Every woodworker understands the need for precision. Whether you’re leveling a large slab or working on custom pieces, the right router sled can make your life a lot easier. But picking the best one depends on several factors.

Let’s break down what you should focus on when choosing a router sled for your projects.

Match Your Router Sled to Your Project’s Size and Material

Before picking a router sled, think about the size of your typical projects:

- Large slabs or resin pours require a bigger sled to handle weight and surface area without shifting. A router sled for flattening slabs is ideal for these types of jobs, as it provides the stability needed for even, precise results.

- Smaller pieces don’t need as much heft. A compact sled may give you more control.

The material you work with is just as important:

- Wood behaves differently than resin or other materials. A sled designed for wood might not work as smoothly on resin.

Make sure your sled is well-suited for the materials you handle regularly. The right match of size and material will ensure smoother, more precise work.

Select the Best Sled Material for Durability and Portability

Router sleds come in a few different materials, and each has its strengths and weaknesses:

- Steel sleds: Extremely durable but heavy, making them ideal for stationary setups where portability isn’t needed.

- Aluminum sleds: Strong yet lightweight. These are perfect for projects where you need to move the sled frequently or work in different locations.

- Plastic sleds: Lightweight and affordable but tend to wear out faster, especially under heavy use.

If you’re always on the move or working in multiple locations, an aluminum sled is a good middle-ground. If your work mainly happens in a shop and durability is a top priority, steel might be the better option.

Get the Right Size Sled for Your Work

Size is key when selecting a sled for your projects:

- Large slabs need a bigger sled to ensure even coverage. These sleds prevent uneven leveling, which is crucial when working with wide surfaces.

- Smaller jobs are better suited for compact sleds, which give you better control and maneuverability.

Some sleds are adjustable, meaning you can modify the size depending on your project. This added flexibility can be a time-saver, especially if you frequently switch between large and small tasks.

Look for Stability and Smooth Movement in a Sled

A stable sled is critical for getting accurate results. A sled that wobbles or shifts during use can ruin a project. Look for:

- A strong, rigid base that stays steady while you work.

- Smooth gliding movement across the surface, avoiding jerky or uneven motions.

- Well-built rail systems to ensure consistent, frictionless movement.

The smoother your sled moves, the easier it is to get a clean, even cut.

Precision and Accuracy in Woodworking

Achieving precise cuts and smooth finishes requires advanced measurement tools in woodworking. A linear encoder ensures accurate positioning and movement in router sleds, improving overall cutting precision.

Consider Portability if You Move Between Job Sites

If your work takes you to different locations, consider how portable your sled is. Heavy sleds can be difficult to transport, but some models are designed to break down easily for travel. Keep in mind:

- Heavy-duty sleds are great for stability but can be tough to move.

- Lighter sleds that break down into portable parts make traveling easier.

However, don’t sacrifice strength and stability for portability. The goal is to find a sled that balances ease of transport with the robustness needed for heavy work.

Choose the Right Type of Sled for Your Needs

Router sleds come in different designs, and each one serves a specific need:

- Fixed-size sleds: These are best if your projects are consistent in size. They offer stability but aren’t as adaptable if you frequently change project dimensions.

- Adjustable sleds: These give you more versatility, as they can handle a wider range of project sizes. They’re ideal if your work varies between large and small jobs.

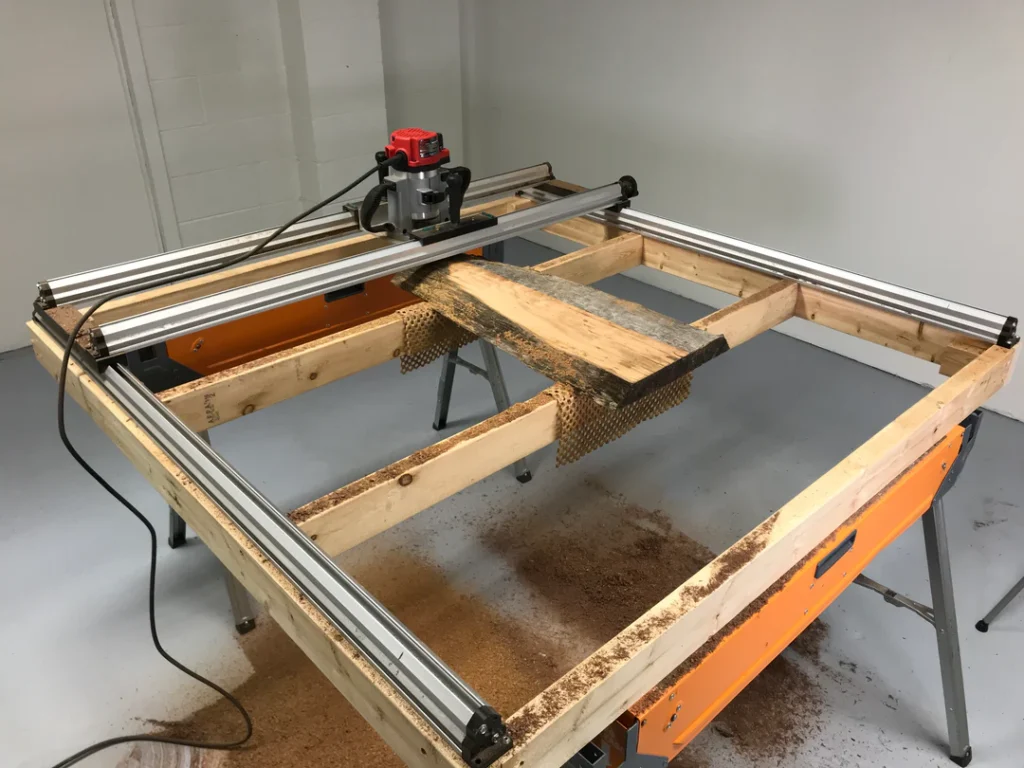

- DIY sleds: If you want something custom-built to your exact specifications, a DIY sled can be an option. It requires time and effort to build, but it allows for full customization.

Pick the type of sled that best matches the variety and size of your work.

Balance Cost with Features

Price often determines the quality and features of a router sled. Basic sleds are easier on the budget but may lack the durability or flexibility of more advanced models. On the other hand:

- Higher-end sleds typically offer smoother movement, better adjustability, and longer lifespan.

- Lower-cost sleds might be fine for simple tasks but may not hold up under frequent or heavy use.

Think of your sled as an investment in your work. Spending a bit more for a well-built sled can save you time and money in the long run.

Conclusion

Choosing the right router sled is about knowing what you need for your projects. Focus on the type of work you do, the material of the sled, its size, and how easy it is to use. A good router sled will help you complete your work faster, with more accuracy, and less frustration. Pick the right one, and it’ll be a reliable tool for years to come.

- 5shares

- Facebook0

- Pinterest2

- Twitter3

- Reddit0