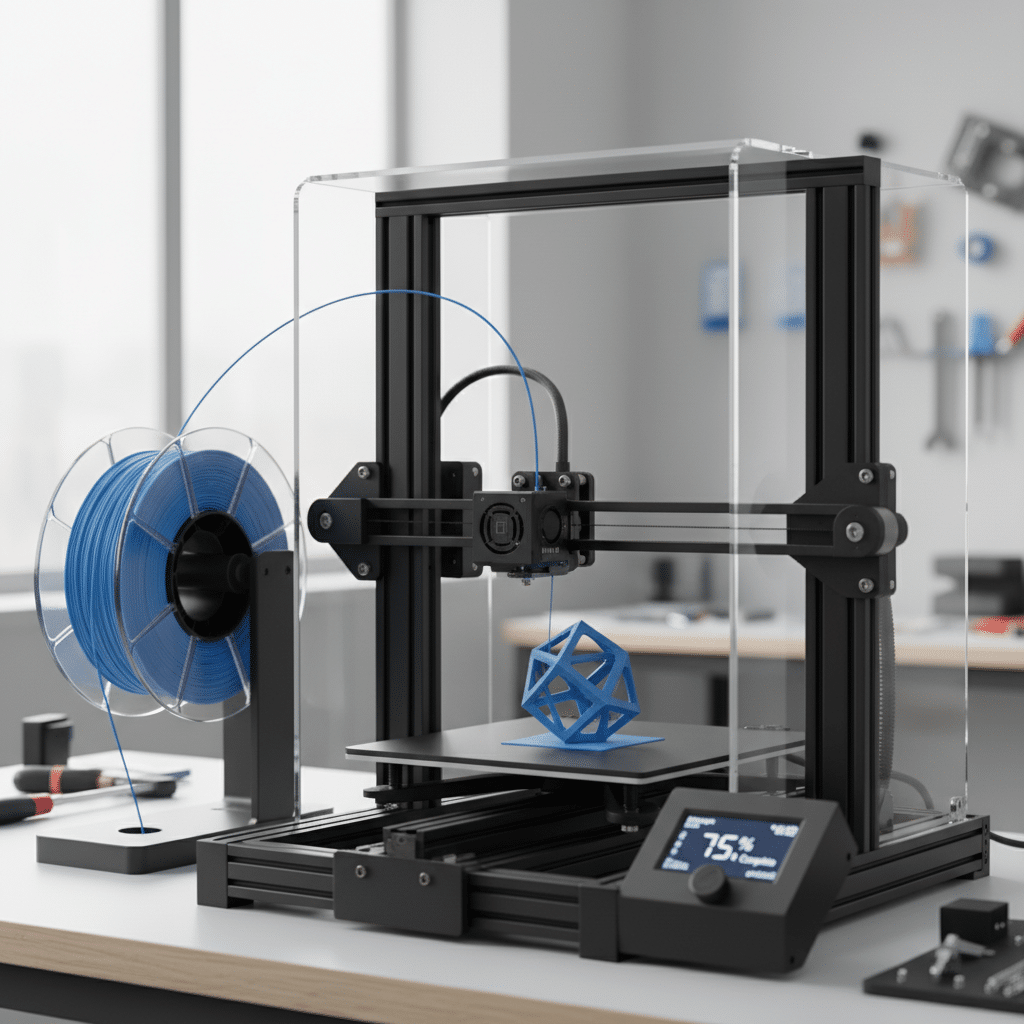

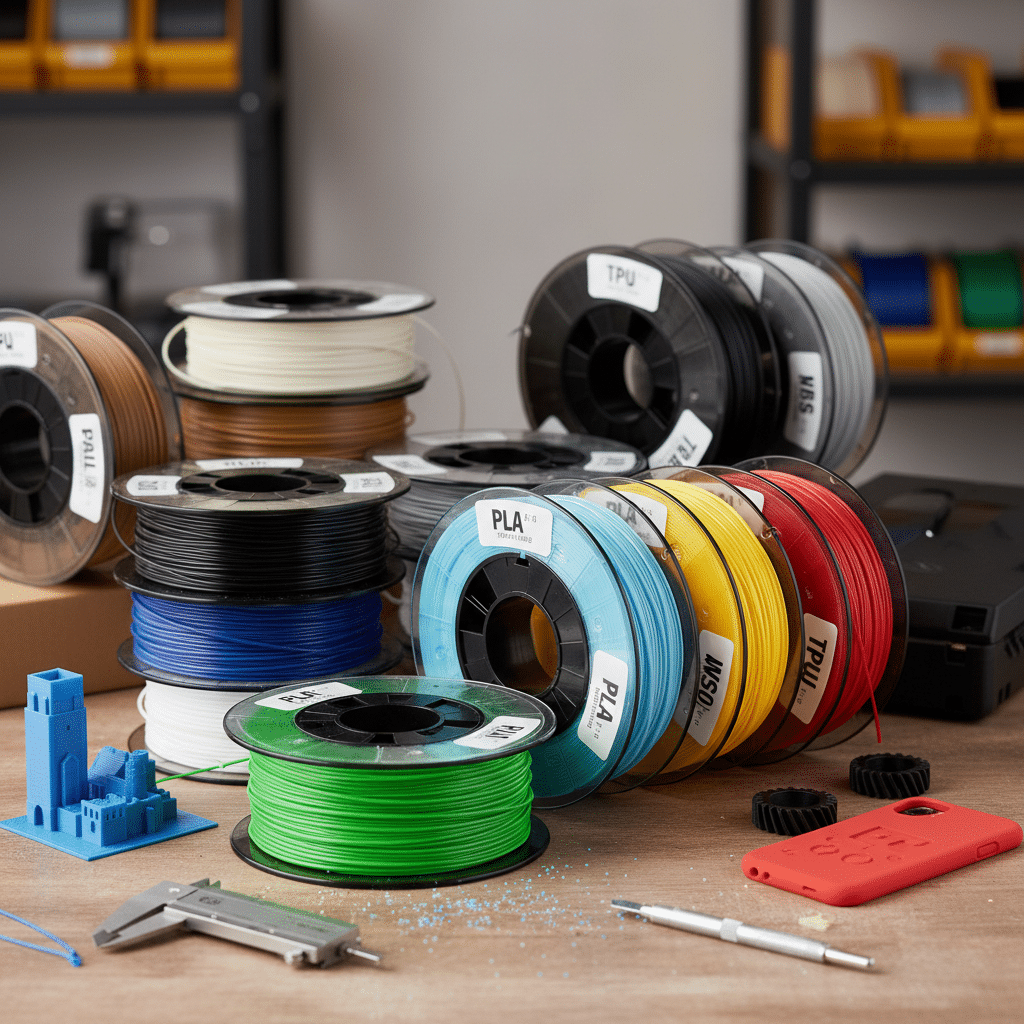

So, you’ve dipped your toes into the exciting world of 3D printing, huh? Maybe you’ve unboxed your first printer, or perhaps you’re already churning out prototypes and fun gadgets. Either way, you’ve probably realized by now that your 3D printer is only as good as the material you feed it. That’s right, we’re talking about 3d printer filament types – the colorful, plastic (and sometimes not-so-plastic) strands that transform into your wildest creations.

It’s easy to get overwhelmed by the sheer number of options out there. From the ubiquitous PLA to exotic composites, each filament has its own quirks, strengths, and weaknesses. Choosing the right one isn’t just about picking a color; it’s about understanding what your project needs in terms of durability, flexibility, appearance, and even how it behaves on your print bed. Think of it like a chef choosing ingredients – a delicate pastry requires different flour than a hearty loaf of bread. In this casual deep dive, we’re going to demystify the most common and some of the more specialized filament types, helping you make informed choices and take your 3D printing game to the next level. Let’s peel back the layers and get printing!

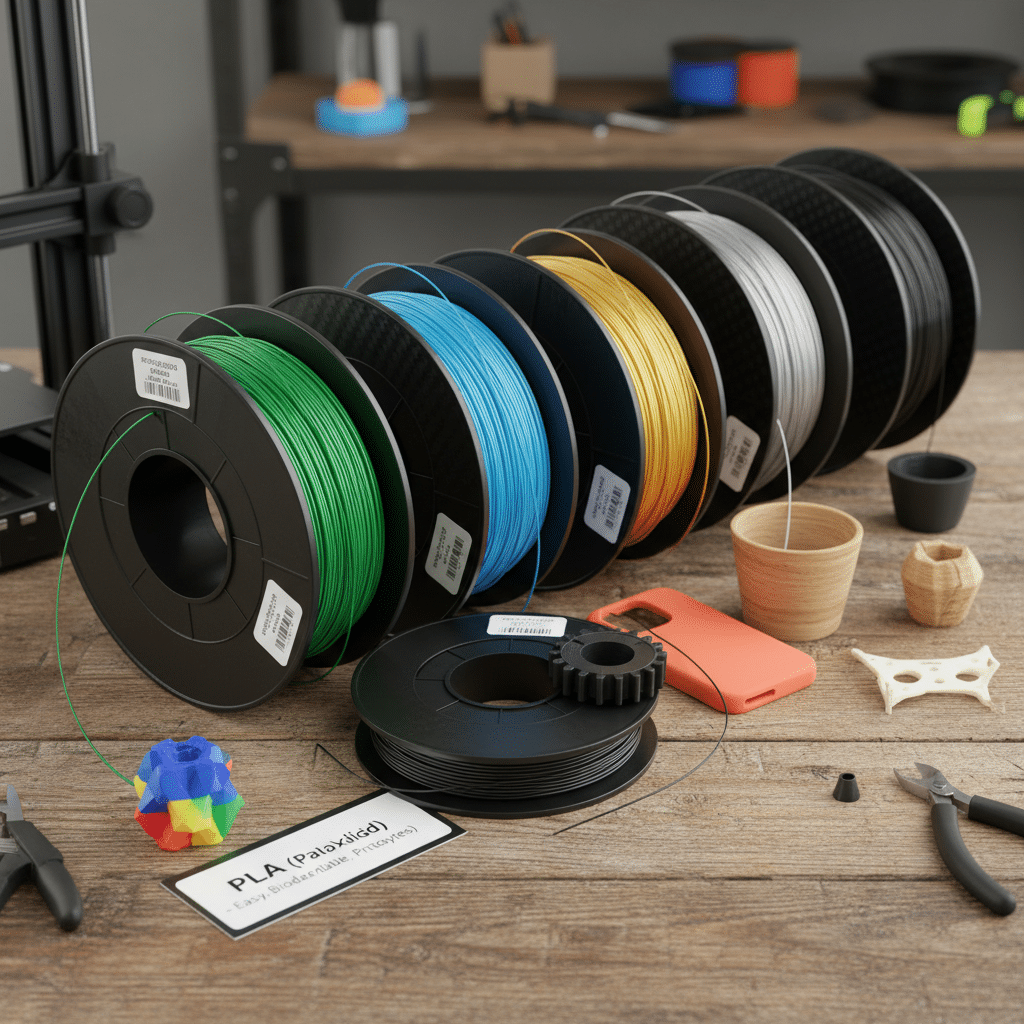

The Everyday Heroes: Your Go-To Filament Types

When you first start with 3D printing, you’ll likely encounter a few staples. These are the workhorses, the reliable friends that most printers are designed to handle with ease. Getting to know these is your first step to mastering filament choice.

#### PLA: The Friendly Beginner

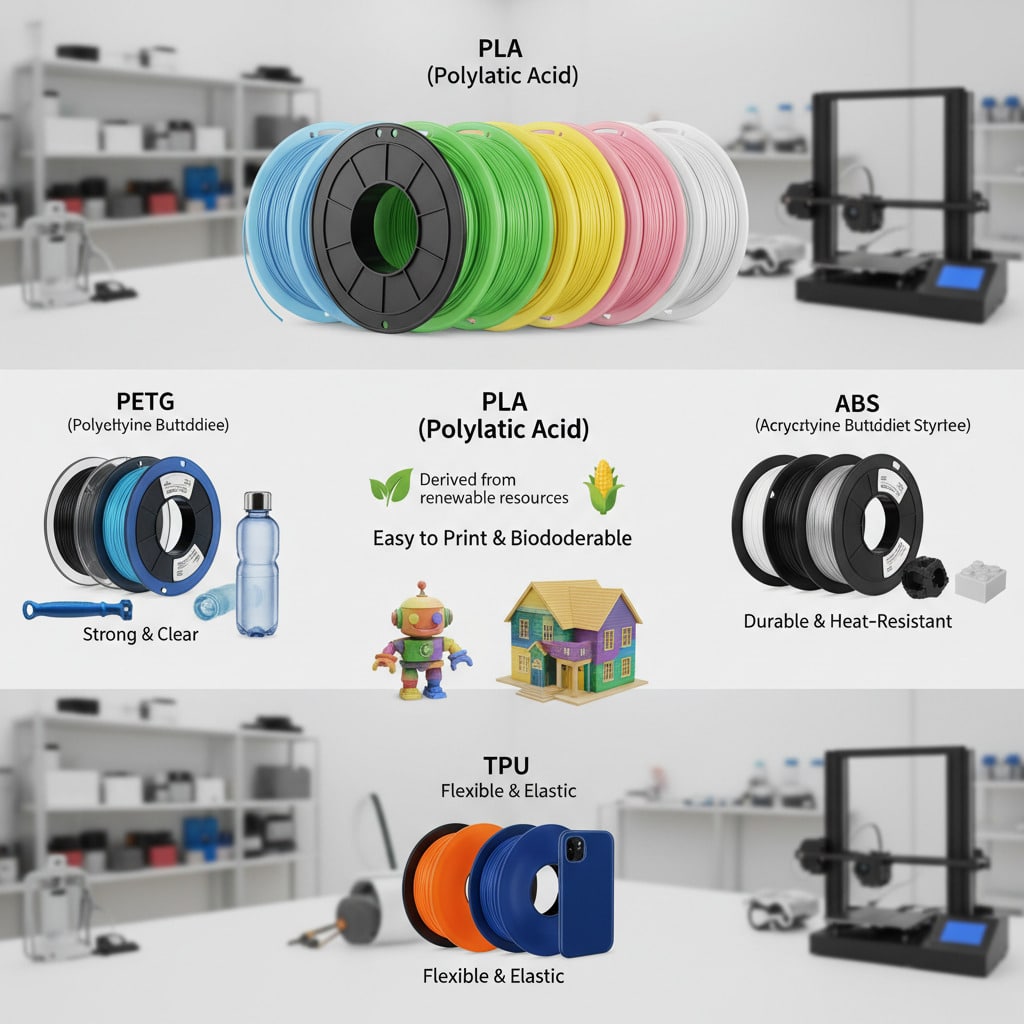

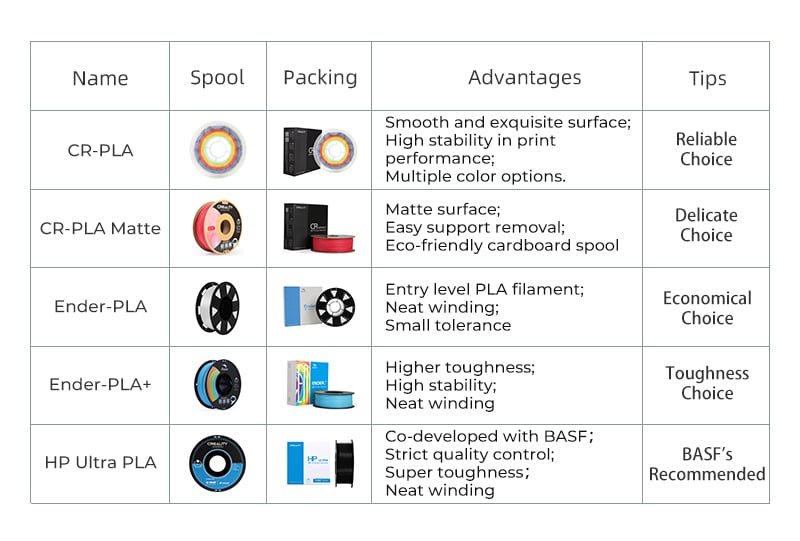

Polylactic Acid, or PLA, is undeniably the most popular kid on the block for good reason. It’s derived from renewable resources like corn starch or sugarcane, making it more environmentally friendly than many other plastics. If you’ve ever printed anything, chances are it was with PLA.

Why we love PLA:

- Easy to Print: PLA boasts a lower printing temperature compared to many other filaments, typically between 180°C and 220°C. This means fewer issues like warping or poor bed adhesion, making it very forgiving for beginners.

- Low Odor: Unlike some other filaments, PLA produces very little odor when printing, which is a big plus for home users.

- Biodegradable: While it won’t disappear overnight in your compost pile, it does break down over time under industrial composting conditions, making it a more sustainable choice.

- Good for Detail: It generally produces prints with good detail and a smooth finish, perfect for decorative items, prototypes, or models that don’t need to withstand extreme conditions.

Where PLA shines: Think decorative items, toys, architectural models, and quick prototypes. If you’re designing a patio that complements your home’s aesthetic, PLA could be great for initial scale models before committing to materials. It’s not ideal for parts that need high heat resistance or extreme durability, as it can become brittle under stress or soften in direct sunlight.

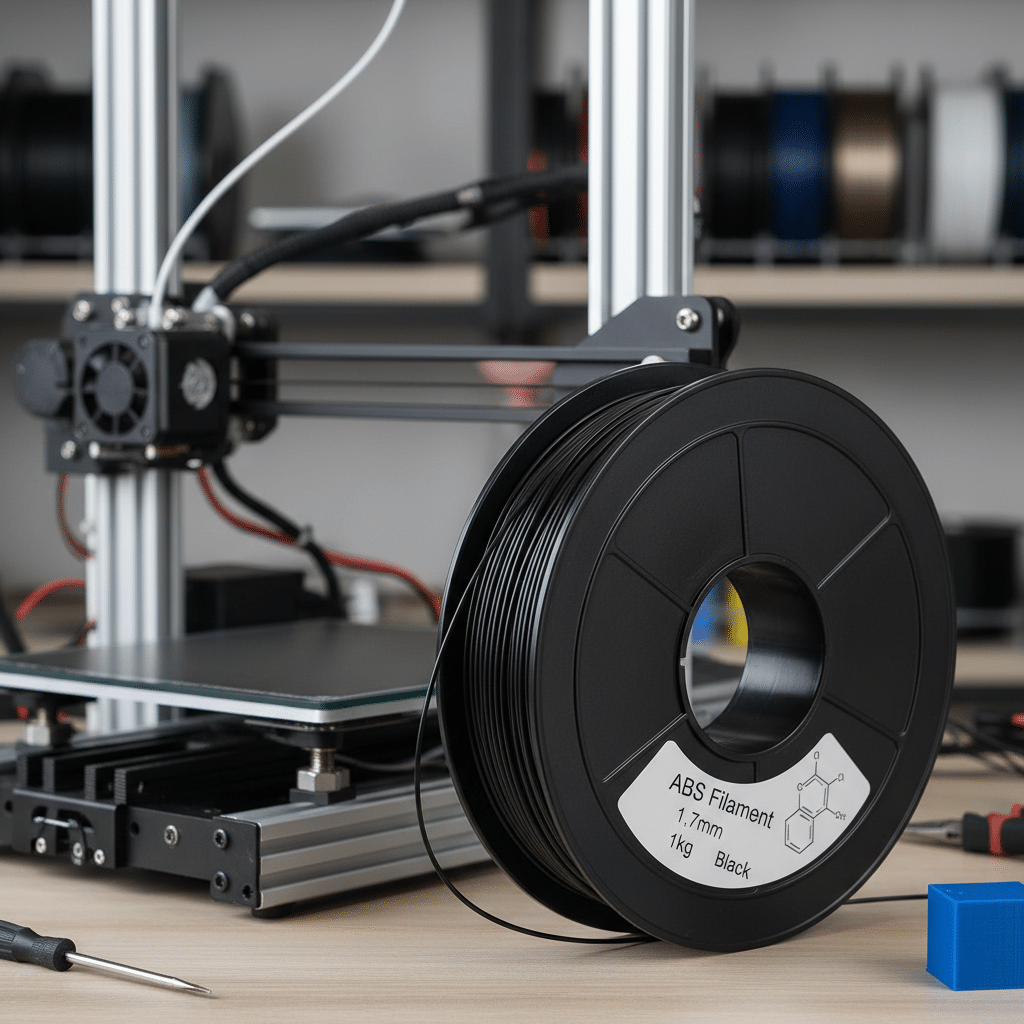

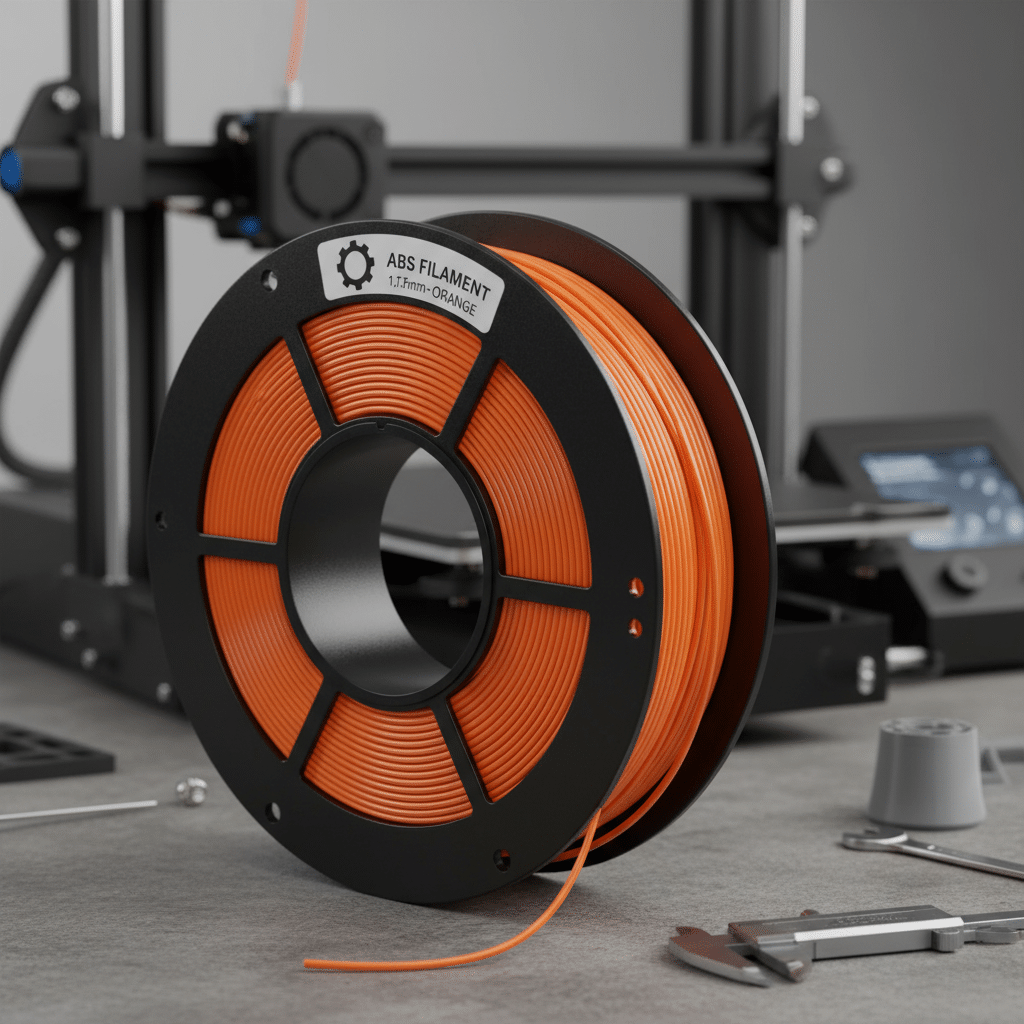

#### ABS: The Tough Guy with a Reputation

Acrylonitrile Butadiene Styrene, or ABS, is probably best known as the plastic used to make LEGO bricks. This tells you a lot about its properties: it’s strong, durable, and impact-resistant. However, it’s also a bit more challenging to print than PLA.

Why you might choose ABS:

- Strength & Durability: ABS is significantly tougher and more impact-resistant than PLA. This makes it suitable for functional parts, tool handles, and enclosures that need to endure some wear and tear.

- Heat Resistance: Unlike PLA, ABS can handle higher temperatures without deforming, making it a good choice for parts exposed to heat, like automotive components or outdoor enclosures.

- Post-Processing Friendly: ABS can be sanded, glued, painted, and even smoothed with acetone vapor (creating a glossy, professional finish). This opens up a world of possibilities for refining your prints.

The ABS challenge: ABS requires higher printing temperatures (typically 220°C to 250°C) and, crucially, a heated print bed (around 80°C to 110°C) to prevent warping. It also emits a stronger plastic odor during printing, so good ventilation is a must. Many users opt for an enclosed printer to help maintain a stable print environment and manage fumes.

#### PETG: The Best of Both Worlds?

Polyethylene Terephthalate Glycol, or PETG, often gets lauded as the “bridge” between PLA and ABS. It takes some of the best characteristics of both and combines them into a versatile, user-friendly package.

The PETG advantage:

- Strength & Flexibility: PETG is stronger than PLA and more flexible than ABS, giving it excellent impact resistance. It’s less brittle than PLA, making it great for parts that might take a knock.

- Temperature Resistance: It offers better heat resistance than PLA, though not quite as high as ABS.

- Water & Chemical Resistance: PETG is quite resistant to water, chemical solvents, and UV light, making it suitable for outdoor applications or containers. If you’re designing elements for an outdoors living space with comfortable ambiance, PETG is a strong contender.

- Relatively Easy to Print: While it requires a heated bed (around 60-80°C) and slightly higher print temperatures than PLA (230-250°C), it’s generally much easier to print with than ABS, with less warping and fewer fumes.

Watch out for: PETG can be a bit stringy or “gooey” during printing, requiring careful retraction settings to minimize oozing. It also tends to be very sticky to the print bed, so a release agent (like painter’s tape or glue stick) is often recommended to protect your bed surface.

#### TPU and Other Flexible Filaments: Bend It, Don’t Break It!

Thermoplastic Polyurethane, or TPU, is the star of the flexible filament world. If you need something that can bend, stretch, and absorb impact without breaking, TPU is your go-to.

When to go flexible:

- Elasticity: TPU is incredibly elastic, perfect for phone cases, watch straps, gaskets, dampeners, or anything that needs to be soft and pliable.

- Durability: Its rubber-like properties make it highly resistant to abrasion and tearing.

- Impact Absorption: It excels at absorbing shocks, protecting whatever it encapsulates.

Printing with flexibility: Printing with flexible filaments can be a challenge. They tend to squish and buckle in the extruder if not properly supported, requiring slower print speeds and often a direct-drive extruder setup for best results. Temperatures usually range from 220-250°C with a heated bed (30-60°C).

#### Nylon: The Underrated Workhorse

Nylon is another fantastic filament for functional parts, though it’s often overlooked by beginners due to its specific requirements. It’s known for its incredible strength, durability, and low friction coefficient.

Nylon’s strengths:

- Exceptional Toughness: Nylon is incredibly tough, abrasion-resistant, and has a high strength-to-weight ratio.

- Flexibility: While strong, it also has a degree of flexibility, making it less brittle than ABS or PLA.

- Low Friction: This property makes it excellent for gears, bearings, and other moving parts.

The hygroscopic hurdle: Nylon’s biggest downside is its extreme hygroscopic nature – it loves to absorb moisture from the air. Wet nylon prints poorly, leading to bubbles, steam, and weak parts. It absolutely needs to be stored in a dry environment and often requires drying before printing. Printing temperatures are high, typically 240-260°C, with a heated bed (around 70-90°C) and an enclosure being highly recommended.

Beyond the Basics: Exploring Specialty Filaments

Once you’ve mastered the main filament types, a whole new world of specialty materials opens up. These can add unique aesthetics, enhanced properties, or provide solutions for specific engineering challenges.

#### Composites: Enhanced with Fillers

Many specialty filaments are essentially a base plastic (like PLA or ABS) mixed with other materials to enhance certain characteristics or create unique finishes.

- Wood-Filled Filaments: These are typically PLA blended with wood fibers. They print easily like PLA but give your prints a beautiful, natural wood-like finish. You can often sand, stain, or paint them for an even more realistic look. Perfect for decorative pieces or models. Be aware that the wood particles can be abrasive, so a hardened steel nozzle might be a good investment if you print a lot of this.

- Metal-Filled Filaments: PLA or ABS blended with fine metal powders (like copper, bronze, or even stainless steel). These prints are surprisingly heavy, can be polished to a metallic sheen, and look incredibly premium. They are also abrasive and can require special post-processing to achieve the desired metallic look.

- Carbon Fiber Reinforced Filaments: These blend plastics like PLA, PETG, Nylon, or ABS with chopped carbon fibers. The carbon fibers dramatically increase stiffness, strength, and reduce weight and warping. This makes them ideal for structural components, drone parts, or anything needing high performance. However, carbon fiber is highly abrasive, so a hardened nozzle is essential. The increase in stiffness can also make parts more brittle.

- Glass Fiber Reinforced Filaments: Similar to carbon fiber, these use chopped glass fibers to enhance strength and stiffness, often at a lower cost. They are also abrasive.

#### High-Performance Engineering Plastics

For advanced users and demanding applications, there are filaments designed for extreme conditions.

- PC (Polycarbonate): Known for its incredible strength, rigidity, impact resistance, and high heat deflection temperature. It’s the material used for bulletproof glass. PC is challenging to print, requiring very high temperatures (260-310°C), a very hot heated bed (100-120°C), and an enclosed printer to prevent severe warping.

- PEEK & ULTEM: These are ultra-high-performance polymers primarily used in industrial applications, aerospace, and medical fields. They offer extreme strength, chemical resistance, and incredibly high-temperature resistance. Printing them requires specialized, industrial-grade 3D printers that can reach extremely high nozzle and chamber temperatures (up to 400-500°C for the nozzle and 150-200°C for the chamber). These are definitely not for your desktop FDM printer!

#### Support Materials: Making the Impossible Possible

Sometimes, your design has overhangs or complex geometries that defy gravity. That’s where support materials come in.

- PVA (Polyvinyl Alcohol): This is a water-soluble filament often used as a support material with dual-extruder printers. You print your main object with one filament and the supports with PVA. After printing, you simply immerse the print in water, and the PVA dissolves away, leaving a clean, support-free final part. It’s highly hygroscopic, so keeping it dry is critical.

- HIPS (High Impact Polystyrene): HIPS is often used as a support material for ABS. It’s soluble in limonene, a citrus-based solvent. It prints similarly to ABS, making it a good pairing for parts needing high heat resistance.

#### Fun & Functional Filaments

- Glow-in-the-Dark Filaments: Usually PLA or PETG with phosphorescent pigments. They charge under light and glow in the dark, great for toys, decorations, or safety markers. The pigments can be slightly abrasive.

- Color-Changing Filaments: These filaments change color based on temperature (thermochromatic) or UV light (photochromatic). Fun for novelty items or educational prints.

- Conductive Filaments: Infused with carbon particles, these filaments allow for low-voltage electrical circuits to be printed directly into your models, opening up possibilities for integrating electronics.

- Magnetic Filaments: Contains iron particles, allowing prints to be attracted to magnets.

Decoding Filament Properties: What Do They Mean for Your Print?

Understanding the jargon around filament properties is crucial for making smart choices. These terms tell you how a material will behave both during printing and in its final application. A good understanding of how polymer coatings improve performance and save money can also provide insight into how different materials achieve their specific characteristics.

- Tensile Strength: This measures how much pulling force a material can withstand before breaking. High tensile strength means the material is good for structural components that will be under tension.

- Flexibility/Elongation at Break: This tells you how much a material can bend or stretch before it breaks. High elongation is characteristic of flexible filaments like TPU, while low elongation means a material is more rigid and brittle.

- Impact Resistance: This indicates how well a material can absorb a sudden shock or blow without breaking. ABS and PETG generally have good impact resistance, making them suitable for parts that might be dropped or bumped.

- Heat Deflection Temperature (HDT): This is a critical metric. It tells you the temperature at which a printed part will start to deform under a specific load. If your part needs to operate in a warm environment (like inside a car on a sunny day or near electronics), a high HDT is essential. PLA has a low HDT, while ABS, PC, and Nylon have much higher ones.

- Chemical Resistance: How does the material react to different chemicals, solvents, oils, or acids? Some filaments are highly resistant (like PETG), while others might degrade or dissolve (like HIPS in limonene or PVA in water).

- Hygroscopy: As mentioned with Nylon, hygroscopy describes a material’s tendency to absorb moisture from the air. Highly hygroscopic filaments (like Nylon, PVA, and some PETG) need careful storage and drying before use to prevent printing issues like bubbling, stringing, and weakened parts.

- Abrasiveness: This refers to how much a filament will wear down your printer’s nozzle. Filaments with fillers like wood, metal, carbon fiber, or glow-in-the-dark pigments are significantly more abrasive than standard PLA or ABS. Printing with these materials will quickly wear down a brass nozzle, requiring a hardened steel or ruby nozzle for longevity.

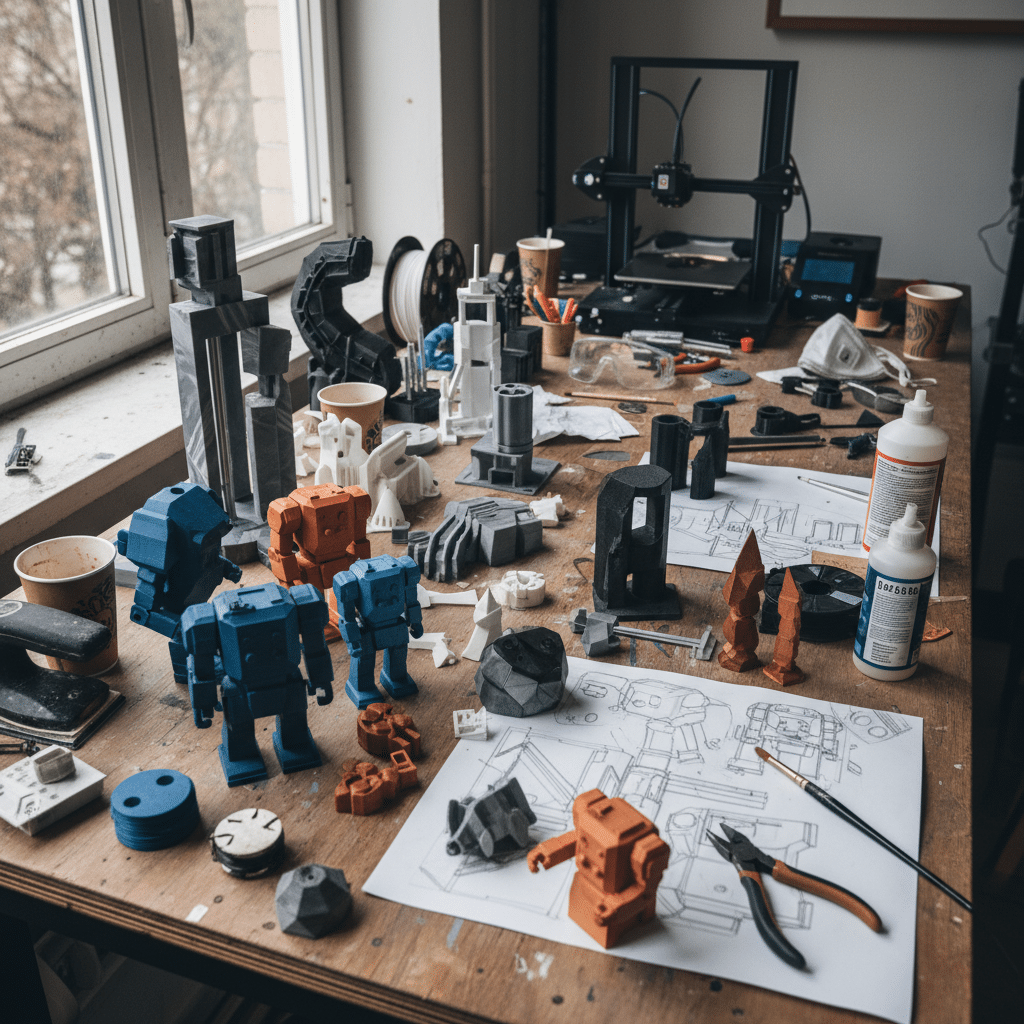

Choosing Your Weapon: Matching Filament to Project

Okay, you know the players. Now, how do you pick the right one for your specific print? It’s all about matching the filament’s characteristics to your project’s needs.

#### Consider the Application

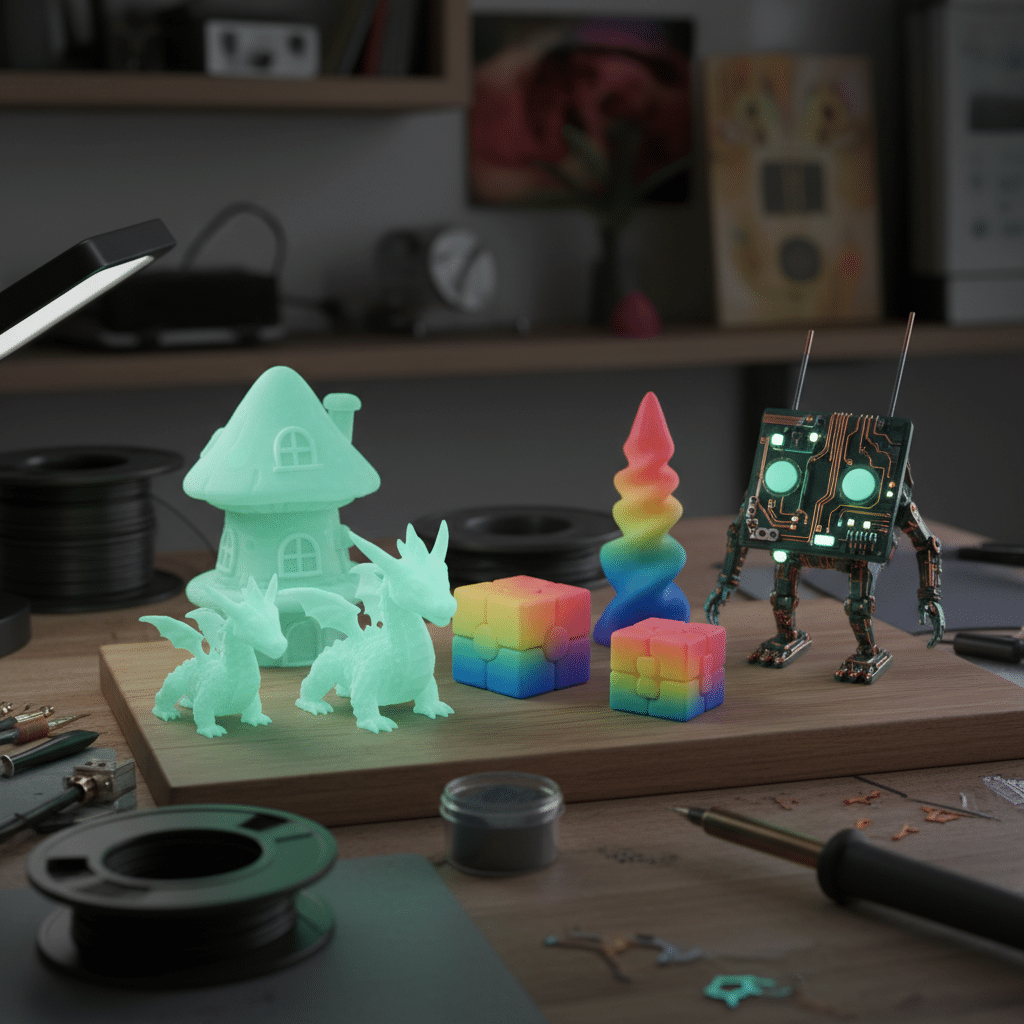

- Decorative/Aesthetic: If it’s just for looks – a cool figurine, a vase, or a display piece – PLA is often the easiest and most cost-effective choice. Wood-filled or metal-filled filaments can add a premium aesthetic.

- Functional/Mechanical: For parts that need to hold up, endure stress, or be load-bearing, you’ll lean towards ABS, PETG, Nylon, or even carbon fiber reinforced options. Think gears, brackets, custom tool parts, or components for a smart home office design for productivity where custom organizers or cable management might be needed.

- Flexible/Wearable: Phone cases, gaskets, shoe inserts, or anything that needs to bend or compress calls for TPU or other flexible filaments.

- Outdoor Use: For items exposed to sunlight, rain, or varying temperatures, PETG, ABS, and ASA (a weather-resistant cousin of ABS) are better choices due to their UV and water resistance.

#### Environmental Factors

- Temperature Exposure: Will your print be in a hot car, near a heat source, or in direct sunlight? Avoid PLA if so, and opt for ABS, PETG, or PC.

- UV Exposure: For outdoor items, UV resistance is key. PETG, ASA, and some specialized outdoor filaments perform best.

- Chemical Exposure: If your part will come into contact with solvents, oils, or certain chemicals, check the filament’s chemical resistance properties.

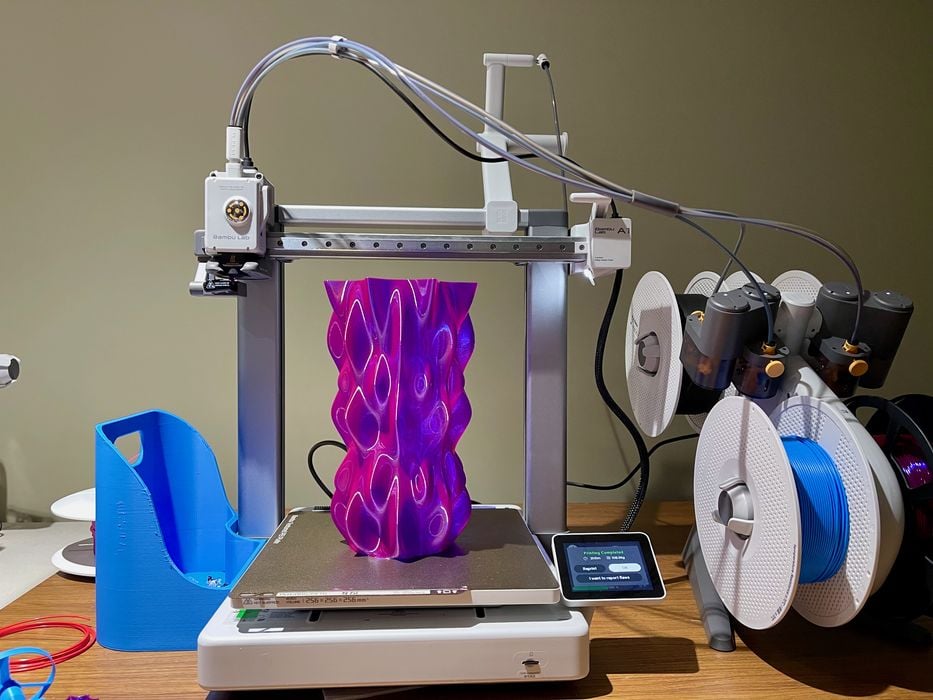

#### Printer Compatibility and Your Comfort Level

- Heated Bed & Enclosure: Many advanced filaments require a heated bed (ABS, PETG, Nylon, PC) and some benefit greatly from an enclosed print chamber (ABS, PC, Nylon) to prevent warping and control fumes. Make sure your printer can handle these requirements.

- Nozzle Type: If you plan to use abrasive filaments (wood, metal, carbon fiber, glow-in-the-dark), a hardened steel or ruby nozzle is a must to prevent premature wear of your standard brass nozzle.

- Extruder Type: Flexible filaments often perform best with direct-drive extruders, which keep the filament path short and constrained. Bowden setups can struggle with very flexible materials.

- Ventilation: Printing with ABS, PC, or certain composite filaments can produce fumes or ultrafine particles that aren’t good to breathe in. Ensure you have adequate ventilation or an air filter system.

#### Post-Processing Needs

- Sanding/Painting: Most filaments can be sanded and painted, but some (like ABS) are particularly good candidates for smoothing with acetone vapor. Wood-filled filaments can be stained.

- Gluing: Consider how easily the material can be glued if your project involves assembling multiple parts. Cyanoacrylate (super glue) works well with many, but specific glues might be needed for others.

Mastering Your Material: Tips for Success with Any Filament

No matter which 3D printer filament type you choose, a few best practices will help you get better prints and make your life easier.

- Storage is Key: Keep it Dry! This cannot be stressed enough. Most filaments, especially Nylon, PVA, and PETG, are hygroscopic and absorb moisture from the air. Wet filament leads to steam bubbles during printing (which you might hear as popping or crackling), poor layer adhesion, stringing, and generally weak, ugly prints. Store your filament in airtight containers with desiccant packets when not in use. A dedicated filament dryer can also be a game-changer, especially for problematic materials.

- Calibrate Your Settings: Every filament, even from the same manufacturer but different batches or colors, can behave slightly differently. Always run calibration prints (like temperature towers, retraction tests, and flow tests) when trying a new filament. Start with the manufacturer’s recommended settings, but be prepared to fine-tune.

- Master Bed Adhesion: Getting that first layer to stick is crucial. Ensure your print bed is clean and level. Different filaments prefer different bed surfaces and adhesion aids:

PLA: Glass with glue stick, PEI sheet, painter’s tape. ABS: PEI sheet, Kapton tape, ABS slurry (ABS dissolved in acetone), heated glass with glue stick. PETG: PEI sheet (with a release agent like glue stick to prevent sticking too well), heated glass with glue stick. Nylon: Garolite (G-10/FR4), blue painter’s tape with glue stick.

- Monitor Nozzle Wear: As mentioned, abrasive filaments can quickly degrade a brass nozzle. If you notice your print quality declining (e.g., under-extrusion, less detail), especially after printing with composites, check your nozzle. A worn nozzle has an enlarged or irregularly shaped opening, leading to inconsistent extrusion. Investing in a hardened steel or ruby nozzle for abrasive materials will save you money and headaches in the long run.

- Ventilation Matters: Be mindful of fumes, especially with ABS, ASA, and some other engineering plastics. Always print in a well-ventilated area, or invest in an enclosure with an air filtration system. Your health is more important than any print.

- Experiment and Document: Don’t be afraid to try new things! The best way to learn is by doing. Keep a log of your successful and unsuccessful print settings for different filaments and projects. This will be invaluable for future reference. Many creative home remodeling solutions start with experimentation, and 3D printing is no different! Maximizing space: creative home remodeling solutions often involves custom parts, and understanding filament behavior helps you print them successfully.

The Future of Filament: A Glimpse Ahead

The world of 3D printer filament is constantly evolving. Researchers are developing new blends, bio-plastics that are even more sustainable, and advanced composites that push the boundaries of strength, conductivity, and even biodegradability. We’re seeing filaments infused with living organisms for bio-printing, materials that can self-heal, and smart filaments that react to their environment. As 3D printing becomes more widespread, expect to see even more accessible and specialized materials emerge, catering to an ever-growing range of applications from aerospace to fashion design, and from creating art to crafting custom home decor. Travel-inspired packable decor ideas might one day include objects printed on the go with specialized, lightweight, and durable filaments.

Understanding your filament is more than just a technical detail; it’s a creative superpower. Each type offers a unique set of possibilities, allowing you to tailor your prints to specific functions, aesthetics, and environmental conditions.

So, go forth and experiment! Don’t be afraid to try new things, push the boundaries of your printer, and discover the perfect filament for your next masterpiece. The journey of exploration is half the fun in 3D printing. Happy printing, and may your layers always be perfect!

What are the most common types of 3D printing filaments and their uses?

The most common filament types are PLA, ABS, PETG, TPU, and Nylon, each suited for different applications such as decorative objects, functional parts, flexible items, and durable components.

Why is PLA considered the best filament for beginners?

PLA is favored by beginners because it is easy to print, requires lower temperatures, produces minimal odor, and is environmentally friendly, making it ideal for decorative items and prototypes.

What makes ABS a good choice for functional, impact-resistant parts?

ABS is tough, impact-resistant, and can withstand higher temperatures compared to PLA, making it suitable for durable parts, enclosures, and tools, although it requires higher printing temperatures and good ventilation.

How does PETG compare to PLA and ABS?

PETG offers a balance of strength, flexibility, and temperature resistance, being easier to print than ABS with less warping, and more impact-resistant than PLA, making it versatile for outdoor and mechanical applications.

What should I consider when choosing filament for outdoor use or high-temperature environments?

For outdoor or high-heat applications, choose filaments like PETG, ABS, ASA, or PC, as they offer better UV resistance, water resistance, and high-temperature stability compared to PLA.

- 19shares

- Facebook0

- Pinterest19

- Twitter0

- Reddit0