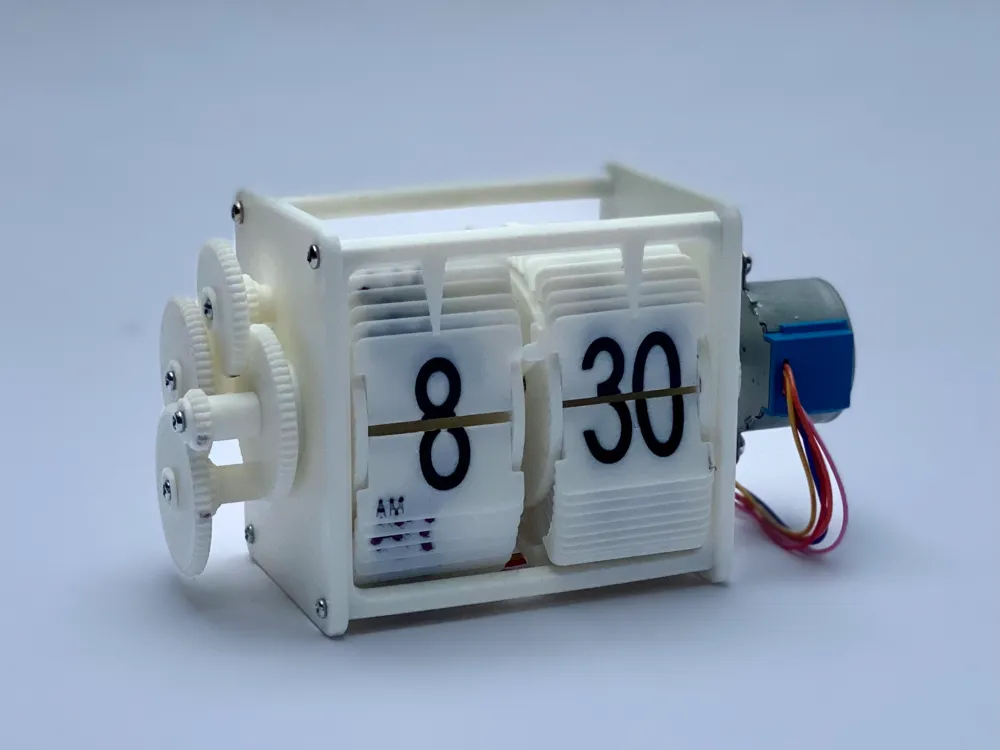

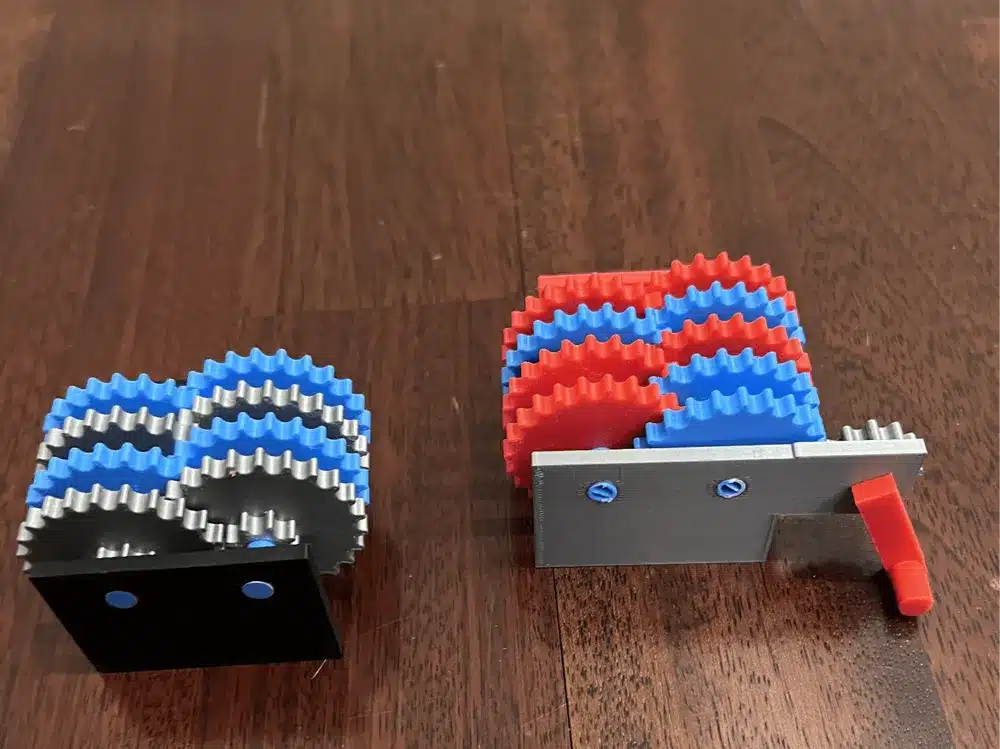

3) Mechanical clocks

Mechanical clocks are a popular project among 3D printing enthusiasts. You can create both decorative and functional timepieces with intricate gears, escapements, and moving parts. Many printable clock designs are available online, ranging from traditional styles to innovative concepts.

Building a 3D printed clock allows you to explore the mechanics behind timekeeping. You typically print the frame, gears, and hands, while using metal rods or standard hardware for axles and weights. This project can help you understand gear ratios and escapement mechanisms in a hands-on way.

You’ll also find clocks designed for educational purposes. Printing and assembling a clock is a valuable STEM activity that demonstrates engineering and physics principles. Some designs focus on visual appeal, showcasing exposed gear trains and creative layouts.

If you want to customize your clock, you can modify the model or add your own design touches. Most 3D printed mechanical clocks operate by winding a weight or spring, and accurate assembly is important for reliable function. Resources online often provide detailed instructions and troubleshooting tips.

4) Guitar picks and accessories

You can 3D print guitar picks in a range of shapes and thicknesses to match your playing style. Many designers share STL files for picks online, so you have plenty of options to choose from.

If you prefer specific materials or flexibility, you can adjust print settings or try different filaments like PLA, PETG, or flexible materials. This lets you experiment and find the feel that works best for you.

Beyond picks, you can also print practical guitar accessories such as capos, wall mounts, strap locks, and holders. Customizing these items means you get exactly what you need, tailored to your own setup.

3D printing allows you to quickly replace lost or broken guitar picks and accessories. This can be especially useful if you want unique designs or can’t find suitable products in stores.

Printing your own accessories saves time and can reduce costs, especially if you play guitar regularly and go through picks often. Customizing colors or adding your own logo is also possible for a personal touch.

https://makerworld.com/en/models/683665-pip-guitar-pick-box-v2?from=search#profileId-612277

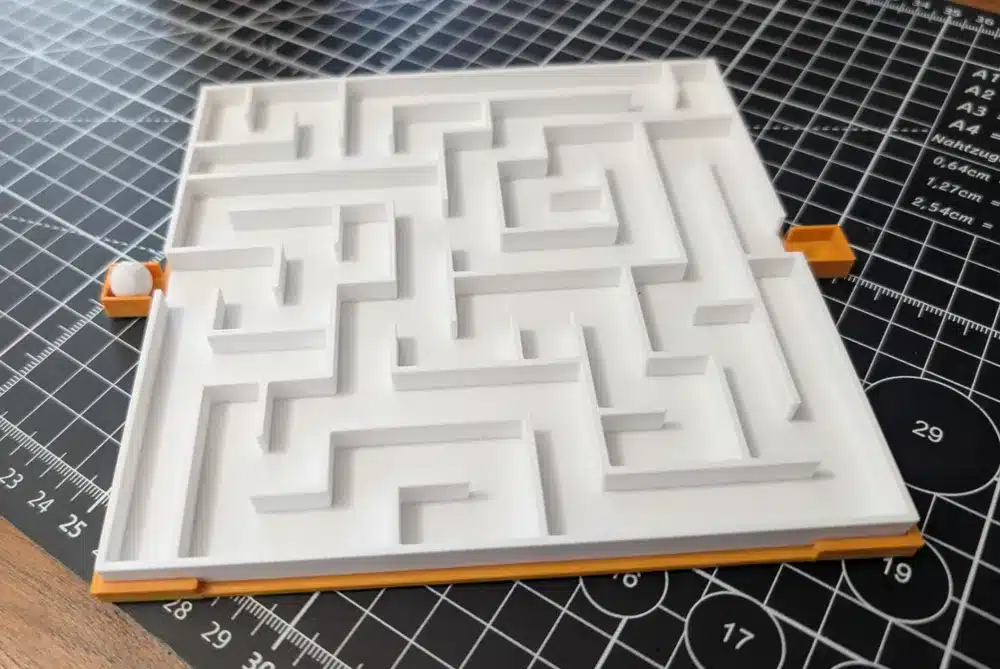

5) Marble maze puzzles

Marble maze puzzles are a classic and engaging 3D printing project that test your design and problem-solving skills. You can create simple tracks or more complex, modular mazes that allow you to change layouts for new challenges.

With 3D modeling software, you design your own unique pathways, twists, and obstacles. There are free STL files and templates available online, letting you get started quickly or customize your own.

Printing a marble maze helps you practice precise tolerances and smooth surface finishes. You can also print maze pieces in different colors for visual appeal. Modular designs let you expand or reconfigure the maze to keep it interesting.

These puzzles are suitable for both beginners and advanced users. They make fun desk toys or thoughtful gifts. Marble mazes highlight creativity and are great for hands-on learning with 3D printing.

6) Wearable tech prototypes

With 3D printing, you can create prototypes for wearable technology quickly and cost-effectively. This process allows you to design, print, and test a variety of custom-fit devices like smartwatches, fitness trackers, and specialized sensor housings.

You have the flexibility to try out different shapes, materials, and sizes. This makes it easier to find the right fit and style for your intended user group. Adjustment and iteration become much simpler since you can revise your design and print a new prototype within hours.

Many hobbyists and small businesses use 3D printing to produce custom jewelry, bands, and even e-textile components tailored for individual needs. The technology supports detailed and intricate designs that might be difficult to create with traditional methods.

By using 3D printers, you can easily test your ideas on real people, gather feedback, and refine the product. This rapid turnaround helps you solve design issues early in the development process.

If you want to validate the comfort and usability of a concept before mass production, 3D printing provides accessible solutions for both small and large-scale projects.

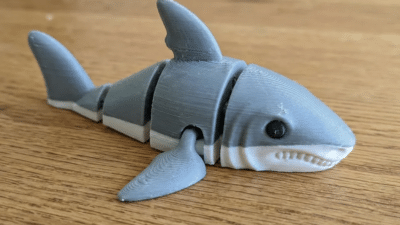

7) Interactive automata models

Interactive automata models bring together mechanical movement and creative design. These 3D prints often use gears, cams, and levers to create motion when you turn a handle or push a button.

You can choose from a wide range of automata, including animals, characters, and simple machines. Moving parts let you see how the mechanical principles work in real time.

Printable automata models are available for free and paid download on several websites. These designs are popular for education, demonstration, or as unique desk toys.

Printing automata often requires precise tolerances, so you may need to fine-tune your printer settings. Some models assemble without glue or screws, while others may need simple post-processing.

Automata are fun to build and watch in action, making them a satisfying project if you like both art and engineering. With your 3D printer, you can explore moving models at your own pace.

https://makerworld.com/en/models/1050244-1-3-gear-ratio?from=search#profileId-1036850

8) Medical model replicas

With 3D printing, you can create accurate medical model replicas for a range of educational and professional uses. These models include human organs, bones, or anatomical structures.

If you’re studying medicine or training staff, 3D printed models help visualize complex anatomy. You can also use them for patient education, giving people a better understanding of their conditions or upcoming procedures.

Hospitals and clinics sometimes 3D print custom replicas from patient scans. This technique helps surgeons plan procedures and improves communication among healthcare teams.

Online repositories offer a wide selection of medical model STL or CAD files. You can find resources for prosthetics, surgical tools, and anatomical models made for different specialties.

Printing your own medical replicas requires careful selection of materials and precise printer calibration. Ensure you follow any regulations and best practices if you intend these models for clinical settings.

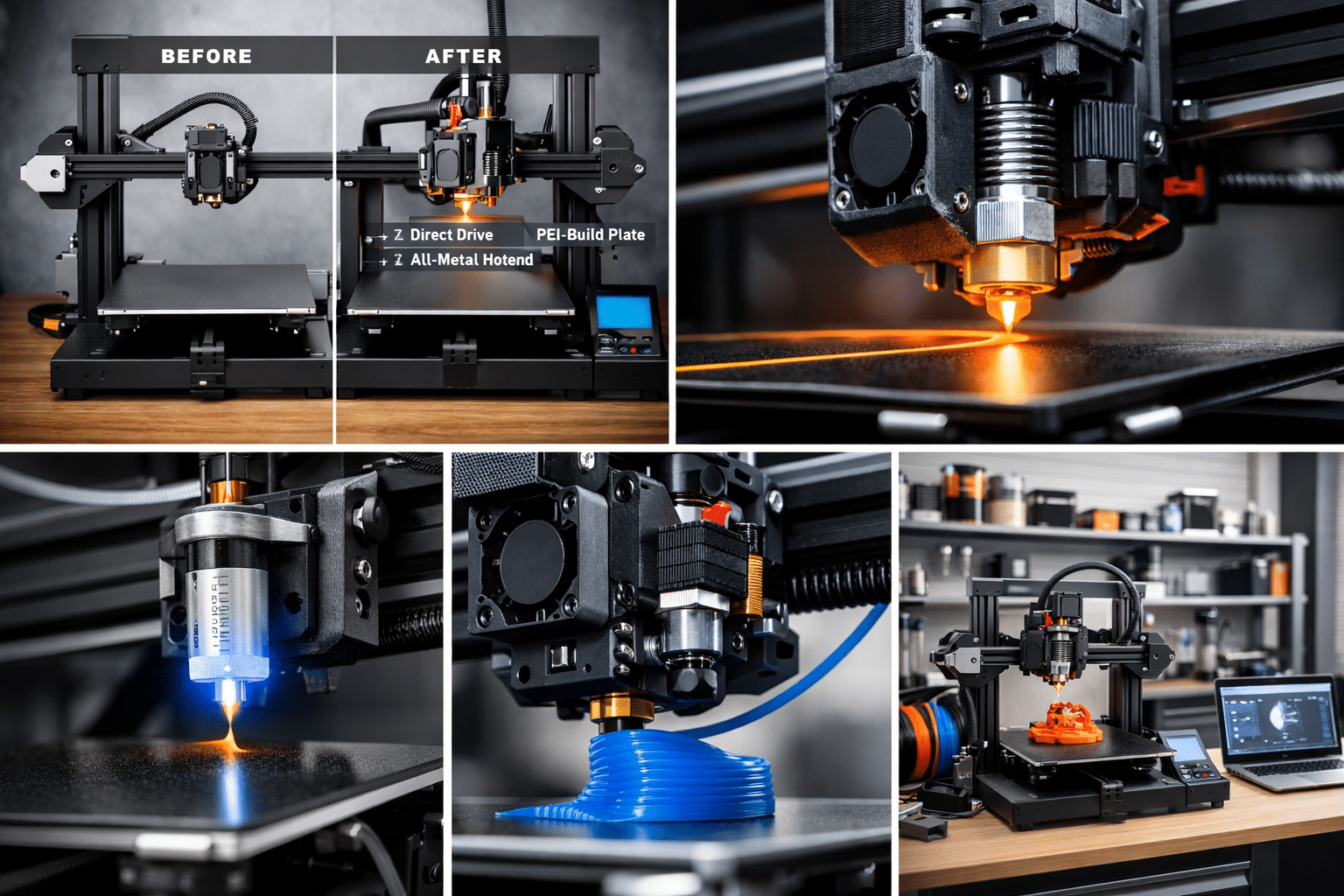

Essential 3D Printing Materials

Knowing which 3D printing materials fit your project will help you achieve the results you want. Different materials have unique strengths, weaknesses, and ideal uses, so understanding your options is crucial.

Overview of Filament Types

The most common 3D printing filaments are PLA, ABS, PETG, and resin. PLA is popular for its ease of use and biodegradability, while ABS offers higher strength and temperature resistance but requires better ventilation due to fumes.

PETG combines impact resistance with good flexibility, making it useful for functional parts. Resin is used in SLA printers for high-detail prints, but handling safety is important due to chemical exposure.

Other materials include TPU (flexible), nylon (durable), and specialty filaments such as carbon fiber or wood-infused. Many printers list which filaments they support, so always check hardware compatibility. The table below summarizes key properties:

| Material | Strength | Flexibility | Print Temp | Ease of Use |

|---|---|---|---|---|

| PLA | Medium | Low | 180-220°C | Very easy |

| ABS | High | Medium | 220-250°C | Moderate |

| PETG | High | Medium | 220-250°C | Easy |

| Resin | Varied | Low | N/A (SLA) | Moderate-Special |

| TPU | Medium | Very High | 210-230°C | Challenging |

Material Selection Tips

Choose your material based on the function and environment of your final object. For models or prototypes, PLA is an efficient and affordable option. If you need durability, heat resistance, or parts under stress, ABS or PETG is preferable.

For detailed miniatures or jewelry, resin provides excellent resolution. When printing flexible items like phone cases or gaskets, TPU is suitable, but it needs a compatible extruder.

Always consider safety—ABS and resin both require ventilation due to fumes or chemicals. Factor in your printer’s capabilities, as not all machines can handle every material. For sustainable projects, eco-friendly filaments like biodegradable PLA or recycled PETG are now widely available.

Optimizing the Design Process

Effective optimization saves time, minimizes printing errors, and ensures your models function as intended. The software tools and core design methods you choose play a significant role in the end results of your 3D prints.

Choosing the Right CAD Software

Selecting a CAD software depends on your project needs, skill level, and the type of printing you intend to do.

If you are a beginner, free programs like Tinkercad or Fusion 360 are user-friendly and provide essential features for basic design work. For advanced capabilities, paid programs such as SolidWorks or Rhino offer powerful tools for complex engineering projects, parametric modeling, and advanced geometry.

Slicer software is also essential for preparing print-ready files. Free slicers like Cura cover most needs, but paid slicers may offer more control, faster processing, and helpful features for intricate models or batch production.

| Software | Ideal For | Key Features |

|---|---|---|

| Tinkercad | Beginners/education | Simple interface, cloud-based |

| Fusion 360 | Hobbyists/professionals | Parametric, assemblies, rendering |

| SolidWorks/Rhino | Engineering/designers | High precision, advanced modeling |

| Cura/PrusaSlicer | Majority of printers | Easy slicing, wide printer support |

Design Best Practices

Start by respecting the physical limitations of 3D printers. Consider wall thickness, overhang angles, and the minimum feature size supported by your printer. Use the fewest support structures possible, and orient parts to reduce the need for supports and maximize surface quality.

Make sure your model is manifold (watertight) and has no intersecting or non-joined faces. It helps to run design checks for common errors and to use mesh repair tools before exporting.

When possible, hollow models can save material and reduce print time, but be sure to add drain holes to avoid trapped resin or filament.

Always follow manufacturer recommendations for fillet radii, clearance gaps, and tolerances. For moving parts, a standard starting clearance is 0.2–0.5 mm, but this can vary with printer and material type. Using chamfers, fillets, and avoiding sharp internal corners increases printed part strength and reduces stress points.

- 2shares

- Facebook0

- Pinterest2

- Twitter0

- Reddit0