Get ready to dive headfirst into the fascinating world where high-octane engineering meets cutting-edge technology! We’re talking about automotive 3D printing, a game-changer that’s literally revving up car innovation and transforming how vehicles are designed, produced, and even customized. Gone are the days when 3D printing was just a niche hobby for creating small plastic trinkets. Today, it’s a powerful industrial force, and nowhere is its impact more visible than in the automotive industry. From crafting intricate prototypes in a flash to producing lightweight, performance-boosting components and even full-scale concept cars, additive manufacturing is putting the pedal to the metal on creativity and efficiency.

The journey of a car, from a designer’s initial sketch to a gleaming model on the showroom floor, is incredibly complex. Traditionally, this process involved countless hours of manual labor, expensive tooling, and lengthy lead times. But what if you could bypass many of those hurdles, iterate designs almost instantly, and create parts with geometries previously thought impossible? That’s precisely what automotive 3D printing brings to the table. It’s not just about speed; it’s about unlocking new levels of design freedom, reducing waste, and ultimately, building better, more personalized cars for the future. So, buckle up, because we’re about to explore how this incredible technology is shaping the vehicles we drive today and will drive tomorrow.

Pros and Cons

| Pros | Cons |

|---|---|

| – Rapid Prototyping: Significantly speeds up design iteration and testing. | – High Initial Cost: Industrial 3D printers and materials can be expensive. |

| – Design Freedom: Allows for complex geometries and lightweight structures. | – Limited Material Range: Still fewer options compared to traditional manufacturing. |

| – Customization: Enables personalized parts and low-volume production. | – Slower Production Speed: Not ideal for true mass production of simple parts. |

| – Reduced Waste: Uses only the material needed, minimizing scrap. | – Post-Processing Required: Many 3D printed parts need additional finishing. |

| – Tooling Elimination: Cuts costs and lead times by removing the need for molds. | – Scalability Challenges: Large-scale, high-volume production is still evolving. |

The Dawn of a New Era: What is Automotive 3D Printing?

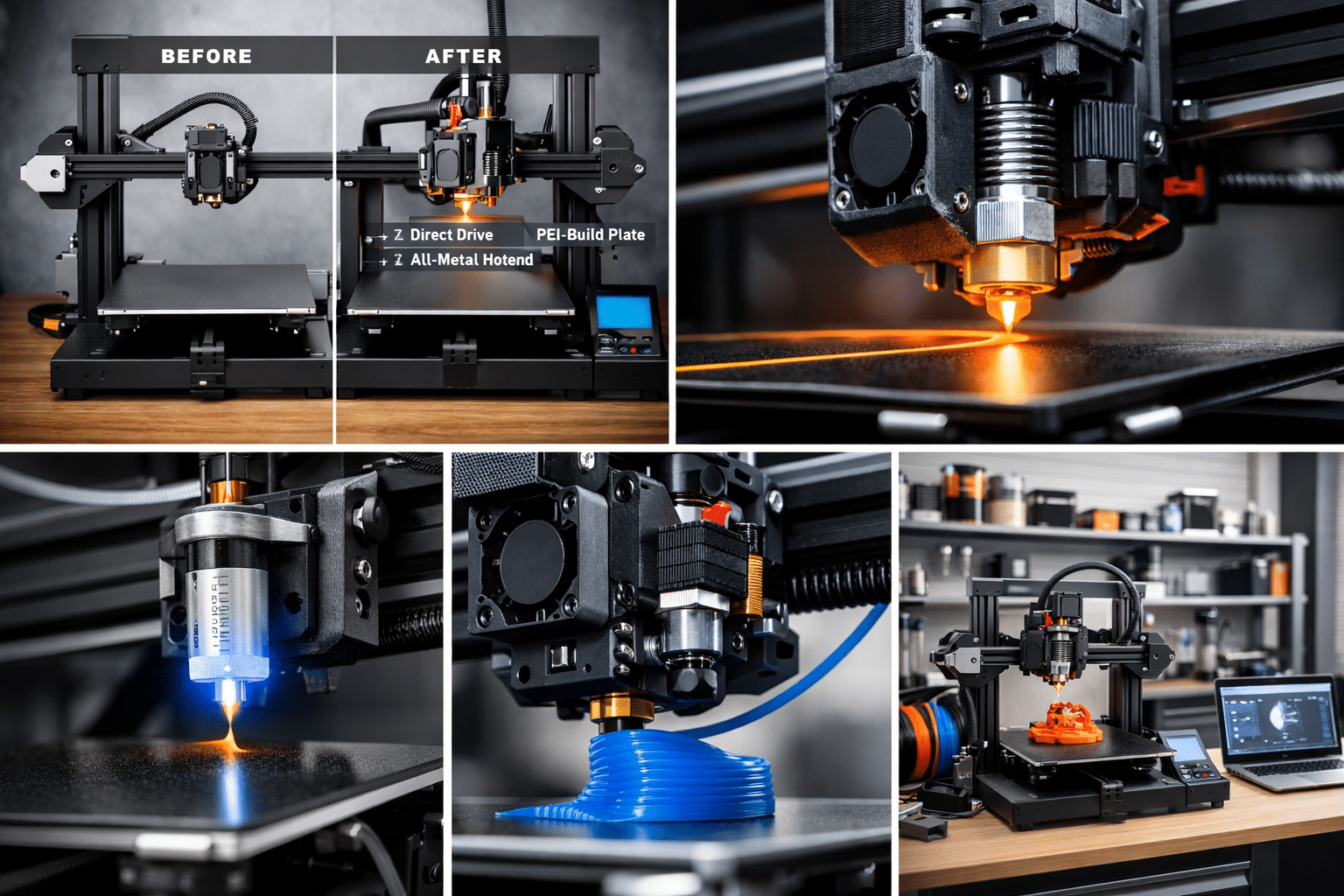

Automotive 3D printing, often referred to as additive manufacturing, is a process where a three-dimensional object is created by building up successive layers of material. Think of it like a highly sophisticated hot glue gun, but instead of glue, it’s extruding or fusing plastics, metals, composites, and even ceramics, layer by incredibly thin layer, based on a digital design file. Unlike traditional “subtractive” manufacturing, which starts with a block of material and carves away what’s not needed, additive manufacturing builds only what’s necessary. This fundamental difference is where many of its revolutionary benefits stem from.

In the automotive world, this means we’re moving beyond simple models. We’re talking about functional components, robust prototypes, and even production-ready parts that go directly into vehicles. The technology isn’t just one thing; it’s a family of different processes, each with its strengths. You’ve got Fused Deposition Modeling (FDM) for plastics, Selective Laser Sintering (SLS) for powdered polymers, and Direct Metal Laser Sintering (DMLS) or Electron Beam Melting (EBM) for incredibly strong metal parts. Each method offers unique advantages in terms of material properties, surface finish, and geometric complexity, allowing engineers to choose the perfect approach for any given automotive challenge.

The adoption of 3D printing in the automotive sector isn’t new, but its growth has accelerated dramatically. Early on, it was mostly used for visual prototypes or fit-and-finish checks. Now, it’s deeply integrated into almost every stage of vehicle development and production, from concept design all the way to aftermarket modifications. It’s a technology that thrives on complexity, offering a powerful tool for innovation in an industry constantly pushing the boundaries of performance, safety, and driver experience.

From Concept to Crossover: How 3D Printing is Used in Design & Prototyping

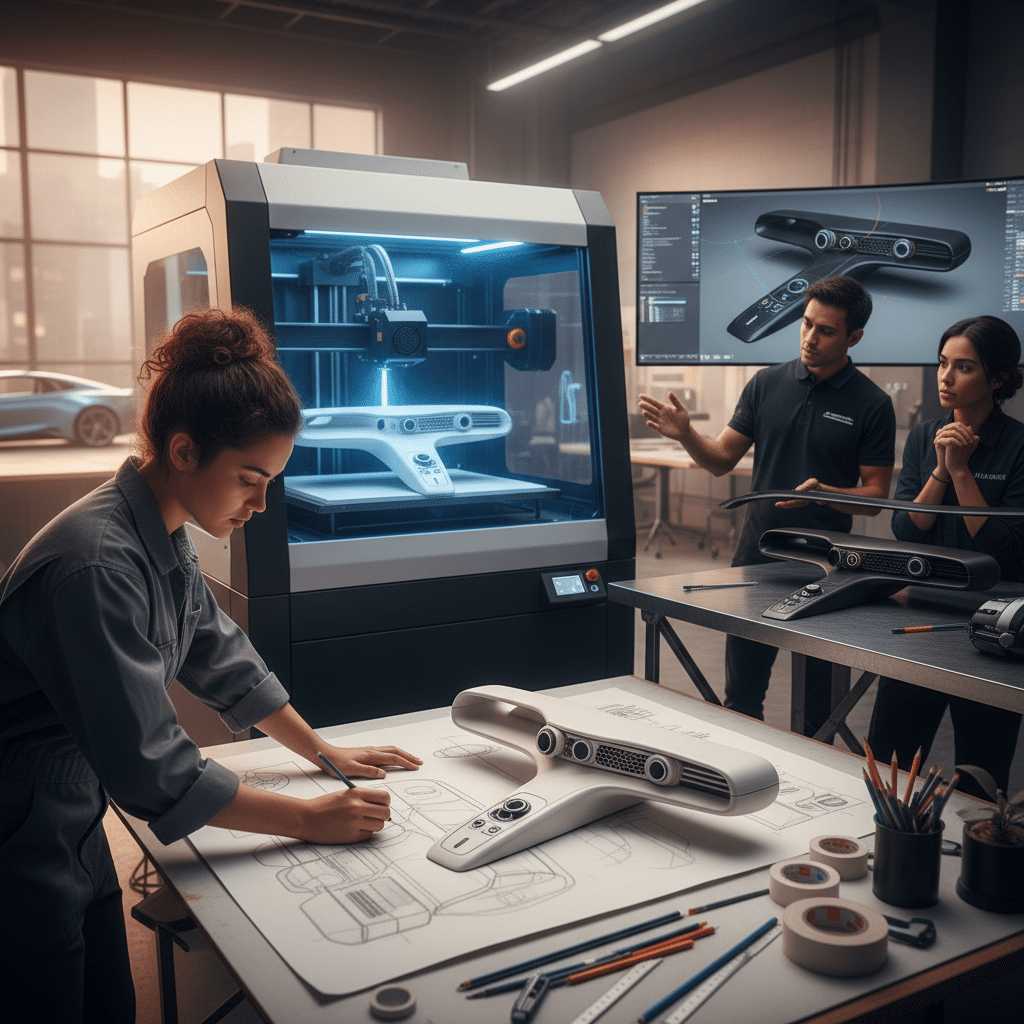

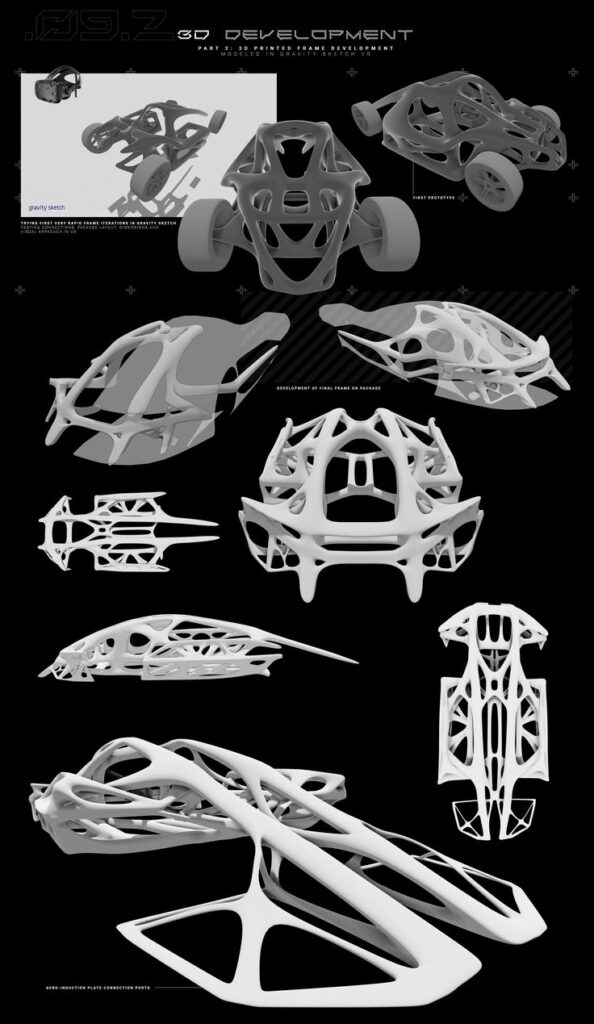

One of the most profound impacts of automotive 3D printing is how it has revolutionized the design and prototyping phases. Before 3D printing became accessible, creating a physical prototype was a painstaking, often manual, and incredibly expensive endeavor. Designers would often have to wait weeks or even months to see their ideas materialize, severely limiting the number of iterations they could explore. Enter 3D printing, and suddenly, the design studio becomes a playground of instant gratification and endless possibilities.

Rapid Prototyping

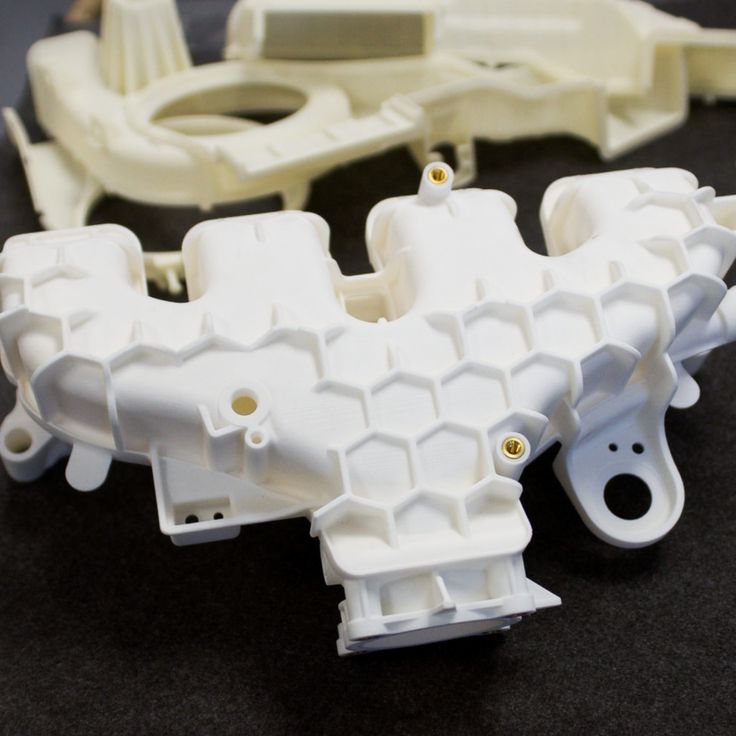

Imagine an automotive designer sketching a new interior console or an aerodynamic wing. With traditional methods, turning that sketch into a physical model would involve machining, molding, or handcrafting. Now, they can send the digital file to a 3D printer, and hours later, have a tangible, full-scale, accurate representation of their design. This rapid prototyping capability is a game-changer. It allows designers and engineers to quickly test form, fit, and even function. They can identify design flaws early, experiment with different shapes and ergonomic considerations, and make informed decisions long before committing to expensive tooling for mass production. This agility significantly compresses development cycles, getting new models and features to market much faster. Companies can iterate on complex designs, from intricate grilles to bespoke dashboard layouts, with unprecedented speed. This process also significantly de-risks the development pipeline, as critical issues are caught and corrected when they are cheapest to fix.

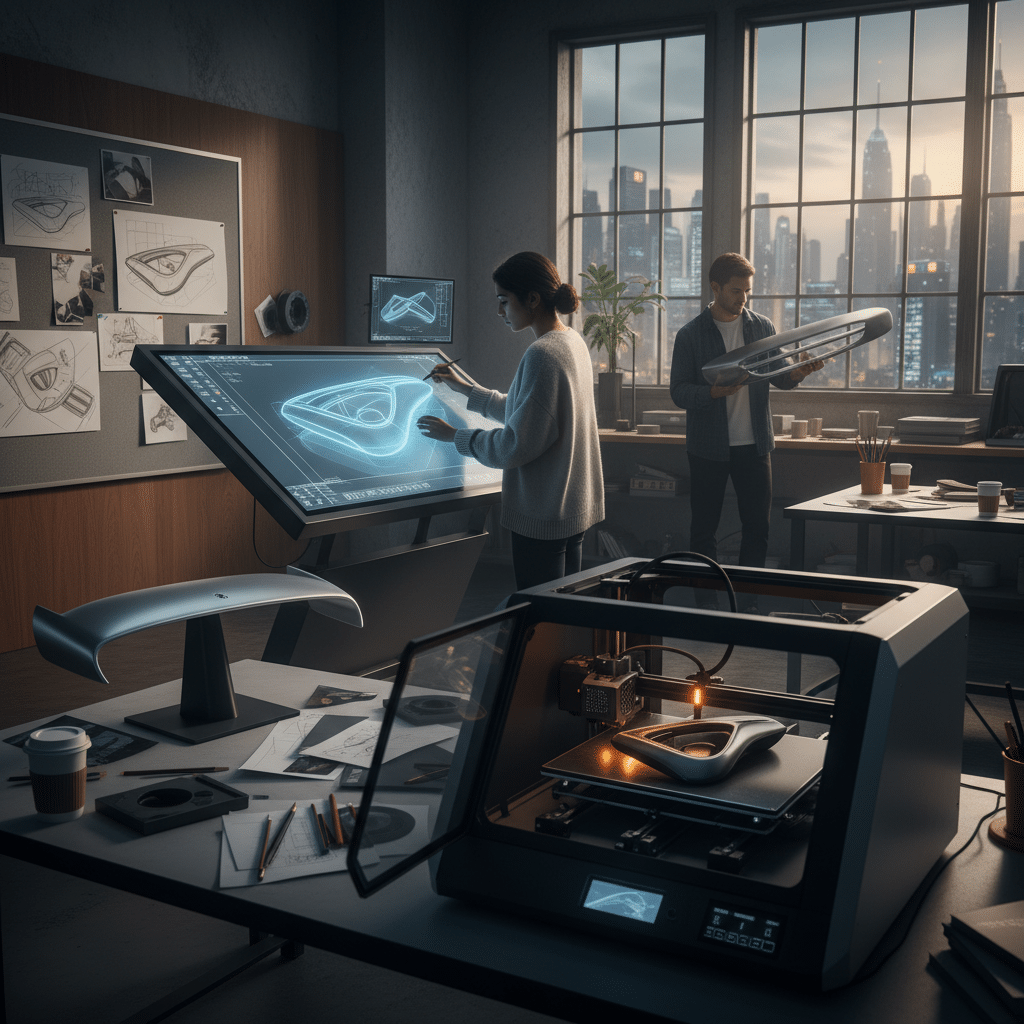

Design Iteration

The ability to quickly print multiple variations of a part means that designers are no longer constrained by cost or time in exploring different options. Want to see if a slightly different curvature on a mirror housing improves airflow? Print it. Wondering if a redesigned HVAC vent looks better in the dashboard? Print both versions and compare them side-by-side. This iterative process is crucial for refining aesthetics, optimizing aerodynamics, and ensuring ergonomic perfection. It fosters a culture of continuous improvement and experimentation, where “what if” questions can be answered with a physical model rather than just a computer simulation.

This freedom isn’t just for external components. Designers are using 3D printing to explore interior layouts, test different button placements, and even experiment with unique textures and finishes for cabin materials. The goal is always to refine the user experience, and 3D printing provides the tactile feedback necessary to make those critical judgments. For more detailed insights into balancing the aesthetic and functional aspects of early-stage automotive development, you might find this guide on from styling to structure: balancing design and manufacturability in automotive prototypes incredibly useful. It delves into the considerations necessary to ensure a beautiful design is also a practical one.

Under the Hood: Manufacturing with Additive Techniques

Beyond the flashy prototypes, 3D printing is making serious inroads into the actual manufacturing process of automotive components. This isn’t just about small, obscure parts; it’s about integrating additive manufacturing into the core production workflow, bringing benefits that extend far beyond the design studio.

Tooling and Jigs

One of the most immediate and widespread applications of 3D printing in automotive manufacturing is in creating custom tools, jigs, fixtures, and guides for the assembly line. Traditional tooling can be incredibly expensive and time-consuming to produce, often requiring complex machining operations. With 3D printing, a custom jig designed to hold a specific part during assembly can be printed overnight at a fraction of the cost. This dramatically reduces lead times for setting up new production lines or adapting existing ones, making manufacturing more agile and responsive.

For instance, workers on an assembly line might need a custom fixture to perfectly align a sensor during installation. Instead of waiting weeks for a machined metal tool, a 3D printed polymer version can be ready in hours. These tools are often lightweight, ergonomic, and can be easily replaced or updated as production needs evolve. This efficiency directly translates to cost savings and faster time-to-market for new vehicle models.

End-Use Parts

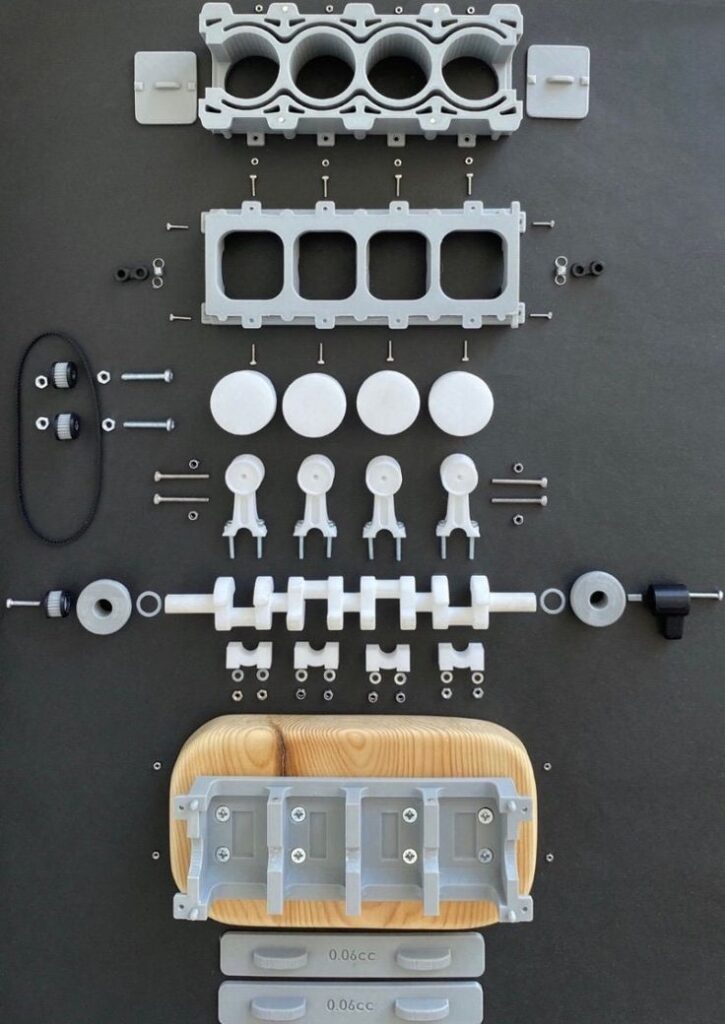

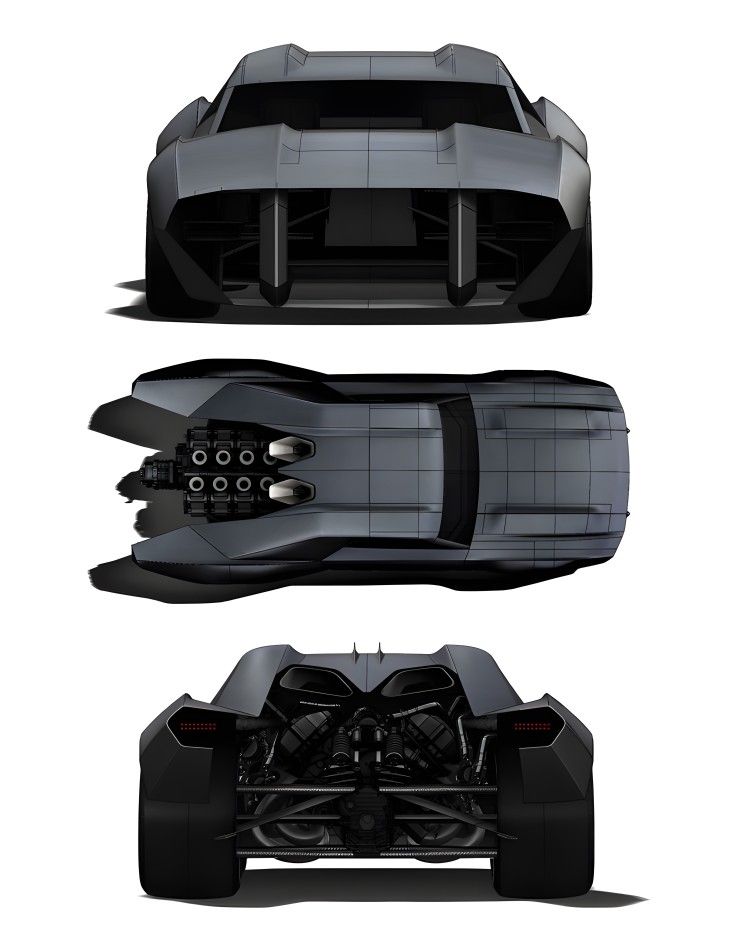

This is where things get really exciting. While not yet ready for every single component in a high-volume car, 3D printing is increasingly used to produce end-use parts that go directly into vehicles. These are often complex, low-volume, or highly optimized components where the benefits of additive manufacturing truly shine.

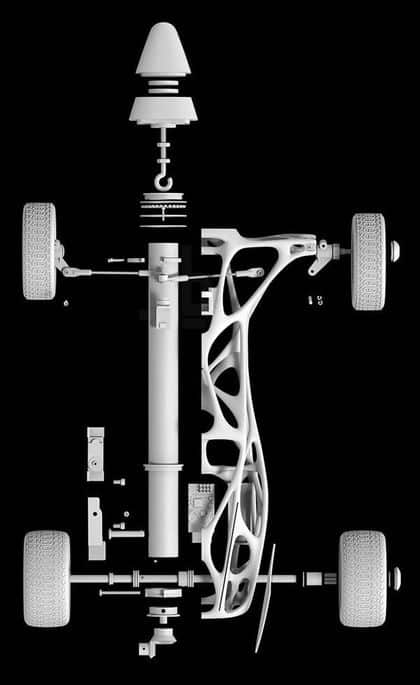

- Lightweighting: By creating intricate lattice structures and hollow designs that traditional manufacturing can’t replicate, 3D printing can produce parts that are significantly lighter than their conventionally made counterparts, without sacrificing strength. This is crucial for improving fuel efficiency (or extending electric vehicle range) and enhancing performance. For example, a bracket that traditionally weighed 500 grams might be redesigned and 3D printed to weigh only 200 grams.

- Consolidation: Multiple parts can often be combined into a single, complex 3D printed component, reducing assembly time, inventory management, and potential points of failure.

- Performance Enhancement: In high-performance vehicles, especially supercars and racing cars, 3D printed metal components like exhaust manifolds, turbocharger impellers, and brake calipers can be optimized for specific aerodynamic or thermal properties, pushing the boundaries of what’s possible.

- Legacy Parts: For older or classic cars, finding replacement parts can be a nightmare. 3D printing offers a viable solution to create exact replicas of discontinued components, keeping beloved vehicles on the road.

Companies like BMW and Porsche are already using 3D printing for various end-use parts, from small plastic clips and dashboard components to larger metal parts for specialized models. Porsche even offers 3D printed custom bucket seats for its 911 and 718 models, allowing for personalized firmness and aesthetics.

Customization and Personalization

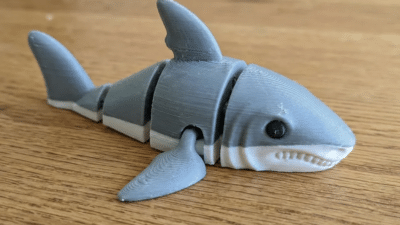

In an age where consumers expect more bespoke products, 3D printing empowers automotive manufacturers to offer unprecedented levels of customization. Imagine a car where you can personalize not just the paint color and interior trim, but specific functional elements. This could be anything from custom-designed shift knobs and vent covers to individualized interior panels with unique textures or even your initials embedded in the design.

For limited edition models or premium brands, 3D printing can create truly unique components that cater to individual customer preferences, offering a level of exclusivity that was previously unattainable or prohibitively expensive. This isn’t just about aesthetics; it can extend to ergonomic adjustments, such as a steering wheel grip tailored to a driver’s hand size, or pedal extensions for drivers of different heights. This level of personalized design extends the appeal of 3D printing beyond just manufacturing, touching on the very essence of individual expression. For designers interested in how this digital flexibility translates to other fields, exploring 3D printed jewelry designs showcases similar principles of customization and intricate detail.

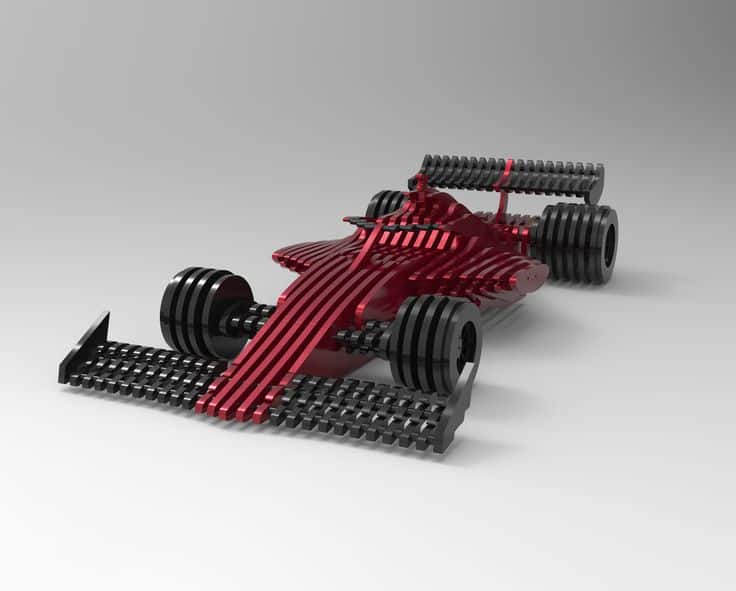

Racing Ahead: 3D Printing in Motorsports

If there’s one arena where every gram counts and every fraction of a second matters, it’s motorsports. Formula 1, endurance racing, and other high-stakes competitions are the ultimate proving grounds for automotive innovation, and 3D printing has become an indispensable tool for racing teams pushing the limits of performance.

In Formula 1, for example, teams constantly develop and refine their cars throughout the season. The ability to rapidly produce new aerodynamic components, internal engine parts, or chassis elements with complex geometries that optimize airflow or reduce weight gives them a crucial competitive edge. A team can design a new winglet on a Monday, 3D print it overnight, test it in a wind tunnel on Tuesday, and potentially have it on the car for a race that weekend. This extreme agility is simply not possible with traditional manufacturing methods.

Teams use advanced metal 3D printing processes like DMLS for critical engine components, gearbox parts, and complex structural elements that need to be both incredibly strong and exceptionally light. They also leverage polymer 3D printing for intricate cooling ducts, brake guides, and other aerodynamic aids that might only be used for a single race or even a specific track configuration. The goal is always to maximize performance while adhering to strict regulations and tight budgets. The insights gained from these extreme applications in motorsports often trickle down into mainstream automotive development, accelerating the adoption of 3D printing technologies in consumer vehicles. When you consider the value of every component in a high-performance vehicle, understanding the balance between investment and output, much like evaluating if an F150 tuner is worth the investment, becomes incredibly clear. Every decision is made to maximize an edge.

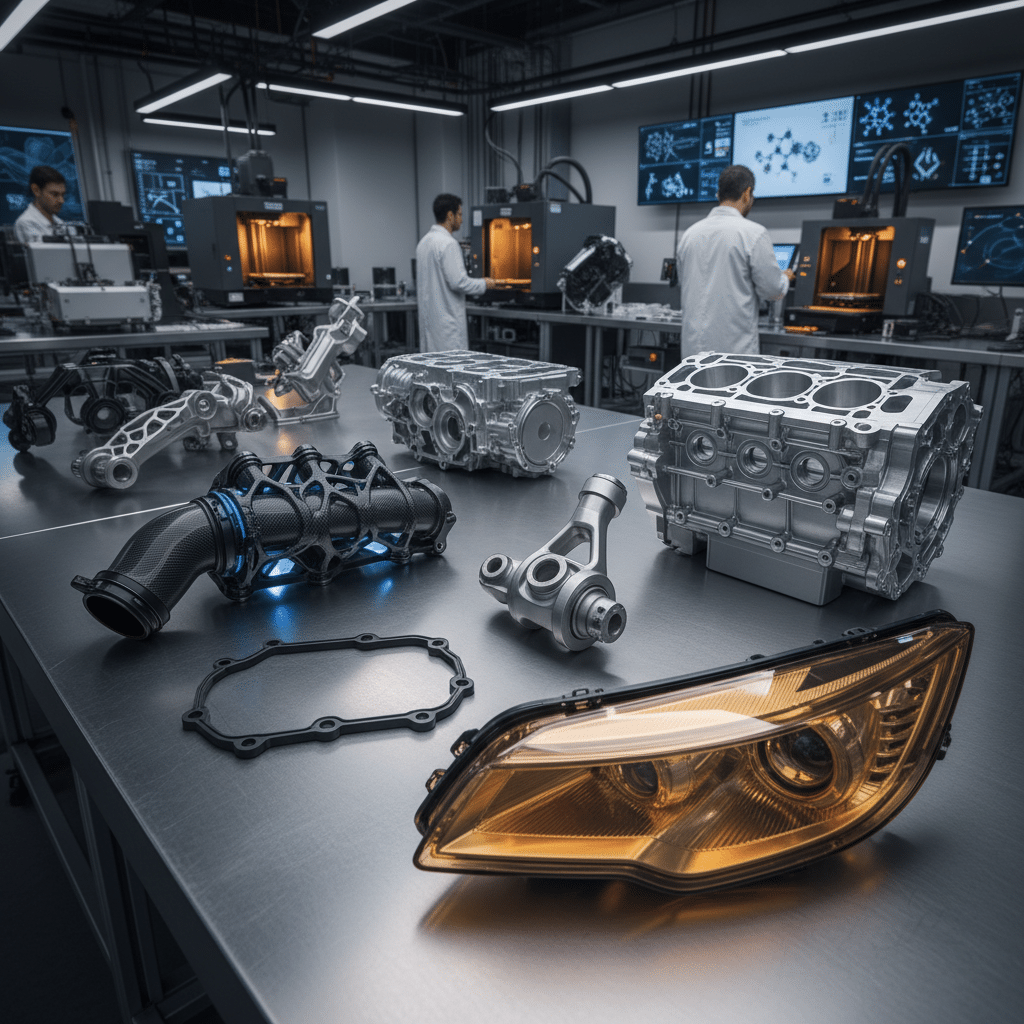

The Materials Revolution: Beyond Plastic

When most people think of 3D printing, they probably picture plastic. While plastics are still fundamental, the materials landscape for automotive 3D printing has expanded dramatically, allowing for parts that meet the stringent demands of the industry. This materials revolution is key to additive manufacturing’s growing influence.

- High-Performance Polymers: Beyond standard ABS or PLA, automotive applications utilize advanced polymers like nylon, carbon fiber-reinforced plastics, and PEEK (Polyether Ether Ketone). These materials offer exceptional strength-to-weight ratios, high temperature resistance, and durability, making them suitable for everything from intake manifolds and electrical connectors to interior components and structural brackets.

- Metals: This is where the real heavy-lifting happens. Direct Metal Laser Sintering (DMLS), Selective Laser Melting (SLM), and Electron Beam Melting (EBM) processes can create parts from powdered metals like aluminum, titanium, stainless steel, and nickel alloys. These parts are often as strong as, or even stronger than, their cast or machined counterparts, with the added benefit of geometric complexity that allows for lightweighting and performance optimization. Think of intricate cooling channels within engine blocks or super-lightweight suspension components.

- Composites: The integration of continuous fiber composites (like carbon fiber) directly into the 3D printing process is another significant leap. This allows for parts with directional strength and stiffness, rivaling traditional composite manufacturing but with much greater design flexibility and faster production times. These are ideal for structural components where specific load paths need to be reinforced.

- Multi-Material Printing: The next frontier involves printers capable of combining different materials within a single print, creating parts with varying properties in different sections – for example, a rigid core with a flexible outer layer, or integrated electrical pathways within a structural component. This opens up entirely new possibilities for functional integration and design.

The continuous development of new and improved materials, coupled with advances in printing technology, is steadily expanding the range of automotive applications where 3D printing is not just viable, but superior.

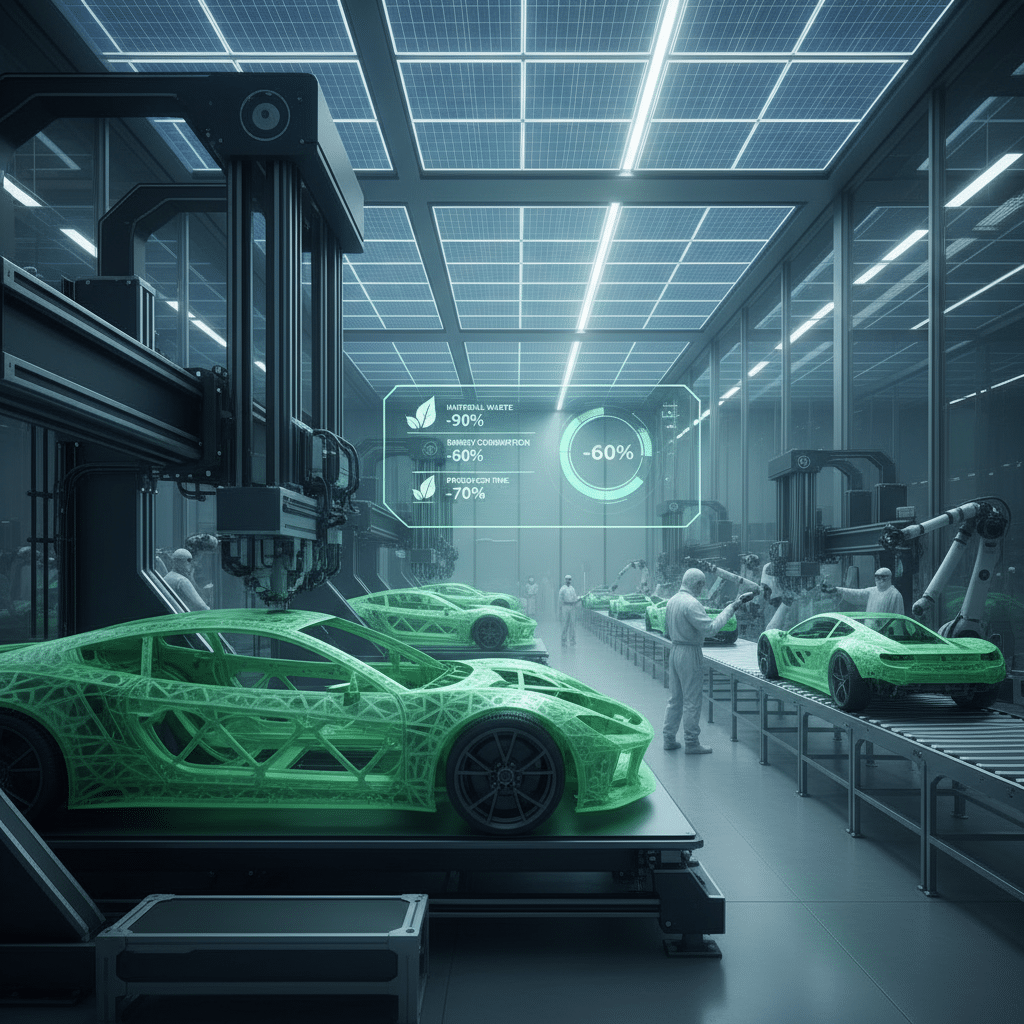

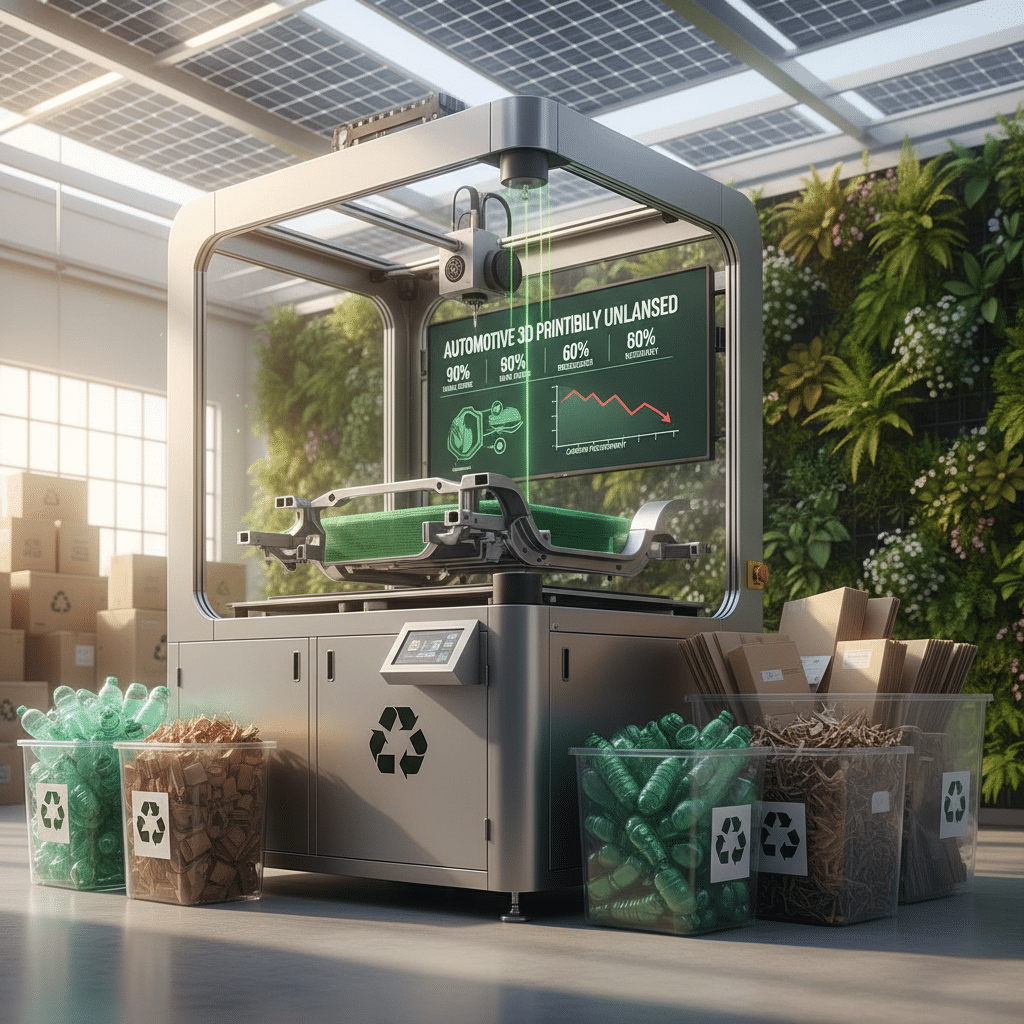

Sustainability and Efficiency: Greening the Auto Industry

In an era increasingly focused on environmental responsibility, automotive 3D printing offers significant advantages in terms of sustainability and resource efficiency. The traditional manufacturing process can be resource-intensive, generating considerable waste and consuming vast amounts of energy. Additive manufacturing presents a greener alternative.

- Reduced Material Waste: As an additive process, 3D printing builds objects layer by layer, using only the necessary material. This contrasts sharply with subtractive methods (like machining), which can generate significant scrap material. For example, machining a complex metal part might mean turning over 90% of the raw material into chips and waste. With 3D printing, material waste is typically less than 10%, often even lower, and unused powder can frequently be recycled for future prints.

- On-Demand Production: The ability to print parts on demand means less need for vast inventories. Manufacturers can produce parts as they are needed, rather than mass-producing and storing components that might never be used. This reduces warehousing needs, transportation, and the risk of obsolescence, further cutting down on waste.

- Lightweighting for Fuel Efficiency: As mentioned earlier, 3D printing excels at creating complex, optimized geometries that result in lighter components. Lighter vehicles require less energy to move, directly translating to improved fuel economy for internal combustion engine cars and extended range for electric vehicles. This reduction in vehicle weight over its lifetime has a substantial positive impact on overall carbon emissions.

- Localized Manufacturing: 3D printing facilitates decentralized production. Instead of shipping parts across continents, a company could theoretically print parts closer to the point of assembly or even directly for consumers at local service centers. This reduces the carbon footprint associated with global logistics and transportation.

- Simplified Supply Chains: By reducing the number of different parts and suppliers (through part consolidation), 3D printing can streamline supply chains, making them less vulnerable to disruptions and more environmentally friendly by cutting down on complex logistical networks.

While the energy consumption of the printing process itself is a factor, the overall life-cycle benefits of 3D printing, especially regarding material waste reduction and lightweighting, position it as a powerful tool for developing more sustainable vehicles and manufacturing practices.

The Road Ahead: Future Trends and Challenges

The automotive 3D printing landscape is evolving at a breakneck pace, with new advancements emerging constantly. What we see today is just the beginning of its potential impact.

Mass Production Potential

While 3D printing currently excels at low-volume, highly customized, or complex parts, the holy grail for the automotive industry is scaling it up for true mass production. Companies like Desktop Metal and HP are developing new additive manufacturing systems designed for higher throughput and lower per-part costs, aiming to make 3D printed parts competitive with traditionally manufactured components even at high volumes. We’re seeing innovations in continuous printing, larger build volumes, and faster print speeds that are steadily moving towards this goal. Imagine entire car components, or even significant sections of a vehicle, being rapidly printed on an assembly line. This future is closer than you might think.

Integration with AI and Automation

The digital nature of 3D printing makes it a perfect candidate for integration with artificial intelligence (AI) and advanced automation. AI can optimize part designs for strength, weight, or specific performance characteristics faster and more efficiently than human engineers. Generative design, a process where AI algorithms create optimal designs based on parameters set by engineers, is already being used to create incredibly complex and efficient structures. Automated post-processing, quality control using machine vision, and robotic material handling will further streamline the 3D printing workflow, reducing labor costs and increasing consistency. These advancements will make the entire process more intelligent, efficient, and reliable.

Addressing Material and Process Limitations

Despite rapid advancements, challenges remain. The range of materials, while growing, is still narrower than traditional manufacturing methods. The speed of printing, especially for large metal parts, can still be a bottleneck for very high-volume production. Surface finish and part consistency also require careful control and often extensive post-processing. Research and development are actively tackling these limitations, with new materials, multi-material printers, and hybrid manufacturing systems (combining additive and subtractive techniques) continually pushing the boundaries of what’s possible. As these limitations diminish, 3D printing’s role in automotive manufacturing will only continue to expand.

Real-World Impact: Case Studies and Examples

It’s one thing to talk about potential; it’s another to see real-world applications. Major automotive players are already deeply invested in 3D printing, showcasing its transformative power.

- BMW: The German automaker is a pioneer in automotive 3D printing, operating one of the largest additive manufacturing campuses in the industry. They use 3D printing for rapid prototyping across their entire vehicle range, from early concept models to interior components. More importantly, BMW has integrated 3D printed parts into series production. Examples include individualized seat inserts, parts for classic cars like the BMW Z4 Roadster, and even functional components for Rolls-Royce vehicles, demonstrating a commitment to both innovation and heritage. Their approach exemplifies how 3D printing can support niche applications and high-volume needs.

- Ford: Ford has been utilizing 3D printing for decades, primarily for prototyping. They’ve used it to rapidly iterate designs for engine parts, ergonomic controls, and even for designing custom tools and fixtures for their assembly lines. One notable example is their use of 3D printed components in the development of the Ford GT supercar, where complex intake manifolds and structural brackets were optimized for performance and weight reduction. Ford also collaborates with companies like Stratasys to explore large-scale 3D printing for potential future applications, including vehicle components and customized accessories.

- Porsche: Luxury sports car manufacturer Porsche has embraced 3D printing for a variety of applications, emphasizing customization and performance. They offer 3D printed custom-fit bodyform full bucket seats as an option for some of their 911 and 718 models, allowing customers to choose different firmness levels. They also produce 3D printed classic car parts on demand, ensuring that older models can still be maintained with authentic components. Porsche even printed an entire electric drive housing for a prototype, showcasing the potential for highly integrated, optimized metal components.

- General Motors (GM): GM has made significant investments in additive manufacturing, establishing an additive industrialization center. They utilize 3D printing for functional prototypes, concept vehicle development, and tooling. A striking example of their application is the development of 3D printed parts for their IndyCar race teams, optimizing aerodynamics and reducing weight. They are also exploring the use of 3D printed polymer components for lightweighting in production vehicles, showcasing how the technology can lead to direct consumer benefits in terms of fuel efficiency and performance.

- Volvo Trucks: It’s not just passenger cars! Volvo Trucks has been using 3D printing for creating spare parts on demand. This is particularly valuable for older truck models or for situations where a specific part is needed urgently, reducing downtime and streamlining their global service network. This application highlights the pragmatic, cost-saving benefits beyond just cutting-edge performance.

These examples underscore that automotive 3D printing isn’t a futuristic dream; it’s a present-day reality, deeply embedded in the operations of leading global manufacturers, driving innovation and efficiency across the board. The ability to quickly visualize and refine designs is a huge boon, much like how an artist uses sketching to refine their vision, as described in guides like automobile sketch.

The Engine of Innovation: Conclusion

Automotive 3D printing is undeniably a monumental force, pushing the boundaries of what’s possible in vehicle design, engineering, and manufacturing. From enabling lightning-fast prototyping and accelerating design iterations to producing lightweight, performance-enhancing end-use parts and offering unprecedented levels of customization, additive manufacturing is literally revving up innovation across the entire automotive landscape.

We’ve seen how it’s revolutionizing the speed at which new concepts go from a digital file to a tangible reality, allowing engineers and designers to experiment more freely and refine products with greater precision. We’ve explored its critical role in creating specialized tooling, manufacturing complex components, and even breathing new life into classic cars. Moreover, the environmental benefits of reduced material waste and lightweighting align perfectly with the industry’s drive towards a more sustainable future. The materials revolution, coupled with the integration of AI and automation, promises an even more impactful role for 3D printing in the years to come, moving steadily towards higher volume production and more intricate applications.

The road ahead is paved with exciting possibilities. As 3D printing technologies continue to mature, become faster, and utilize an even broader range of advanced materials, their influence on how we design, build, and interact with our vehicles will only grow. We’re on the cusp of a new era where cars are not just mass-produced but intelligently crafted, highly customized, and inherently more efficient, all thanks to the power of additive manufacturing.

So, as you see the next cutting-edge vehicle roll off the production line, remember the intricate, layer-by-layer magic that often went into its creation. Automotive 3D printing isn’t just a trend; it’s the engine driving the next generation of car innovation.

Ready to explore the future of automotive design? Dive deeper into the technologies shaping tomorrow’s vehicles and consider how these advancements could impact your own automotive experiences. What part of automotive 3D printing excites you the most?

- 255shares

- Facebook0

- Pinterest255

- Twitter0

- Reddit0