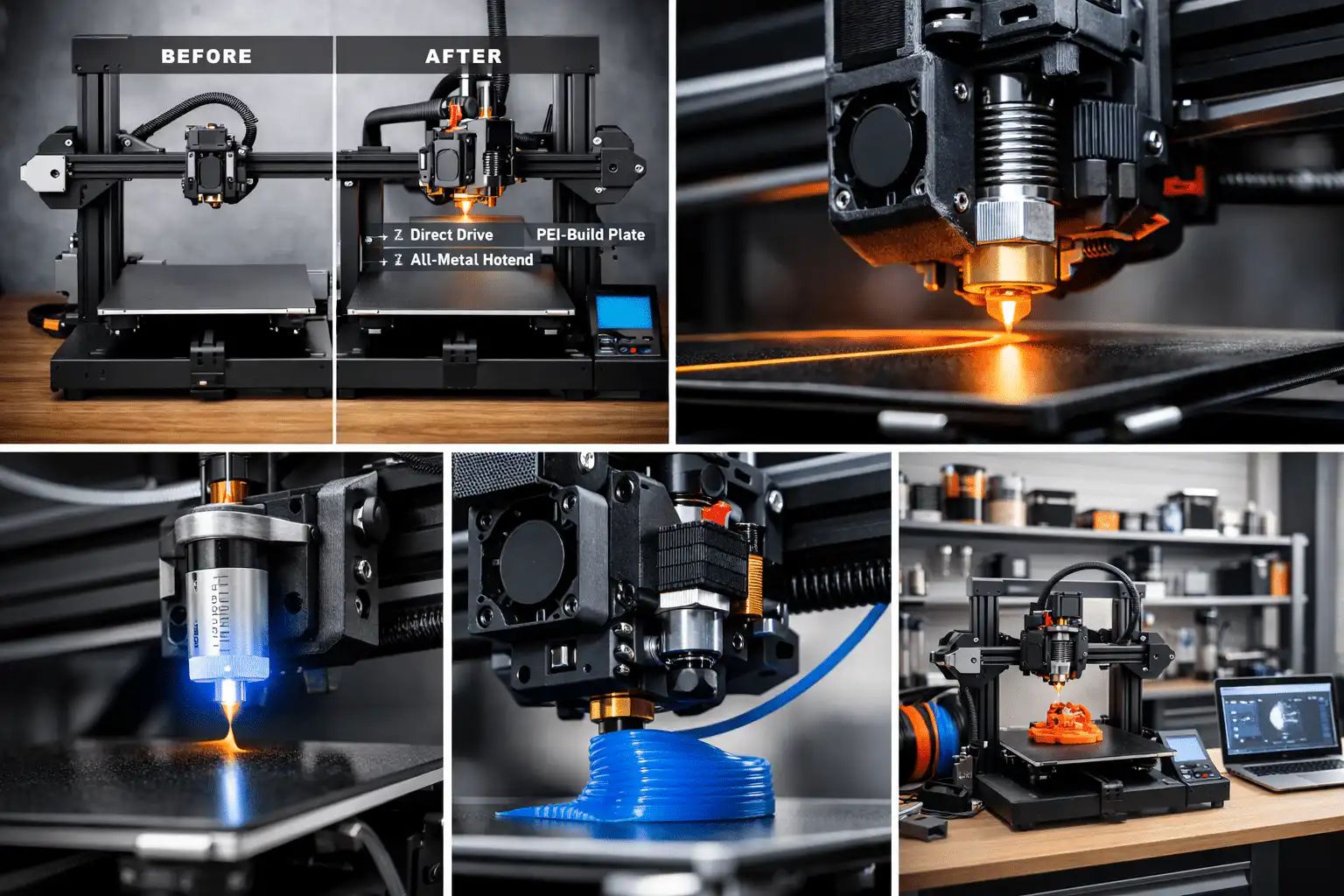

Your 3D printer is probably collecting dust right now. After the initial excitement of printing a few Pokémon figures and maybe a phone stand, most machines end up sitting idle. I get it—novelty prints are fun for about a week, then they become clutter.

But here’s what changed my perspective: I started printing things that actually solve problems. Not decorative items that sit on a shelf. Not “cool” designs that serve no purpose. Actual useful objects that I reach for daily.

The difference is immediate. A custom cable clip that fits exactly where you need it. A tool organizer that matches your specific screwdriver set. A replacement knob for an appliance that would otherwise need replacing. These prints earn their existence.

- 1. Ultimate Cable Management Clips and Organizers

- 2. Personalized Headphone Stands

- 3. Modular Desk Organizers

- 4. Custom Tool Organizers for Your Workshop

- 5. Smart Kitchen Gadgets

- 6. Decorative and Functional Planters

- 7. Custom Shower Caddies and Holders

- 8. Personalized Keychains and Bag Tags

- 9. Wall Hooks and Mounts for Everything

- 10. Battery Organizers

- 11. Custom Bookmarks

- 12. Personalized Coasters

- 13. Pet Bowl Stands and Feeders

- 14. Doorstops and Wedges

- 15. Repair Parts and Adapters

- Conclusion

- FAQ

I’ve narrowed this list to 15 useful 3D printed items that have genuinely improved my daily life. Each one addresses a specific annoyance, saves money, or solves a problem that store-bought solutions can’t quite fix. No novelty prints, no dust collectors—just practical objects that justify the cost of filament.

1. Ultimate Cable Management Clips and Organizers

Cable chaos is universal. Behind every desk, entertainment center, and nightstand lurks a tangle of charging cables, HDMI cords, and power strips fighting for space. Store-bought cable clips exist, but they’re either too small, too large, or designed for cables you don’t own.

3D printed cable management solves this precisely. I’ve printed clips sized for my exact cable diameters—USB-C charging cables (3.5mm), ethernet (6mm), and power cords (7mm)—each with the right grip tension. They mount where I need them: on the edge of my nightstand for the phone charger, under the desk for the keyboard cable, behind the TV for the HDMI bundle.

The real advantage is iteration. My first cable clip design was too loose. Five minutes of adjustment in the slicer, another 20-minute print, and version two held perfectly. Try getting that kind of customization from Amazon.

Print time: 10-30 minutes per clip

Recommended filament: PLA for indoor use, PETG for areas with heat exposure

Tip: Print with 100% infill for maximum grip strength

2. Personalized Headphone Stands

Good headphones deserve better than being tossed on a desk or hung from a monitor corner. The ear cups compress, the headband stretches, and cables get kinked. A proper stand costs $20-50 for something generic that might not even fit your specific pair.

I’ve printed stands tailored to my headphones’ exact dimensions—the curve of the headband, the width of the ear cups. The result is a stand that cradles them perfectly without pressure on the padding. Some designs incorporate a hook for the cable, a small tray for the dongle, or even a spot for a USB hub.

Beyond function, there’s the customization factor. My current stand has a hexagonal base that matches my desk aesthetic. It cost about $0.50 in filament and took two hours to print.

Print time: 2-4 hours depending on complexity

Recommended filament: PLA or PETG

Tip: Use tree supports for overhanging headband curves—easier to remove and cleaner finish

3. Modular Desk Organizers

Store-bought desk organizers assume everyone uses the same pens, the same scissors, the same sticky notes. They don’t. My desk has mechanical pencils (5.5mm diameter), Micron pens (9mm), and a collection of USB drives that need their own compartment.

Modular 3D printed organizers let you build exactly what you need. I started with a basic pen holder, then added interlocking modules: a slot for my phone, a tray for paper clips, a holder for my X-Acto knife. When my needs changed, I printed a new module and swapped it in.

The modularity matters. Most commercial organizers are one-piece designs—if one compartment doesn’t work, the whole thing fails. With printed modules, you adjust one piece without replacing everything.

Print time: 30 minutes to 2 hours per module

Recommended filament: PLA for most uses

Tip: Design with 0.2mm tolerance between interlocking pieces for a snug fit

https://makerworld.com/en/models/144270-modular-mario-desk-organizer?from=search#profileId-156852

4. Custom Tool Organizers for Your Workshop

Workshop organization separates productive makers from frustrated ones. Every minute spent hunting for the right hex key is a minute not spent building. Commercial tool organizers exist, but they’re designed for generic tool sets—not your specific combination of brands and sizes.

I’ve printed holders for my exact screwdriver collection, bit organizers that match my drill set, and drawer inserts that fit my toolbox dimensions. Each tool has its designated spot. When something’s missing, I notice immediately.

The precision matters here. A hex key holder with slots 0.5mm too large lets tools rattle around and fall out. 3D printing lets you measure your actual tools and design slots that fit snugly. My 4mm hex key slot is exactly 4.3mm—tight enough to hold, loose enough to remove easily.

Print time: 1-4 hours depending on size

Recommended filament: PETG for durability, PLA for light-duty use

Tip: Print tool holders vertically for maximum layer adhesion and grip strength

5. Smart Kitchen Gadgets

Kitchens are full of small annoyances that 3D printing fixes elegantly. Bag clips that actually seal cereal bags. A holder for your specific brand of sponge. A drain cover that catches food particles without blocking water flow.

My most-used kitchen print is a simple spoon rest that fits my countertop corner exactly. Store-bought versions were either too large or the wrong shape. The printed version tucks into the corner beside my stove, holds two utensils, and doesn’t slide around.

Other practical kitchen prints: a tablet stand for recipes (angled for reading while standing), a coffee pod organizer (sized for my specific pods), and a bag clip with an integrated squeeze mechanism (no more wrestling with twist ties).

Print time: 20 minutes to 2 hours

Recommended filament: PETG for items near heat, PLA for room temperature use

Note: For anything touching food, consider food-safe filament and thorough cleaning—or design items that don’t contact food directly (holders, organizers, stands)

6. Decorative and Functional Planters

Finding planters that match your space and fit your plants is surprisingly difficult. Nursery pots come in standard sizes; your shelf doesn’t. A 4-inch plant in a 4-inch pot looks cramped in a 6-inch decorative planter, but the 5-inch planter you need doesn’t exist.

3D printed planters solve the size problem and add features commercial planters lack. I’ve designed planters with integrated drainage trays (no separate saucer needed), self-watering reservoirs for forgetful plant parents, and wall-mounted versions for vertical gardening.

The aesthetic control is equally valuable. Want a geometric planter that matches your modern decor? Print it. Prefer a textured surface that mimics concrete? Adjust the settings. My current planters are simple cylinders with a subtle wood-grain texture—$2 in filament each, exactly the size I needed.

Print time: 2-6 hours depending on size

Recommended filament: PETG for water resistance

Tip: Print with 3+ perimeter walls for waterproofing; consider a food-safe sealant for extra protection

7. Custom Shower Caddies and Holders

Shower caddies will eventually rust and give up the ghost . The wire ones are the worst , corroding to nothing in a matter of months ; Target’s plastic ones just wont fit your specific bottles . The height of your shampoo bottle is a hair too tall for the shelf so its stuck at an angle till its inevitably knocked to the shower floor as you’re rushing to get ready in the morning.

3D printed bathroom organisers are a game changer – they’re made to fit your actual products. I measured my shampoo bottle (65mm in diameter, 210mm tall), my conditioner (55mm, 180mm) & my soap bar dimensions, then knocked up a caddy that fits them all like a glove. And the best bit? it just clips to my existing shower rail & hasnt dropped a bottle in six months.

The materials you use for the print are important here. PLA’s pretty useless in a wet environment – it just falls to bits. PETG, on the other hand, handles the shower environment just fine – I’ve had prints going for over a year now with no warping or degradation to show for it.

Print time: 3-6 hours is all you can expect

Recommended filament: As I said , PETG only – you really dont want to be messing around with some moisture-sensitive plastic

Tip: – make sure you design with drainage in mind , just to stop water pooling & any mildew from setting in

8. Personalized Keychains and Bag Tags

Simple, fast and utterly useful – a customised keychain takes all of 20 minutes to print and lets you spot your keys at a glance. A personalised luggage tag (your name in big letters on one side, your phone number or email address discreetly tucked away on the other) makes it impossible to mistake your bag at the baggage claim.

These nifty prints are ideal for anyone getting the hang of their printer, they don’t gobble up too much filament, pop out of the printer in no time and you can start enjoying the fruits of your labour straight away. I personally keep a collection of custom luggage tags – all bright orange and emblazoned with my surname in big, bold text. Let me tell you, I’ve never lost a bag yet.

Print Time: 15 – 45 minutes – depending on the complexity of the design

Recommended filament: You can’t go wrong with PLA, PETG or any sort of durable filament that can withstand the rigours of travel

Tip: If you want your text to stand out nicely, use colours that contrast with the background- and make sure the text is at least 3mm thick so it doesn’t wear off quickly

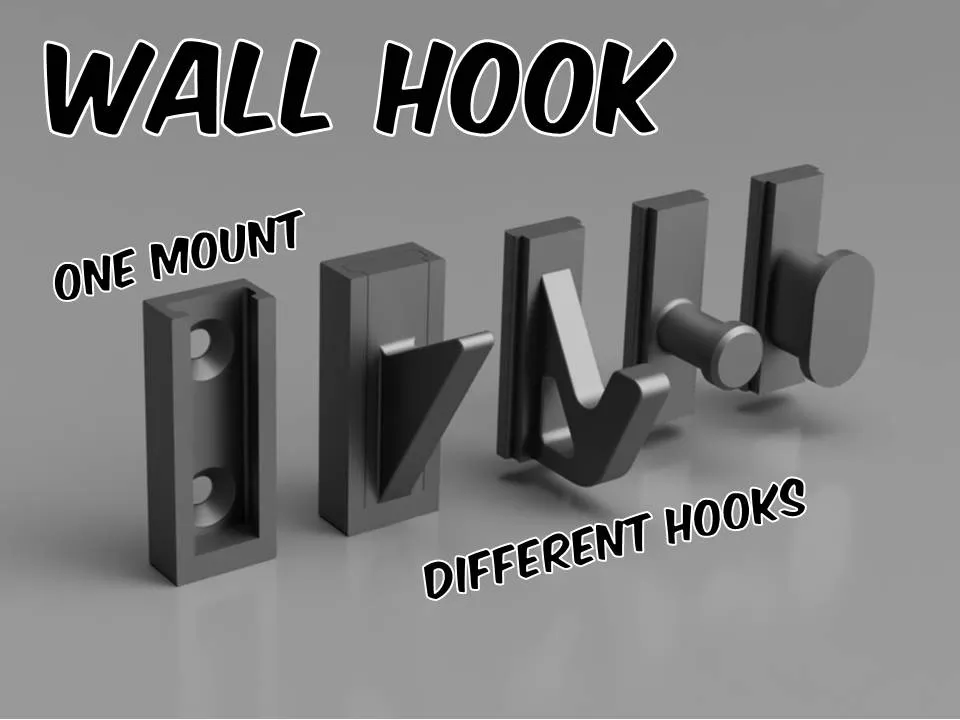

9. Wall Hooks and Mounts for Everything

Walls are crying out for some use of the storage space they offer. 3D printing gives you the chance to knock up mounts for the specific items you’ve got lying around – rather than just some half-useful hooks that kinda sorta do the job, but never quite right. What I really love is being able to create purpose built holders that are tailored to fit each thing you need to hang just right.

In my home office for example I’ve managed to print mounts for: my headphones (they’re great when not stuck on that stand thingy), not one but two game controllers (made to perfectly match the shape of each one), a smart speaker (angle it downwards and sound is suddenly heaps better), and my keys (includes a teeny tray for my wallet and spare change). Depending on how heavy the item is I usually use either command strips or good old fashioned screws to stick them to the wall.

Its the precision fit that really makes this kind of thing worthwhile. A generic hook will just hold a controller in some haphazard way – but with a custom made mount it’s just perfectly cradled, and the controller is nice and secure. It doesn’t try to fall off, or wobble or look like some half-baked job.

Print time – anything from 30 minutes to a couple of hours

Recommended filament – give PLA or PETG a go

Tip: when designing these just make sure to include a few command strip slots for stress free mounting – or if the item’s gonna be really heavy then add some screw holes for good measure

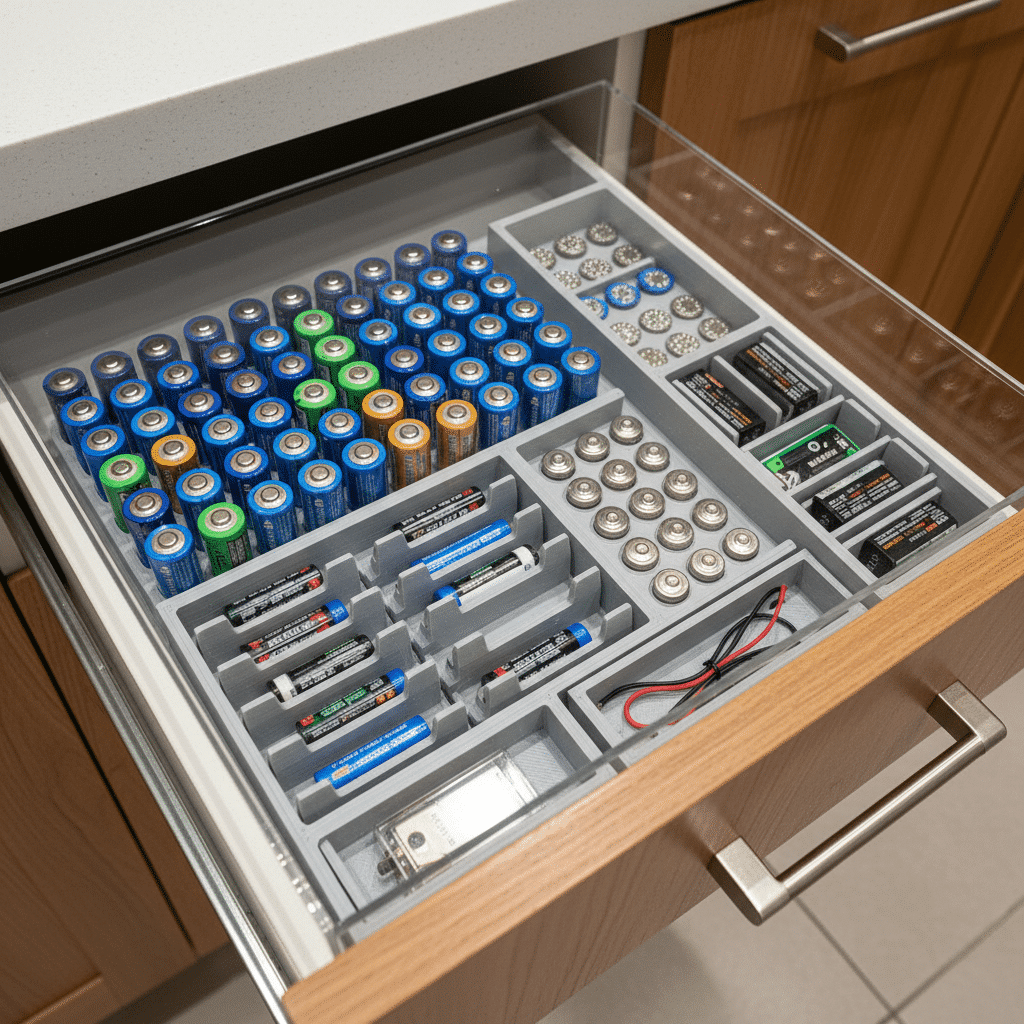

10. Battery Organizers

Loose batteries in a drawer are chaos. You can’t tell which are fresh and which are dead. They short-circuit against each other. You buy new ones because you can’t find the ones you already have.

A printed battery organizer changes this completely. Mine has separate slots for AA, AAA, 9V, and coin cells, with a “tested” and “untested” section. When I grab a battery, I know it’s fresh. When I remove one from a device, it goes in the testing queue.

The design is simple—basically a tray with sized slots—but the daily utility is significant. No more buying batteries I already own. No more risking shorts from metal contact.

Print time: 1-2 hours

Recommended filament: PLA

Tip: Include a small compartment for a battery tester if you use one

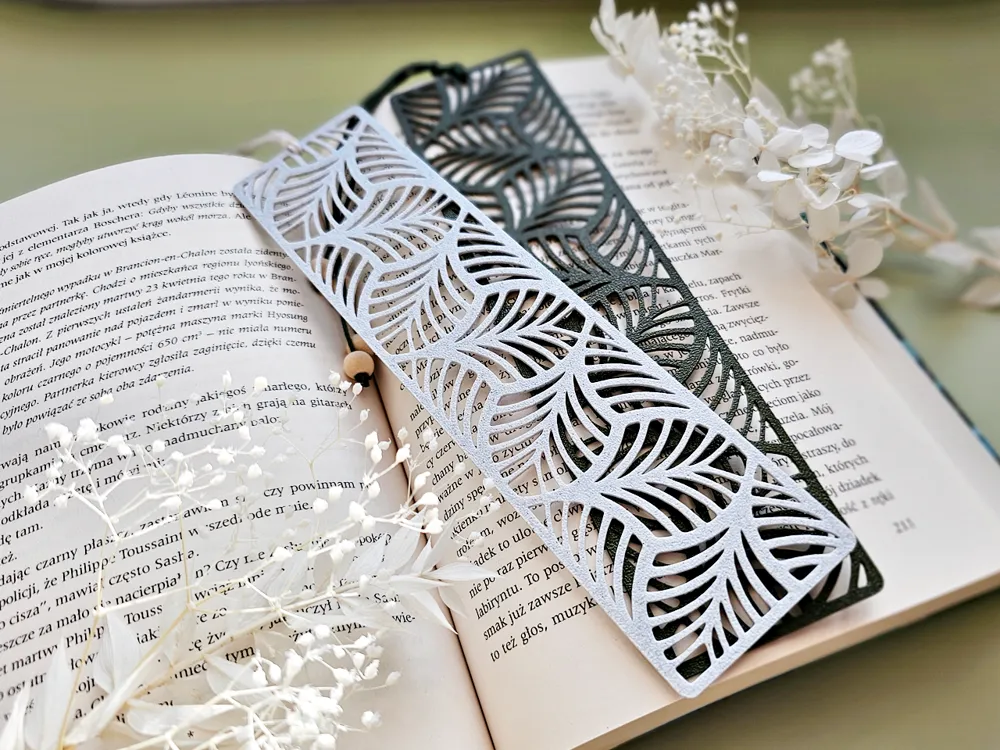

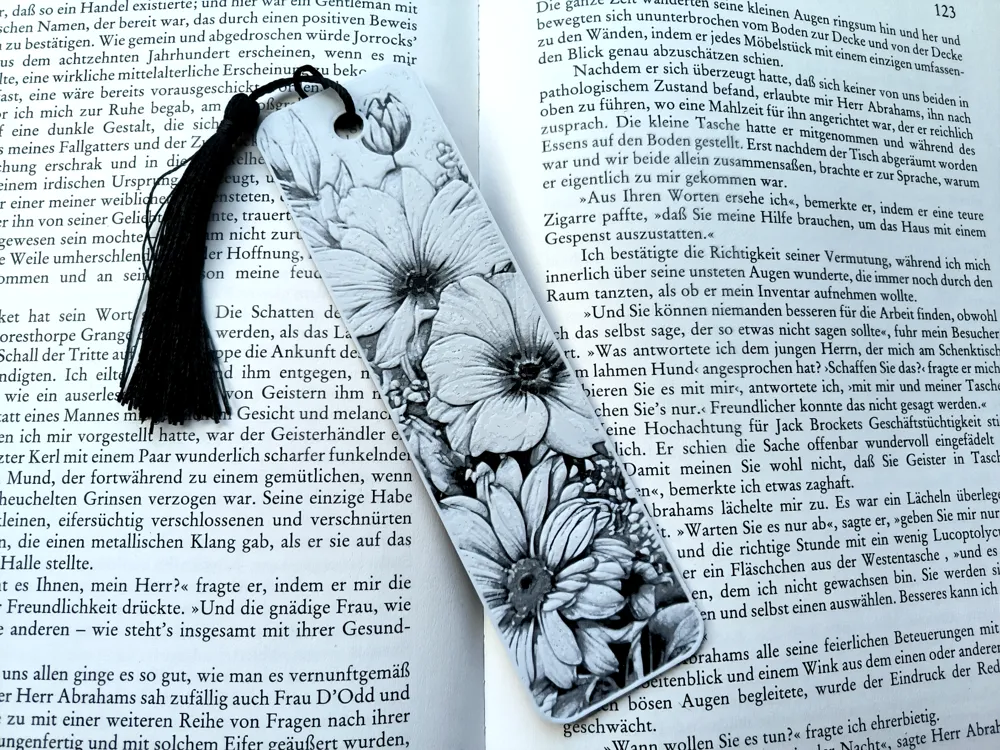

11. Custom Bookmarks

A quick print with genuine utility. Paper bookmarks get lost, bent, or forgotten. A 3D printed bookmark is durable, distinctive, and easy to find.

I’ve printed bookmarks that clip onto pages (won’t fall out when the book tips), corner markers that slide over page corners, and traditional flat bookmarks with enough thickness to be felt through pages. Total print time is usually under 30 minutes.

These make excellent small gifts. Print someone’s name, a meaningful symbol, or a design related to their interests. Cost: about $0.10 in filament.

Print time: 15-30 minutes

Recommended filament: PLA

Tip: Print flat bookmarks horizontally for maximum strength; print 1-2mm thick for flexibility without breaking

12. Personalized Coasters

Functional, customizable, and fast to print. Coasters protect furniture from drink rings and add personality to your space. Store-bought coasters are generic; printed coasters can be anything.

I’ve made coasters with geometric patterns, minimalist designs, and one set with each coaster featuring a different coffee origin (for guests to learn where their coffee comes from while they drink it). They’re conversation starters that also serve a practical purpose.

Design tip: include a slightly raised edge to contain condensation, and print with enough infill (40%+) to provide weight and stability.

Print time: 30 minutes to 1 hour each

Recommended filament: PLA or PETG

Tip: Print with a textured top layer for grip; smooth bottoms prevent scratching furniture

13. Pet Bowl Stands and Feeders

Elevated food bowls improve digestion for dogs and reduce neck strain for older pets. But commercial stands rarely match both your pet’s height and your bowl’s diameter.

A custom printed stand solves both problems. Measure your existing bowls, measure from your floor to your pet’s chest height, and design a stand that fits exactly. I printed one for my dog that’s 4 inches tall with cutouts for her specific bowl size. Total cost: about $3 in filament.

Beyond stands, you can print slow-feeder inserts (maze patterns that prevent fast eating), treat-dispensing toys, and custom name tags.

Print time: 2-5 hours

Recommended filament: PETG for durability and moisture resistance

Tip: Design with thick walls (2mm+) for stability under bowl weight

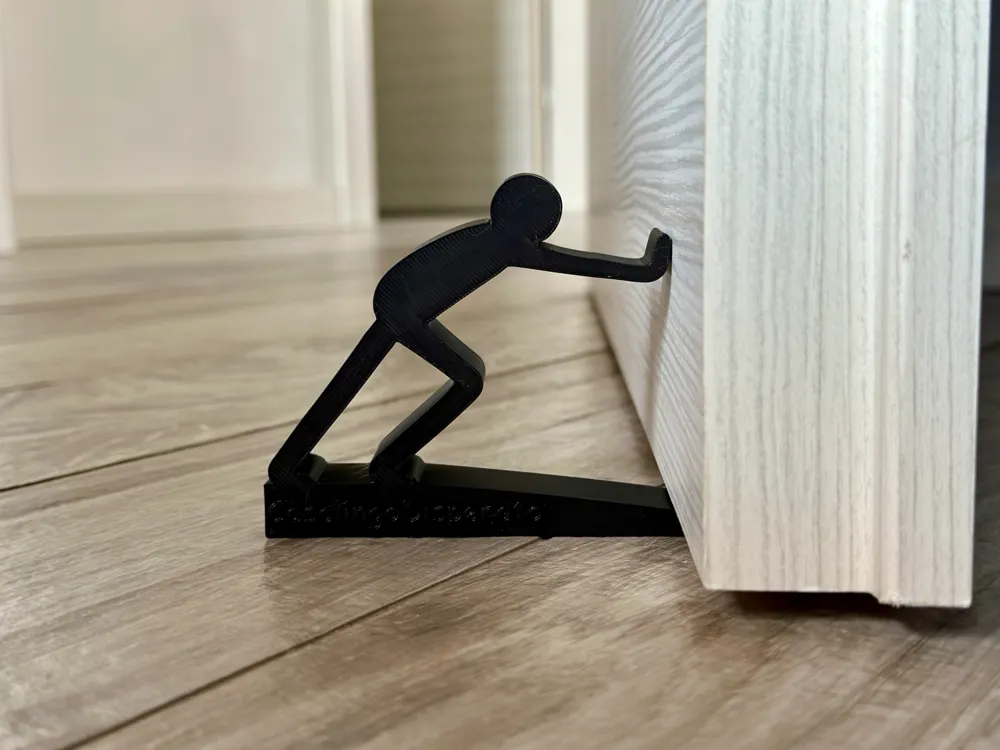

14. Doorstops and Wedges

Simple useful things are often the ones we overlook. A good doorstop is just that – it keeps doors open when you need a bit of airflow, stops them from slamming shut when you’re lugging groceries home, or holds the workshop door open while you’re moving heavy stuff.

Off the shelf doorstops are just plain triangles – but you can print your own doorstop to fit your door perfectly, with a weight that’s right for your flooring, and with grip textures that actually work as they’re supposed to.

I’ve printed doorstops for three doors in my house – each one is custom-made for the gap between the door and the frame, the weight is adjusted for the flooring type (carpet, hardwood , tile – you name it) and the grip pattern on the bottom is tailored to the surface. And I managed all three of them in under two hours.

Print time – usually around 20-45 minutes per door

Recommended filament – use something sturdy like PETG or a good PLA with a high infill setting

**Tip – add some grip texture to the bottom surface of your design, and play around with the angle a bit before you commit to the final print – it makes a big difference

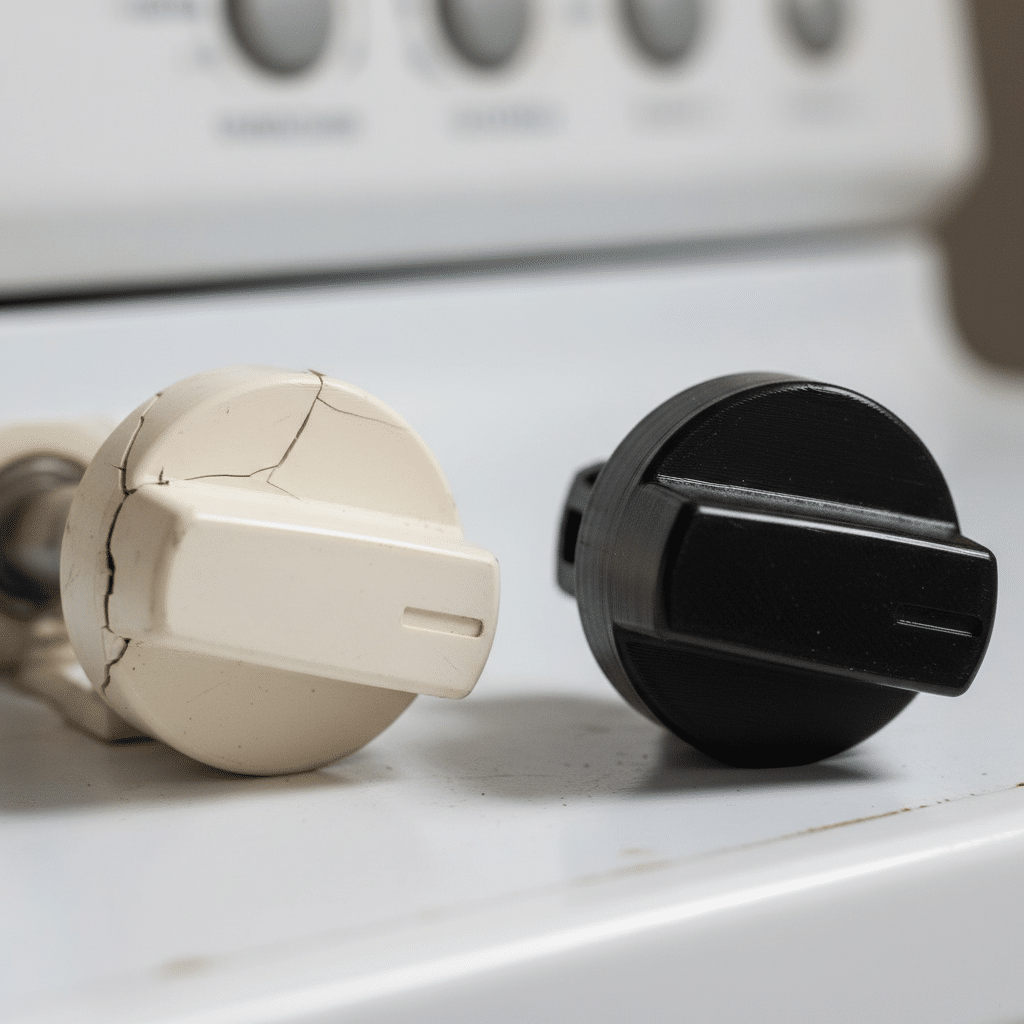

15. Repair Parts and Adapters

This is where 3D printing starts to get truly revolutionary . A busted $2 plastic part no longer means having to send a pricey $200 appliance to waste. A missing knob, a cracked clip, a worn out hinge – all fixable with a 3D print.

I’ve swapped out: a $35 oven knob from the manufacturer, a vacuum clip that’s vanished from existence, a dishwasher basket bracket that slapped out on me after a paltry five years of use, and a car vent clip that gave up the ghost in the middle of a cold winter.

The maths are certainly persuasive. Most replacement parts come in at a ridiculously low $0.10-$1.00 in filament costs. And if the manufacturer still sells them, they’ll often cost $20-50 plus shipping. And then, of course, there are the times when the parts just aren’t available any more – that’s when 3D printing becomes the only show in town unless you want to replace the whole thing.

Print time: Varies wildly – some of these prints are done in no time, others take ages

Recommended filament: Get one that matches the original material – PETG for when you need some give, PLA for all the times you need something stiff, and ASA if you’re going to be exposing it to the outdoors or some heat

Tip: Take some care when measuring up the broken part – design with at least 0.2mm-0.3mm clearance in mind for bits that need to move

Beyond the Basics: Practical Design Considerations

A few principles make the difference between useful prints and filament waste:

Filament selection matters. PLA works for most indoor items. PETG handles moisture, heat, and impact better. ABS/ASA excel outdoors. Choose based on where the item will live, not what’s cheapest.

Design for printability. Avoid overhangs beyond 45 degrees when possible. Use chamfers instead of fillets on bottom edges. Orient parts to minimize support material.

Measure twice, print once. Digital calipers cost $15 and save hours of failed prints. Measure the actual items your print will interact with—don’t trust published dimensions.

Iterate quickly. Print small test sections before committing to full prints. A 10-minute test of a critical dimension beats a 3-hour failed print.

Conclusion

Here are 15 super useful 3D printed items all sharing one thing in common : they tackle specific problems that generic products just can’t seem to solve . Your exact cable gets clipped in place by the cable clip , your actual tools get a home thanks to the tool organizer and a faulty appliance gets a replacement part that keeps on going.

That’s what a 3D printer is really for – not to be some novelty churn out a few trinkets that end up collecting dust, but to help you make solution after solution that you actually need .

Start with the low-hanging fruit like making cable clips, keychains and small organizers – build your confidence and your skills before you tackle something that really makes a difference in your daily life.

Your printer’s been sitting idle. Give it a job to do that’ll actually make a difference.

FAQ

What’s the most useful thing to 3D print first?

Cable management clips. They’re small, fast to print (under 30 minutes), immediately useful, and teach you about sizing and fit. Print one clip, test it, adjust, and print again. You’ll learn more from iterating on a simple design than from attempting complex prints too early.

Is 3D printing actually cheaper than buying things?

For some items, significantly cheaper. A replacement appliance knob: $0.15 vs. $35 from manufacturer. Cable clips: $0.05 each vs. $1-2 retail. Custom organizers: $1-3 vs. nothing available that fits. The savings accumulate, though the real value is getting exactly what you need rather than compromising with what’s available.

What filament should beginners use?

PLA for learning, PETG for utility. PLA is forgiving—prints at lower temperatures, minimal warping, easy to dial in. Once you’re comfortable, PETG offers better durability, moisture resistance, and heat tolerance for practical items. Avoid ABS as a beginner; the fumes and warping make it frustrating to learn with.

How do I design my own 3D prints?

Start with Tinkercad (free, browser-based) for simple geometric shapes. Move to Fusion 360 (free for hobbyists) when you need precision dimensions and parametric design. Most useful prints are simpler than you’d think—basic shapes combined and sized correctly. You don’t need artistic skill, just accurate measurements.

Where do I find ready-to-print useful designs?

Thingiverse, Printables, and MakerWorld have thousands of practical designs. Search for specific items (“AA battery organizer,” “headphone stand,” “cable clip 5mm”) rather than browsing categories. Many designs include customizable parameters—adjust dimensions to fit your needs without learning CAD software.

How long do 3D printed items actually last?

Years for most indoor items. I have PLA prints from 2019 still in daily use. PETG items in my shower have survived 18+ months. The key is matching filament to environment—PLA fails in heat and prolonged moisture; PETG handles both well. Outdoor items need ASA or UV-resistant materials.

- 101shares

- Facebook0

- Pinterest101

- Twitter0

- Reddit0