Manufacturing downtime due to broken parts can cost thousands of dollars per hour, but 3D printing technology offers a revolutionary solution. You can now produce replacement parts on-demand using 3D printing, eliminating long wait times for traditional manufacturing and reducing inventory costs significantly. This approach transforms how businesses manage spare parts by creating digital inventories instead of physical stockpiles.

3D printing spare parts works across multiple industries, from automotive to aerospace, where critical components can be recreated quickly and cost-effectively. You have access to various 3D printing technologies including FDM, resin, and SLS systems, each suited for different part requirements and material properties. The technology allows you to maintain operations while traditional supply chains face delays or obsolescence issues.

The shift toward additive manufacturing for spare parts represents a fundamental change in inventory management and production planning. You can digitize your spare parts catalog, reduce storage requirements, and produce components closer to where they’re needed. This approach particularly benefits operations with legacy equipment where original manufacturers no longer produce replacement parts.

Key Takeaways

- 3D printing enables on-demand spare part production, reducing downtime and inventory costs

- Digital spare part inventories replace physical stockpiles and solve obsolescence challenges

- Multiple 3D printing technologies accommodate different part requirements across various industries

How 3D Printing Transforms Spare Parts Production

Additive manufacturing creates spare parts layer by layer from digital files, enabling on-demand production that eliminates traditional inventory requirements. Digital file management systems replace physical warehouses, allowing instant access to production-ready designs.

Additive Manufacturing Process Overview

Additive manufacturing builds spare parts by depositing material layer upon layer according to digital specifications. The process begins with a 3D computer model that gets sliced into thousands of horizontal cross-sections.

Your 3D printer reads these digital instructions and deposits material precisely where needed. Each layer bonds to the previous one, gradually forming the complete spare part from bottom to top.

Common 3D printing technologies for spare parts include:

- Fused Deposition Modeling (FDM) for polymer components

- Selective Laser Sintering (SLS) for metal and plastic parts

- Stereolithography (SLA) for high-precision components

This layer-by-layer approach allows you to create complex geometries impossible with traditional manufacturing. Internal channels, lattice structures, and integrated assemblies can be produced in a single print job.

Material options range from basic plastics to aerospace-grade metals. Your choice depends on the spare part’s mechanical requirements, operating environment, and expected lifespan.

On-Demand Manufacturing for Spare Parts

On-demand manufacturing eliminates the need to maintain physical spare parts inventory. You produce components only when orders arrive, reducing storage costs and obsolete stock risks.

Traditional spare parts require minimum order quantities that often exceed actual demand. With 3D printing, you can manufacture single units economically, making rare or discontinued components viable to produce.

Key benefits of spare parts on demand:

- Reduced lead times from weeks to hours

- Lower inventory costs by eliminating storage requirements

- Extended product lifecycles for legacy equipment

- Customization capabilities for specific applications

Supply chains become more responsive when you can manufacture spare parts locally. Transportation costs decrease, and delivery times shrink from days to hours for critical components.

Emergency repairs benefit significantly from on-demand production. When equipment fails unexpectedly, you can start printing replacement parts immediately rather than waiting for shipping from distant warehouses.

Digital Inventories and File Management

Digital inventories store spare part designs as computer files rather than physical components. Your entire parts catalog exists on servers, accessible instantly from any location with proper authorization.

File management systems organize these digital designs by part number, equipment model, and production specifications. Version control ensures you always access the most current design revisions.

Digital inventory advantages include:

- Unlimited storage capacity without physical space constraints

- Instant global access to part designs

- Automatic backups preventing data loss

- Easy updates for design improvements

You maintain quality control through standardized file formats and validated printing parameters. Each digital file contains specific instructions for material type, print settings, and post-processing requirements.

Security protocols protect intellectual property while enabling authorized access. Encrypted files and user authentication prevent unauthorized reproduction of proprietary designs.

Search capabilities let you locate specific parts quickly using keywords, part numbers, or equipment specifications. Advanced systems can even suggest alternative designs when exact matches aren’t available.

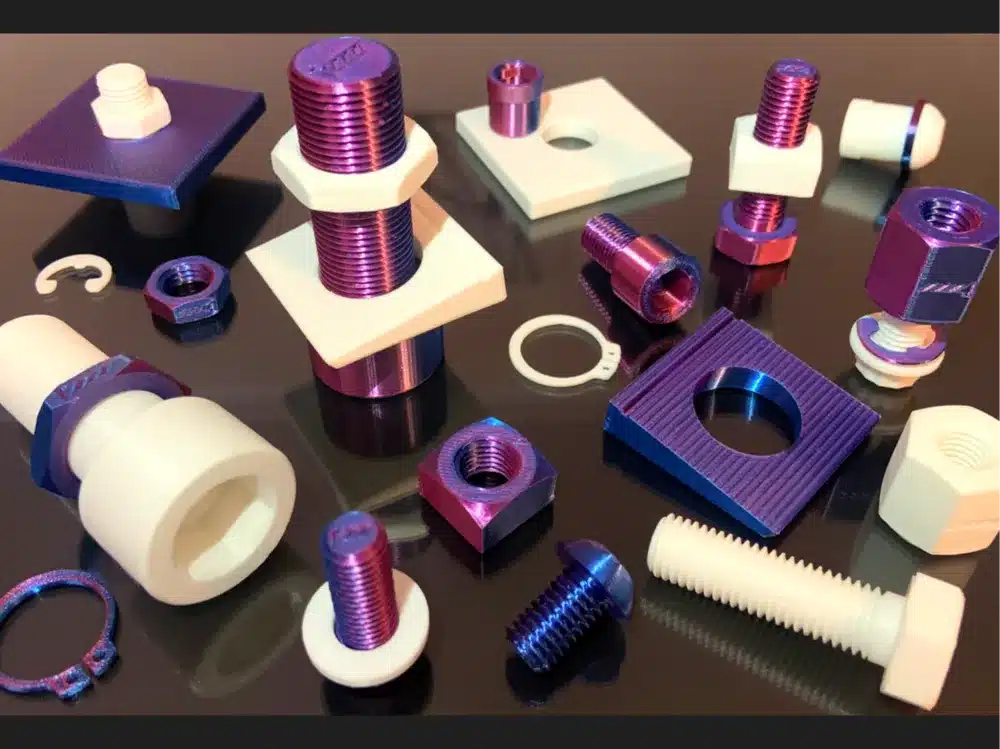

Imperial bolts and nuts

Nuts, Bolts & Washers

Design and Quality Considerations

Creating functional 3D printed spare parts requires careful attention to design principles, material properties, and quality control measures. Success depends on understanding how additive manufacturing constraints affect part geometry and selecting appropriate materials for your specific application.

Designing Spare Parts for 3D Printing

Your design approach must account for the fundamental differences between traditional manufacturing and 3D printing. Additive manufacturing builds parts layer by layer, which creates unique opportunities and limitations.

Wall thickness represents a critical design parameter. You should maintain minimum wall thickness of 0.8mm for most desktop printers and 0.4mm for high-resolution systems. Thinner walls may fail during printing or lack sufficient strength for functional use.

Support structures affect both surface quality and design complexity. You can minimize support requirements by:

- Keeping overhangs below 45 degrees

- Avoiding horizontal holes and bridges longer than 5mm

- Orienting parts to reduce unsupported features

Feature sizing requires specific attention to your printer’s capabilities. Most FDM printers cannot reliably produce features smaller than 0.4mm. Details like threads, snap-fits, and moving parts need generous tolerances compared to injection-molded originals.

Print orientation significantly impacts strength and surface finish. Layer adhesion creates anisotropic properties where parts are weakest along the Z-axis. Orient your part so critical stress directions align with the strongest layer bonding.

Material Selection and Compatibility

Your material choice directly affects the spare part’s performance, durability, and compatibility with existing components. Different applications require specific material properties.

PLA offers ease of printing and dimensional accuracy but lacks temperature resistance and long-term durability. Use PLA for low-stress indoor applications where temperatures stay below 50°C.

ABS provides better impact resistance and temperature stability up to 80°C. This material works well for automotive parts, housings, and components exposed to moderate heat. ABS requires heated bed printing and proper ventilation.

PETG combines the printability of PLA with improved chemical resistance and toughness. You can use PETG for food-safe applications and parts requiring transparency or flexibility.

For demanding applications, consider these advanced materials:

| Material | Temperature Range | Key Properties |

|---|---|---|

| Nylon | -40°C to 120°C | High strength, wear resistance |

| PC | -135°C to 140°C | Impact resistance, flame retardant |

| TPU | -30°C to 80°C | Flexible, rubber-like properties |

Chemical compatibility matters when your spare part contacts oils, solvents, or cleaning agents. Test material samples with expected chemicals before committing to production.

Ensuring Print Quality and Performance

Print quality directly affects your spare part’s dimensional accuracy, surface finish, and mechanical properties. Multiple factors influence the final result.

Printer calibration forms the foundation of quality output. Your bed must be perfectly leveled, and extruder steps per millimeter should be calibrated precisely. Even small deviations compound across the entire part.

Layer height affects both quality and strength. Use 0.2mm layers for general applications and 0.1mm for parts requiring fine detail. Thicker layers print faster but reduce surface quality and may create weak layer bonds.

Print speed requires balancing productivity with quality. Slower speeds around 30-50mm/s typically produce better dimensional accuracy and surface finish. High-detail features may require speeds as low as 20mm/s.

Temperature control impacts layer adhesion and dimensional stability. Your hotend temperature should match material specifications, while bed temperature prevents warping and improves first-layer adhesion.

Post-processing can improve both appearance and functionality. Common treatments include:

- Sanding for smooth surfaces

- Vapor smoothing for ABS parts

- Heat treatment to relieve stress and improve strength

- Drilling and tapping for precise holes and threads

Quality testing should verify dimensional accuracy, fit, and function before installing your spare part. Use calipers to check critical dimensions and test-fit with mating components.

Supply Chain and Inventory Impact

3D printed spare parts fundamentally change how you manage inventory by enabling production only when needed rather than maintaining large stock levels. This shift reduces storage costs while improving response times through localized manufacturing capabilities.

Reducing Lead Times and Costs

Traditional spare parts procurement can take weeks or months due to complex supplier networks and inventory constraints. 3D printing eliminates these delays by producing parts within hours or days at your facility.

You avoid the costs associated with maintaining large inventories of slow-moving spare parts. Storage expenses, insurance, and obsolescence risks decrease significantly when you switch to on-demand manufacturing.

Supply chain disruptions become less problematic when you can print critical components locally. Your operations remain functional even when traditional suppliers face delays or shortages.

The technology reduces dependency on multiple suppliers for different components. You consolidate manufacturing through a single 3D printing setup rather than coordinating with various vendors.

Local and Distributed Manufacturing

You can establish printing capabilities at multiple locations rather than relying on centralized warehouses. This distributed approach places spare parts production closer to where you need them most.

Remote facilities benefit significantly from local 3D printing capacity. Oil rigs, mining operations, and overseas installations can produce parts on-site instead of waiting for shipments.

Manufacturing becomes more resilient when you distribute production capabilities across your network. Regional disruptions no longer affect your entire spare parts supply chain.

You reduce transportation costs and delivery times by producing parts where they’re needed. Expedited shipping fees for urgent repairs become unnecessary expenses of the past.

Spanner Set of 20

Wrench / Spanner Holders – Tool Grid

Legacy and Discontinued Parts

Obsolete equipment presents unique challenges when original manufacturers no longer produce replacement components. 3D printing solves this problem by recreating parts from digital files or reverse engineering.

You can maintain older machinery longer by reproducing discontinued spare parts as needed. This extends equipment lifecycles and delays expensive replacement purchases.

Original equipment manufacturers often charge premium prices for legacy components due to limited production runs. On-demand manufacturing through 3D printing reduces these costs substantially.

Digital part libraries replace physical inventory for discontinued items. You store files instead of physical components, eliminating storage costs while maintaining repair capabilities indefinitely.

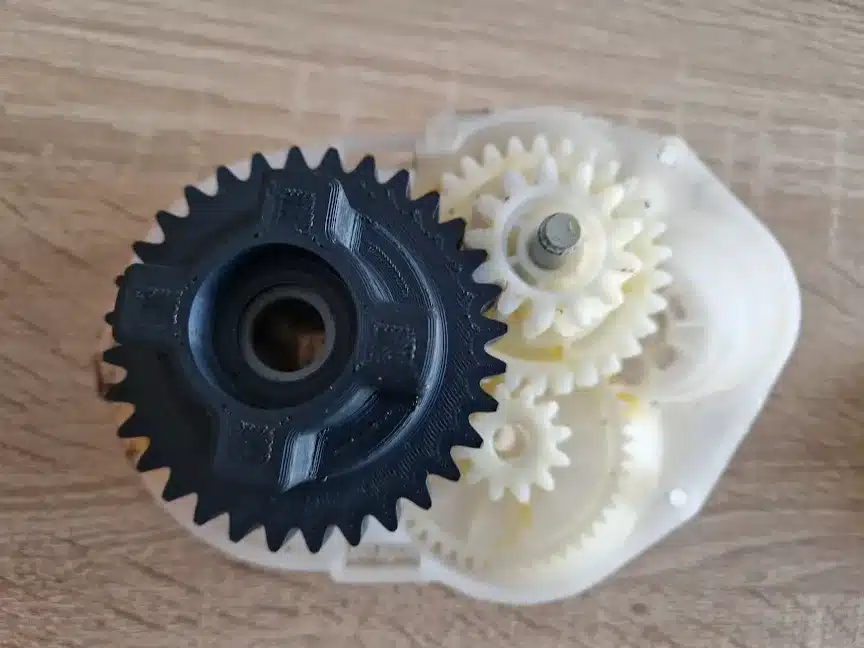

Peg Perego Gator Drive Gear

4-in-1 PTFE Adapter – Spare Parts

Applications and Real-World Examples

3D printed spare parts deliver practical solutions across diverse industries, from manufacturing plants producing custom tooling to homeowners repairing appliances. These applications span from complex aerospace components to simple household fixes, demonstrating the versatility of additive manufacturing for on-demand part production.

Industrial and Manufacturing Uses

Manufacturing facilities use 3D printed spare parts to minimize downtime and reduce inventory costs. You can produce custom tooling, jigs, and fixtures on-demand instead of waiting weeks for traditional manufacturing.

GE Aviation revolutionized their fuel nozzle production by 3D printing a single integrated component that previously required 20 assembled parts. This approach reduced production time and eliminated potential failure points.

Industrial applications include:

- Custom tooling for specific production needs

- Prototype parts for testing before mass production

- Legacy component replacement when original manufacturers discontinue parts

Whirlpool adopted 3D printing for spare parts manufacturing, allowing them to produce components quickly without maintaining large inventories. You benefit from reduced storage costs and faster response times to equipment failures.

Complex geometries impossible with traditional manufacturing become achievable through 3D printing. This enables you to create lightweight, optimized parts that improve equipment performance while reducing material usage.

Depth gauge set for 5-16 mm drills

Drill storage

Consumer and Home Repair Scenarios

Home users leverage 3D printing to repair appliances, toys, and household items instead of purchasing expensive replacement parts. You can fix broken items that manufacturers no longer support or customize parts to meet specific needs.

Common household applications include:

- Appliance components like knobs, handles, and brackets

- Electronic device parts such as battery covers and mounting clips

- Furniture hardware including hinges and connectors

You save money by printing replacement parts for discontinued items. A broken dishwasher handle that costs $50 from the manufacturer might cost $2 in materials to 3D print at home.

Customization opportunities allow you to modify parts for improved functionality. You can create ergonomic handles, add features not included in original designs, or adapt components to fit unique requirements.

Online repositories provide downloadable designs for common spare parts, eliminating the need to create models from scratch.

License Plate Holder for EU 180x200mm

Multi spare box Bambulab MINI

Automotive and Specialized Sectors

Automotive manufacturers use 3D printing for both production parts and repair components. You can create lightweight components that enhance fuel efficiency while maintaining structural integrity.

BMW produces over 1 million 3D printed parts annually, including production components and custom tooling. Their approach demonstrates how automotive companies integrate additive manufacturing into regular operations.

Specialized sector applications include:

| Sector | Applications | Benefits |

|---|---|---|

| Aerospace | Engine components, brackets | Weight reduction, complex geometries |

| Medical | Surgical tools, device parts | Customization, biocompatibility |

| Marine | Corrosion-resistant components | On-demand production, material optimization |

Classic car restoration benefits significantly from 3D printed spare parts. You can reproduce obsolete components that are no longer manufactured, preserving vintage vehicles without compromising authenticity.

Racing teams create custom parts for specific track conditions or vehicle modifications. This allows you to optimize performance without the lead times associated with traditional manufacturing methods.

- 18shares

- Facebook0

- Pinterest18

- Twitter0

- Reddit0