The real estate and interior design industries embrace custom plastics as game-changing materials for contemporary spaces. From furniture to architectural accents, how custom plastics are shaping real estate and interiors reflects their ability to merge style with function. These versatile solutions offer architects and designers unprecedented flexibility in creating unique, functional environments.

Modern properties showcase custom plastic elements that enhance both aesthetic appeal and practical functionality. The integration of these materials represents a significant shift toward innovative design approaches in residential and commercial spaces.

Transforming Architectural Elements With Custom Solutions

Custom plastic components revolutionize how architects approach structural and decorative elements in modern buildings. These materials provide lightweight alternatives to traditional construction materials while maintaining exceptional durability and design flexibility. Designers create intricate facades, room dividers, and decorative panels that were previously impossible with conventional materials. The manufacturing process allows for precise customization that meets specific architectural requirements and aesthetic visions.

Innovative Interior Applications Drive Market Growth

Interior designers increasingly specify custom plastic elements for furniture, lighting fixtures, and accent pieces in high-end projects. Understanding how custom-made plastic parts are created enables designers to push creative boundaries and achieve unique visual effects. These materials offer superior moldability, allowing the creation of complex shapes and intricate details that enhance spatial design concepts. The versatility of custom plastics supports both minimalist and maximalist design approaches in contemporary interior projects.

Sustainable Benefits Attract Environmentally Conscious Clients

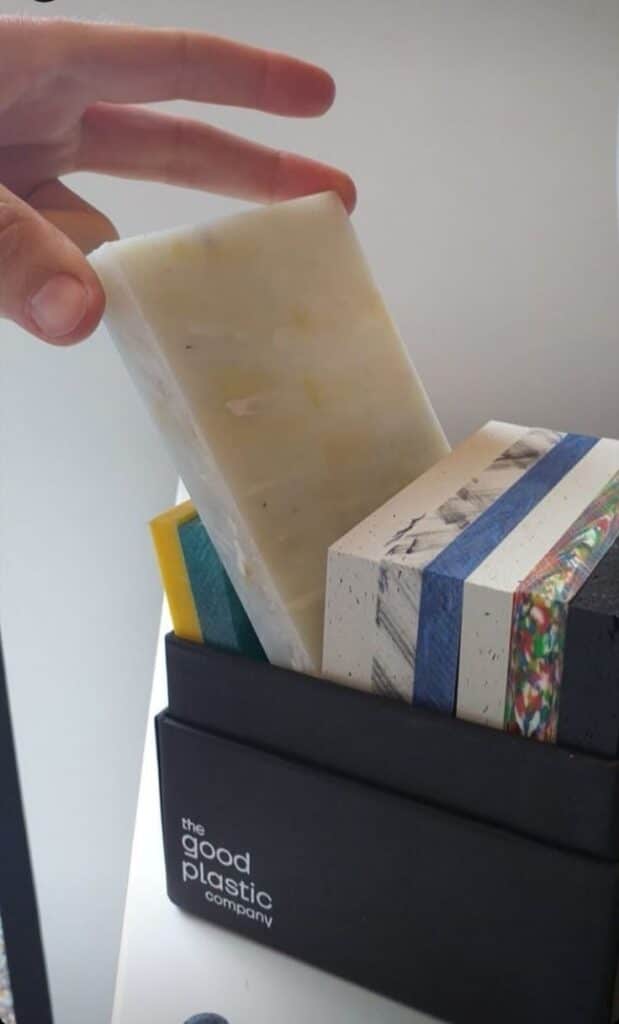

Modern custom plastic manufacturing processes prioritize environmental responsibility by utilizing recycled materials and employing efficient production methods. Real estate developers recognize that sustainable building materials appeal to environmentally conscious buyers and tenants seeking eco-friendly spaces. These materials often outperform traditional alternatives in terms of energy efficiency and long-term maintenance requirements. The recyclable nature of many custom plastics aligns with green building certifications and sustainability goals in commercial developments.

Cost-Effectiveness Enhances Project Profitability

Custom plastic solutions offer significant cost advantages over traditional materials, delivering superior performance and aesthetic results. Property developers reduce construction timelines through faster installation processes and lower labor requirements for custom plastic components. The durability of these materials minimizes long-term maintenance costs, increasing overall return on investment for real estate projects. Budget-conscious clients appreciate the ability to achieve high-end appearances without premium material costs traditionally associated with luxury finishes.

Future Trends Shape Industry Standards

The custom plastics industry continues advancing through technological innovations that expand design possibilities for real estate and interior applications. Innovative plastic materials with integrated technology features represent the next frontier in building automation and interactive design elements. Architects and designers increasingly collaborate with custom plastic manufacturers to develop proprietary solutions for signature projects and branded environments. These partnerships drive innovation while establishing new industry standards for material performance and aesthetic excellence in modern spaces.

- 0shares

- Facebook0

- Pinterest0

- Twitter0

- Reddit0