Printing vivid designs on dark fabrics has always been one of the biggest challenges in the custom apparel world. Traditional methods like Direct-to-Garment (DTG) and sublimation often fall short — colors fade, details blur, and the finish doesn’t quite pop against black fabric. These techniques either require pretreatment, have limited color saturation, or struggle with opacity on darker materials. That’s where DTF printing (Direct-to-Film printing) comes in. With its built-in white underbase and flexible application process, DTF delivers rich, durable, and consistent results on virtually any fabric color, making it one of the most reliable printing methods for achieving vibrant designs on black apparel.

Why Printing on Black Apparel Is So Challenging

At first glance, black clothing might seem like the perfect backdrop for a bold design. In reality, dark fabrics absorb light, which can dull or distort printed colors. Printing bright tones like yellow, pink, or teal on a black shirt can make them look muted or uneven if the ink doesn’t have a solid foundation underneath.

In techniques like DTG (Direct-to-Garment), inks are sprayed directly onto the fabric fibers. To achieve brightness on dark materials, the fabric needs a pretreatment layer and a carefully printed white base. If either step isn’t perfect, the design looks washed out or fades after a few washes.

Sublimation printing faces similar issues but for different reasons. It relies on special polyester-coated materials and heat to transfer ink into the fibers. While sublimation produces vibrant results on white or light-colored polyester, it doesn’t adhere well to dark or cotton fabrics. This limits its versatility and makes it unsuitable for most black apparel.

In short: traditional methods struggle to maintain true color vibrancy on dark fabrics. DTF printing changes that equation entirely.

What Makes DTF Printing Different

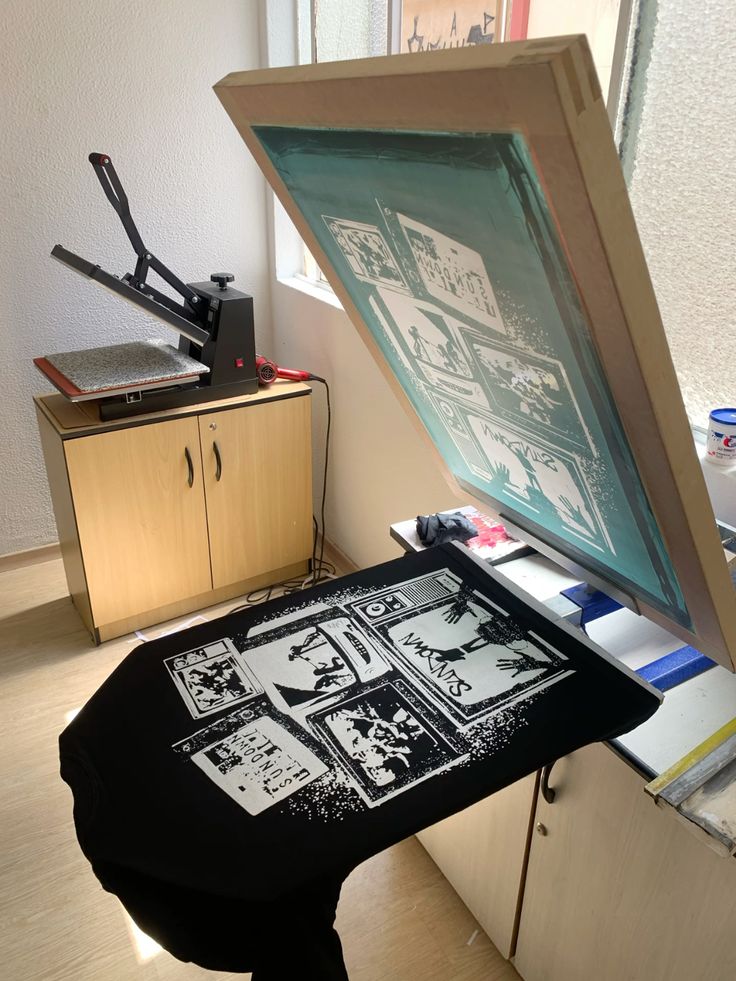

The key advantage of DTF printing lies in its built-in white underbase and transfer process. Instead of printing directly onto fabric, the design is printed onto a special film using pigment inks — including a layer of white ink beneath the colored layers. This white base ensures that every hue, from neon green to bright red, stays opaque and vivid, even when applied to black fabric.

After printing, a powder adhesive is applied and cured, turning the design into a heat-transferable print. It’s then pressed onto the garment with heat and pressure, bonding the design securely to the fabric. The result is a smooth, vibrant image that feels soft yet durable — without the need for pretreatment or complex setup.

This process works on cotton, polyester, blends, and even unconventional materials like canvas or denim. That flexibility makes DTF one of the most practical and efficient printing technologies for small-scale creators and large production setups alike.

The Science Behind the Vibrancy

So, why do DTF prints look so good on black apparel? The secret is the white underbase. Think of it like a fresh coat of primer on a wall before painting — it gives the color something to sit on, preventing it from soaking into the background.

This white layer acts as a reflective surface that enhances the brightness of every color printed on top. Instead of being absorbed by dark fibers, the pigments remain vibrant and consistent, resulting in designs that truly “pop.”

Additionally, the transfer film used in DTF printing captures fine details with exceptional accuracy. This allows for sharp text, intricate patterns, and smooth gradients — elements that often get lost in other printing methods when applied to black fabric.

Durability and Feel: Beyond the First Wash

One of the most common frustrations with printing on black garments is how quickly the design fades or cracks after washing. DTF printing solves this issue through its heat-transfer bonding process. Because the ink and adhesive fuse directly into the fabric’s surface, the print remains flexible and long-lasting.

Users often describe DTF prints as having a soft, slightly matte texture — unlike the heavy, rubbery feel of some heat transfers. The design can stretch with the fabric, resist peeling, and maintain its brightness over time. For apparel that sees frequent use — like t-shirts, hoodies, or workwear — this longevity is a major advantage.

Simplifying the Workflow

DTF printing isn’t just about better results — it’s also about simplifying the process. Traditional DTG printing requires pretreatment sprays, drying time, and precise settings for each fabric type. Sublimation demands polyester materials and light-colored garments.

DTF streamlines everything. You print your design on film, apply adhesive powder, cure it, and transfer it to the garment. There’s no pretreatment, no complex calibration, and no material limitations. This makes it ideal for quick production runs, custom orders, and limited-edition drops where speed and flexibility matter most.

Versatility Beyond T-Shirts

While most people associate fabric printing with t-shirts, DTF printing extends far beyond that. Its ability to adhere to multiple materials opens up creative opportunities for all kinds of products — tote bags, sweatshirts, caps, aprons, and even shoes.

Because the prints are transferred rather than dyed into the fabric, the colors remain consistent across different materials and textures. This consistency is particularly valuable for brands or creators who want to maintain a unified aesthetic across a product line — from apparel to accessories.

A New Standard for Color

The rise of DTF printing represents more than just another printing trend. It’s part of a broader movement toward technology that combines quality, efficiency, and creative freedom. Designers no longer have to compromise between bold color and durable finish — they can have both, even on black apparel.

For creators who’ve struggled with fading designs, limited fabric choices, or expensive setup processes, DTF offers a practical, vibrant, and adaptable solution. The white underbase ensures color accuracy, while the process itself keeps production simple and cost-effective.

In the end, the technology proves that achieving stunning, full-color prints on black fabric doesn’t have to be complicated. With DTF printing, the vivid possibilities are endless — from small-scale artistic projects to full-scale apparel collections that turn heads for all the right reasons.

- 0shares

- Facebook0

- Pinterest0

- Twitter0

- Reddit0