3D printing has revolutionized countless aspects of our daily lives, often in ways we don’t immediately recognize. From the personalized phone case in your pocket to the advanced medical implants saving lives, this technology has silently transformed how products are designed, manufactured, and distributed. 3D printing has fundamentally changed our world by democratizing manufacturing, enabling unprecedented customization, and solving complex problems that traditional production methods simply couldn’t address.

You might not realize it, but 3D printing touches almost every industry today. In healthcare, doctors are printing patient-specific surgical models and even human tissues. Manufacturing companies have slashed prototyping time from weeks to hours. The construction industry is experimenting with printing entire homes, potentially solving housing crises around the world. This technology has made what once seemed impossible not just possible, but increasingly common.

Key Takeaways

- 3D printing has democratized manufacturing by making production more accessible, flexible, and cost-effective for businesses and individuals alike.

- The technology enables unprecedented personalization in everything from consumer products to medical treatments tailored to your specific needs.

- 3D printing is actively reshaping industries like healthcare, construction, and education while promising even more transformative applications in the future.

The Evolution of 3D Printing

3D printing has transformed from a niche technology to a revolutionary manufacturing process that affects many aspects of our daily life. The journey from prototype-focused applications to mainstream production has been remarkable, with significant improvements in accessibility, capabilities, and industry adoption.

From Prototyping to Production

When 3D printing first emerged, it was primarily used for creating prototypes. Designers and engineers could quickly turn their digital designs into physical objects for testing and visualization before committing to traditional manufacturing methods.

As the technology matured, 3D printing began shifting from merely creating prototypes to actual production. Companies now use additive manufacturing to create final products, not just test versions. This shift has been possible due to improvements in printing materials, including metals, ceramics, and various polymers.

You can now find 3D-printed components in aerospace, automotive, and medical industries. For example, GE Aviation produces fuel nozzles for jet engines using 3D printing, resulting in parts that are 25% lighter and five times more durable than traditionally manufactured versions.

Maintaining a clean environment is crucial in these industries, and facilities often use specialized tools like an industrial vacuum cleaner to remove fine particles and ensure optimal printer performance and material quality.

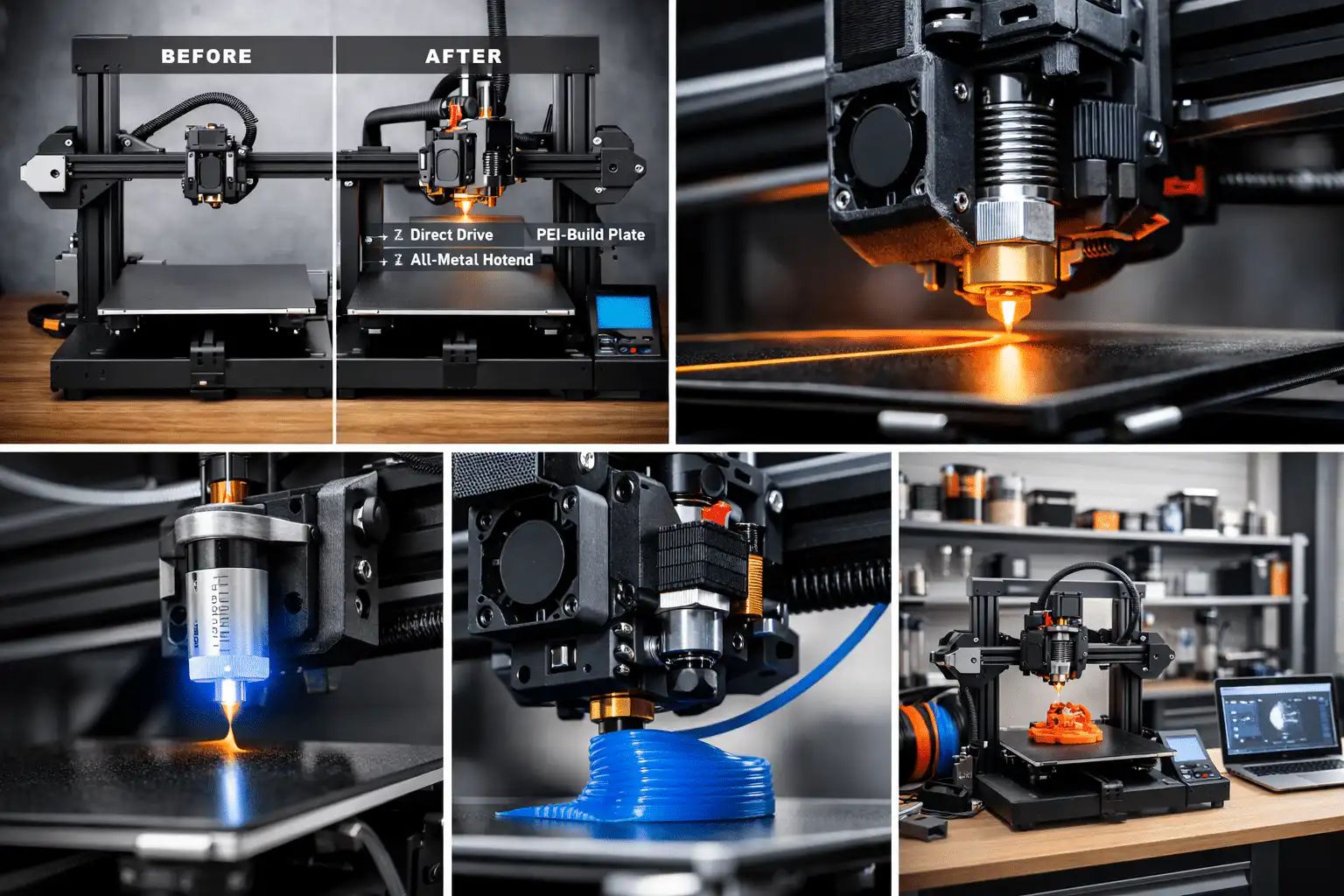

The Rise of Desktop Printers

The early 2010s saw a major breakthrough with the introduction of affordable desktop 3D printers. What was once industrial equipment costing hundreds of thousands of dollars became accessible to small businesses, schools, and even home users.

Companies like MakerBot and Ultimaker pioneered user-friendly machines that brought 3D printing technology to your desktop. These printers typically use FDM (Fused Deposition Modeling) technology, melting plastic filament and building objects layer by layer.

You can now purchase a decent entry-level 3D printer for under $300, opening up possibilities for hobbyists, educators, and entrepreneurs. This democratization has sparked innovation as more people experiment with creating custom objects, replacement parts, and unique designs from the comfort of their homes.

Growth of the 3D Printing Industry

The 3D printing industry has experienced remarkable growth, expanding from a $4.4 billion market in 2013 to over $18 billion by 2025. This growth reflects wider adoption across multiple sectors.

Major companies have invested heavily in advancing additive manufacturing technologies. HP, for instance, has developed Multi Jet Fusion technology that prints at speeds up to 10 times faster than previous methods, making production-scale 3D printing more viable.

You can see the impact of this growth in specialized applications like bioprinting, where living tissues are being created for medical research, and in construction, where companies are printing entire houses. The industry continues to evolve with innovations in materials, printing speeds, and precision, promising even more transformative applications in your future.

Transforming Manufacturing and Engineering

The manufacturing and engineering landscapes have been completely reimagined through 3D printing technologies. Traditional production constraints have fallen away as additive manufacturing enables new design possibilities, faster development cycles, and more cost-effective production methods.

Shifts in Manufacturing Jobs

3D printing has created exciting new roles while transforming existing ones in manufacturing. You’ll find designers now need skills in 3D modeling software like CAD to create printable designs. Machine operators require different expertise too – instead of traditional machining knowledge, they’re learning to maintain and optimize 3D printers.

Small businesses can now compete with larger manufacturers since the cost of entry has decreased dramatically. You no longer need massive factories or expensive tooling to create products.

Some traditional manufacturing positions have evolved or diminished, but new opportunities have emerged:

- 3D printer technicians who maintain equipment

- Materials specialists who develop new printing media

- Design optimization experts who ensure printability

Local manufacturing has seen a resurgence as production can happen closer to customers, reducing shipping and storage costs.

Enabling Rapid Prototyping

Rapid prototyping through 3D printing has dramatically accelerated product development. You can now transform a digital design into a physical prototype in hours instead of weeks.

This speed allows you to test multiple design iterations quickly and affordably. Identifying flaws and making improvements happens much earlier in the development process, saving time and resources.

Companies can now involve customers in the design process by creating prototypes for testing and feedback before final production. This user-centered approach leads to better products that truly meet customer needs.

The financial benefits are substantial too. Traditional prototyping often required expensive mold-making or machining processes. With 3D printing, you only use the material needed for the model, reducing waste and costs.

Even complex geometries that would be impossible to create with traditional methods can be printed easily, unlocking new design possibilities.

Driving Innovation in Engineering

3D printing has removed many traditional design constraints, allowing you to create structures previously impossible to manufacture. Complex internal geometries, organic shapes, and integrated moving parts can now be produced in a single print.

Engineers are rethinking entire products around additive manufacturing capabilities. Aircraft components now feature weight-saving lattice structures that maintain strength while using less material. Medical devices can be precisely customized to patient anatomy.

Design software has evolved alongside printing technology, offering specialized tools for:

- Topology optimization

- Generative design

- Structure simulation

You can now solve engineering challenges in entirely new ways. Rather than asking “how can we make this?” engineers now ask “what’s the ideal solution?” knowing that complex designs are now printable.

The sustainability impact is significant too. With additive manufacturing, you use only the material needed, reducing waste compared to subtractive methods where excess material is cut away.

Personalization and Customization in Daily Life

3D printing technology has revolutionized how you can personalize everyday items to match your exact preferences and needs. This innovation empowers both individuals and companies to create unique solutions that weren’t possible before.

Custom Products for Consumers

Have you ever wished for a phone case that perfectly fits your hand or kitchen gadgets that work exactly how you want them to? 3D printing makes this possible! You can now design and create items that are uniquely yours.

Many companies offer platforms where you can customize jewelry, home décor, and accessories. For example, you can design your own lamp that matches your interior perfectly or create personalized gifts for loved ones.

The days of settling for mass-produced items are fading. With accessible 3D printing services, you can modify existing designs or create something entirely new. Even furniture pieces can be customized to fit your specific space requirements.

The best part? These personalized items often cost less than you might expect. As 3D printing technology becomes more mainstream, creating custom products is becoming increasingly affordable for everyday consumers.

Healthcare and Prosthetics

3D printing has brought remarkable changes to healthcare, especially in creating personalized medical solutions. You might be surprised at how this technology is improving patients’ lives worldwide.

Custom prosthetics are perhaps the most heartwarming application. Children who quickly outgrow traditional prosthetics can now receive affordable, perfectly-fitted limbs that can be easily replaced as they grow.

Medical professionals can create anatomical models from your scans to plan surgeries with greater precision. This personalization reduces risks and improves outcomes significantly.

Hearing aids and dental implants are now commonly 3D printed to match your exact anatomy. The perfect fit improves comfort and functionality while often reducing costs.

Even medication can be personalized through 3D printing, with researchers developing techniques to create pills with customized dosages and release patterns tailored to your specific needs.

Creative and Artistic Applications

Your creative expression can reach new heights with 3D printing! Artists and designers now use this technology to create pieces that were previously impossible to manufacture.

Fashion designers are incorporating 3D printed elements into clothing and accessories. You can find unique jewelry, shoes, and even complete garments that showcase intricate designs only possible through this technology.

In home décor, you can print custom lighting fixtures, vases, and sculptures that perfectly complement your space. Many artists offer customizable designs that you can modify to suit your taste and needs.

Musicians have embraced 3D printing to create custom instruments with unique acoustic properties. You could play a guitar that’s designed specifically for your hand size and playing style.

Educational models and toys can be personalized too. Teachers are printing learning aids tailored to specific lessons, while parents can create toys that address their children’s particular interests or developmental needs.

Advancing Education and Research

The integration of 3D printing technology has revolutionized how we learn and conduct research. Educational institutions and research facilities now utilize these powerful tools to create tangible learning experiences and accelerate scientific discovery.

Integrating 3D Printing in Classrooms

3D printers have transformed traditional classroom environments by bringing abstract concepts to life. You can now see students creating real-life replicas of fossils, bones, and historical artifacts that were previously only viewable in textbooks or behind museum glass.

Teachers report increased student engagement when complex topics are supported by 3D printed models. For example, biology students can hold anatomically correct organs while learning about human systems, making abstract concepts tangible.

STEM education particularly benefits from this technology. When you introduce 3D printing to young learners, they develop critical thinking skills through the design process—from concept to finished product.

Schools with limited resources can print affordable lab equipment and educational materials, democratizing access to quality hands-on learning experiences regardless of budget constraints.

Accelerating Scientific Research

3D printing has dramatically shortened the research and development cycle across scientific disciplines. You can now prototype ideas quickly, test them, and refine designs within days instead of weeks or months.

Researchers use 3D printers to create customized equipment that previously didn’t exist or was prohibitively expensive. This capability enables novel experiments that weren’t previously possible.

Medical research has particularly flourished with this technology. Researchers print patient-specific anatomical models to practice complex surgeries or test new treatment approaches before touching actual patients.

The collaborative nature of research has improved too. You can easily share digital designs with colleagues worldwide, who can then print and test them in their own labs, fostering global scientific cooperation.

The Future Impact of 3D Printing

3D printing technology is poised to transform our world in profound ways. The future holds exciting possibilities as this technology continues to evolve, particularly in creating sustainable solutions and introducing groundbreaking innovations.

Sustainability and Environmental Benefits

3D printing offers remarkable potential for reducing waste in manufacturing processes. Unlike traditional manufacturing that cuts away material, additive manufacturing builds objects layer by layer, using only the necessary materials.

You’ll likely see more construction projects using 3D printing technology in the coming years. As search results indicate, this approach can dramatically reduce construction times from months to mere days, while simultaneously decreasing environmental impact.

Material innovations will expand to include more biodegradable and recycled options. This shift will help you reduce your carbon footprint when choosing 3D-printed products.

Local production enabled by 3D printing will cut transportation emissions. When items can be printed near where they’re needed, shipping distances shrink significantly.

Emerging Technologies and Trends

Bioprinting represents one of the most promising frontiers in additive manufacturing. You might soon benefit from customized medical implants or even 3D-printed organs tailored specifically to your body.

Food printing is evolving beyond novelties like the “cheesecake” mentioned in search results. You’ll have access to personalized nutrition through precisely formulated printed foods.

Multi-material printing technologies are advancing rapidly. This means you’ll see more complex products with varying properties—like electronics with both rigid and flexible components—created in a single print.

Democratization of manufacturing will continue as 3D printers become more affordable. You’ll have increasing opportunities to design and create custom solutions for your specific needs.

- 0shares

- Facebook0

- Pinterest0

- Twitter0

- Reddit0