3D printing lamps is a creative way to bring unique lighting designs into any space. Using a 3D printer, people can make lamps with intricate shapes and patterns that regular manufacturing methods can’t easily achieve. These lamps combine art and technology, allowing for personalized, custom lighting that fits different styles and needs.

Many 3D printed lamps are inspired by nature, with patterns like honeycombs, leaves, or waves. They not only light up a room but also act as stylish decorations. The materials used can be eco-friendly, adding a sustainable touch to the design process.

Whether for ambient light or statement pieces, 3D printing opens up a world of possibilities. It allows designers and hobbyists to experiment with shapes, sizes, and colors easily, making it a fun and accessible option for anyone interested in lighting.

What Are 3D Printing Lamps?

3D printing lamps combine technology, design, and lighting to create unique, customizable light fixtures. They often showcase patterns inspired by nature or modern art, and offer options not possible with traditional lamps. These lamps vary in shape, size, and materials, making them practical and decorative.

Definition and Core Concepts

A 3D printing lamp is a light fixture made using additive manufacturing. Layers of material, often plastic or resin, are built up to form the lamp’s shape. This process lets designers create detailed and complex structures that would be hard to produce with standard methods.

These lamps typically include a 3D printed lampshade or body, combined with electrical parts like bulbs and wiring. The design can range from simple geometric shapes to intricate patterns mimicking natural forms like leaves or coral.

3D printing allows for rapid prototyping and easy customization. It also supports small batch production, reducing waste compared to mass manufacturing.

Types of 3D Printed Lamps

There are several types based on design and function:

- Table Lamps: Small, often artistic, suitable for desks or bedside tables.

- Pendant Lamps: Hang from the ceiling, often featuring open, airy designs.

- Floor Lamps: Larger, standing lights with unique printed bases or shades.

- Wall Lamps: Mounted on walls and designed for space-saving or accent lighting.

Materials vary but often include PLA, ABS plastics, or eco-friendly resins. Some lamps are designed to work with LED bulbs, optimizing energy use.

Designs can be purely decorative or focused on functionality, like diffusing light softly or casting patterned shadows.

Advantages Over Traditional Lamps

3D printed lamps offer several benefits compared to typical lamps:

- Customization: Users can personalize shapes, sizes, and patterns easily.

- Complex Designs: 3D printing can produce detailed structures that are hard to make with other methods.

- Sustainability: Local printing reduces shipping and waste from excess materials.

- Cost-Effective Prototypes: Makers and designers can quickly test ideas without expensive molds or tools.

Additionally, these lamps often use lightweight materials and innovative forms, making them easier to move and integrate into modern homes. They blend function with artistic expression more freely than traditional lamps.

Materials Used in 3D Printing Lamps

3D printing lamps rely on a variety of materials, each with unique features that affect the look, feel, and sustainability of the final product. These materials range from common plastics to eco-friendly options, and safety is a key concern when choosing the right filament for lighting.

PLA and Other Popular Filaments

PLA (Polylactic Acid) is one of the most widely used filaments for 3D printing lamps. It is derived from natural sources like corn starch, making it biodegradable and easy to print. PLA offers good detail and smooth finishes, which help create intricate lamp designs.

Other common filaments include ABS and PETG. ABS is strong and heat-resistant, but requires careful handling due to fumes during printing. PETG is tougher than PLA and has good durability, ideal for parts exposed to light heat.

These plastics come in different colors and finishes, like matte or glossy, allowing for custom lamp styles. They also tend to be lightweight, which is helpful for table lamps or hanging fixtures.

Recycled and Eco-Friendly Materials

A growing trend in 3D printing lamps is using recycled or bio-based materials. Recycled PLA, made from reused plastics, helps reduce waste and carbon footprints without sacrificing print quality.

Eco-friendly filaments like corn starch-based PLA offer translucency, which is perfect for lamps that need to softly diffuse light. These bio-plastics break down faster than traditional plastics.

Additionally, some pellet-based 3D printing methods focus on minimizing waste by printing only the needed amount. This approach avoids offcuts and excess materials common in traditional manufacturing, making lamp production greener.

Material Safety Considerations

Safety is important when choosing materials for 3D printed lamps, especially since lamps produce heat. PLA is generally considered safe because it burns cleanly and emits minimal fumes.

ABS and other plastics may release harmful gases when heated, so proper ventilation during printing and use is important. Some filaments can also melt under high temperatures, risking damage to the lamp or surrounding surfaces.

It’s best to use materials rated for heat resistance when parts will be near light sources like bulbs. Testing low-heat LED lights with the printed lamp parts is a common practice to avoid overheating issues.

Knowing material properties helps ensure lamps are both safe and long-lasting.

Designing Your Own 3D Printed Lamp

Creating a 3D printed lamp requires choosing or making the right design, using proper software to shape the parts, and planning how to add lights and wiring. Each step matters for a lamp that looks good and works well.

Finding and Customizing 3D Models

Many websites offer free and paid 3D lamp models ready to print. These models can vary from simple bases to detailed shades. Users should look for files in STL format, which most printers accept.

Customizing a model means changing size, shape, or patterns. This can help fit specific bulbs, sockets, or décor styles. Some models come with options to swap parts like bases or shades.

It’s best to start with a design made for 3D printing. Look for details like appropriate wall thickness and no unsupported overhangs. These factors ensure the lamp will print without errors.

Design Software for Lamp Creation

A variety of programs can help create or modify lamp designs. Beginner-friendly options like TinkerCAD offer easy tools to combine shapes. More advanced tools like Fusion 360 or Blender allow detailed, precise control.

Software should support exporting to STL files since this format guides the printer. Some programs also simulate printability and check for issues.

Users can design each lamp part separately, like the base, shade, or joints. This modular approach lets them print in pieces and assemble later.

Incorporating Electronics and Lighting

Planning the lighting setup is key. The lamp must fit light sources like LEDs or bulbs and include wiring safely. Designs should have hollow spaces for cords and mounts for sockets.

LED strips and small bulbs are popular because they generate little heat and have various colors. The lamp’s material and thickness affect light diffusion.

Adding switches or USB power ports requires extra room inside the lamp. Proper ventilation and material choice prevent overheating and improve safety.

Using standard bulb and socket sizes makes replacement easier. Some designs include holders specifically matched to common sockets.

Step-by-Step Guide to 3D Printing Lamps

This process involves getting the right digital model ready, setting up the printer with the best settings, and then finishing the lamp with some cleanup and assembly. Each part is important to make sure the final lamp looks good and works well.

Preparing the Model for Print

The first step is choosing or designing a 3D model for the lamp. Many use programs like Tinkercad or Fusion 360 to create shapes that fit their style and the lamp’s function. It’s key to check the model for any errors, like holes or flipped faces, which can cause trouble when printing.

After design, the model is exported as an STL file. This format is common and works with most printing software. Then, it’s loaded into slicing software, which cuts the model into layers for the printer to build. The model might need supports, especially for overhangs, so the lamp keeps its shape during printing.

Choosing Print Settings

Setting the right printing parameters is vital. Most lamps print well with a layer height of around 0.1 to 0.2 mm. A lower layer height means smoother surfaces, but takes longer. The print speed should be moderate, around 40-60 mm/s, to balance detail and time.

Material choice matters too. PLA is popular because it’s easy to print and safe for indoor use, but PETG is stronger and heat-resistant. Infill density between 10-20% is usually enough for lamp parts, keeping them lightweight but sturdy.

Temperature settings depend on the filament. For PLA, a nozzle temp of 200-210°C and a heated bed around 50-60°C work well. Adjust these based on your printer’s recommendations.

Post-Processing and Assembly

Once printing finishes, removing supports carefully is next to avoid damaging the lamp. Sanding rough edges smooths the surface and prepares it for painting or sealing. Some lamps need extra cleaning to reduce layer lines.

If the lamp design includes multiple parts, they are assembled using glue or screws. Electrical components like LED lights and wiring are added last. It’s important to test the electrical parts separately before installing to ensure safety and function.

Finishing touches may include painting or adding a clear coat to protect the lamp and give it a polished look. The final lamp should be sturdy, safe, and ready to light up any room.

Popular 3D Printing Lamp Styles

3D printing offers a wide range of lamp designs, from simple shapes to complex artistic pieces. These lamps can fit different tastes and rooms, combining creativity with function. Some focus on clean lines, others on bold art, and some capture fun themes.

Modern and Minimalist Designs

Modern and minimalist 3D printed lamps often use smooth surfaces and simple shapes like cylinders, spheres, or geometric forms. These designs focus on clean, uncluttered looks that fit well in contemporary homes or offices.

Materials like white or translucent PLA are popular because they diffuse light softly and evenly. Many lamps use open frameworks or lattice patterns to create interesting shadows without overwhelming the space.

These lamps are easy to customize with size, shape, or LED color. They suit people who want lighting that feels calm and stylish without drawing too much attention.

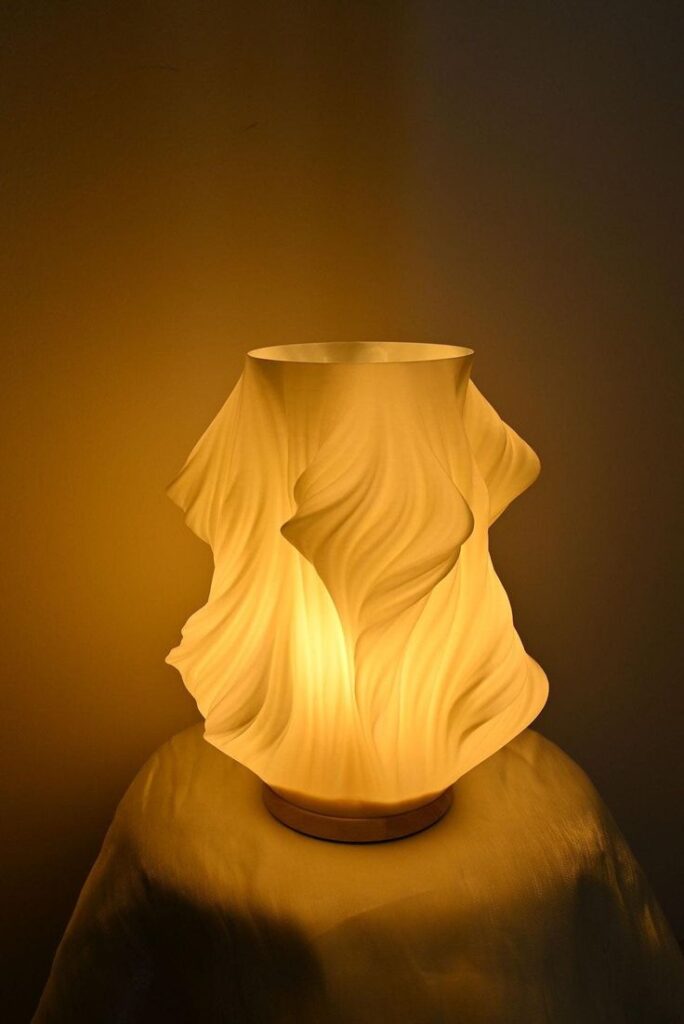

Artistic and Sculptural Lamps

Artistic lamps made with 3D printing bring sculptural ideas to life using curves, twists, and overlays. These lamps often become a centerpiece in a room because they look like movable art rather than just a light source.

Designers use intricate patterns that play with light and shadow. Some models use lithophane techniques, where light reveals detailed images or textures in thin, translucent layers.

They can be inspired by nature, abstract forms, or modern art. This style appeals to anyone who wants lighting that doubles as creativity and craftsmanship.

Themed and Novelty Lamps

Themed and novelty 3D printed lamps embrace playful or unique subjects, such as moons, animals, or pop culture icons. These lamps often add personality and fun to bedrooms, game rooms, or kids’ spaces.

Popular examples include moon lamps that glow softly with the lunar surface visible, or lamps built to look like famous characters or objects.

These models often combine bright colors and unusual shapes, making them great gifts or conversation starters. They suit those who want lighting with strong character and theme.

Tips for Successful 3D Printed Lamp Projects

Good 3D printed lamps need clear planning and attention to detail. Careful design, printer settings, and troubleshooting can make the difference between a strong, beautiful lamp and a failed print. Knowing these key steps helps anyone improve their projects.

Optimizing Print Quality

To get the best print quality, the first step is choosing the right material. PLA is popular for lamps because it’s easy to print and has good strength. Using a higher resolution, like 0.1-0.2 mm layer height, helps create smooth surfaces that look professional.

Bed leveling is crucial. If the print bed isn’t level, parts may warp or not stick well. A clean, heated bed improves adhesion and reduces warping, especially for larger lamp parts.

Adjusting print speed can also help. Slower speeds often increase detail and reduce errors but may take longer. Using proper infill (20-30%) makes the lamp sturdy without wasting material.

Finally, cooling fans should be set correctly to avoid overheating or warping delicate lamp details. Testing small samples before printing the full lamp can save time and material.

Troubleshooting Common Issues

Warping and cracking are common problems. These happen when the plastic cools unevenly. Using a heated bed and controlling room temperature can reduce this risk. Adding a brim or raft in the slicing software helps the print stick better during the first layers.

If parts fail to stick to the bed, cleaning the surface with isopropyl alcohol removes oils that prevent adhesion. A textured surface or glue stick can also improve grip.

Layer shifts occur when the printer’s motors miss steps. Tightening belts and checking printer calibration reduces this. It’s important to watch prints closely during the first layer, as early issues often cause bigger failures later.

Clogged nozzles can block filament flow. Regular cleaning and using good-quality filament help prevent clogs, maintaining steady extrusion for smooth prints.

Showcasing and Selling 3D Printed Lamps

Presenting 3D printed lamps well and choosing the right platforms to sell them are key to reaching customers. Good photos highlight the unique design and materials, while the right online marketplaces connect sellers with buyers interested in custom or eco-friendly lighting.

Photography and Marketing

High-quality photos are essential when showcasing 3D printed lamps. Clear images from multiple angles help buyers see details like texture, color, and shape. Using natural or soft lighting improves how the lamp looks without harsh shadows.

Including photos of the lamp in use, such as lit in a room, helps customers imagine how it will fit in their space. Close-ups on special features, like intricate patterns or eco-friendly materials, add appeal.

Marketing should focus on what makes the lamp unique—whether it’s the design, the 3D printing process, or sustainability. Descriptions that explain these details alongside clear photos help buyers understand the value. Sharing images on social media platforms can also build interest and direct traffic to sales pages.

Selling on Online Marketplaces

Choosing the right online marketplace is important to reach people interested in 3D printed lamps. Platforms like Etsy, eBay, and specialized 3D product sites offer tools to list products and manage sales easily.

When listing lamps, clear titles and detailed descriptions aid search visibility. Including keywords like “3D printed,” “custom lighting,” or “eco-friendly lamp” helps buyers find products quickly. Setting competitive prices requires considering material costs and time spent printing.

Some sellers use multiple marketplaces to widen their audience. Offering customization options or bundles can attract more buyers looking for unique or personalized lighting. Many marketplaces also provide customer review features, which help build trust and improve the seller’s reputation over time.

What materials are commonly used for 3D printing lamps?

Popular materials include PLA, ABS, and eco-friendly bio-based filaments like recycled or corn starch-based PLA, which are chosen for their safety, durability, and sustainability, with some designed specifically for safe lighting use.

How do I design my own 3D printed lamp?

Creating your own 3D printed lamp involves selecting or customizing existing 3D models using software like TinkerCAD or Fusion 360, planning the electronic components, and designing spaces for wiring and bulbs to ensure safety and functionality.

What are some popular styles of 3D printing lamps?

Popular styles include modern and minimalist designs with smooth, geometric shapes, artistic and sculptural pieces that serve as visual art, and themed or novelty lamps featuring playful or distinctive subjects like moons or pop culture icons.

What steps are involved in printing a 3D lamp?

The process includes preparing a suitable digital model by checking for errors, slicing it with appropriate settings, printing with the right filament and layer height, then post-processing by removing supports, assembling parts, and installing electronic components.

What are 3D printing lamps?

3D printing lamps are unique lighting fixtures created through additive manufacturing, where layers of material like plastic or resin are built up to form detailed and customizable shapes, combining art and technology for personalized illumination.

- 94shares

- Facebook0

- Pinterest94

- Twitter0

- Reddit0