3D printing has moved far beyond prototypes and hobby projects. Today, it stands as a core part of industrial production, powering everything from aerospace components to medical devices. You can now see additive manufacturing deliver real-world value by cutting costs, speeding up production, and enabling designs that traditional methods cannot achieve.

You benefit from a technology that adapts to multiple industries. Automotive companies use it for lightweight parts, healthcare applies it for patient-specific implants, and manufacturers rely on it for custom tools and fixtures. With industrial-grade machines driving over three-quarters of market revenue, 3D printing has become indispensable in large-scale production.

The growth of this market shows no signs of slowing. Forecasts project billions in expansion through the next decade, fueled by new materials, smarter automation, and sustainability goals. By understanding how these trends shape the future, you can see where opportunities for innovation and efficiency are opening.

Key Takeaways

- 3D printing is now a critical tool in industrial production

- Multiple industries apply it for cost savings and design flexibility

- Market growth continues with new materials and advanced automation

Core 3D Printing Technologies in Industry

When you look at industrial 3D printing, you’ll find that different technologies are suited to very different purposes. Each method has its own strengths in terms of materials, accuracy, speed, and cost, which directly impacts how you can use it in production.

Fused Deposition Modeling (FDM) and Fused Filament Fabrication (FFF)

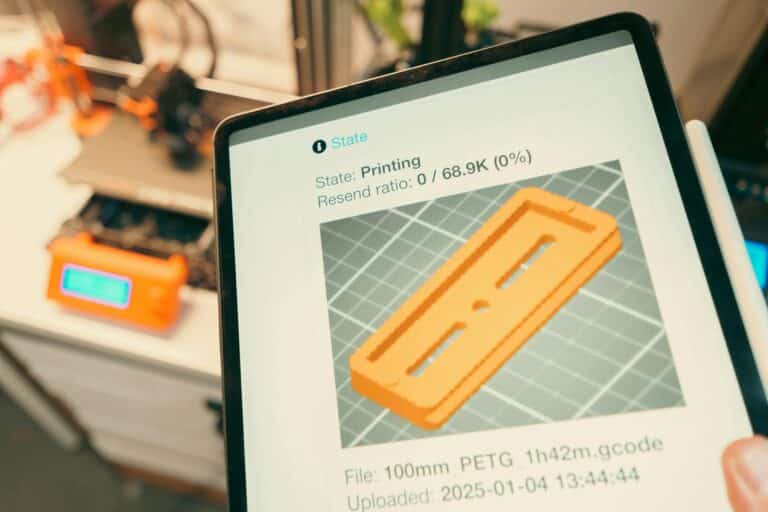

FDM, also called FFF, is the most common form of 3D printing you’ll encounter. It works by heating and extruding thermoplastic filament through a nozzle, which deposits material layer by layer.

You can use this method for quick prototypes, low-cost tooling, and even some end-use parts. Materials like PLA, ABS, and PETG are widely available, and industrial-grade printers also support carbon fiber or glass-filled composites.

FDM/FFF is valued for its affordability and simplicity. However, layer lines are visible, and surface finish often requires post-processing. Dimensional accuracy depends heavily on machine calibration and material choice.

Key advantages:

- Low machine and material costs

- Wide range of thermoplastics

- Easy to operate and maintain

Limitations:

- Lower resolution compared to resin-based methods

- Mechanical strength varies by print orientation

Stereolithography (SLA) and Digital Light Processing (DLP)

SLA and DLP both use liquid resins that are cured by light, but they differ in how the light is applied. SLA uses a laser to trace each layer, while DLP projects an entire layer at once using a digital light source.

These processes give you very high precision and smooth surface finishes. They are popular for dental models, jewelry casting patterns, and functional prototypes that need fine details.

Resins range from rigid and transparent to flexible and heat-resistant, giving you flexibility depending on the application. Post-curing with UV light is usually necessary to reach full material strength.

Comparison table:

| Feature | SLA | DLP |

|---|---|---|

| Light Source | Laser | Digital projector |

| Speed | Slower | Faster for small parts |

| Resolution | Very high | High |

Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF)

SLS and MJF both work with powdered materials, usually nylon or other polymers. In SLS, a laser fuses powder particles layer by layer, while in MJF, ink agents and infrared energy are used to fuse areas more efficiently.

You don’t need support structures because the surrounding powder holds the part in place. This allows you to produce complex geometries, moving assemblies, and durable end-use components.

SLS is widely used for functional prototypes, aerospace ducting, and automotive parts. MJF offers faster build times and more consistent surface quality, making it attractive for production runs.

Strengths you get:

- Strong, isotropic parts

- High design freedom

- No support structures required

Things to consider:

- Machines are expensive

- Post-processing (depowdering, finishing) is required

Metal 3D Printing Methods: DMLS, SLM, and EBM

Metal additive manufacturing gives you the ability to produce complex metal parts directly from digital designs. DMLS (Direct Metal Laser Sintering) and SLM (Selective Laser Melting) both use lasers to fuse metal powders, but SLM fully melts the powder while DMLS partially sinters it.

EBM (Electron Beam Melting) uses an electron beam instead of a laser and requires a vacuum environment. This makes it well-suited for titanium and other reactive alloys often used in aerospace and medical implants.

These methods allow you to create lightweight lattice structures, consolidate multiple parts into one, and reduce material waste compared to traditional machining. However, they require strict process control and extensive post-processing such as heat treatment and machining.

Applications include:

- Aerospace turbine components

- Medical implants tailored to patients

- Lightweight automotive structures

Key trade-offs:

- High equipment and material costs

- Slower throughput compared to polymer printing

- Excellent mechanical properties with proper finishing

Industrial Applications of 3D Printing

You can use 3D printing to shorten design cycles, create small production runs, replace parts quickly, and produce shapes that traditional methods cannot achieve. Each of these applications helps you reduce costs, improve flexibility, and expand what you can design or manufacture.

Rapid Prototyping and Design Iteration

3D printing makes it easier for you to move from a digital model to a physical prototype in hours instead of weeks. This speed lets you test form, fit, and function without waiting for tooling or machining.

You can print multiple iterations of a design, compare them side by side, and refine details before committing to production. This reduces costly errors later in the process.

Many industries rely on this approach for product development. For example, consumer electronics companies use rapid prototyping to validate ergonomics, while automotive teams test aerodynamic models.

Because the process is additive, you avoid material waste common in subtractive methods. This efficiency is especially useful when experimenting with complex designs or expensive materials.

Low-Volume Production and On-Demand Manufacturing

3D printing supports low-volume production runs where traditional manufacturing would be too expensive. You can produce tens or hundreds of units without investing in molds or dies.

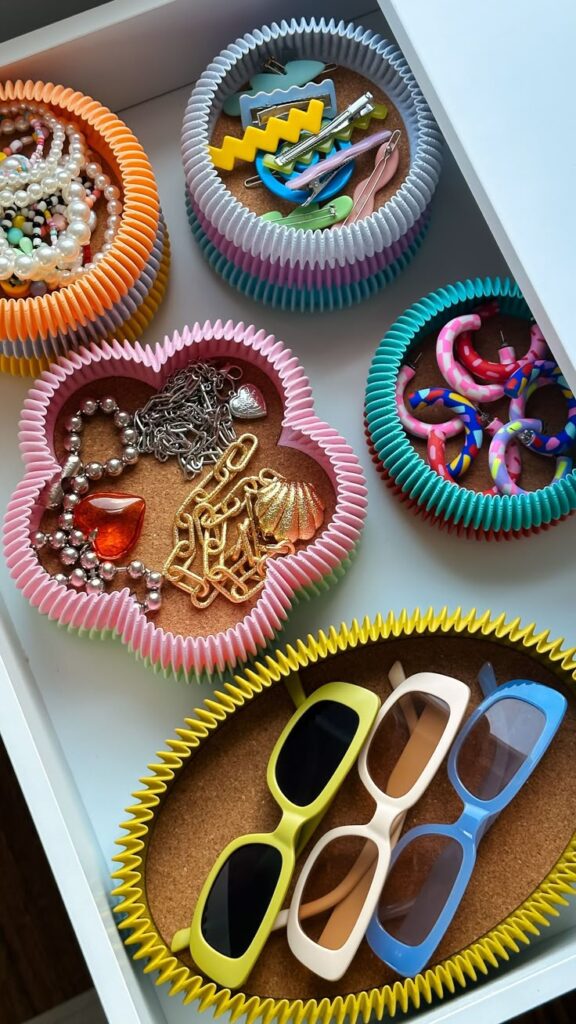

This flexibility is valuable for customized products, pilot launches, or niche markets. For example, medical device companies often print patient-specific implants or surgical guides in small quantities.

On-demand manufacturing also reduces storage needs. Instead of keeping large inventories, you can print parts when orders arrive. This approach lowers warehousing costs and helps you respond quickly to market changes.

Some businesses use hybrid manufacturing, combining 3D printing with conventional methods. You might print complex sections of a part and then machine critical surfaces for precision. This balance improves efficiency without sacrificing quality.

Replacement Parts and Tooling

You can print replacement parts directly from digital files, which minimizes downtime when equipment breaks. This is especially helpful for older machines where spares are no longer available.

Industries such as aerospace and automotive rely on this capability to keep critical systems running. You can also adapt designs to improve durability or performance, rather than just replicate the original part.

Tooling is another strong application. Jigs, fixtures, and molds can be printed quickly and at lower cost than traditional methods. For example, a custom fixture for assembly can be produced overnight, saving you days of waiting.

By integrating 3D printing into your maintenance and production workflows, you reduce lead times and keep operations more agile.

Complex Geometries and Topology Optimization

3D printing allows you to create geometries that traditional machining cannot produce. Internal channels, lattice structures, and organic shapes are practical to print but nearly impossible to mill or cast.

Topology optimization software helps you design parts that use less material while maintaining strength. You can pair this with generative design tools to explore multiple lightweight configurations.

Aerospace and automotive industries apply these techniques to reduce mass without compromising safety. For instance, a bracket redesigned with lattice structures can be 40–60% lighter than a solid version.

When you combine advanced design methods with additive manufacturing, you gain parts that are both efficient and highly functional. This opens new opportunities for performance-driven products across many sectors.

Key Industries Embracing 3D Printing

You can see 3D printing making a measurable impact in fields that demand precision, customization, and efficiency. From lighter airplane parts to patient-specific medical devices and even full-scale building components, the technology is being applied where traditional methods fall short.

Aerospace and Defense

You benefit from 3D printing in the aerospace and defense industry because it reduces weight without sacrificing strength. Aircraft components like brackets, fuel nozzles, and turbine blades are now produced with optimized geometries that improve performance.

Major players such as Airbus, Boeing, and GE Aviation rely on additive manufacturing to shorten supply chains. Instead of waiting weeks for replacement parts, you can produce them directly at or near the point of use.

In defense, 3D printing helps create complex parts for vehicles, drones, and weapon systems. This flexibility is especially useful in remote locations where logistics are difficult. By lowering material waste and enabling on-demand production, it adds both cost savings and operational efficiency.

Healthcare and Medical Devices

You see some of the most personalized uses of 3D printing in healthcare. Patient-specific implants, such as hip joints or cranial plates, are designed using scans of your body for a precise fit.

Custom prosthetics are another area where 3D printing shines. Instead of relying on standardized models, you can create lightweight, affordable prosthetics tailored to individual needs. This improves comfort and usability for patients.

Bioprinting is advancing as well, with researchers working on tissue models and experimental organ structures. While not yet mainstream, these developments show how 3D printing could one day support regenerative medicine.

Dentistry also benefits with 3D-printed dental implants, crowns, and aligners. The speed of production allows you to deliver treatments faster and at lower cost compared to traditional methods.

Automotive and Industrial Manufacturing

You can use 3D printing in automotive and industrial manufacturing to speed up prototyping and lower tooling costs. Engineers quickly test new designs without committing to expensive molds or machining.

In production, lightweight parts improve fuel efficiency and performance. For example, automotive companies are exploring 3D-printed brackets, housings, and interior components that reduce weight while maintaining durability.

Industrial 3D printing also supports spare parts management. Instead of storing large inventories, you can produce components on demand, cutting down warehouse space and costs. This approach is particularly valuable for older equipment where spare parts are no longer in regular production.

Construction and Architecture

You can see 3D printing reshape the construction industry through large-scale printers that build walls, foundations, and even entire houses. By layering concrete or other materials, these systems reduce labor needs and speed up project timelines.

Architects use 3D printing to create complex models and prototypes that help visualize designs before full-scale construction. This improves communication with clients and reduces costly design errors.

Robotics often works alongside 3D printing in construction. Automated systems handle repetitive tasks, while printers manage precise structural elements. Together, they improve efficiency and reduce material waste.

For disaster relief and affordable housing projects, 3D-printed structures offer a practical solution. You can build durable shelters faster and at lower cost compared to conventional methods.

Materials and Innovations in Industrial 3D Printing

When you look at industrial 3D printing today, the biggest changes come from new materials, the ability to combine them in a single build, and the scale of machines available. These factors shape how you design parts, how strong they are, and how practical it is to produce them in real-world manufacturing.

3D Printing Materials: Polymers, Metals, and Ceramics

You can choose from a wide range of 3D printing materials, each suited to specific needs. Polymers remain the most common, with options like PLA for prototyping, ABS for durability, and high-performance thermoplastics such as PEEK for aerospace and medical use.

Metals have become central to industrial applications. Stainless steel, titanium, and aluminum are widely used for strong, lightweight parts in automotive and aerospace. Metal additive manufacturing often requires powder bed fusion or directed energy deposition, which can handle complex geometries that traditional machining cannot.

Ceramics, while less common, provide unique advantages. They can withstand high temperatures and chemical exposure, making them valuable in electronics, biomedical implants, and specialized tooling. Although more challenging to process, ceramic 3D printing is expanding as new formulations and sintering methods improve.

Specialized and Multi-Material Printing

Specialized materials are designed for specific performance needs. For example, biodegradable polymers support sustainable production, while composites reinforced with carbon fiber increase strength without adding weight. Conductive filaments, flame-retardant blends, and heat-resistant resins are also gaining traction in industrial use.

Multi-material printing lets you combine properties in a single part. You could print a component with a rigid core and a flexible exterior, or integrate conductive pathways directly into a structural piece. This reduces assembly steps and allows you to create parts that perform multiple functions.

In practice, multi-material systems are still more common in research and prototyping than in large-scale production. However, as software and hardware integration improve, you can expect broader adoption across industries that need complex, functional designs.

Large-Format and Desktop 3D Printers

Large-format 3D printing makes it possible to build full-scale prototypes, molds, and even end-use parts without assembly. These machines can print in thermoplastics, composites, or even metals, opening doors for aerospace tooling, automotive panels, and construction components. The trade-off is higher cost, slower build times, and significant space requirements.

On the other end, desktop 3D printers remain a reliable option for quick prototyping and small-batch production. They are affordable, compact, and versatile, with materials ranging from standard filaments to experimental resins. Many companies use desktop printers alongside industrial systems to test designs before scaling up.

By pairing large-format printers for production and desktop 3D printers for iteration, you can balance flexibility, cost, and speed in your workflow. This combination helps you move from concept to final part more efficiently while keeping development cycles shorter.

Market Trends and Industry Leaders

You can see how the 3D printing market is scaling quickly, shaped by rising investments, new materials, and the growing role of automation. At the same time, industry leaders continue to refine additive manufacturing solutions that fit into digital production systems and Industry 4.0 strategies.

Global 3D Printing Market Size and Growth

The global 3D printing market has moved beyond niche prototyping into large-scale manufacturing. In 2025, estimates place the market at around $23–24 billion, with projections reaching $100 billion+ by 2032. Growth rates vary by source, but most analyses suggest a strong CAGR between 17% and 23%.

You’ll notice that the expansion is not uniform across all regions. North America and Europe remain major hubs for adoption, while Asia-Pacific is rapidly scaling production capacity. This regional spread shows how additive manufacturing is becoming a global production tool.

Different segments of the market also grow at different speeds. Industrial printers dominate revenue, while desktop systems continue to expand in education and small-scale businesses. Materials like polymers still lead, but metals and alloys are gaining traction in aerospace and automotive applications.

Adoption Drivers and Industry 4.0

When you look at why companies adopt 3D printing, customization, rapid prototyping, and cost efficiency stand out. But the real shift happens when additive manufacturing integrates with Industry 4.0 technologies.

Machine learning and AI are increasingly used to optimize designs and predict material performance. You also see automation in post-processing, which reduces labor costs and improves consistency. The result is a more connected production chain where 3D printers operate alongside robotics, sensors, and digital twins.

Sustainability also drives adoption. By reducing material waste and enabling lightweight components, additive manufacturing supports greener supply chains. This matters in industries like aerospace, where efficiency and compliance with emissions standards are critical.

Notable Companies and Additive Manufacturing Solutions

Several companies lead the way in shaping the 3D printing market. 3D Systems and Stratasys remain pioneers, offering a wide range of industrial and professional printers. GE Additive focuses on metal printing for aerospace and energy, while SLM Solutions specializes in selective laser melting for high-performance parts.

Voxeljet stands out with large-format printers, often used in tooling and casting applications. Materialise plays a different role, providing software and services that help you manage workflows and scale production. Together, these firms represent the backbone of commercial additive manufacturing solutions.

These leaders continue to refine their technologies with better speed, accuracy, and material compatibility. As you adopt or expand 3D printing in your operations, their offerings often define the benchmarks for quality and reliability in the market.

- 5shares

- Facebook0

- Pinterest5

- Twitter0

- Reddit0