Selecting the right equipment in today’s fast-paced industrial world can directly define any operation’s efficiency level. It is especially critical for operations that rely on liquefied petroleum gas. Choosing the correct vaporizer could be all-important to some businesses. LPG vaporizer electric dry type presents a reliable, safe, and energy-efficient solution for many industries. The choice, however, can be intimidating due to many models available with specific specifications. The following is a guide breaking down essential factors to consider when choosing an electric dry LPG vaporizer for your business and how I-MAXIMUM can support your decision.

Understanding Electric Dry LPG Vaporizers

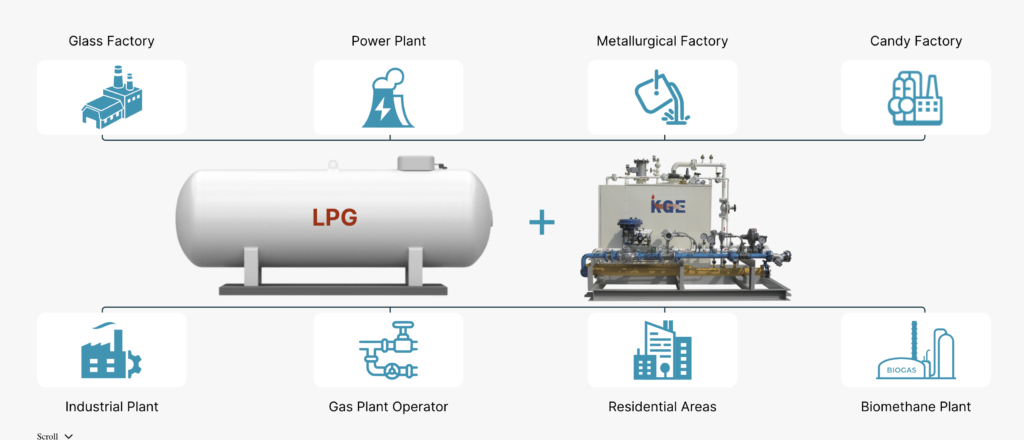

First, let us understand what an electric dry LPG vaporizer does. As the name suggests, it is a device that converts liquid LPG to gas. LPG is kept under pressure in a fluid state; in industrial applications, it is used in gaseous form. Vaporizers perform this conversion through the application of heat to liquid LPG. Electric dry vaporizers realize heat from electricity and operate without water; this makes them more efficient and less susceptible to freezing issues, as sometimes seen in their traditional water-based counterparts.

Key advantages of electric dry vaporizers include:

- Low Maintenance: No water system means fewer components to maintain.

- Compact Design: Ideal for businesses with limited space.

- Energy Efficiency: Optimized to consume less power while delivering consistent performance.

- Enhanced Safety Features: Designed to prevent overheating and ensure safe operation.

Factors to Consider When Choosing an Electric Dry LPG Vaporizer

Selecting the right vaporizer for your business requires evaluating several critical factors. Let’s explore these in detail:

- Capacity Requirements

The first step is to establish your business’s LPG consumption rate. Vaporizers are rated based on their output capacity, expressed in kg/h (kilograms per hour) or GPH (gallons per hour). Too small can cause disruptions, and too large is wasteful energy consumption. Determine your peak demand and choose a vaporizer that meets or slightly exceeds this requirement.

- Energy Efficiency

Energy costs do have a significant bearing on your operational budget. Furthermore, modern dry electric vaporizers come with much-improved heating elements and insulation; therefore, energy loss is minimal. When choosing a model, find those with automatic temperature control and energy-saving modes. It has a variety of energy-efficient vaporizers for different industrial performances that will work best at reducing as much energy waste as possible.

- Space Constraints

In addition to its benefits, the physical size of the vaporizer is also significant, especially for businesses that operate in small spaces. Generally, an electric dry vaporizer will be much smaller than a water-based one; however, there are variations in sizes among models. One should choose a comfortable unit that would fit in its available space without compromising accessibility for maintenance purposes.

- Safety Features

Safety should never be compromised, mainly when dealing with LPG. Look for vaporizers equipped with:

- Overheat protection mechanisms

- Pressure relief valves

- Automatic shutoff features

These features protect your equipment and ensure the safety of your personnel and facilities.

- Reliability and Maintenance

Downtime can be costly, so it’s essential to select a vaporizer known for reliability. Electric dry vaporizers have fewer moving parts and no water system, reducing the likelihood of mechanical failures. Regular maintenance is straightforward and involves checking electrical connections and cleaning components as needed. Recent challenges, such as delays in LPG deliveries reported by The Guardian, have left many households in the UK without heating. These disruptions highlight the importance of choosing reliable equipment that minimizes dependency on external factors.

- Compliance and Certifications

Ensure that the vaporizer complies with local and international safety and quality standards. Certifications such as ISO, CE, or UL indicate that the equipment meets rigorous testing requirements. I-MAXIMUM vaporizers are fully certified, providing peace of mind that you’re investing in a high-quality product.

Recent developments, such as EU discussions on phasing out traditional gas boilers, highlight the increasing regulatory scrutiny the gas industry faces. According to a report from The Guardian , lobbying efforts by gas companies attempt to influence these changes. Businesses choosing LPG equipment should ensure compliance with current and anticipated future regulations, as these could significantly impact operational and financial planning.

- Cost and ROI

The upfront cost is important, but so too is the long-term return on investment. Although energy-efficient machines are more expensive in the beginning, they make up for it with time by consuming less energy and needing less maintenance work—parts are often included in some contracts. Think about the total cost of ownership instead of just the buying price.

Tailoring Your Choice to Your Industry

Different industries have unique requirements for LPG usage. Here are some examples of how electric dry vaporizers cater to specific sectors:

- Manufacturing: High-capacity models ensure uninterrupted fuel supply for production lines.

- Hospitality: Compact units are perfect for restaurants and hotels with limited space.

- Agriculture: Reliable performance supports heating systems for greenhouses and livestock facilities.

- Energy Production: Advanced safety features meet the stringent requirements of power plants and refineries.

Installation and Maintenance Tips

Adhere to the best practices highlighted below if you wish to achieve maximum lifespan and top performance from your electric dry LPG vaporizer:

- Correct Installation: Install the unit in a well-ventilated area by professionals and keep it away from flammable materials.

- Routine Inspections: Schedule these occasionally to detect issues that might cause harm.

- Manufacturer’s Guidelines: Adhere to the manufacturer’s recommendations for maintenance and operation.

- Staff Training: Provide your team with sufficient knowledge to properly handle and take care of the machine.

Conclusion

Selecting the appropriate electric dry LPG vaporizer can profoundly influence the efficiency, safety, and, ultimately, your business’s bottom line. Then, considering all the factors- capacity, energy efficiency, safety features, and last but not least, compliance- can help make a well-informed choice suited to your operating needs. The assistance of a reliable supplier such as I-MAXIMUM ensures proper investment in a quality, dependable product, and expertise support- be it manufacturing, hospitality, agriculture, or energy production. An appropriate dry vaporizer will improve operations in these fields and prove valuable over the long term.

- 0shares

- Facebook0

- Pinterest0

- Twitter0