The best 3D printers in 2026 offer reliable performance, impressive print quality, and features that match your needs—whether you’re a beginner or an experienced maker. With options ranging from budget-friendly FDM models to high-resolution resin printers, you can find a device that easily fits your workspace and projects. The technology has evolved to be more user-friendly and accessible, enabling you to create professional-level designs at home or in your workshop.

Understanding the differences between FDM and resin printers, as well as key features like print speed, build volume, and supported materials, is important for making the right choice. Your experience with setup and ongoing maintenance will also play a big role in how much you enjoy 3D printing. With the right tools and insights, you can jump straight from unboxing to printing your ideas.

Key Takeaways

- Top 3D printers in 2026 cater to different skill levels and budgets.

- Choosing the right features and technology is key for a successful experience.

- Proper setup and maintenance help you get the best results.

Top Picks: The Best 3D Printers in 2026

Whether you’re after top-tier performance, affordability, detail in resin printing, or something user-friendly for your home, there’s a leading 3D printer model tailored for each need. Each pick below is selected for reliability, print quality, and ease of use.

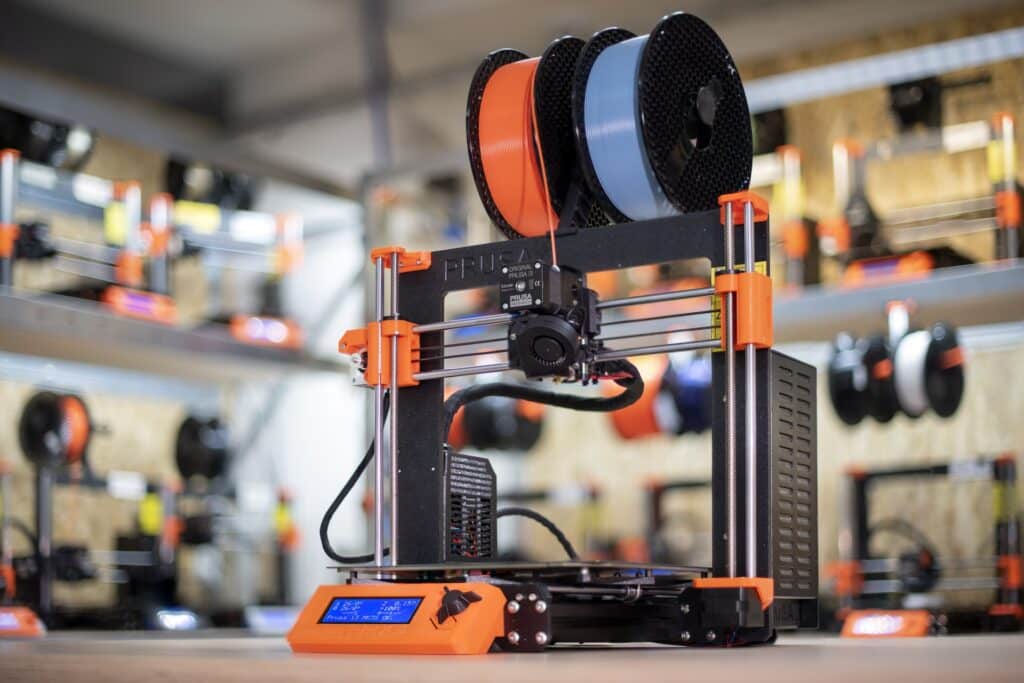

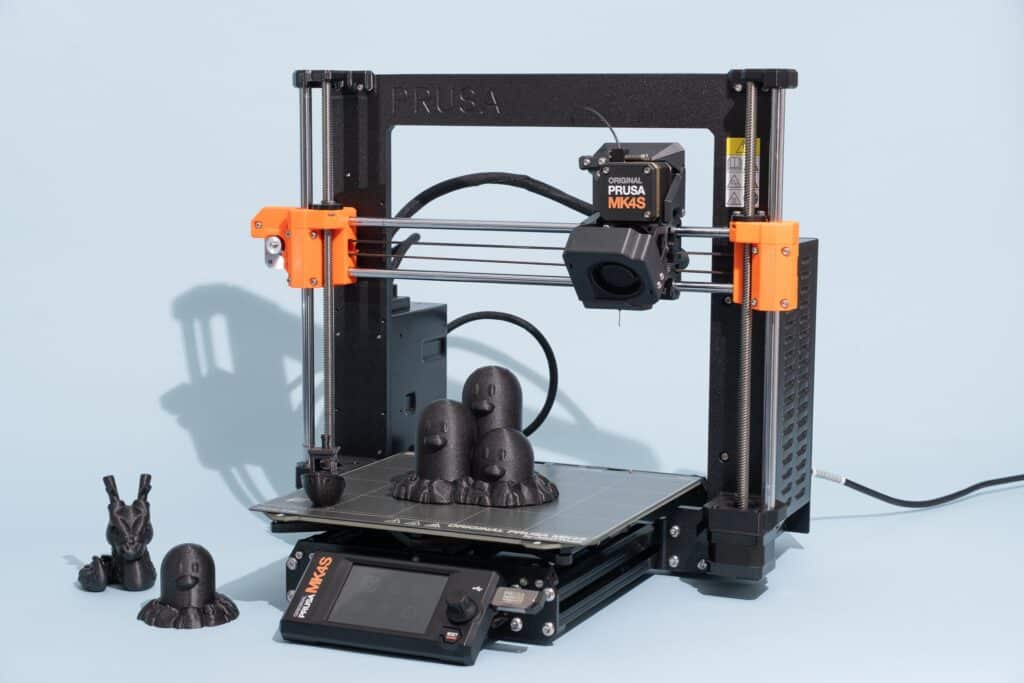

Best Overall 3D Printer

The Prusa MK4 stands out in 2026 as your best all-around 3D printer thanks to its impressive blend of precision, speed, and support. Its auto bed leveling and quick-swap nozzles make maintenance and setup convenient even for beginners. Wi-Fi connectivity and a responsive touchscreen streamline the printing process.

You get compatibility with a wide range of filaments, including PLA, PETG, ABS, and flexible TPU. The open-source design means you can easily access parts and upgrades. Consistent firmware updates and active community support further enhance its long-term value.

| Key Specs | Details |

|---|---|

| Print Volume | 250 x 210 x 220 mm |

| Max Print Speed | Up to 250mm/s |

| Supported Materials | PLA, PETG, ABS, TPU |

| Connectivity | Wi-Fi, USB |

The Prusa MK4 makes high-quality prints accessible whether you’re a hobbyist or looking for dependable results for business prototyping.

Best Budget 3D Printer

If you’re cost-conscious but still want excellent performance, the Creality Ender-3 V3 (and its close sibling the Ender-7) remains a standout budget choice. You benefit from easy assembly, reliable print results, and plenty of online guides and mods.

This printer offers a sturdy metal frame, silent stepper drivers, and decent print speeds for its price class. It supports basic materials like PLA and PETG which are great for most hobby projects. The Ender-3 V3’s open-source nature means you can upgrade components like the mainboard or extruder as your skills grow.

| Key Specs | Details |

|---|---|

| Print Volume | 220 x 220 x 250 mm |

| Max Print Speed | Up to 180mm/s |

| Supported Materials | PLA, PETG |

| Connectivity | microSD, USB |

For budget-minded users or beginners, the Ender-3 V3 offers a reliable entry point into 3D printing without unnecessary complexity.

Best Resin 3D Printer

For highly detailed figures, jewelry, or prototypes, the Anycubic Photon Mono 2 is a top pick among resin printers in 2026. Its 6.6-inch monochrome LCD allows for faster curing times and longer lifespan compared to traditional RGB LCD screens.

You get high detail at layer heights as fine as 0.025mm. The build volume is competitive for its class, and the machine includes safety features like a covered vat to minimize exposure to resin fumes. Simple bed leveling and a user-friendly interface make it approachable, even if you’re new to resin printing.

| Key Specs | Details |

|---|---|

| Build Volume | 143 x 89 x 165 mm |

| LCD Resolution | 4K Monochrome |

| Layer Height | 0.025-0.1 mm |

| Connectivity | USB |

If precise, smooth surfaces and intricate detail matter most to you, the Photon Mono 2 is a smart choice.

Best Home 3D Printer

For home use, the Bambu Lab A1 Mini is widely recognized for its quiet operation, compact size, and multicolor printing capability. Its automated calibration and filament loading make setup and daily use straightforward.

A built-in camera lets you monitor prints from your phone. The A1 Mini achieves excellent results with PLA, PETG, and TPU, making it suitable for school projects, home repairs, and creative hobbies. The build volume is ideal for most home applications, balancing size and desk space.

| Key Specs | Details |

|---|---|

| Build Volume | 180 x 180 x 180 mm |

| Color Printing | Yes (up to 4 colors) |

| Max Print Speed | Up to 500mm/s |

| Connectivity | Wi-Fi, SD card |

You can trust the Bambu Lab A1 Mini to deliver smooth, vibrant prints without the noise or maintenance hassle. For most households, this model checks all the right boxes.

Key Features to Consider When Choosing a 3D Printer

Finding the right 3D printer means weighing various specifications. Print quality, printer speed, machine size, and support for multiple materials all play major roles in what your experience will be like.

Print Quality and Speed

Print quality is measured in layer height (resolution) and accuracy. The lower the layer height, the finer the detail you’ll see in your prints—for example, a 0.1 mm layer will reveal more detail than a 0.3 mm layer. Reliable stepper motors and improved extruder designs help maintain consistent results.

Some printers include lidar sensors that improve precision by scanning each layer as it’s printed, ensuring dimensional accuracy. However, these are usually found in higher-end models.

Print speed is often a trade-off with quality. Fused Deposition Modeling (FDM) printers generally work faster but may produce less detailed surfaces than resin-based printers. Faster speeds are great for prototypes, but complex or large objects benefit from slower, higher-resolution settings.

Build Volume and Size

Build volume tells you the largest object you can print. Typical desktop printers offer a build volume between 150×150×150 mm and 300×300×400 mm.

If you plan to create bigger objects—like helmet props or engineering prototypes—look for larger build volumes. However, remember that a bigger printer also takes up more space and may be heavier or less portable.

A comparison table makes it easy to see differences:

| Printer Type | Typical Build Volume (mm) |

|---|---|

| Mini FDM | 120 × 120 × 120 |

| Standard FDM | 220 × 220 × 250 |

| Large-format | 300 × 300 × 400 or higher |

| Resin | 130 × 80 × 160 |

Check your workspace before choosing a model, and think about the print sizes you’ll create most often.

Multi-Material and Color Printing

Multi-material and color printing let you use several types of filaments or resins in one print. Some printers use dual or quad extruders to handle multiple materials, such as PLA, TPU, or dissolvable support filament.

For color, a few advanced machines can blend filaments or use different nozzles. Most consumer models offer single-color printing by default, but multi-material upgrades are available for some brands.

With multi-material capabilities, you can create parts with flexible hinges, soluble supports, or aesthetic color effects. This is very useful for prototyping parts that require different characteristics within a single print job. Always check compatibility, as software control and hardware requirements can differ widely between models.

FDM vs. Resin: 3D Printing Technologies Explained

When comparing 3D printers, the differences between FDM and resin technologies matter a lot. Your choice will shape print quality, material options, cost, maintenance, and the type of projects you can do.

FDM Printers

FDM printers use a spool of plastic filament, such as PLA, ABS, or PETG, which gets heated and extruded through a nozzle. Layer by layer, your design comes to life on the build plate. This technology is the most popular among hobbyists and beginners thanks to its affordability and ease of use.

You can expect prints to be strong and durable, though layer lines will usually be visible. FDM models are ideal for functional prototypes, mechanical parts, and larger prints. Maintenance is straightforward, with basic cleaning and occasional nozzle replacements.

Pros:

- Wide material compatibility

- Low operating costs

- Simple post-processing (usually just removing supports)

Cons:

- Usually lower detail/resolution than resin

- Visible layer lines

- Can be noisy during operation

| Feature | FDM Printer |

|---|---|

| Print Volume | Larger |

| Print Speed | Moderate |

| Detail Level | Medium |

| Cost | Lower |

Resin 3D Printing

Resin 3D printers, including SLA, MSLA, and DLP types, use liquid photopolymer resin cured by a light source. This approach achieves much higher resolution and intricate details—perfect for figurines, jewelry, and dental models.

Set-up and maintenance are different from FDM. You’ll need gloves and isopropyl alcohol for cleaning parts and the printer. Finished prints look smoother, with sharp details and minimal visible layers, but they’re often more brittle than FDM prints.

Pros:

- High detail and smooth finishes

- Excellent for small, complex parts

- Minimal visible layer lines

Cons:

- More involved post-processing (washing and curing)

- Smell and chemical handling

- Print costs are usually higher

| Feature | Resin Printer |

|---|---|

| Print Volume | Smaller |

| Print Speed | Often slower |

| Detail Level | High |

| Cost | Higher |

Essential Software and Materials for 3D Printing

To get reliable, high-quality prints from your 3D printer, you’ll need the right combination of software and materials. Choosing user-friendly slicing programs, sourcing quality digital models, and using compatible filaments can make your printing experience smoother and more fun.

Slicer Software Options

A slicer is crucial because it translates your 3D design file into instructions your printer can understand. PrusaSlicer is a popular choice that works especially well with Prusa printers, but also supports models from other brands. It offers advanced features for adjusting layer height, infill patterns, and material settings.

For beginners, Ultimaker Cura is free, widely compatible, and easy to navigate. If you’re looking for something for resin printing, Lychee Slicer is user-friendly and comes with built-in support generation.

Here’s a quick comparison:

| Slicer | Platform | Best For | Cost |

|---|---|---|---|

| PrusaSlicer | Windows, Mac | Prusa/Versatile | Free |

| Ultimaker Cura | All | Beginners | Free |

| Lychee Slicer | All | Resin Printers | Freemium |

Selecting the slicer that matches your skill level and printer model can help you avoid failed prints and wasted filament.

Where to Find 3D Models

You don’t always need to design everything from scratch. Reliable sources like Thingiverse, Printables, and MyMiniFactory offer a huge range of ready-to-print 3D models.

- Thingiverse is one of the largest repositories with models for everything from phone stands to mechanical parts.

- Printables (formerly PrusaPrinters) is curated with high-quality designs, often with good documentation and printer settings.

- If you want to design your own models, Tinkercad is a free, browser-based CAD tool that’s very approachable for beginners.

Always check licensing information and user reviews. Look for models marked as “tested” or “remixed” for improved chances of printing success.

Popular Filament Types

Choosing the right filament affects the strength, finish, and flexibility of your print. PLA is the most common—it’s easy to use and available in many colors. If you want something stronger and more heat-resistant, PETG filament is a great option. It’s less brittle than PLA and won’t warp as easily as ABS.

Here’s a snapshot of popular filaments:

- PLA: User-friendly, biodegradable, good for prototypes and decorative prints.

- PETG: Durable, flexible, food-safe, and ideal for functional parts.

- ABS: Tough and heat-resistant, but can be tricky due to warping and fumes.

Keep your filament stored in a dry place. Moisture can cause printing defects, so consider using airtight containers or filament dryers.

Setup, Maintenance, and Tips for Getting the Best Results

A reliable 3D printer depends on proper assembly, consistent care, and smart troubleshooting. Following a few structured practices will help you maximize performance and print quality year-round.

Machine Assembly and Calibration

Begin by carefully assembling your 3D printer following the manufacturer’s manual, making sure every screw is tightened and each cable is securely plugged in. Level the print bed first, as even a slight tilt can cause poor adhesion and uneven prints. Most printers offer either manual or assisted bed leveling—double-check this step before every major project.

Calibrate your extruder and check the Z-axis height to avoid jams or under-extrusion. It’s important to fine-tune print settings such as layer height, print speed, and nozzle temperature based on the filament you use. Before you print complex models, run a few test prints to confirm that all axes move smoothly and that the extruder feeds plastic evenly. This reduces headaches later and ensures reliable results from your 3D printer.

Routine Maintenance

Regular maintenance keeps your 3D printers running smoothly. Start by inspecting the print bed for dust or residue before every use; clean with isopropyl alcohol as needed. Check belts and screws for tightness at least once a month—loose parts can affect accuracy.

Examine the extruder gear for filament buildup and remove any debris. Lubricate any moving rods or bearings as recommended by your printer’s guide. Key tasks include:

- Cleaning the nozzle to prevent clogs

- Re-aligning and tensioning belts

- Checking cables for tangles or wear

Use a checklist to track maintenance intervals. Staying ahead of wear helps you avoid unexpected downtime and protect your printer’s lifespan.

Troubleshooting Common Issues

If your Best 3D Printer for Home shows poor adhesion, first re-level the bed and make sure it’s free of dust or grease. Stringing or blobs typically mean you need to lower the print temperature or adjust retraction settings within your slicer software. Intermittent extrusion can result from a partially clogged nozzle, so clean it promptly.

Layer shifting during prints often points to loose belts or stepper drivers skipping. Inspect for mechanical obstructions and confirm that your firmware is up-to-date. Use the following table to quickly spot and address frequent issues:

| Problem | Solution |

|---|---|

| Poor bed adhesion | Level bed, clean surface |

| Stringing/blobs | Lower temp, adjust retraction |

| Layer shifts | Tighten belts, check mechanics |

| Under-extrusion | Clean nozzle, recalibrate steps |

Addressing these problems methodically helps you get consistent, high-quality prints with minimal frustration.

- 3shares

- Facebook0

- Pinterest2

- Twitter1

- Reddit0