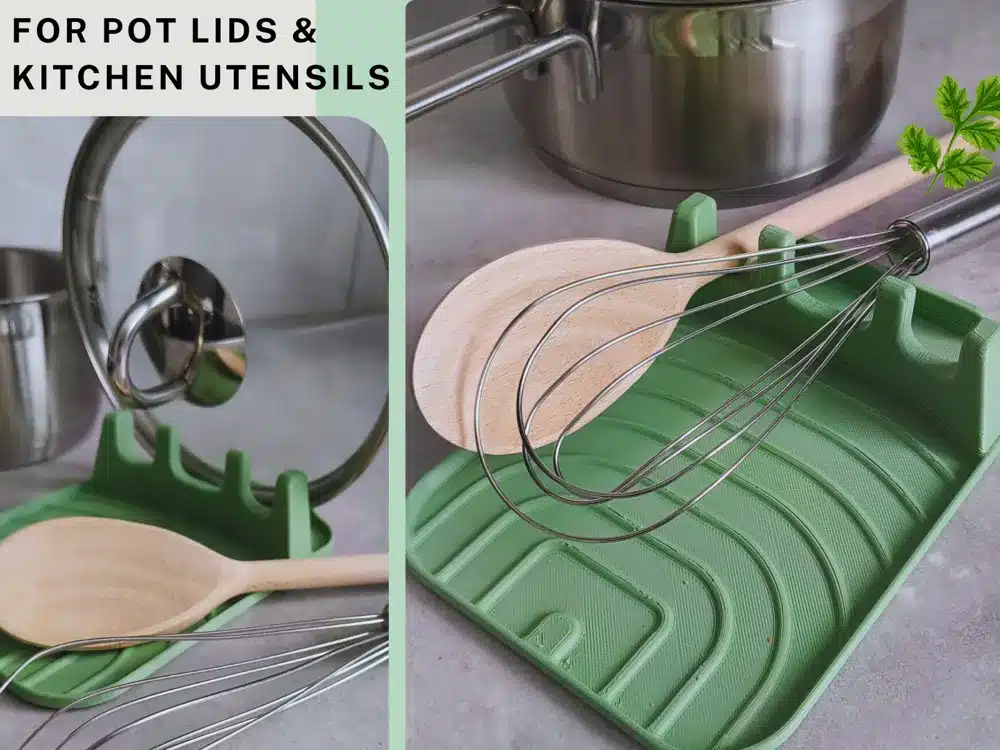

3D printing has transformed how you can create and customize kitchen tools at home. You can now print functional kitchen gadgets like pot lid holders, spice racks, bag clips, and utensils directly from your 3D printer using food-safe materials. These printable items solve common kitchen problems while offering the flexibility to design tools that fit your specific needs.

The world of 3D printed kitchen accessories extends far beyond basic utensils. You can create organizational solutions, replacement parts for broken appliances, and specialized tools that aren’t readily available in stores. Whether you need a custom-sized drawer organizer or a unique bottle opener design, 3D printing puts the power of kitchen innovation in your hands.

Understanding which materials work best for kitchen use and how to properly maintain your printed items ensures both safety and longevity. This comprehensive guide will walk you through everything from selecting the right designs to caring for your finished products, helping you build a more functional and personalized kitchen space.

Key Takeaways

- 3D printed kitchen items offer customizable solutions for organization, cooking tools, and replacement parts at low cost

- Food-safe materials and proper design considerations are essential for creating durable and safe kitchen accessories

- Regular maintenance and following safety guidelines ensure your 3D printed kitchen tools remain functional and hygienic

What Are 3D Printed Kitchen Items?

3D printed kitchen items are functional tools, utensils, and accessories created using additive manufacturing technology. These items range from simple measuring tools to complex organizational solutions that address specific kitchen needs.

Definition and Overview

3D printed kitchen items are physical objects created by building up layers of material through additive manufacturing processes. These items are designed using digital files and printed using various materials suitable for food contact.

The technology allows you to create both replacement parts and entirely new gadgets. Common materials include food-safe plastics like PLA and PETG that meet safety standards for kitchen use.

You can print these items on budget-friendly home 3D printers. The process involves downloading or creating digital designs, then using a 3D printer to build the physical object layer by layer.

These items serve the same functions as traditional kitchen tools but offer customization options. You can modify sizes, shapes, and features to match your specific kitchen requirements.

Common Uses in the Kitchen

Organization and Storage

- Spice racks and holders

- Drawer organizers

- Pot lid holders

- Collapsible baskets

Cooking Tools

- Measuring cups and spoons

- Sink strainers

- Bag clips and sealers

- Bottle openers

Replacement Parts

- Broken appliance components

- Missing drawer handles

- Damaged utensil parts

You can print functional items like measuring cubes that combine multiple measurements in one tool. Organizational solutions include custom-sized containers that fit specific cabinet dimensions.

Many designs focus on solving common kitchen problems. Bag sealers keep opened packages fresh, while specialized holders organize frequently used items.

https://makerworld.com/en/models/138919-bottle-beer-opener?from=search#profileId-473005

Benefits of Customization and Personalization

3D printing lets you create kitchen items tailored to your exact needs. You can adjust dimensions to fit specific spaces or modify designs for left-handed use.

Cost savings represent a major advantage. You can print replacement parts instead of buying entire new appliances or tools.

Key Customization Options:

- Size adjustments for storage spaces

- Color matching to kitchen decor

- Ergonomic modifications for comfort

- Functional improvements to existing designs

You can create bespoke items that don’t exist in stores. Custom measuring tools for specific recipes or specialized holders for unique appliances become possible.

The technology supports sustainable practices by reducing waste. You print only what you need and can recycle failed prints in many cases.

Personal preferences drive design choices. You control materials, colors, and features to match your cooking style and kitchen aesthetics.

Popular 3D Printed Kitchen Tools and Accessories

Kitchen enthusiasts can create functional utensils, specialized food preparation tools, and custom storage solutions using standard 3D printing materials. These printable items range from replacement parts to entirely new gadgets designed specifically for home cooking needs.

Utensils and Gadgets

Measuring tools represent some of the most practical 3D printed kitchen items. You can print custom measuring spoons, adjustable measuring cups, and portion control scoops in exact sizes that match your recipes.

Specialized utensils include pasta servers, egg separators, and citrus reamers. These tools often feature unique geometries that work better than traditional alternatives for specific tasks.

Bottle openers and bag clips are popular beginner projects. You can customize these items with personal designs or specific grip patterns that suit your hands.

Kitchen timers and thermometer holders provide functional organization. Many STL files include mounting systems that attach to refrigerators or cabinet doors.

Collapsible tools take advantage of 3D printing’s ability to create complex moving parts. Collapsible funnels, measuring cups, and strainers save drawer space while maintaining full functionality.

Food Preparation Accessories

Cutting boards and trivets can be printed in custom sizes to fit your specific cookware. These accessories often include raised edges or specialized grooves for different food types.

Spice mixing tools include mortar and pestle sets, spice grinding aids, and custom blend measuring devices. You can print these in food-safe materials for direct contact with ingredients.

Baking accessories cover cookie cutters, cake decorating tools, and dough guides. Custom cookie cutters allow you to create unique shapes that aren’t available commercially.

Food molds and forms help shape burgers, rice balls, and other foods. These tools can be customized to create consistent portions or decorative presentations.

Prep bowls and sorting trays organize ingredients during cooking. You can print these in stackable designs or with built-in pour spouts for easy transfer.

Storage and Organization Solutions

Spice racks represent the most popular 3D printed storage solution. You can design these to fit your specific cabinet dimensions and jar sizes perfectly.

Drawer organizers create custom compartments for utensils, gadgets, and small tools. These systems maximize space usage better than store-bought alternatives.

Stackable containers provide modular storage for dry goods. Many designs include airtight sealing systems and transparent viewing windows.

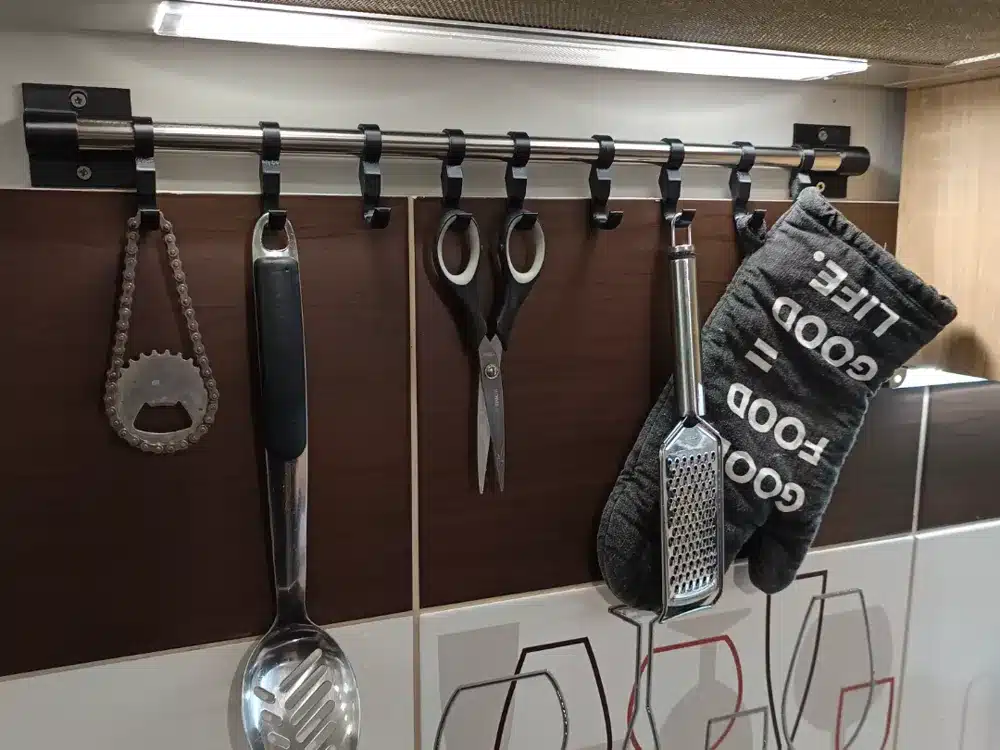

Magnetic holders attach to refrigerators or metal surfaces. These accessories hold knives, spice jars, or frequently used tools within easy reach.

Shelf and cabinet accessories include under-shelf baskets, cabinet door organizers, and stackable shelf risers. You can print these to match your exact cabinet measurements and storage needs.

Materials and Design Considerations for Kitchen 3D Prints

Material selection and design planning determine the safety and functionality of 3D printed kitchen items. Food-safe filaments require careful evaluation while proper design ensures durability and practical use.

Choosing Food-Safe Filaments

Food-safe 3D printing requires specific materials that meet health regulations and avoid toxic contamination. Not all filaments are suitable for direct food contact.

PLA (Polylactic Acid) stands as the most accessible food-safe option. It derives from natural materials like corn starch and sugarcane. PLA produces minimal toxic fumes during printing and maintains relatively stable properties.

PETG (Polyethylene Terephthalate Glycol) offers superior chemical resistance and durability. It withstands higher temperatures than PLA and resists cracking under stress.

PP (Polypropylene) provides excellent chemical resistance and flexibility. It handles temperature variations well but requires specialized printing equipment.

Avoid ABS and other petroleum-based filaments for food contact applications. These materials can leach harmful chemicals and produce toxic fumes during printing.

Always verify that your chosen filament meets FDA food contact regulations. Purchase materials from reputable suppliers who provide safety certifications.

The Role of PLA in Kitchen Printing

PLA dominates kitchen 3D printing due to its safety profile and ease of use. Its biodegradable nature makes it environmentally friendly compared to petroleum-based alternatives.

PLA prints at lower temperatures (190-220°C) which reduces warping and printing complications. This temperature range makes it compatible with most entry-level 3D printers.

The material handles cold and room temperature foods effectively. However, PLA softens around 60°C, making it unsuitable for hot liquids or dishwasher use.

PLA works well for cookie cutters, cake decorating tools, and food storage containers. It also excels in creating custom measuring tools and kitchen organizers.

Surface finish affects food safety significantly. PLA’s layer lines can harbor bacteria, so smooth finishing becomes essential for food contact items.

Consider PLA’s limitations when designing heated applications. Steam, hot water, or prolonged heat exposure can deform PLA objects permanently.

Designing for Functionality and Durability

Effective kitchen tool design balances usability with manufacturing constraints. Layer adhesion and print orientation directly impact structural integrity.

Wall thickness should exceed 2mm for utensils and tools that experience stress. Thin walls may crack under normal kitchen use or washing.

Design smooth, curved surfaces instead of sharp angles where possible. Curved geometries distribute stress more evenly and reduce crack initiation points.

Orient prints to align stress directions with layer adhesion. Print spoons and spatulas flat to maximize strength along the handle length.

Surface texture requires careful consideration for food contact areas. Smooth surfaces clean more easily but may require post-processing like sanding or coating.

Include drainage features in containers and organizers. Small holes or sloped surfaces prevent water accumulation and bacterial growth.

Avoid complex internal geometries that cannot be cleaned properly. Simple, accessible designs ensure thorough washing and sanitization.

How to Get and Use STL Files for Kitchen Items

STL files serve as digital blueprints for 3D printing kitchen gadgets and tools. The process involves locating quality files online, preparing them through slicing software, and following specific guidelines for food-safe printing.

Finding STL Files Online

Multiple platforms offer kitchen-focused STL files for download. Popular repositories include Cults 3D, Thingiverse, and specialized 3D printing communities that host thousands of kitchen-related models.

Free vs. Premium Options:

- Free STL files provide basic kitchen tools and gadgets

- Premium files often include more detailed designs and professional documentation

- Some platforms offer both free and paid content from the same designers

Search using specific keywords like “kitchen tools,” “food prep,” or “cooking gadgets” for better results. Many sites allow filtering by category, complexity level, and print requirements.

Check file ratings and user reviews before downloading. Look for files with clear printing instructions and material recommendations. Some creators provide multiple format options including STL, OBJ, and 3MF files.

Customizing and Slicing STL Files

Import your STL file into slicing software like Cura, PrusaSlicer, or Bambu Studio. These programs convert the 3D model into printable layers and generate the G-code your printer needs.

Key Slicer Settings for Kitchen Items:

- Layer Height: 0.2-0.3mm for functional items

- Infill: 15-25% for lightweight tools, 40-60% for heavy-duty items

- Print Speed: 40-60mm/s for detailed parts

Adjust orientation to minimize support material and improve surface finish. Kitchen items often print best with flat surfaces on the build plate.

Consider scaling objects to fit your needs. A spatula handle might need lengthening, or a measuring cup might require size adjustments.

Preview the sliced model to identify potential issues before printing. Check for overhangs, bridges, and areas that might need supports.

Best Practices for Kitchen STL File Use

Choose food-safe materials like PETG or PLA for items touching food. Avoid ABS and other materials that may release harmful chemicals during food contact.

Material Selection Guide:

- PLA: Safe for cold foods, biodegradable, easy to print

- PETG: Dishwasher safe, chemical resistant, durable

- Food-safe PLA: Specifically certified for food contact

Print with smooth surface finishes to prevent bacteria growth. Higher resolution settings create fewer surface irregularities where contaminants can hide.

Design kitchen items with cleaning in mind. Avoid complex internal geometries that trap food particles. Simple, accessible surfaces work best for kitchen tools.

Test printed items thoroughly before regular use. Check for layer adhesion, structural integrity, and any sharp edges that need post-processing.

Store STL files in organized folders by category. Keep notes about successful print settings for future reference.

https://makerworld.com/en/models/1141367-kitchen-hanger?from=search#profileId-1143805

Care, Maintenance, and Safety for 3D Printed Kitchen Items

Proper care and maintenance of 3D printed kitchen items requires attention to cleaning protocols, material limitations, and safety considerations. Understanding these factors helps ensure both food safety and extended tool lifespan.

Cleaning and Sanitizing 3D Prints

Cleaning 3D printed kitchen items presents unique challenges due to their layered construction. The microscopic ridges between print layers can harbor bacteria and food particles.

Hand washing is the preferred method for most 3D printed items. Use warm soapy water and a soft brush to reach into surface grooves. Avoid abrasive scrubbers that can damage the surface finish.

Many 3D printed materials cannot withstand dishwasher temperatures. PLA typically begins to soften around 140°F, making it unsuitable for most dishwashers. Check your material’s heat resistance before machine washing.

Sanitizing requires extra attention to material compatibility. Bleach solutions can degrade certain plastics over time. Food-safe sanitizing wipes or diluted vinegar solutions often work better for regular maintenance.

For items with complex geometries, consider using a bottle brush or pipe cleaner to reach internal surfaces. Thorough drying prevents moisture accumulation in layer lines.

Avoiding Common Hazards

Several safety risks exist when using 3D printed kitchen tools. Understanding these hazards helps prevent accidents and health issues.

Heat exposure poses the primary risk for most printed materials. PLA becomes soft and potentially toxic when heated beyond safe temperatures. Never use PLA items near stovetops, in ovens, or with hot liquids above 120°F.

Sharp edges can form during printing or develop through use. Sand down any rough edges before first use and inspect items regularly for damage.

Chemical migration from non-food-safe materials can contaminate food. Only use filaments specifically certified for food contact. Avoid recycled materials or those with unknown additives.

Cross-contamination occurs when printers used for general projects create food-contact items. Dedicate specific printers or thoroughly clean equipment between uses.

Watch for structural failures in load-bearing items like jar openers or can crushers. Layer adhesion can fail under stress, creating sharp fragments.

Maximizing Longevity of Printed Tools

Proper storage and handling significantly extend the life of 3D printed kitchen items. These practices prevent premature wear and maintain food safety.

Store items in dry locations away from direct sunlight. UV exposure degrades most plastics over time, causing brittleness and discoloration.

Avoid temperature extremes during storage. Rapid temperature changes can cause warping or cracking in printed materials.

Rotate usage of duplicate items when possible. This prevents overuse of single tools and allows for thorough cleaning between uses.

Replace items showing signs of wear, cracking, or permanent staining. These conditions indicate potential bacterial harboring or structural weakness.

Keep replacement files organized for easy reprinting. Digital storage allows quick reproduction when items reach end-of-life.

Regular inspection helps identify problems early. Check for loose parts, surface degradation, or dimensional changes that could affect performance or safety.

- 51shares

- Facebook0

- Pinterest51

- Twitter0

- Reddit0