You’ve spent months perfecting your product. The recipe is spot on. The packaging looks great. Then someone stores your product in a fridge, and your label starts peeling off.

That’s the moment most business owners realise regular stickers won’t cut it. If your product touches water, sits in cold storage, or gets handled with wet hands, you need labels that can take a beating. Water-resistant stickers aren’t just nice to have. They’re the difference between a product that looks professional and one that looks like it’s falling apart.

Let’s talk about what actually matters when you’re choosing labels for your business. Because getting this wrong costs you more than just money. It costs you credibility.

Why water matters more than you think

Most products don’t live in perfect conditions. Your craft beer sits in ice buckets at festivals. Your skincare range gets stored in steamy bathrooms. Your food products go in and out of cool rooms and refrigerated trucks.

Regular paper labels hate moisture. They curl. They smudge. They peel at the corners like they’re trying to escape. And once a label starts looking tatty, your whole product looks cheap.

Water-resistant stickers handle all of this without breaking a sweat. They’re made from polypropylene or similar synthetic materials that repel water instead of absorbing it. The ink doesn’t run. The adhesive stays stuck. Your branding stays intact from the production line to the customer’s hand.

What actually makes a sticker water-resistant

Not all water-resistant labels are created equal. Some can handle a bit of condensation. Others can survive being fully submerged. The difference comes down to materials and construction.

Synthetic materials like polypropylene form the base. These plastics don’t absorb water the way paper does. The printing process matters too. Quality prints use UV or solvent-based inks that bond to the surface rather than sitting on top, where moisture can lift them off.

The adhesive is perhaps the most critical part. Permanent adhesives create strong bonds that moisture can’t break. Cheaper options might stick fine in dry conditions, but fail the moment things get damp.

When you actually need them

Here’s a quick reality check. Do your products spend time in any of these places?

Fridges or freezers where condensation forms constantly. Ice buckets at events or restaurants. Bathrooms where steam is part of daily life. Outdoor settings where rain or dew are factors.

If you answered yes to any of these, water-resistant stickers aren’t optional. They’re essential.

Food and beverage businesses learn this fast. A brewery in Sydney can’t afford labels that fall off beer bottles. A sauce manufacturer needs labels that survive restaurant kitchens. Cosmetics brands know bathroom humidity will destroy paper labels in weeks.

The real cost of getting it wrong

Bad labels don’t just look unprofessional. They create actual business problems.

Customers lose trust when your product looks damaged or poorly made. Retailers reject products with peeling labels because they won’t sell. You waste money reprinting and relabelling products that should have been right the first time.

Perhaps worse, you miss sales opportunities. That potential stockist who saw your product at a trade show? They remember the curling label more than they remember your brand story. First impressions stick, and peeling labels stick in all the wrong ways.

Material options that actually work

You’ll mainly choose between two types of water-resistant materials. Polypropylene leads the pack for durability and affordability. It handles water, oil, and general wear without complaint. The surface takes print beautifully, whether you want matte or gloss finishes.

Vinyl offers similar protection with slightly different characteristics. It’s more flexible, which helps on curved surfaces like bottles. Both materials come in clear options if you want that modern, minimal look where your product shows through.

Synthetic silver labels give you that premium metallic appearance without expensive foiling processes. They’re still fully water resistant but add visual impact that helps products stand out on crowded shelves.

Size and shape considerations

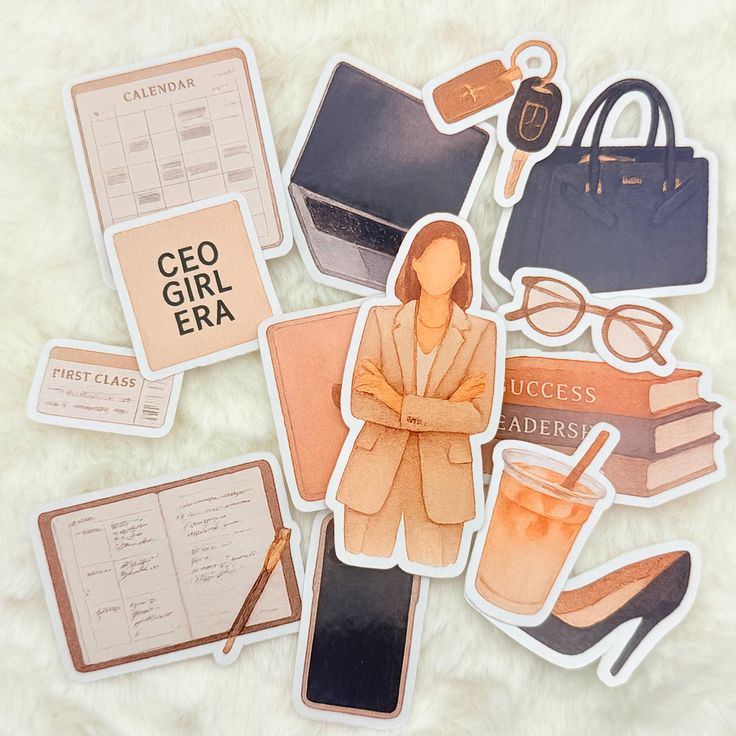

Water-resistant stickers come in standard shapes like circles, squares, and rectangles. Custom shapes are possible, but might push your budget up depending on complexity.

Think about the application here. Round labels work brilliantly on jars and bottles. Rectangular labels suit boxes and flat surfaces. The shape affects how water runs off, too. Rounded corners tend to stay stuck better than sharp corners that can catch and lift.

Size matters for visibility and information requirements. You need enough space for legally required details while keeping your design clean. Cramming too much onto a small label makes everything harder to read and looks cluttered.

Finish types and what they mean

Gloss finishes catch light and make colours pop. They’re popular for products that want to look premium or eye-catching. The shiny surface is easy to wipe clean, which suits food products particularly well.

Matte finishes give a more subtle, sophisticated look. They don’t show fingerprints as readily, and some people find them easier to read because there’s no glare. Both finishes offer the same water resistance. The choice is purely about the look you’re after.

Print quality that lasts

Water resistance means nothing if your print fades or smudges. Quality printing uses inks designed for synthetic materials. They bond properly and resist UV light that can cause fading over time.

Colours should stay true even after months in varying conditions. Black text needs to stay crisp and readable. Barcodes must scan reliably because retailers won’t stock products with dodgy barcodes.

Test samples before committing to large runs. See how they handle actual conditions your products will face. Stick them on bottles, put them in the fridge, get them wet. Better to find problems at the sample stage than after you’ve printed thousands.

Local production advantages

Getting labels printed locally in the city of Sydney makes practical sense. Faster turnaround means you’re not waiting weeks for the stock to arrive. If there’s an issue, you can sort it quickly rather than dealing with international shipping and time zones.

Local suppliers understand Australian labelling requirements and industry standards. They’re familiar with the conditions your products face in this market. Communication is easier when you’re in the same time zone and speak the same language.

Supply chains have become unpredictable. Having a local supplier reduces risks around shipping delays and quality control issues that come with long-distance logistics.

Getting started without overthinking

Start with your actual needs. What products need labelling? What conditions will they face? What information must appear on the label?

Request samples from suppliers to see quality firsthand. Compare materials, finishes, and print quality. Check how the adhesive performs on your specific packaging.

Most suppliers offer online ordering systems that let you upload designs and get quotes quickly. The process doesn’t need to be complicated. You specify size, material, quantity, and finish. They print and deliver.

Final thoughts

Choosing water-resistant stickers isn’t complicated once you know what matters. Focus on materials that suit your product’s environment. Make sure the print quality will last. Work with suppliers who understand your needs and can deliver reliably.

Your labels represent your brand every time someone picks up your product. Getting them right means your branding stays sharp regardless of where your products end up. That’s worth doing properly from the start.

- 9shares

- Facebook0

- Pinterest6

- Twitter3

- Reddit0