In robotic design and integration, joint motors serve as the core drive components, directly determining the system’s dynamic performance, load capacity, and control precision. With the widespread adoption of brushless DC motors (BLDC), developers are faced with a critical decision: whether to choose a standard flange-structured NEMA 42 BLDC motor, or opt for a non-standard outrunner BLDC motor structure.

This article will provide an in-depth analysis across multiple dimensions including structural characteristics, application scenarios, and performance comparisons.

Before we dive into the technical comparisons, let’s first examine two practical application scenarios. These will offer concrete guidance on how to choose suitable motors for different robotic joint needs.

Two Typical Joint Application Scenarios with Model Recommendations

To help engineers efficiently select robotic joint motors, we present two typical joint scenarios with specific parameters, structural advice, and recommended off-the-shelf motor models.

Scenario 1: Shoulder/Base Joint of Collaborative Robot Arm (6kg Load)

Applications: Educational arms, auto-sorting arms, multi-axis assembly robots

This joint typically bears the heaviest load, requiring stable output, high-precision control, closed-loop feedback, and gear integration.

- Recommended Structure: NEMA 42 Flange BLDC (internal rotor, with gearbox)

- Control Method: FOC vector control + encoder closed-loop

- Torque Range: 2.5 – 4.0 Nm (amplified through gearbox)

- Power Range: 400 – 600W

- Voltage Platform: 48V DC

Recommended Model (Available for Purchase):

- Model: 48V 1000W Brushless DC Motor

- Power: 1000W (with performance redundancy)

- Rated Torque: 3.18 Nm

- Speed: 3000 RPM

- Flange: 110mm (NEMA 42 compatible)

- Price: ~$415.85

- Options: Encoder support + FOC controller compatibility

Why Recommended:

This industrial-grade motor meets the torque demands of primary joints. When used with a 1:3~1:5 planetary gearbox, the output torque reaches 9.5–15.9 Nm, suitable for high-load arms. 48V compatibility supports standard controllers and is ideal for general industrial/educational platforms.

Supporting Components:

- Controller: 48V FOC BLDC controller (supports encoder feedback)

- Gearbox: 1:3 ~ 1:5 planetary gearbox (110 flange compatible)

Integration Tips: Reserve heat dissipation space and damping structures to optimize long-term performance and force feedback.

Scenario 2: Exoskeleton Arm Joint / Soft Robotic Finger Joint

Applications: Wearable assistive systems, rehab exoskeletons, bionic hands/feet

This use case requires high torque density in a small, lightweight form, often embedded along human joint paths.

- Recommended Structure: Outrunner BLDC motor, short shaft or direct-drive

- Control Method: Low-voltage DC + Hall feedback / custom FOC driver

- Torque Range: 0.4 – 0.6 Nm

- Power Range: 60 – 120W

- Voltage Platform: 24V DC

Recommended Model (Available for Purchase):

- Model: Frameless BLDC Outrunner Motor 130W

- Power: 130W

- Voltage: 24V

- Speed Options: 450 RPM / 1800 RPM

- Outer Diameter: 56mm

- Feedback: Hall sensor support

- Price: ~$181.56

Why Recommended:

This outrunner motor offers excellent torque density and startup response, suitable for exoskeleton joints or bionic fingers. Low voltage enhances safety and portability. Its frameless design allows flexible integration with custom brackets and sensors.

Supporting Components:

- Controller: 24V BLDC mini controller (Hall sensor compatible)

- Gearbox (Optional): 1:3 micro gear set (or soft-link drive)

Integration Tips: Use with a lithium battery pack or lightweight motor controller board for optimal system integration.

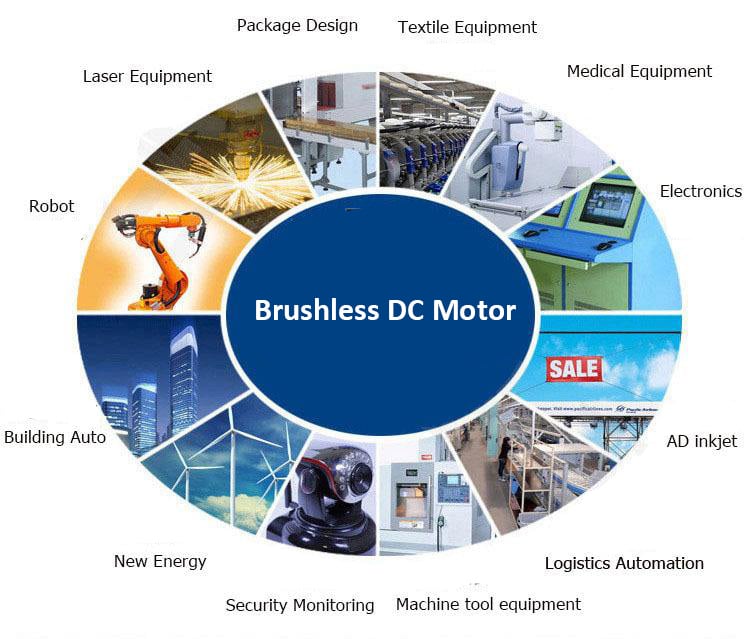

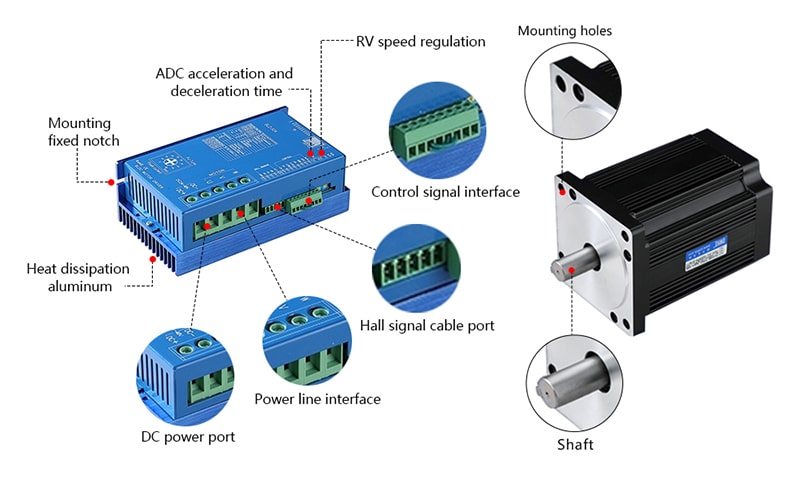

NEMA 42 BLDC Motor: Standardization Meets Controllability

NEMA 42 refers to a motor with a 110mm mounting flange, a widely used industrial standard interface. Originally popular in stepper motor applications, this specification has increasingly been adopted in BLDC motor systems for applications that require high precision, heavy loads, and versatile installation.

Key features of NEMA 42 flange BLDC motors:

- Unified dimensions, ideal for modular design and easy replacement

- Standard mounting, compatible with various gearboxes and robotic frames

- Support for encoders and Hall sensors, enabling closed-loop control

- Suited for high-inertia, heavy-load joints such as robot base axes or shoulder joints

NEMA 42 flange BLDC motors are ideal for collaborative robotic arms at shoulder/base joints, supporting encoder-based closed-loop control and industrial-grade standard structures.

This type of motor is well-suited for standard industrial robotic arms, particularly excelling in repeatability, structural reliability, and ease of maintenance.

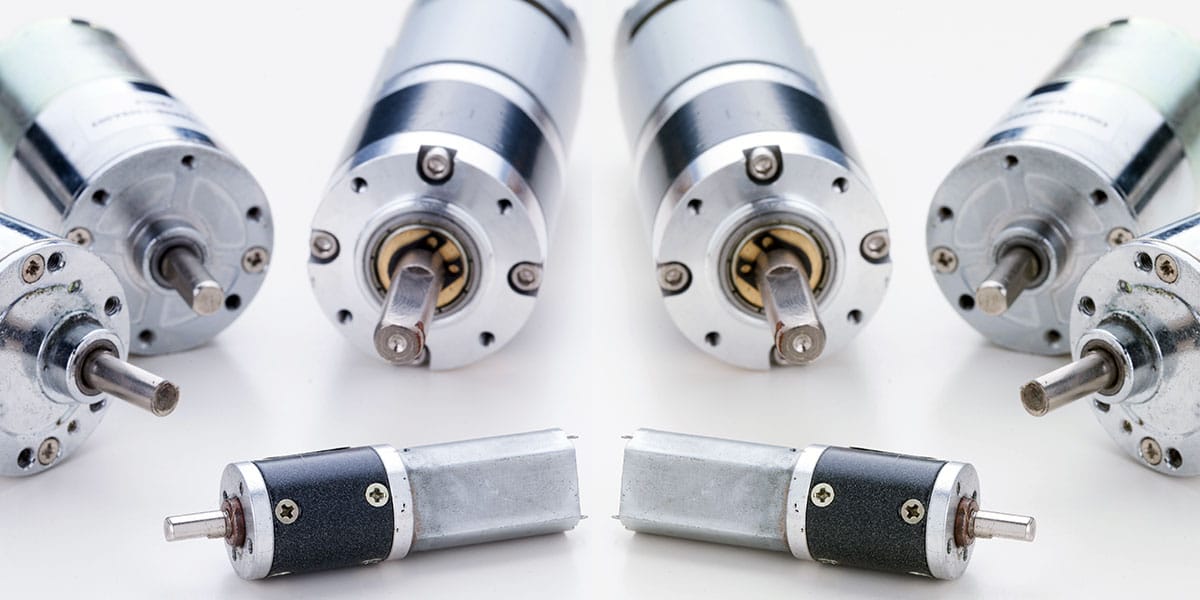

Outrunner BLDC Motors: Compact and High Torque-Density

Outrunner BLDC motors place the rotor on the outer shell, making the motor housing itself the rotating part. This design significantly enhances torque density, delivering high startup torque within a compact volume—ideal for space-constrained, responsive lightweight robotic joints.

Features of outrunner BLDC motors:

- Higher starting torque, suitable for direct-drive or low gear ratio designs

- Compact design, mass concentrated on the outer shell, facilitating wiring and integration

- Commonly used in lightweight robots, exoskeletons, and dexterous end-effectors

- Flexible control, suitable for custom FOC (Field-Oriented Control) systems

Outrunner BLDC motors are ideal for biomimetic finger joints, exoskeletons, and other space-constrained scenarios requiring high torque density and tight integration.

Motor Parameter Guidelines by Joint Application (Power, Torque, RPM)

To help users better match appropriate BLDC motors, the following table outlines typical parameters for common robot joints across various applications:

| Application Scenario | Joint Location | Recommended Power | Rated Torque Range | Recommended Speed | Encoder Recommended |

| Collaborative arm (<3kg payload) | Wrist / Elbow | 100–200W | 0.3–0.8 Nm | 1000–2000 RPM | Recommended |

| Collaborative arm (5–10kg) | Shoulder / Base | 300–600W | 1.5–4.0 Nm | 800–1500 RPM | Required |

| SCARA / Delta Robot | Main / Translation Axes | 200–400W | 1.0–2.5 Nm | 1500–3000 RPM | Optional |

| Bionic Hand / Exoskeleton | Finger / Small Joint | 50–120W | 0.1–0.5 Nm | 1000–3000 RPM | Recommended |

| Mobile Robot Steering | Servo Joint | 150–300W | 0.8–1.8 Nm | 500–1500 RPM | Optional |

Notes:

- Power and torque selection should consider reduction ratio, load weight, and control strategy

- For high-precision tasks, closed-loop BLDC motors with encoders are recommended

- Outrunner motors are better suited for low- to mid-power, compact, high-torque applications

- For large inertia or standardized interfaces, NEMA flange motors are preferable

Application Comparison and Selection Advice

When selecting robot joint motor structures, it’s crucial to consider load requirements, spatial constraints, wiring, control methods, and service life. The following table compares NEMA 42 BLDC motors and outrunner BLDC motors in joint applications:

| Dimension | NEMA 42 BLDC Motor | Outrunner BLDC Motor |

| Structural Standardization | High, easy to install and replace | Non-standard, custom mounting required |

| Starting Torque | Moderate | High, ideal for direct-drive |

| Installation Space | Larger footprint, fits open frames | Compact, easy to embed in joints |

| Heat Dissipation | Good, suited for continuous use | Moderate, thermal management needed |

| Control Method | Compatible with common servo drivers | Often requires custom FOC control |

| Target Applications | Medium-to-heavy load arms, industrial robots | Lightweight cobots, mobile platforms, biomimetic joints |

Recommendations:

- Choose NEMA 42 flange BLDC motors for projects emphasizing standardization, maintainability, and mass production

- Choose outrunner BLDC motors for projects that demand lightweight design, high integration, and rapid dynamic response. Pair with specialized FOC controllers for optimal performance

Price Expectations and Budget Advice

BLDC motor pricing for robotic joints depends on structure, voltage/power, encoder options, and whether an integrated driver is included. Below is a general market price range:

| Motor Type | Power Range | Typical Price Range (Unit) | Key Features |

| NEMA 42 BLDC | 300–800W | $80 – $160 | Industrial flange standard, high compatibility |

| Outrunner BLDC | 100–500W | $90 – $180 | High torque density, compact design |

| Closed-loop with Encoder | +10–30% | +$10 – $50 | For precise positioning and feedback control |

| Integrated Driver Model | +40–100% | +$50 – $120 | Simplifies integration and wiring |

Notes:

- Prices are based on MOQ ≥ 1, motor only (no gearbox or driver included)

- Custom specs (encoder resolution, temperature rating, IP rating) may increase cost

- It’s recommended to define budget early and choose from mature models to reduce risk and integration time

A typical collaborative robotic joint may use a 300W closed-loop BLDC motor priced around $100–$150, offering a good balance between cost and performance.

If budget allows, selecting an integrated-driver outrunner motor can significantly shorten development cycles, ideal for rapid prototyping and compact robot platforms.

Conclusion and Sourcing Recommendations

For robotic joint applications, whether selecting NEMA 42 or outrunner BLDC motors, the key is coordination between the motor, mechanical structure, and control system. If lacking experience in driver tuning or integration, it is recommended to prioritize mature, highly compatible products.

The two recommended products cover typical needs:

- 48V 1000W Brushless DC Motor (NEMA 42 Flange Series)

- Industrial standard, 1000W power, 3.18 Nm torque

- Ideal for high-load joints in collaborative robot arms

- Supports encoder feedback and common 48V control platforms

- Industrial standard, 1000W power, 3.18 Nm torque

- 130W Frameless BLDC Outrunner Motor (56mm OD Series)

- Outrunner structure, compact, high torque density

- Suitable for bionic hands, exoskeletons, and space-constrained applications

- Outrunner structure, compact, high torque density

For selection guidance, datasheets, sample requests, or integration documents, please contact our technical support team. We can assist with:

- Wiring diagrams

- Motor–driver matching suggestions

- 3D CAD files

- Prototype testing support

With proper selection and professional integration, BLDC motors can unlock greater performance and efficiency in robotic joints, empowering advanced, compact, and responsive robot systems.

- 0shares

- Facebook0

- Pinterest0

- Twitter0

- Reddit0