In the world of 3D printing, it’s the everyday items that often bring the most value to our lives. From simple phone stands to clever storage solutions, practical 3D prints have become essential tools in many homes. These functional creations solve common problems while demonstrating how accessible technology can transform our daily routines.

The beauty of everyday 3D prints lies in their utility and customization potential. Glasses holders, bottle drainage stands, cable management boxes, and coffee filter holders might seem mundane, but they address specific needs that mass-produced products often overlook. As we move through 2025, the library of practical designs continues to expand, offering solutions for organization, utility, and home improvement.

You don’t need elaborate designs to make a significant impact in your living space. Many of the most useful 3D prints are surprisingly simple yet solve persistent problems we face daily. Whether it’s a custom hook for your headphones or a specialized tool that fits your exact requirements, these practical prints demonstrate the true promise of home 3D printing technology.

Key Takeaways

- Practical 3D prints solve everyday problems while being customizable to your specific needs and space constraints.

- Popular everyday items include organizers, stands, holders, and utility tools that see constant use around the home.

- Successful everyday 3D prints balance functionality, durability, and design simplicity to address real-world challenges.

Overview of Everyday Use 3D Prints

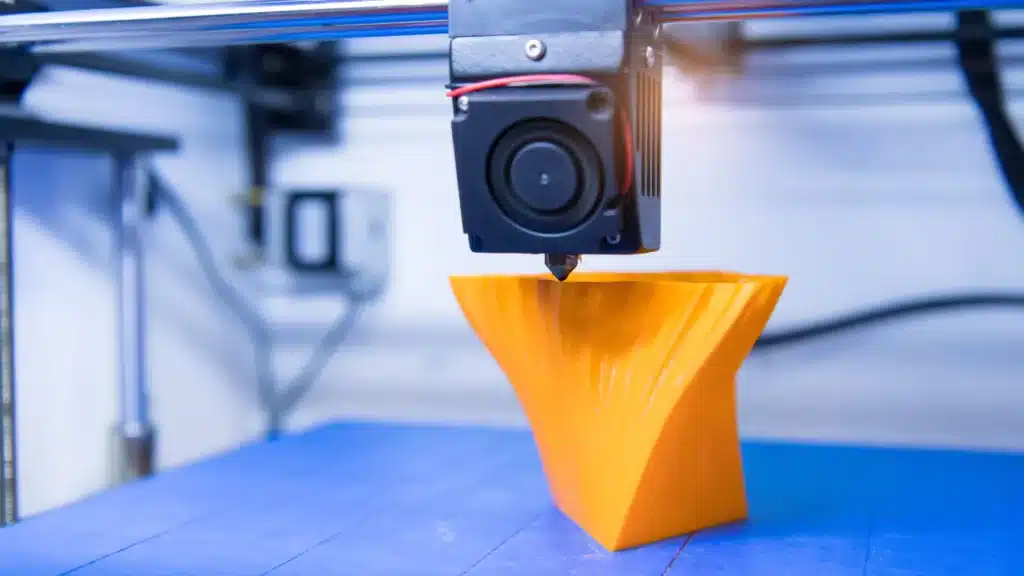

3D printing has transformed from a novelty technology into a practical solution for creating useful items that solve real problems in our daily lives. The ability to design and produce custom objects has opened up countless possibilities for home use.

Common Applications in Daily Life

Phone stands and cable organizers rank among the most frequently printed everyday items. These simple solutions help keep your desk tidy and devices accessible. Many users print custom kitchen gadgets like jar openers, measuring spoons, and specialized utensil holders that fit their specific needs.

Bathroom organizers, toothbrush holders, and soap dishes are practical prints that improve daily routines. These items can be customized to fit exact dimensions of your space, unlike mass-produced alternatives.

Wall hooks, picture frames, and decorative planters allow you to personalize your living space with functional art. You can print replacement parts for appliances and furniture when originals break or wear out, extending the lifespan of your possessions.

Key organizers, wallet accessories, and bag clips represent small but impactful prints that solve common frustrations in daily life.

Benefits of 3D Printed Objects

Customization is perhaps the greatest advantage of 3D printed items. You can tailor dimensions, shapes, and features to your exact specifications, something impossible with store-bought products.

Cost savings become significant when printing replacement parts or specialized items that would otherwise be expensive or unavailable. A $25 spool of filament can produce dozens of useful objects.

Sustainability improves as you print only what you need, reducing packaging waste and transportation emissions. Many filaments are recyclable or biodegradable, further reducing environmental impact.

Rapid iteration allows you to improve designs over time. If a printed item doesn’t work perfectly, you can adjust the design and print an improved version within hours.

Growth in Personal and Home Use

Additive manufacturing has seen explosive growth in home settings as printer prices have dropped below $200 for entry-level models. This accessibility has created a robust community of makers sharing thousands of practical designs online.

The technology continues to evolve with multi-material printing becoming more common, allowing for objects with both rigid and flexible components. This advancement enables more complex and functional everyday items.

Print farms are emerging as small businesses that provide printing services to those without their own equipment. This development has made 3D printed solutions accessible to even more households.

Educational institutions increasingly incorporate 3D printing technology into their curriculum, ensuring future generations view additive manufacturing as a standard tool for problem-solving in daily life.

Popular Types of Everyday 3D Printed Items

3D printing has revolutionized how we solve everyday problems and enhance our living spaces. From fixing broken appliances to creating custom organizers, these practical prints have become essential tools in many households.

Replacement Parts and Repairs

When something breaks in your home, 3D printing offers an immediate solution without waiting for ordered parts. Replacement knobs for kitchen appliances, drawer pulls, and cabinet handles can be printed in just a few hours.

Broken vacuum cleaner attachments, which manufacturers often discontinue, can be recreated with precision. Many people print washing machine dial replacements, refrigerator shelf clips, and dishwasher rack wheels when the originals fail.

Remote control battery covers and game controller parts are among the most commonly printed replacements. You can find these designs on platforms like MakerWorld or create custom versions tailored to your exact specifications.

The durability of these prints depends on the material used. PLA works for light-duty parts, while PETG or ABS provides greater strength for components under stress or heat.

Personalized Products for Daily Convenience

Custom organizers transform cluttered spaces into efficient systems tailored to your exact needs. Cable management solutions keep your desk tidy with precisely sized clips and boxes for your specific cable types.

Kitchen organization benefits tremendously from 3D printing:

- Spice rack organizers designed for your cabinet dimensions

- Cutlery trays that maximize drawer space

- Custom-fit refrigerator bins

Bathroom accessories like toothbrush holders, soap dishes, and shower caddies can be designed to match your décor and fit awkward spaces. Many users print shower drain covers, towel hooks, and toilet paper holders when commercial options don’t quite fit.

Wall-mounted organizers for keys, mail, and small items help keep entryways organized. These can be customized with your family name or designed to match your home’s aesthetic perfectly.

Educational and Hands-On Learning Tools

3D printing creates tangible learning experiences for students of all ages. Anatomical models help medical and biology students understand complex structures through tactile exploration rather than just viewing 2D images.

Mathematical concepts become clearer with printed geometric shapes, function models, and puzzles. Teachers use these to demonstrate abstract ideas like calculus or topology in physical form.

Engineering concepts can be demonstrated through working mechanical models:

- Planetary gear systems

- Simple engines

- Architectural principles

For younger learners, alphabet blocks, counting aids, and puzzle maps make learning interactive. These can be customized for specific educational needs or to address learning gaps.

Chemistry teachers print molecular structures to help students visualize atomic arrangements. Physics classes benefit from custom-designed experimental apparatus that may not be commercially available or affordable.

Custom Phone Cases and Accessories

Your smartphone deserves protection that reflects your personality. Custom phone cases can include your name, favorite designs, or functional features like card holders or integrated stands.

Phone stands designed for specific viewing angles make video calls or media consumption more comfortable. Some designs incorporate cable management or charging dock functionality for added convenience.

Desk organizers for your devices keep everything powered and accessible:

- Multi-device charging stations

- Earbud holders

- Cable routing systems

Car mounts can be customized to fit both your specific phone model and vehicle. These provide secure holding while accommodating your case and preferred orientation.

Phone accessories like camera lens attachments, tripod mounts, and gaming grips extend your device’s capabilities. Many users print replacement parts for phone accessories when the originals break or wear out.

Materials and Techniques for Everyday Use Prints

Selecting the right materials and techniques for your 3D printing projects significantly impacts durability, functionality, and appearance. The materials you choose should align with your specific needs, whether you’re creating kitchen gadgets, organizational tools, or decorative items.

Choosing the Right Printing Materials

When selecting materials for everyday 3D prints, consider the object’s intended use and environment. Kitchen items require food-safe materials that can withstand heat and washing. Bathroom accessories need water-resistant properties to prevent mold growth.

For outdoor applications, choose UV-resistant filaments that won’t degrade in sunlight. Load-bearing items like hooks and brackets demand stronger materials with good structural integrity.

Consider the layer adhesion properties, especially for functional parts that might experience stress or strain. The printing temperature also matters—some materials require higher temperatures, which might not be achievable on entry-level printers.

Always check your printer’s compatibility with your chosen material before purchasing. Some filaments require specialized nozzles or heated beds to print properly.

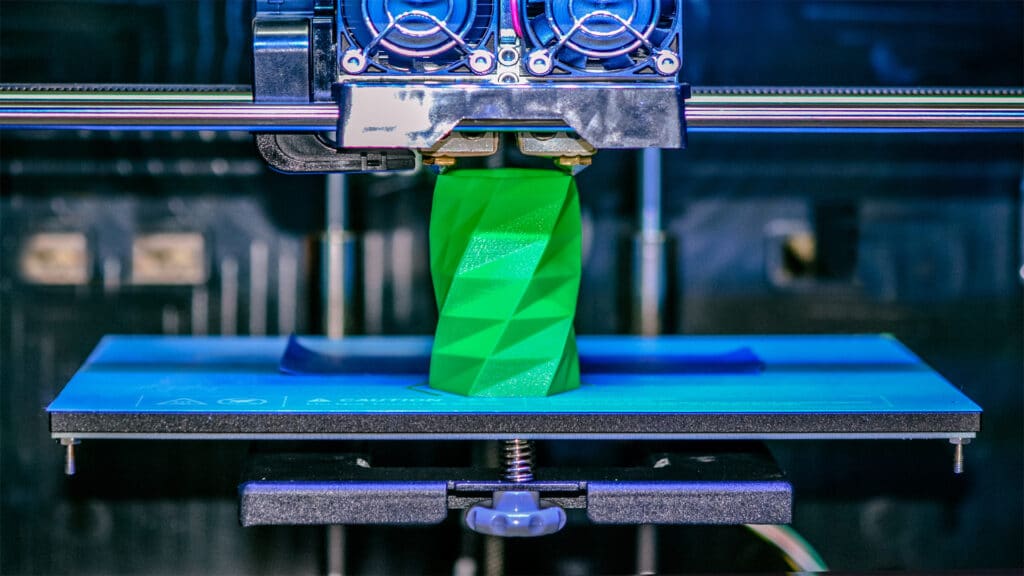

Commonly Used Filaments: PLA and ABS

PLA (Polylactic Acid) remains the most popular filament for everyday items due to its ease of use and biodegradability. It prints at lower temperatures (180-220°C) and doesn’t require a heated bed, making it perfect for beginners.

PLA produces minimal odor and comes in countless colors and finishes, including wood, metal, and glow-in-the-dark variants. It’s ideal for decorative items, organizers, and low-stress applications.

ABS (Acrylonitrile Butadiene Styrene) offers superior durability and heat resistance compared to PLA. It can withstand temperatures up to 105°C without deforming, making it suitable for kitchen gadgets or automotive parts.

However, ABS requires higher printing temperatures (220-250°C), a heated bed (95-110°C), and preferably an enclosed printing environment. It produces noticeable fumes during printing, so good ventilation is essential.

Resin Printing for Functional Items

Resin printing delivers exceptional detail and smooth surface finishes that filament printing cannot match. This makes it ideal for intricate household items like custom jewelry organizers, detailed figurines, or replacement parts with fine features.

Modern functional resins offer impressive durability comparable to engineering-grade filaments. ABS-like resins provide impact resistance while maintaining detail quality, perfect for household fixtures and tools.

Water-washable resins have simplified the post-processing workflow, making resin printing more accessible for home users. No longer requiring isopropyl alcohol for cleaning, these resins reduce both cost and environmental impact.

Remember that resin prints need proper curing under UV light to reach their full mechanical properties. Without this step, your prints may remain brittle and unsuitable for everyday use.

https://makerworld.com/en/models/1472828-watch-stand-no-ams-required#profileId-1537016

Designing and Customizing Everyday 3D Prints

Creating personalized 3D prints involves learning design tools, understanding customization techniques, and adding creative touches to make truly unique objects. The process combines technical skills with artistic vision to produce practical items tailored to your specific needs.

Using CAD and 3D Modeling Software

CAD (Computer-Aided Design) software forms the backbone of 3D print design. Programs like Fusion 360, TinkerCAD, and Blender offer varying levels of complexity for different skill levels.

Beginners should start with TinkerCAD due to its intuitive interface and browser-based accessibility. For more complex projects, Fusion 360 provides parametric modeling capabilities that allow precise measurements and adjustments.

Blender excels at organic shapes and artistic models, though it has a steeper learning curve. Many designers use it for creating decorative elements or character models.

Free resources like video tutorials and online courses can help you master these tools. Most software offers measurement tools to ensure your designs fit real-world objects perfectly.

Popular CAD Software Options:

- TinkerCAD (beginner-friendly)

- Fusion 360 (engineering focus)

- Blender (artistic focus)

- FreeCAD (open-source alternative)

Tips for Effective Customization

Start customization by identifying specific problems you want to solve. Measure twice before finalizing designs, as precision matters for functional prints like adapters, holders, or replacement parts.

Consider the limitations of your printer when designing. Account for print orientation, support structures, and material properties to ensure successful prints. Avoid large overhangs and thin walls that might fail during printing.

Create parametric designs when possible, allowing easy adjustment of dimensions without rebuilding the entire model. This approach is particularly useful for items that need to fit with existing objects.

Test designs with small prototypes before committing to full-size prints. This practice saves time, material, and frustration when developing complex or precise items.

Incorporating Art and Creativity

Beyond pure functionality, creative elements can transform everyday prints into conversation pieces. Consider adding textures, patterns, or personalized engravings to make utilitarian objects visually appealing.

Color choices significantly impact the final appearance. Plan your filament selection based on both aesthetic preference and practical considerations like UV resistance for outdoor items.

Combine multiple printed parts with different materials or colors to create visual interest. This technique works well for items like planters, desk organizers, and home décor.

Draw inspiration from nature, architecture, or art movements when designing. Organic shapes from nature often provide both aesthetic appeal and structural strength.

Don’t be afraid to iterate. Each design version can incorporate new ideas or refinements that improve both functionality and appearance. The digital nature of 3D design makes experimentation accessible and affordable.

Best Practices for Successful Everyday Prints

Creating functional 3D prints for daily use requires attention to detail and understanding of key technical concepts. The difference between a print that breaks after a few uses and one that lasts for years often comes down to these fundamental practices.

Optimizing Print Settings: Layer Height and Build Plate

Layer height is perhaps the most critical setting affecting your print’s quality and strength. For everyday items, use 0.2mm as your baseline – this provides a good balance between detail and print speed. When durability matters more than aesthetics, increase to 0.3mm for stronger layer adhesion.

The build plate is your foundation for success. Always ensure it’s properly leveled before starting a print. Apply appropriate adhesion methods based on your filament type:

- PLA: Light coating of glue stick or blue painter’s tape

- PETG: Clean glass with light hairspray

- ABS: Kapton tape or ABS slurry

Temperature matters tremendously. For most everyday items, heat your build plate to 60°C for PLA and 80-90°C for PETG. This prevents warping and ensures proper first-layer adhesion.

Improving Durability and Functionality

Infill percentage directly impacts strength. For household items that need to withstand regular use, set infill between 25-40%. For hooks, brackets or anything load-bearing, increase to 50-70%.

Choose the right filament for the job. PLA works for most indoor applications, but consider these alternatives:

| Filament | Best For | Considerations |

|---|---|---|

| PETG | Kitchen items, outdoor use | Higher temp resistance, water-resistant |

| TPU | Grips, protective cases | Flexible, absorbs impacts |

| ABS | Mechanical parts | Requires enclosure, higher temps |

Wall thickness is crucial – use minimum 3 perimeters (1.2mm) for items that will experience stress. This creates a solid outer shell that resists breaking.

Prototyping and Iterative Design

Always start with a test print at reduced size or thickness. This saves time and material while revealing potential issues with your design. For complex functional parts, print at 50% scale first to validate basic geometry.

Keep detailed notes of what works and what doesn’t. Document your settings, temperatures, and observations for each iteration. Use these insights to guide modifications.

Test your prototypes rigorously under real-world conditions. If you’re printing a phone stand, actually use it with your phone for several days. This reveals weaknesses that aren’t obvious from visual inspection alone.

Consider designing in modular components. This approach allows you to refine and reprint only the problematic sections rather than the entire object.

Supporting Structures: Rafts and Supports

Rafts create a stable foundation for prints with small contact areas. Use them when printing tall, narrow objects that might otherwise topple during printing. Configure your raft with 2-3mm offset from your part for easy removal.

Support structures are essential for overhangs exceeding 45 degrees. Configure them with:

- 15-20% density for everyday items

- 0.2mm Z-distance for clean separation

- “Touching buildplate” option when possible to minimize material use

Consider your support type carefully. Tree supports work exceptionally well for complex geometric shapes and typically use less material than traditional supports.

Post-processing is important – invest in quality flush cutters specifically for removing supports. Clean separation points with light sanding using 220-grit sandpaper for a professional finish.

Innovative and Niche Everyday 3D Printed Solutions

3D printing has expanded beyond simple household items into specialized solutions that address unique needs. These innovations are transforming accessibility, DIY construction, and personal manufacturing in ways that were unimaginable just a few years ago.

Assistive Devices and Prosthetics

Custom 3D printed prosthetics have revolutionized accessibility by dramatically reducing costs while increasing personalization. You can now create functional prosthetic hands for under $50, compared to traditional options costing thousands.

Organizations like e-NABLE connect volunteer makers with individuals needing assistive devices, creating a global community of support. Their open-source designs are continuously improved by users worldwide.

Specialized tools for daily living include easy-grip utensils, button fasteners, and jar openers that adapt to specific user needs. These devices often incorporate flexible filaments that mimic natural movement and provide comfort.

Recent advances in biocompatible materials have enabled the creation of custom splints, braces, and mobility aids that perfectly match the user’s anatomy. These solutions offer immediate relief without lengthy waiting periods for traditional medical devices.

Robotics and DIY Construction

Educational robot kits printed at home provide affordable entry points into robotics and programming. You can create functioning robots with movable joints, sensors, and control systems using downloadable blueprints.

Construction enthusiasts are printing specialized tools like custom jigs, alignment guides, and component holders that make complex projects more accessible. These purpose-built tools often outperform general-purpose alternatives.

Modular construction systems allow you to print interlocking structural components for larger projects. These systems enable the creation of furniture, garden structures, and even small shelters without specialized equipment.

Advanced makers are combining 3D printed parts with microcontrollers to create automated home solutions like custom security systems and environmental monitors. These integrated devices offer functionality previously available only in expensive commercial products.

Emerging Trends in Personalized Manufacturing

On-demand replacement parts represent one of the most practical applications of home 3D printing. You can now create exact matches for discontinued components, extending the life of appliances and equipment.

Multi-material printing enables the creation of complex functional objects with varying properties in a single print. This technology allows for soft grips on hard tools, flexible joints in rigid structures, and other integrated designs.

Local manufacturing networks are emerging where individuals with printers fulfill neighborhood needs. These micro-factories reduce shipping costs and environmental impact while supporting community resilience.

The combination of 3D scanning and printing has opened possibilities for creating perfect-fit solutions like custom ergonomic handles, device mounts, and organization systems tailored to your exact measurements and preferences.

- 25shares

- Facebook0

- Pinterest25

- Twitter0

- Reddit0