Ever wished you could bring your wildest toy ideas to life, right from your living room? Imagine crafting personalized action figures for your kids, designing unique gifts for friends, or even building a miniature city for your desk. Well, that dream is more achievable than ever thanks to the magic of 3D printing! Finding the best 3d printer for toys can transform your creative concepts into tangible, playful realities. It’s not just about buying toys anymore; it’s about making them, customizing them, and injecting a whole lot of personality into every plastic creation.

Gone are the days when 3D printing felt like something straight out of a sci-fi movie or exclusive to industrial labs. Today, affordable, user-friendly 3D printers are making their way into homes worldwide, opening up a universe of DIY possibilities. Whether you’re a parent looking for endless entertainment, a hobbyist eager to expand your creative toolkit, or an aspiring entrepreneur, a 3D printer designed for toy-making can be your ultimate companion. This isn’t just a gadget; it’s a gateway to limitless imagination, offering a unique blend of technology and artistry to spark joy in every print.

The Magic of 3D Printing Toys

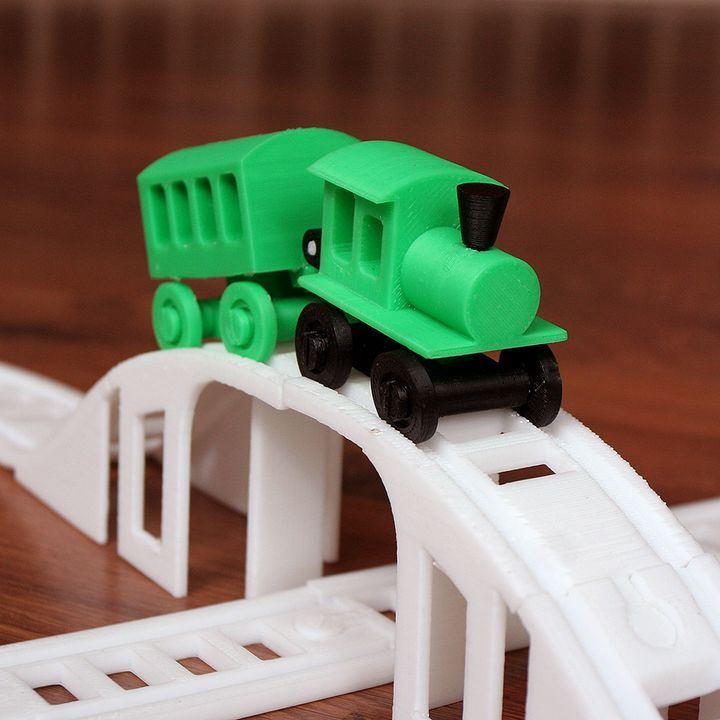

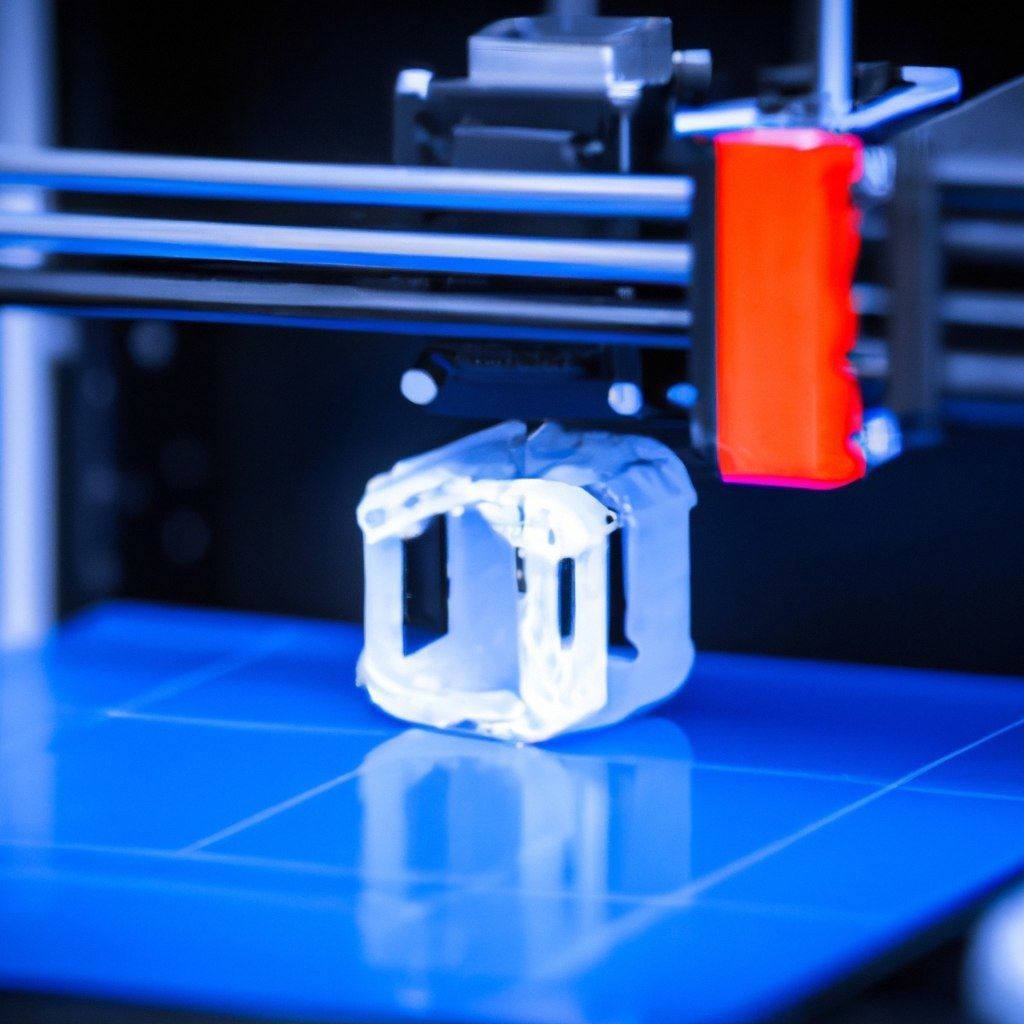

Think about the sheer joy of watching a digital design slowly materialize into a physical object. That’s the core appeal of 3D printing, especially when it comes to toys. It’s an empowering experience, allowing you to move beyond passive consumption and into active creation. From articulated figures and intricate puzzles to functional gadgets and educational models, the scope is truly astounding.

One of the biggest advantages is customization. Off-the-shelf toys are great, but they lack that personal touch. With a 3D printer, you can scale models up or down, add custom engravings, choose unique color combinations, or even combine elements from different designs to make something truly one-of-a-kind. It’s an incredible tool for turning basic drawing ideas into actual objects. Beyond just fun, 3D printing also offers a fantastic educational opportunity, introducing concepts of design, engineering, and problem-solving to both kids and adults in a hands-on way.

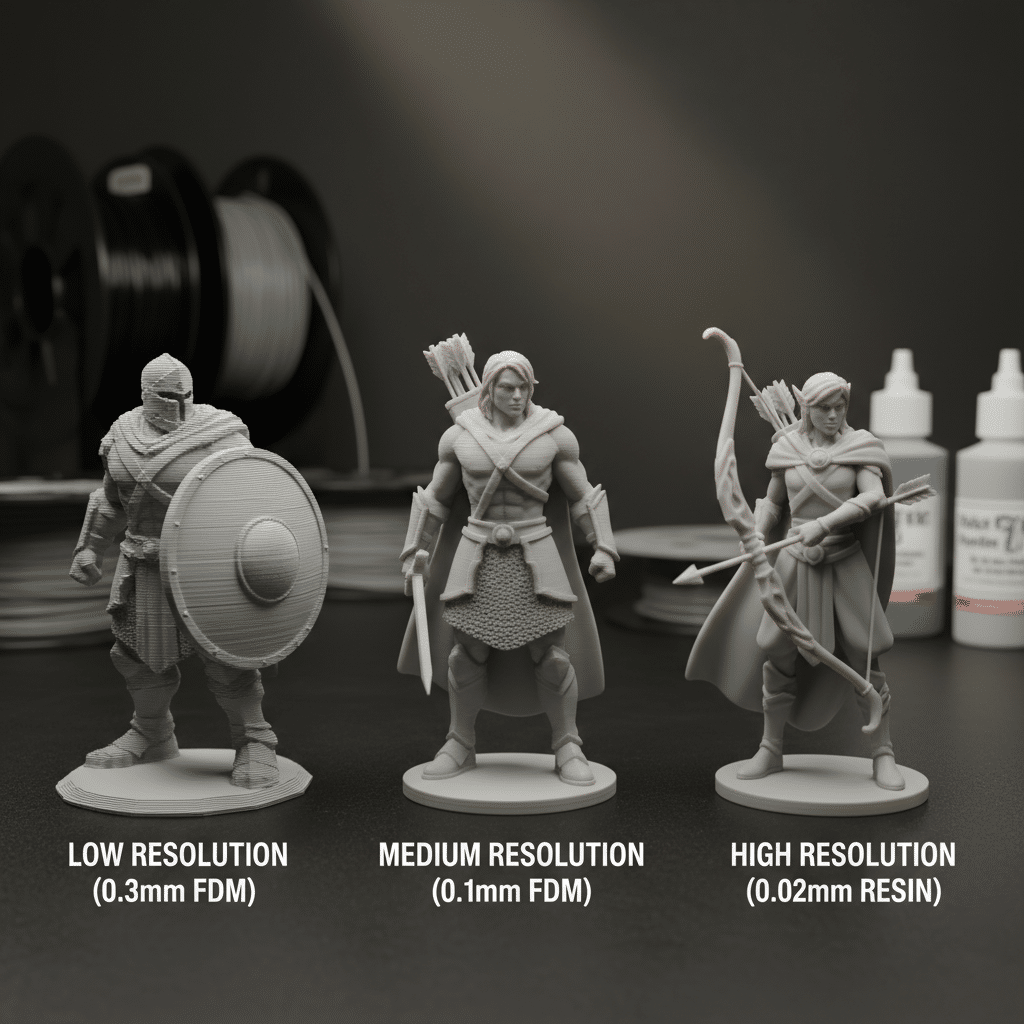

FDM vs. Resin: A Quick Look

When diving into 3D printing for toys, you’ll primarily encounter two main technologies: FDM (Fused Deposition Modeling) and Resin (SLA/DLP).

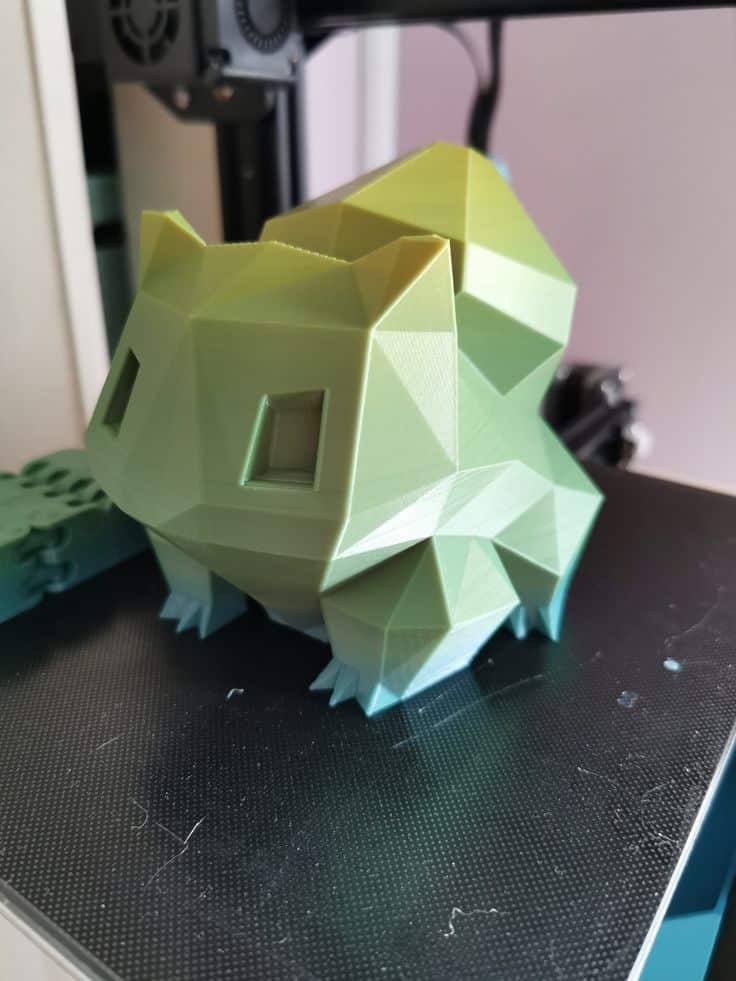

FDM printers are the most common and budget-friendly. They work by extruding a heated plastic filament layer by layer, building up the object from the bottom. Think of it like a very precise hot glue gun. They’re excellent for larger, more robust toys, prototypes, and general use. The prints might have visible layer lines, but they’re strong and safe for handling.

Resin printers, on the other hand, use a liquid resin cured by UV light. They offer incredible detail and smooth surfaces, making them perfect for highly intricate miniatures, figurines, and display pieces where aesthetic perfection is key. However, they typically have smaller build volumes, require more post-processing (washing and curing), and the resin itself needs careful handling due to its chemical nature. For most general toy-making, especially those that will be played with robustly, FDM is often the go-to choice due to its simplicity and cost-effectiveness.

Pros and Cons

| Pros | Cons |

|---|---|

| – Endless customization and unique creations | – Initial investment cost can be high |

| – Educational and skill-building experience | – Learning curve for beginners |

| – Cost-effective for creating many toys/parts | – Requires time for printing and post-processing |

| – Repair existing toys by printing replacement parts | – Some materials require good ventilation |

| – Great for personalized gifts and small businesses | – Maintenance and troubleshooting are necessary |

Key Features to Look For in a Toy 3D Printer

Choosing the right 3D printer can feel overwhelming with so many options available. When your primary goal is creating toys, a few key features should guide your decision.

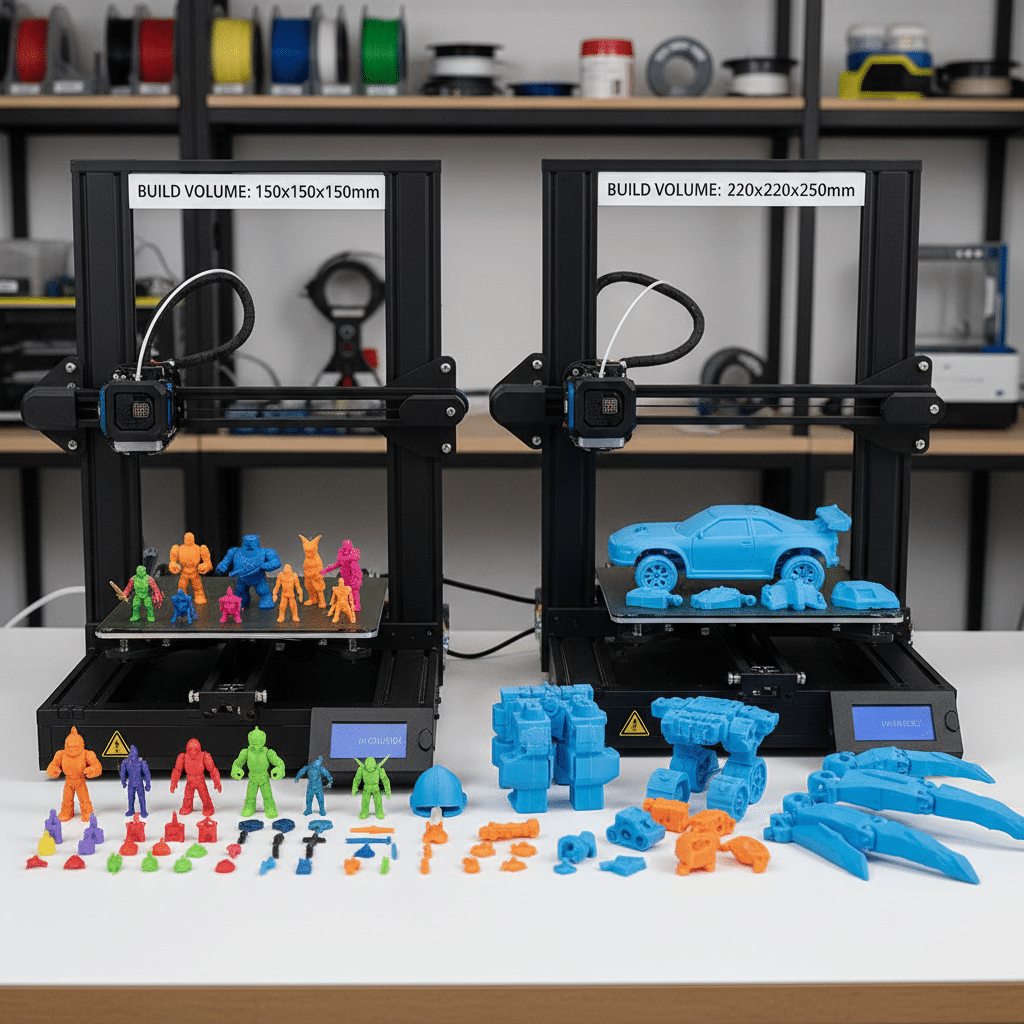

Build Volume: How Big Can Your Imagination Go?

This refers to the maximum size of an object your printer can create. If you’re planning on printing small action figures or miniature accessories, a smaller build volume (e.g., 150x150x150mm) might suffice. However, if you envision larger models, remote control car bodies, or even multi-part projects that combine into a bigger toy, you’ll want a printer with a more generous build volume (e.g., 220x220x250mm or larger). Remember, you can always print larger objects in pieces and assemble them, but a bigger build volume means fewer assemblies!

Print Speed: Patience is a Virtue, But Speed Helps

3D printing isn’t an instant gratification kind of hobby. A complex toy can take many hours to print. Faster print speeds mean less waiting, which is great, especially if you have an impatient audience (like kids!). While raw speed isn’t the only factor (print quality can suffer at extreme speeds), modern printers offer a good balance. Look for machines that can comfortably print at 150-250mm/s without sacrificing too much detail. Some newer, more advanced printers can even hit speeds of 500mm/s or more!

Resolution and Print Quality: The Devil is in the Details

Resolution dictates how fine the details on your prints will be and how visible the layer lines are. For smooth, high-quality toys, especially figurines or models with intricate features, you’ll want a printer capable of low layer heights (e.g., 0.1mm or less). FDM printers typically offer good enough detail for most toys, but if hyper-realism and tiny features are your priority, a resin printer might be worth considering for its superior resolution.

Ease of Use: Getting Started Without the Headaches

Especially for beginners, an easy-to-use printer is crucial. Look for features like:

- Auto-bed leveling: This automatically calibrates the print bed, saving you from a common source of print failures.

- Intuitive interface: A clear touchscreen and easy-to-navigate menus make operation much smoother.

- Quick assembly: Some printers come almost fully assembled, while others require more DIY effort.

- Reliable software (slicer): This program converts your 3D model into instructions for the printer. User-friendly slicers like PrusaSlicer or Cura are a big plus.

- Good community support: An active online community can be a lifesaver for troubleshooting and sharing tips. This aspect can make all the difference in your DIY journey.

Safety Features: Peace of Mind for Your Home

When 3D printing at home, especially with children around, safety is paramount.

- Enclosed design: Helps contain heat, fumes, and noise, and prevents curious hands from touching hot parts.

- Filament run-out sensor: Pauses the print when filament runs out, preventing air prints.

- Power loss recovery: Resumes printing after a power outage, saving long prints.

- Quiet operation: Less noise means a more pleasant environment.

- Proper ventilation: While PLA is generally safe, good ventilation is always recommended to disperse any potential fumes, especially with other filament types like ABS.

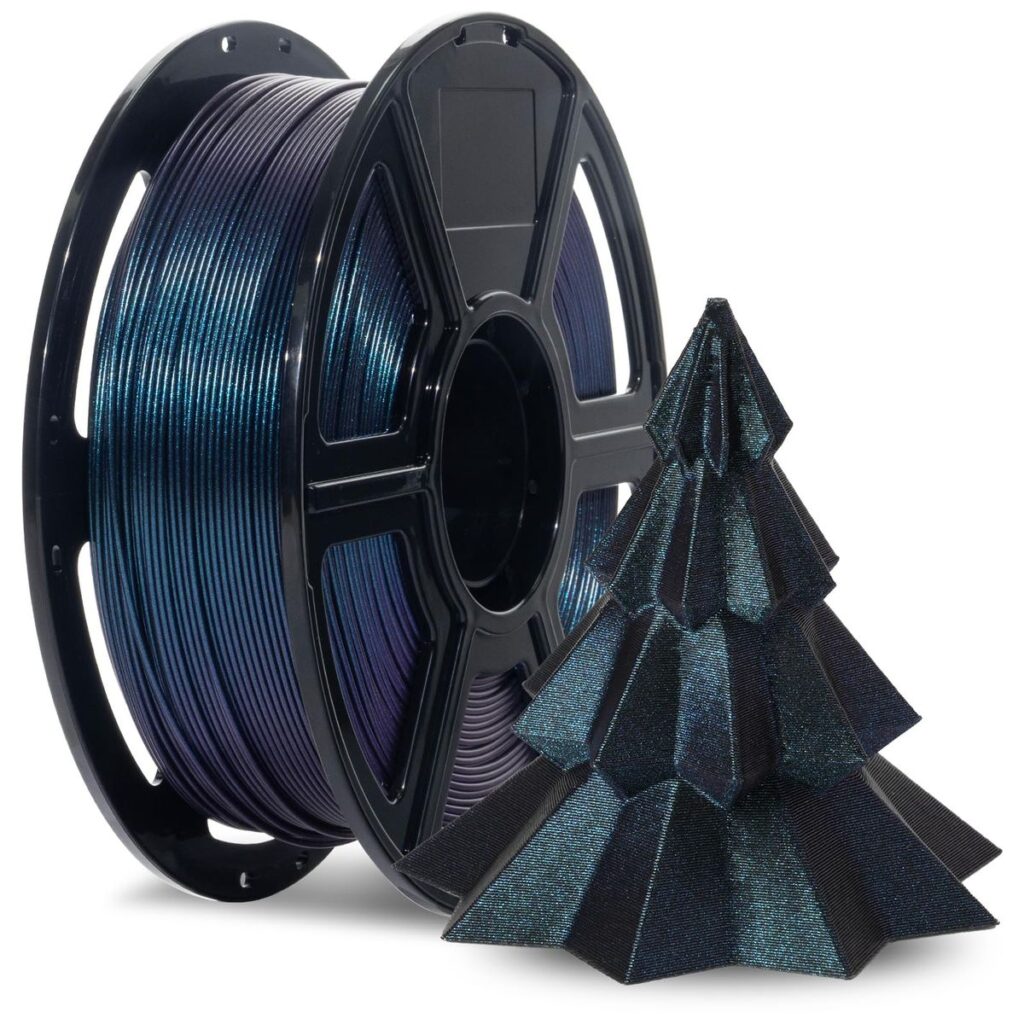

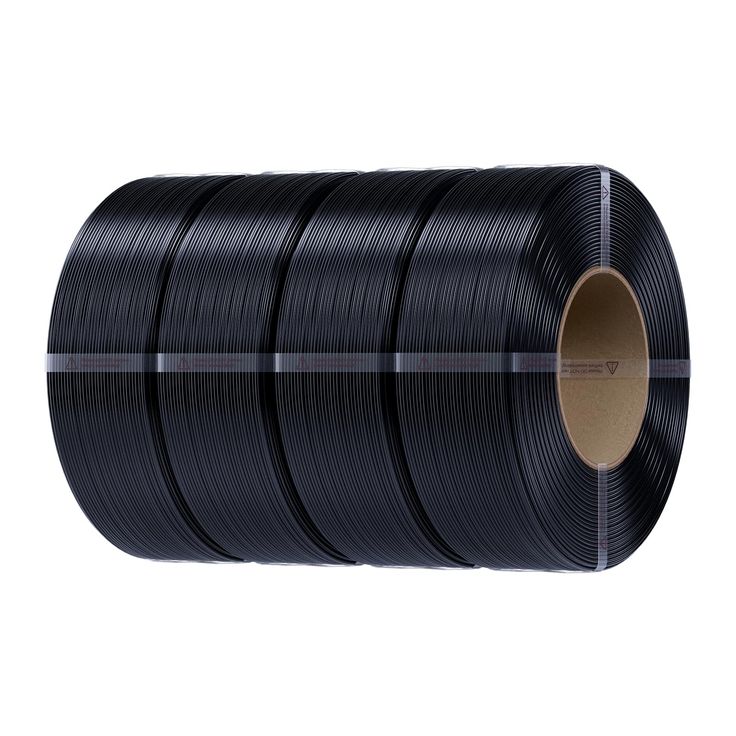

Filament/Resin Compatibility: Materializing Your Ideas

For FDM printers, PLA (Polylactic Acid) is king for toys. It’s non-toxic, biodegradable, easy to print, and comes in a rainbow of colors. Look for a printer that handles PLA beautifully. Compatibility with other filaments like PETG (more durable) or even flexible filaments (for squishy toys) can add versatility. For resin printers, make sure it’s compatible with various standard resins, and consider “tough” or “ABS-like” resins for more durable toy parts.

Top Contenders: Best 3D Printers for Toys

Let’s dive into some specific recommendations that generally perform well for toy creation, catering to different budgets and experience levels.

Best Budget-Friendly Option: The Ender Series (e.g., Ender 3 V3 SE)

Creality’s Ender series has long been a gateway for beginners into 3D printing, and for good reason. The Ender 3 V3 SE, for example, offers incredible value for its price.

- Why it’s great for toys: It’s very affordable, has a decent build volume (220x220x250mm), and can produce surprisingly good prints once dialed in. PLA prints beautifully on it, opening up a world of colorful toy possibilities.

- Considerations: While newer models offer more user-friendly features like auto-bed leveling, older Enders might require a bit more tinkering and manual setup. This is a workhorse that might need a bit of patience, but the results are rewarding. It’s also very popular, meaning a huge online community for support.

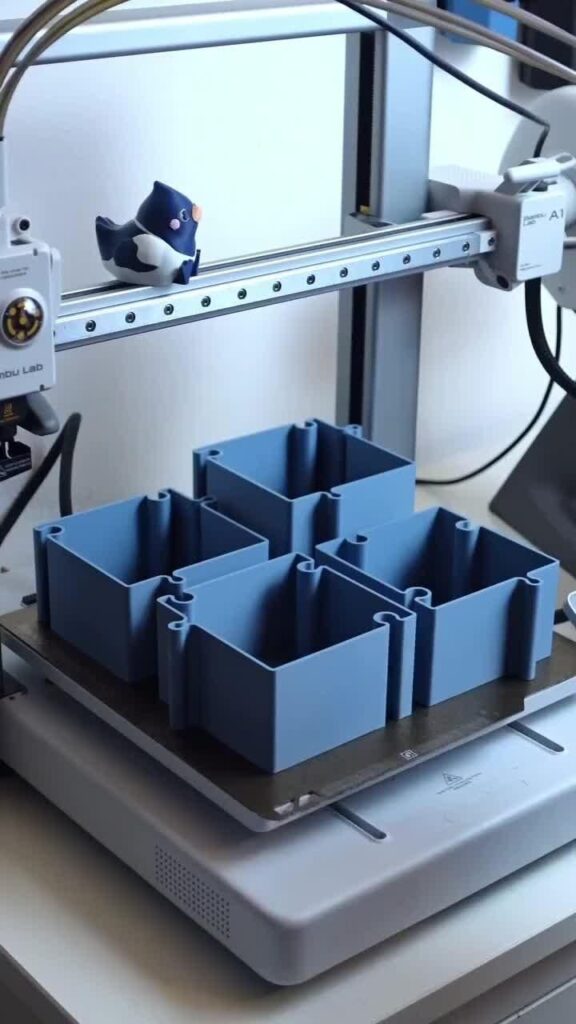

Best for Beginners (FDM): Bambu Lab A1 Mini or Prusa Mini+

These printers are designed for ease of use and reliability right out of the box, making them perfect for those who want to jump straight into printing without a steep learning curve.

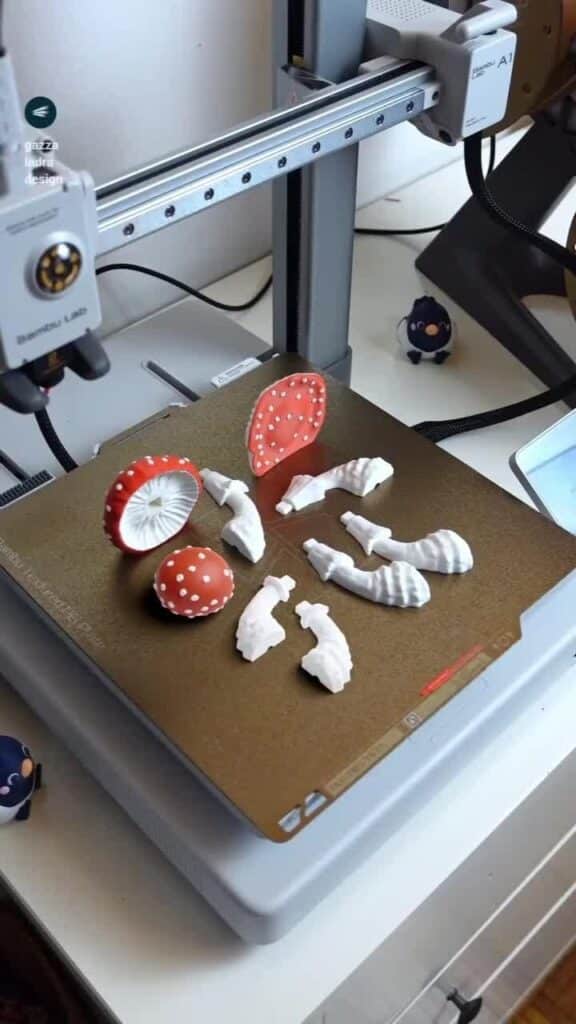

Bambu Lab A1 Mini: This compact powerhouse has taken the market by storm.

- Why it’s great for toys: It’s incredibly fast, features impressive auto-calibration, and offers fantastic print quality. Its optional AMS (Automatic Material System) allows for multi-color printing, which is a game-changer for toys, letting you create vibrant models without manual filament changes. The small footprint is also great for home use.

- Considerations: The build volume is smaller than some competitors, so larger toys will need to be printed in parts. It’s also a bit pricier than entry-level Enders, but the user experience often justifies the cost.

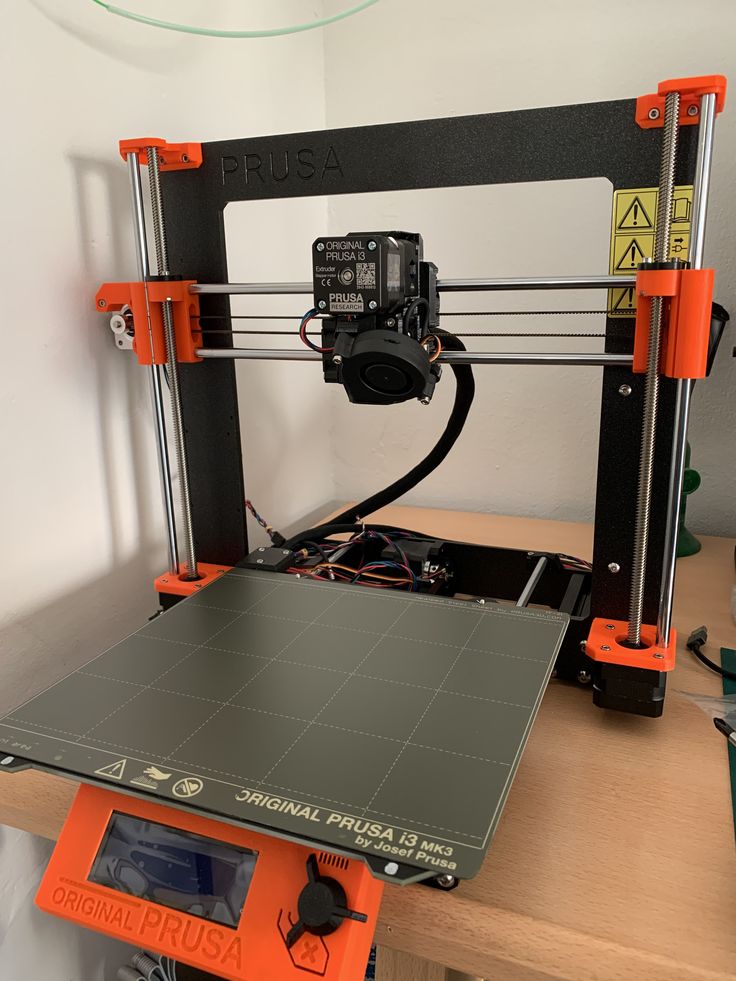

Prusa Mini+: A veteran in the easy-to-use category, known for its reliability.

- Why it’s great for toys: Prusa printers are renowned for their robust build quality, excellent software, and phenomenal customer support. The Mini+ is compact, reliable, and delivers consistent, high-quality prints. It’s an ideal choice for someone who wants a “set it and forget it” experience.

- Considerations: It’s not the fastest printer on the market, and its build volume is mid-range. The price is higher than budget options, but you’re paying for reliability and a strong ecosystem.

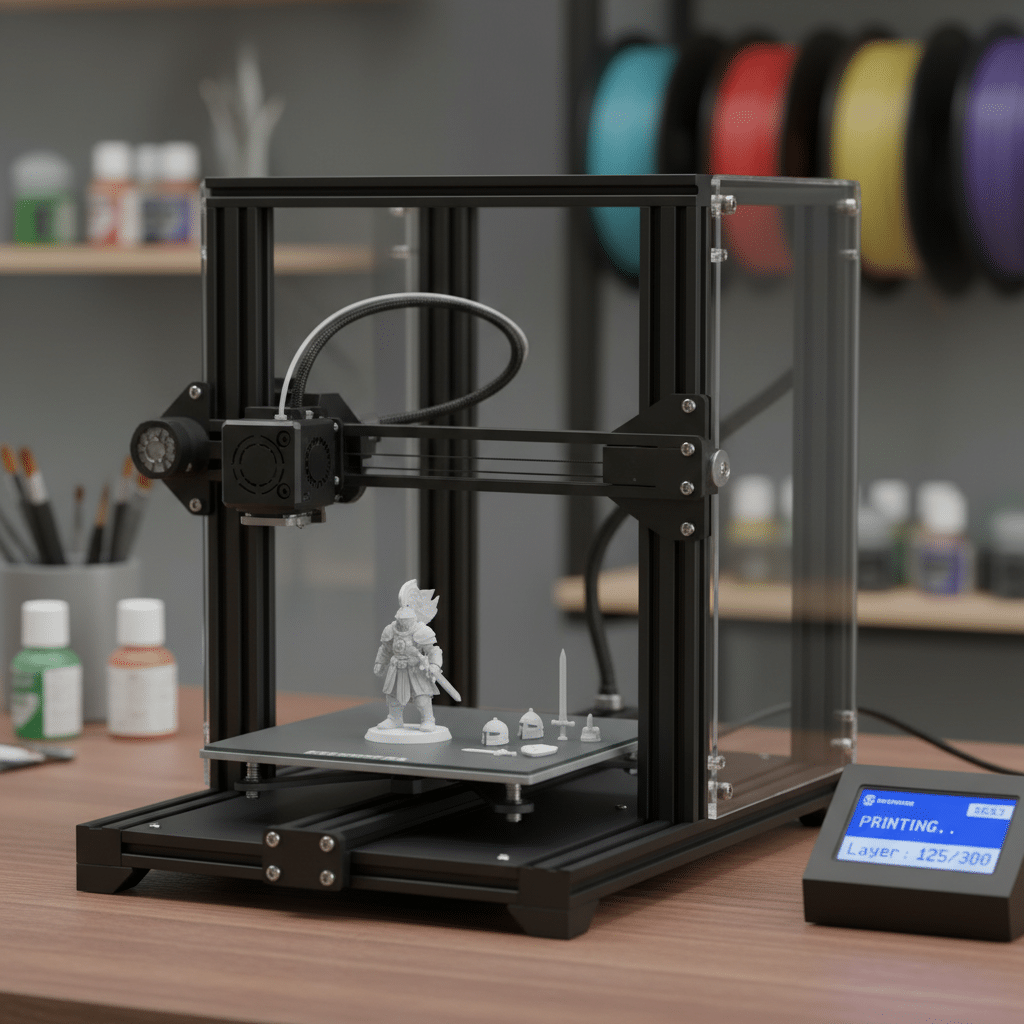

Best for Advanced Enthusiasts & Detailed Models (Resin): Elegoo Mars 4 or Anycubic Photon Mono M5S

If your toy-making vision leans towards highly detailed miniatures, anime figures, or intricate statues, a resin printer is your best bet.

Elegoo Mars 4: Elegoo’s Mars series is a consistent favorite in the resin world.

- Why it’s great for toys: It offers superb resolution for its price, producing unbelievably detailed and smooth prints. Perfect for small action figures, board game pieces, or custom accessories. You can even 3D print anime figures with stunning accuracy.

- Considerations: Resin printing requires more safety precautions (gloves, ventilation, careful handling of uncured resin) and post-processing (washing and UV curing). The build volume is also typically much smaller than FDM printers.

Anycubic Photon Mono M5S: Anycubic is another strong contender, and the M5S offers high resolution and decent speed.

- Why it’s great for toys: Similar to the Mars, it excels at detailed prints, allowing for intricate toy designs to come to life with incredible fidelity. Many users appreciate its performance and ease of use within the resin printing ecosystem.

- Considerations: All the same considerations for resin printing apply here – safety, post-processing, and smaller build volumes.

Best All-Rounder (FDM): Prusa MK4 or Bambu Lab P1P/P1S

For those who want a high-performance FDM printer that balances speed, quality, and reliability for a wide range of toy projects, these are excellent choices.

Prusa MK4: The latest iteration of a legendary printer.

- Why it’s great for toys: It combines the proven reliability and open-source nature of Prusa with modern upgrades like next-generation load cell auto-bed leveling and faster printing speeds. The print quality is top-notch, and the user experience is incredibly refined. It’s built like a tank and designed for long-term, consistent performance.

- Considerations: It’s a significant investment, making it less suitable for those on a tight budget. However, for a serious hobbyist or even a small business, it’s a fantastic long-term choice.

Bambu Lab P1P/P1S: These printers offer blazing-fast speeds and impressive quality at a more accessible price point than the X1C.

- Why it’s great for toys: With speeds that rival some of the fastest printers on the market, the P1P/P1S can churn out toys quickly without sacrificing much detail. The optional AMS system for multi-color printing makes them ideal for creating visually striking toys. The P1S comes enclosed, offering better temperature control and fume containment.

- Considerations: While more affordable than the X1C, they are still a mid-to-high-range investment. The closed-source nature means less opportunity for community-driven modifications compared to some open-source machines.

Materials Matter: Choosing the Right Filament/Resin for Toys

The material you choose is just as important as the printer itself, especially for toys that will be handled and played with.

PLA (Polylactic Acid)

- The King for Toys: PLA is derived from renewable resources like corn starch, making it biodegradable and generally considered food-safe and non-toxic. It’s incredibly easy to print, comes in a vast array of colors and finishes, and produces rigid, vibrant prints. Most FDM toy printing starts and often stays with PLA. It’s ideal for static models, display pieces, and toys that won’t experience extreme stress.

PETG (Polyethylene Terephthalate Glycol)

- Durability Upgrade: If you need something tougher than PLA, PETG is a great step up. It’s more flexible, less brittle, and more heat-resistant than PLA, making it suitable for toys that might get dropped or need to withstand a bit more wear and tear. It’s also water-resistant and often used for food containers, so it’s a good choice for children’s toys where durability is key. It’s slightly harder to print than PLA but offers a significant strength advantage.

TPU/Flexible Filaments

- Squishy Fun: Want to print a rubber duck, a bouncy ball, or flexible parts for an action figure? TPU (Thermoplastic Polyurethane) is your answer. It’s a flexible, rubber-like material that can absorb impact and bend without breaking. Printing with TPU can be challenging as it requires specific printer setups (like a direct drive extruder) and slower speeds, but the results for flexible toys are unique and fun.

Resin (for SLA/DLP Printers)

- Detail and Smoothness: Standard resin provides exceptional detail and smooth surfaces, perfect for display models, delicate figurines, and highly detailed components. For toys that will be handled, consider “tough” or “ABS-like” resins, which offer increased durability and impact resistance compared to standard resin. Always prioritize safety when working with resins due to their chemical nature.

Designing Your Own Toys vs. Ready-Made Files

You don’t need to be a CAD wizard to start making toys. There are two main paths:

Ready-Made Files: Instant Gratification

The internet is overflowing with 3D model files (often in .STL format) ready for you to download and print.

- Where to find them: Websites like Thingiverse, Printables, MyMiniFactory, Cults3D, and Thangs offer thousands of free and paid models. You can find everything from intricate articulated dragons to simple blocks, popular characters, and educational puzzles. This is a fantastic way to start immediately.

- Licensing: Always check the license. Many files are free for personal use but require permission or payment for commercial use.

Designing Your Own: Unleash Your Inner Engineer

Want something truly unique? Designing your own toys is incredibly rewarding.

- Beginner-Friendly Software:

- Tinkercad: This free, web-based software is incredibly intuitive for beginners. It uses a block-building approach, making it easy to combine basic shapes to create complex models. It’s perfect for simple toys, custom keychains, or modifying existing designs.

- SketchUp Free: Another accessible option for creating 3D models, with a slightly more traditional CAD interface but still very approachable.

- Intermediate/Advanced Software:

- Fusion 360: A powerful, industry-standard CAD software that offers a free hobbyist license. It has a steeper learning curve but provides immense capabilities for complex, functional designs.

- Blender: Primarily a 3D animation and rendering tool, but it’s also incredibly powerful for sculpting organic shapes, making it great for character models and figurines. It’s free but has a very steep learning curve.

Embracing design can be a creative outlet in itself, similar to exploring creative fonts for digital design or learning to draw.

Safety First: Essential Tips for 3D Printing Toys at Home

While 3D printing is generally safe, especially with PLA, a few precautions ensure a smooth and healthy experience.

- Ventilation is Key: Even with PLA, it’s wise to print in a well-ventilated area. While PLA fumes are generally considered benign, any melted plastic can release ultra-fine particles. For PETG, ABS, or resins, good ventilation (or even an enclosure with a filter) is absolutely crucial.

- Supervise Children: Never leave children unsupervised around a running 3D printer. Hot components, moving parts, and sharp tools for post-processing all pose risks. Teach them about the dangers and involve them safely in the process.

- Post-Processing Safety: Be careful when removing prints from the build plate, especially with sharp spatulas. Always wear safety glasses, and if working with resin, wear gloves and eye protection.

- Filament Storage: Store filaments in a dry, cool place, preferably in airtight containers with desiccant packs. Moisture absorption can lead to poor print quality and nozzle clogging.

- Small Parts Hazard: Be mindful of small 3D printed parts that could be choking hazards for very young children. Design toys appropriately for the intended age group.

Beyond Printing: Finishing and Painting Your 3D Printed Toys

The raw print is just the beginning! Finishing and painting can truly elevate your 3D printed toys from cool prototypes to professional-looking masterpieces.

Essential Finishing Steps

- Removing Supports: Most complex prints require support structures to prevent overhangs from collapsing. Carefully remove these using pliers, flush cutters, or by hand.

- Sanding: For a super smooth finish, especially on FDM prints, sanding is your friend. Start with a coarser grit (e.g., 200-400) and progressively move to finer grits (up to 1000 or 2000). Wet sanding can help achieve an even smoother surface.

- Filling Gaps/Layer Lines: If layer lines are still visible or there are small gaps, you can use a filler primer or Bondo spot putty. Apply, sand smooth, and repeat as needed.

- Priming: A good primer provides a uniform surface for paint to adhere to and helps reveal any remaining imperfections. Automotive spray primers work well.

Bringing Color to Life

- Acrylic Paints: These are widely available, water-soluble, and come in a vast range of colors, making them perfect for hand-painting 3D prints.

- Spray Paints: For larger areas or a quick, even base coat, spray paints (specifically those formulated for plastic) work wonders. Always do light, even coats to avoid drips.

- Airbrushing: For advanced users, an airbrush offers incredible control, smooth gradients, and fine detail work, ideal for professional-looking toy painting.

- Clear Coat: Once painted, apply a clear protective coat (matte, satin, or gloss) to seal the paint, protect against wear, and achieve your desired finish. This is especially important for toys that will be handled frequently.

The process of finishing and painting is where your artistic flair truly shines, transforming your printed objects into unique, vibrant creations – a craft that can be as fulfilling as showcasing and selling your art at a craft fair.

The Joy of Giving: Turning Prints into Gifts

One of the most heartwarming aspects of owning a 3D printer is the ability to create incredibly thoughtful and personalized gifts.

- Personalized Action Figures: Imagine designing a mini-figure of a loved one or even their pet!

- Custom Board Game Pieces: Elevate game night with unique pieces designed to match the theme or players.

- Educational Toys: Print intricate puzzles, molecular models, or even a mini solar system for a budding scientist.

- Fandom Collectibles: Recreate props, characters, or vehicles from beloved movies, games, or comics. From a tiny replica of a superhero’s shield to a personalized character, the possibilities are vast.

- DIY Wedding/Party Favors: Instead of generic trinkets, 3D print unique, personalized favors that guests will cherish. This can be an extension of your creative approach to DIY gifts for weddings.

The time, effort, and personal touch that go into a 3D printed gift make it truly special and memorable.

Maintenance and Troubleshooting for Your 3D Printer

Like any piece of equipment, a 3D printer needs a little love and attention to keep running smoothly. Regular maintenance prevents many common issues.

Basic Upkeep

- Clean the Build Plate: After every print, clean your build plate. For glass or PEI sheets, isopropyl alcohol usually does the trick. A clean surface ensures good first layer adhesion.

- Clean the Nozzle: Periodically check your nozzle for any plastic buildup and gently clean it with a brass brush. For clogs, a “cold pull” or needle can often clear it.

- Lubricate Moving Parts: Apply a small amount of lubricant (like SuperLube or specific 3D printer grease) to the Z-axis lead screw and smooth rods every few months.

- Tighten Belts: Loose belts can lead to “ghosting” or inaccuracies in prints. Gently check and tighten your X and Y axis belts if they feel too slack.

- Firmware Updates: Keep your printer’s firmware updated to benefit from bug fixes, new features, and improved performance.

Common Print Issues and Fixes

- Poor First Layer Adhesion: This is the most common issue. Ensure your bed is level, clean, and the nozzle is at the correct height (often called “Z-offset”). Sometimes, a little glue stick or hairspray on the build plate helps.

- Stringing/Oozing: Fine strings of plastic appearing between printed parts. Adjust retraction settings (retraction distance and speed) in your slicer, and ensure your filament is dry.

- Under-extrusion/Clogging: Gaps in layers or very thin lines indicate not enough plastic is coming out. Check for a clogged nozzle, tangled filament, or incorrect extrusion settings.

- Warping: Corners of the print lifting off the build plate. Ensure good bed adhesion, use a brim or raft, and if possible, print in an enclosure to maintain stable temperatures.

- Layer Shifting: Layers of the print are misaligned. This is often due to loose belts, obstacles on the print path, or printing too fast.

By understanding these common issues and implementing regular maintenance, you’ll spend more time printing awesome toys and less time troubleshooting.

Bringing Your Toy Dreams to Life

Stepping into the world of 3D printing is an exciting adventure, especially when your goal is to create fun models and gifts. It’s a realm where digital designs meet physical reality, where imagination takes tangible form, and where the joy of creation knows no bounds. Whether you opt for an accessible FDM printer like the Ender 3 V3 SE, a user-friendly workhorse like the Prusa Mini+, or a detail-oriented resin printer like the Elegoo Mars 4, the right machine will unlock a universe of creative possibilities.

The best 3D printer for toys is ultimately the one that fits your budget, skill level, and aspirations. It’s an investment not just in a machine, but in endless hours of creativity, learning, and the unique satisfaction of saying, “I made that!” So, go ahead, explore the options, pick your perfect partner in creation, and start transforming your toy dreams into vibrant, physical realities right at home. The only limit is your imagination!

- 676shares

- Facebook0

- Pinterest676

- Twitter0

- Reddit0