Remember those days when architects would spend countless hours meticulously crafting physical models by hand? Cutting, gluing, sanding – it was a labor of love, but also a significant time and resource sink. Fast forward to today, and we’re seeing a seismic shift in how buildings are designed and constructed, all thanks to a revolutionary technology: 3D printing. This incredible innovation is rapidly transforming architecture, moving us from mere blueprints to tangible reality faster and more efficiently than ever before. For architects, 3D printing isn’t just a fancy gadget; it’s a powerful tool that’s reshaping the entire design and construction workflow, unlocking new levels of creativity, efficiency, and sustainability.

From Concept to Tangible: The Power of Prototyping

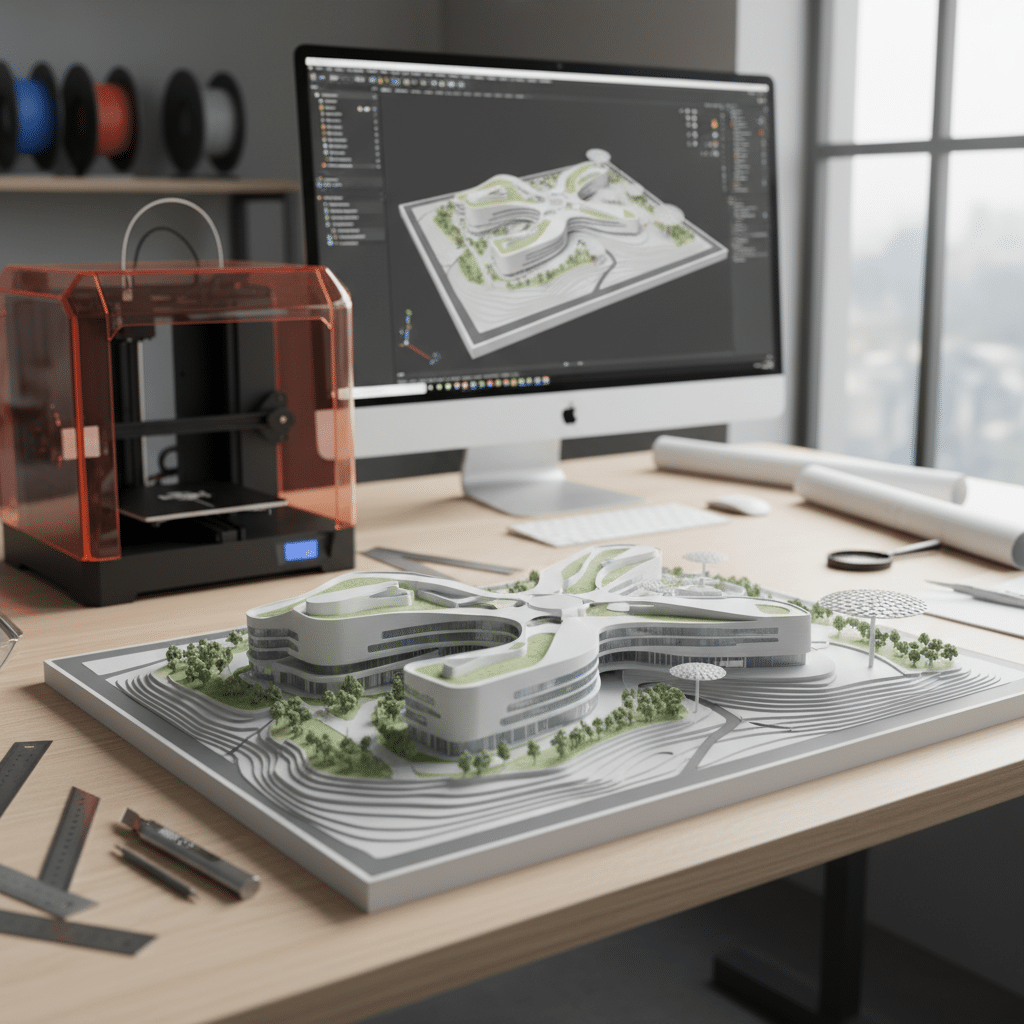

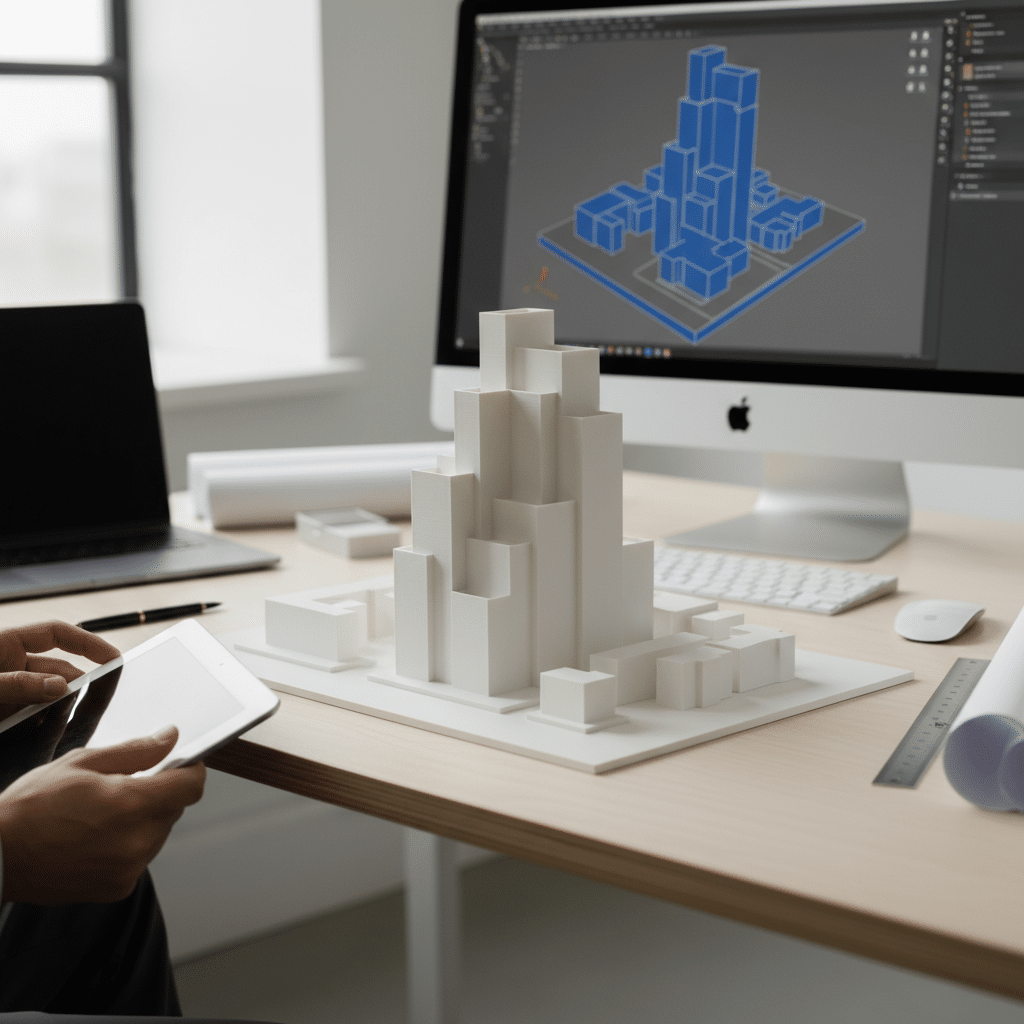

One of the most immediate and impactful ways 3D printing has revolutionized architecture is in the realm of prototyping and model making. Gone are the days of basic, static models. Now, architects can produce highly detailed, accurate, and complex physical representations of their designs with unparalleled speed and precision.

Rapid Prototyping for Design Iteration

Imagine a design process where you can print multiple iterations of a complex building facade or an intricate structural component overnight. That’s the reality 3D printing offers. Architects can quickly test different design choices, evaluate spatial relationships, and identify potential issues early in the design phase. This rapid iteration cycle significantly shortens project timelines and allows for more thorough exploration of creative ideas. It empowers designers to be bolder, knowing that physical prototypes are just a print button away. This iterative process is crucial for refining concepts, just as understanding what to look for in a layout before buying a home helps refine your property search.

Enhanced Visualization and Client Communication

Presenting a 2D drawing or a digital render to a client is one thing; handing them a tangible, scaled-down model of their future building is entirely another. 3D printed models offer an immersive way for clients, stakeholders, and even community members to visualize a project. They can literally hold the design in their hands, understanding its scale, form, and intricate details in a way that digital representations often fail to convey. This clarity fosters better communication, reduces misunderstandings, and significantly enhances the client’s confidence in the design. It’s about bringing the abstract into concrete reality, making complex ideas instantly comprehensible.

Cost and Time Efficiency in Model Making

Traditional model making is notoriously labor-intensive and expensive. Materials, skilled labor, and the sheer time required to construct intricate models can add up quickly. 3D printing streamlines this process dramatically. While the initial investment in a high-quality 3D printer might seem substantial, the long-term savings in labor, materials, and time for model production are immense. Architects can print models on demand, reducing reliance on external model shops and allowing for greater in-house control over the design process. This efficiency directly impacts project budgets and schedules, freeing up resources for other critical design tasks.

Beyond Models: Full-Scale Construction with 3D Printing

While prototyping is a fantastic application, the real groundbreaking potential of 3D printing for architects lies in its ability to construct full-scale buildings. This isn’t science fiction anymore; it’s happening all over the world, from single-family homes to larger commercial structures.

Residential and Commercial Structures

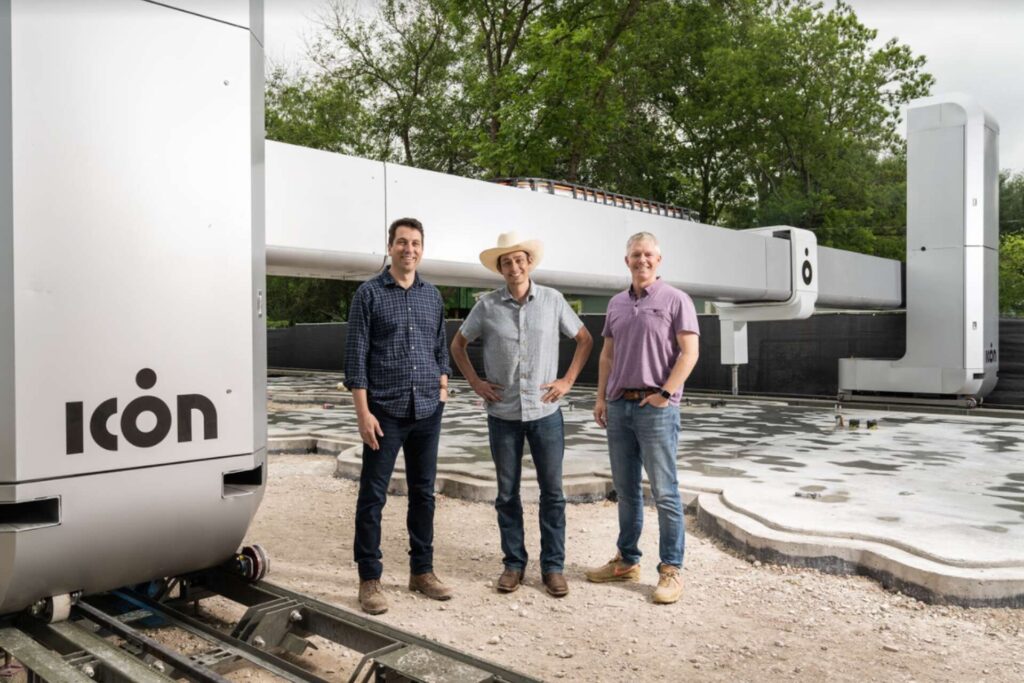

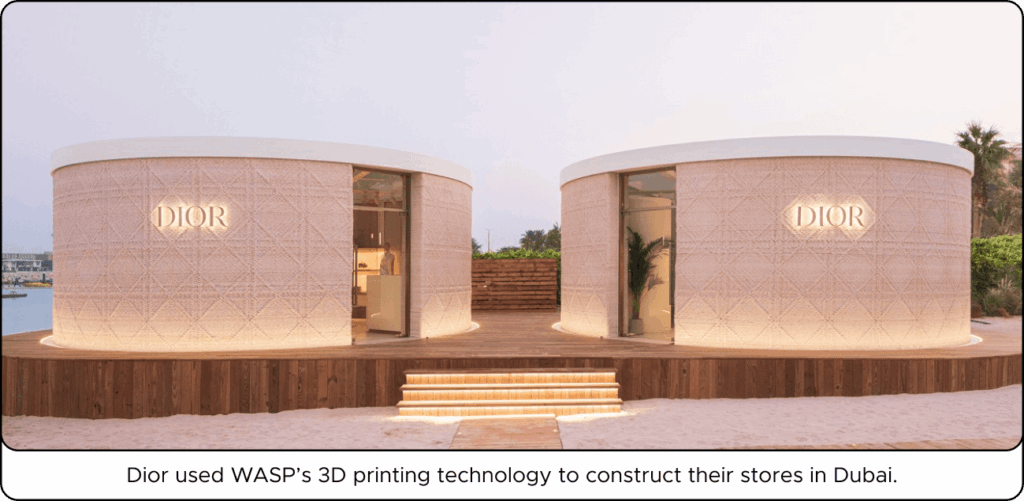

We’re already seeing impressive examples of 3D printed houses, some built in a matter of days or even hours. Companies like ICON in the US and WASP in Italy are leading the charge, printing everything from affordable housing solutions to multi-story buildings. These projects demonstrate the technology’s capacity to create durable, structurally sound buildings using various materials, including concrete, geopolymers, and even local soil. For architects, this opens up a new frontier, allowing them to design buildings that can be rapidly deployed, customized, and potentially contribute to solving global housing shortages. This level of innovation in residential construction mirrors the advanced thinking behind dual living home designs for modern families.

Sustainable and Efficient Building Practices

One of the most compelling advantages of 3D printing in construction is its inherent sustainability. Additive manufacturing, by nature, is highly efficient with materials. It builds layer by layer, depositing material only where it’s needed, which drastically reduces waste compared to traditional construction methods that often involve cutting materials to size, leading to scraps. Furthermore, many 3D printing technologies can utilize locally sourced or recycled materials, minimizing transportation costs and the environmental footprint. This focus on efficiency extends to energy consumption during construction and, with clever design, can also lead to homes that are easier to keep cozy and cool all year round.

The Rise of Robotic Construction

The full-scale application of 3D printing in architecture is fundamentally tied to robotics. Massive gantry systems or robotic arms precisely extrude building materials according to digital designs. This automation not only speeds up the construction process but also enhances accuracy and safety on site. Architects can design complex forms knowing that robots can execute them with consistent precision, day or night, in conditions that might be challenging for human workers. This shift towards robotic construction promises a future where building is faster, safer, and more aligned with digital design workflows.

Unleashing Architectural Freedom: Complex Geometries and Customization

Traditional construction often imposes limitations on design, favoring straight lines and standardized components due to cost and manufacturing constraints. 3D printing shatters these limitations, offering architects unprecedented freedom to explore new aesthetic and structural possibilities.

Design Flexibility and Organic Forms

Think about the intricate, organic shapes found in nature – flowing curves, hyperbolic paraboloids, complex lattices. Replicating these with traditional methods is either extremely difficult, prohibitively expensive, or both. 3D printing thrives on complexity. It can create structures with curvilinear forms, hollow core walls, and intricate internal geometries that optimize for strength, insulation, or unique aesthetics. This capability empowers architects to move beyond the orthogonal, designing buildings that are truly sculptural and responsive to their environment, pushing the boundaries of what’s architecturally possible. For those interested in innovative design and custom pieces, exploring 3D printed art projects can offer further inspiration into the possibilities of the technology.

Mass Customization and Personalization

In a world increasingly valuing individuality, 3D printing allows for mass customization in architecture. Instead of standardized building components, every element can be uniquely designed and printed to fit a specific project’s needs without incurring significant additional costs. Imagine a housing development where each home, while following a general aesthetic, features bespoke architectural details tailored to the owner’s preferences – a unique facade pattern, custom window frames, or personalized interior elements. This level of personalization was once reserved for high-end, custom-built homes, but 3D printing makes it accessible on a larger scale. This trend towards personalization is even shaping interior design, with new interior design trends for 2025 focusing heavily on unique, curated spaces.

Material Innovation in 3D Printing

The materials used in architectural 3D printing are rapidly evolving. Beyond concrete and polymers, researchers are experimenting with sustainable bio-plastics, recycled aggregates, carbon fiber composites, and even metal alloys. This material diversification expands the functional and aesthetic palette available to architects. Imagine a building printed from a material that can self-heal, or one that changes its properties based on environmental conditions. As material science advances, the possibilities for creating high-performance, responsive, and aesthetically diverse structures through additive manufacturing will only grow.

Addressing Challenges and Overcoming Hurdles

Despite its incredible potential, 3D printing in architecture isn’t without its challenges. Like any nascent technology, it faces hurdles that need to be addressed for widespread adoption.

Material Limitations and Structural Integrity

Currently, the range of suitable materials for large-scale 3D printing in construction is somewhat limited compared to traditional methods. While concrete is widely used, developing new materials that meet stringent structural, thermal, and aesthetic requirements is an ongoing process. Ensuring the structural integrity and durability of 3D printed structures, especially in varied climates and seismic zones, requires extensive research, testing, and validation. Architects need confidence that their 3D printed designs will stand the test of time and environmental forces.

Regulatory and Code Compliance

Building codes and regulations are often slow to adapt to new technologies. Integrating 3D printed structures into existing regulatory frameworks presents a significant challenge. Architects and construction companies must work closely with code officials to demonstrate that 3D printed buildings meet or exceed current safety, energy efficiency, and accessibility standards. This involves rigorous testing, documentation, and potentially advocating for new code amendments specific to additive construction.

Investment and Accessibility

The initial investment in large-scale 3D printing equipment can be substantial. For smaller architectural firms or construction companies, this can be a barrier to entry. While the long-term cost savings are evident, the upfront capital expenditure requires careful consideration. Making the technology more accessible, perhaps through service bureaus, standardized smaller-scale systems, or collaborative initiatives, will be crucial for broader adoption.

The Future is Now: Emerging Trends and What’s Next

The trajectory of 3D printing in architecture points towards an incredibly exciting future. What we’re seeing today is just the beginning.

Integration with AI and Generative Design

The synergy between 3D printing, artificial intelligence, and generative design is poised to be a game-changer. Generative design algorithms can explore thousands of design permutations based on specified parameters (structural efficiency, material usage, aesthetics, climate response) and propose optimized solutions. These designs, often incredibly complex and organic, are perfectly suited for 3D printing. AI can further optimize printing paths, material mixes, and even monitor construction quality in real-time. This integration will empower architects to design more efficiently and create buildings that are not only beautiful but also hyper-optimized for performance.

On-Demand Construction and Remote Building

Imagine a future where a disaster strikes, and temporary shelters can be 3D printed on-site within hours, or where remote exploration outposts are constructed layer by layer by autonomous 3D printers. The ability to quickly and efficiently print structures on-demand, even in challenging or remote locations, has profound implications for humanitarian aid, military applications, and even space colonization. Architects will play a critical role in designing these adaptable, resilient, and rapidly deployable structures.

Repair, Renovation, and Historic Preservation

3D printing isn’t just for new builds. It also holds immense promise for the repair and renovation of existing structures, particularly in historic preservation. Intricate architectural elements, damaged beyond traditional repair methods, can be scanned, digitally reconstructed, and 3D printed with precise accuracy, seamlessly integrating into original structures. This capability allows architects to restore historical buildings to their former glory, preserving cultural heritage in ways previously unimaginable.

Real-World Impact: Case Studies and Success Stories

Across the globe, projects are demonstrating the tangible benefits of 3D printing in architecture. For example, in Dubai, the government aims for 25% of its new buildings to be 3D printed by 2030, showing a massive commitment to the technology. The world’s largest 3D printed building, an administrative office for the Dubai Future Foundation, is a testament to this vision. Built by an architect team, it showcases both the aesthetic and functional capabilities of the technology.

Another inspiring example is the 3D printed school in Madagascar, a project aimed at providing rapidly deployable and sustainable educational infrastructure in underserved communities. These initiatives highlight not only the structural capabilities but also the social impact potential of 3D printing in creating essential infrastructure efficiently. Architects involved in these projects are literally building a better future, one layer at a time.

The journey from a digital blueprint to a physical building has never been more exciting. 3D printing for architects isn’t just a trend; it’s a fundamental shift in how we conceive, design, and construct our built environment. It offers unparalleled opportunities for creativity, efficiency, sustainability, and customization. While challenges remain, the rapid pace of innovation suggests that these hurdles are temporary. Architects who embrace this technology will be at the forefront of shaping the cities and spaces of tomorrow, transforming visions into reality with unprecedented speed and ingenuity. The future of architecture is being printed, one layer at a time.

How has 3D printing transformed architectural prototyping and model making?

3D printing has revolutionized prototyping by enabling architects to produce highly detailed, accurate, and complex physical models swiftly, facilitating faster design iterations and enhanced visualization.

In what ways does 3D printing improve communication with clients and stakeholders?

3D printed models offer a tangible representation of architectural designs, allowing clients and stakeholders to better understand scale, form, and details, thereby improving understanding and confidence in the project.

What are the benefits of using 3D printing for full-scale construction projects?

3D printing allows for rapid, customizable, and potentially more cost-effective construction of buildings, including residential and commercial structures, using diverse materials like concrete and geopolymers, and can help address housing shortages.

What challenges does the integration of 3D printing in architecture currently face?

Key challenges include material limitations and ensuring structural integrity, navigating regulatory and code compliance, and the high initial investment required for large-scale 3D printing equipment.

What does the future hold for 3D printing in architecture?

The future includes integration with AI and generative design for optimized building solutions, on-demand and remote construction capabilities for rapid deployment, and applications in repair, renovation, and historic preservation, shaping innovative and resilient built environments.

- 10shares

- Facebook0

- Pinterest10

- Twitter0

- Reddit0