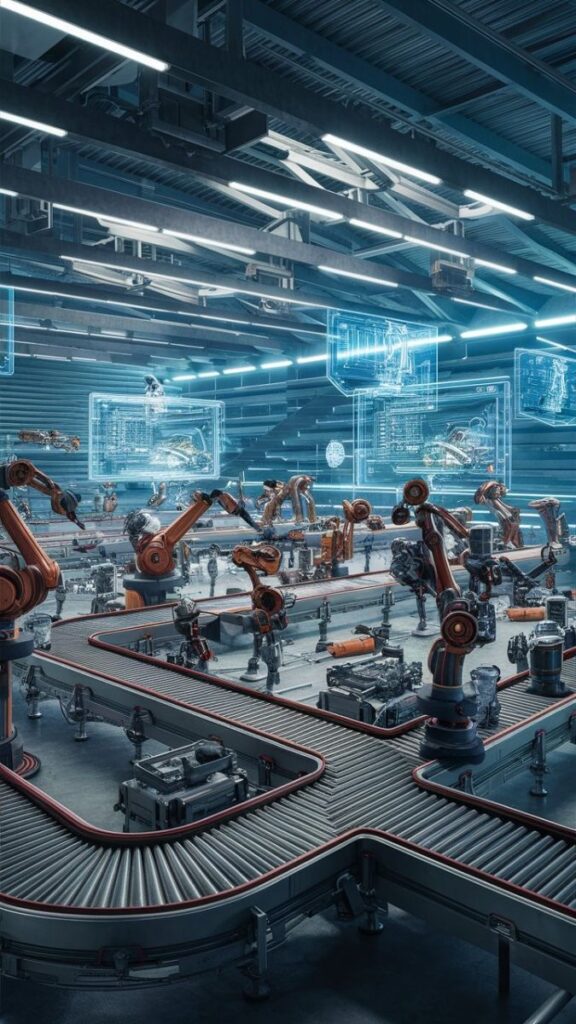

Robotics in production has moved far beyond simple machines on an assembly line. Today, you see robots handling complex tasks with precision, speed, and consistency that directly impact product quality and efficiency. Robotics in production helps you cut costs, improve safety, and adapt faster to changing demands.

You now work in an environment where automation is not just about replacing repetitive tasks but about creating smarter, more flexible systems. Robots equipped with sensors, AI, and collaborative features can work alongside people, boosting productivity while reducing risks. This shift is shaping how factories operate and how industries stay competitive.

By understanding how robotics integrates into production, you gain insight into the technologies driving modern manufacturing and the opportunities they create for growth and innovation.

Key Takeaways

- Robotics improves efficiency, safety, and quality in production.

- Smart automation enables flexible and adaptive manufacturing.

- Emerging trends show greater collaboration between humans and machines.

Core Technologies in Robotics for Production

You rely on several core technologies when applying robotics in production. These include the physical machines that perform tasks, the sensing systems that guide them, and the programming and automation tools that make them adaptable to changing needs.

Industrial Robots and Robotic Systems

Industrial robots form the backbone of modern production environments. You see them most often as robotic arms that weld, assemble, or package goods with high precision. These robots handle repetitive or hazardous tasks, reducing risks for human workers while maintaining consistent output.

Different robotic systems serve different roles. Articulated robots provide flexibility for complex movements, while SCARA robots excel at fast assembly tasks. Delta robots are used for high-speed picking and placing, and collaborative robots (cobots) safely share workspace with people.

Robots integrate with industrial automation networks, linking to sensors, controllers, and management systems. This allows you to coordinate multiple machines across a production line. When combined with AI-driven scheduling, robotic systems can adapt to production changes without requiring major downtime.

Sensors and Machine Vision

Robots depend on sensors to interact accurately with their environment. You will find force sensors, proximity detectors, and motion sensors built into many systems to ensure safe and reliable operation. These components help robots detect obstacles, measure torque, or align parts correctly.

Machine vision plays a critical role in quality control. Cameras and imaging software let robots inspect products for defects, measure dimensions, or verify alignment. This reduces errors and ensures consistent standards across high-volume production.

Advanced vision systems now use 3D imaging and AI-based recognition. With these tools, you can guide robots to handle irregular objects, sort mixed components, or adapt to variations in raw materials. This flexibility makes robotic systems more useful in industries where precision and adaptability are equally important.

Robot Programming and Automation

Robot programming determines how machines perform tasks. You can use traditional methods like teach pendants, where you guide the robot through motions, or offline programming, which allows you to simulate tasks on a computer before deployment. Both approaches help reduce trial-and-error on the production floor.

Automation frameworks expand what robots can do. By linking robots with Industrial Internet of Things (IIoT) systems, you enable real-time monitoring and coordination with other machines. This makes it easier to adjust workflows when demand shifts or when a machine needs maintenance.

Modern tools also include low-code programming platforms and graphical interfaces. These reduce the need for specialized coding skills, letting you reconfigure robots faster. As a result, production teams can adapt automation systems to new products or processes without long delays.

Key Applications of Robotics in Production

Robotics improves efficiency in repetitive tasks, increases precision in complex processes, and reduces risks in hazardous work environments. You benefit from faster operations, consistent results, and better use of human skills in areas that require judgment or problem-solving.

Assembly and Material Handling

You can use robots in assembly to handle repetitive part fitting, fastening, and component placement. This improves speed and ensures that every product matches the same standard. Robots also reduce strain on workers who would otherwise perform tasks that require constant repetition.

In material handling, robots move parts, raw materials, or finished goods across production lines. Automated guided vehicles (AGVs) and robotic arms streamline loading, unloading, and palletizing. This reduces delays and minimizes errors caused by manual handling.

Key benefits include:

- Reduced workplace injuries from heavy lifting

- Faster throughput with continuous operation

- Improved accuracy in part positioning

By combining assembly and material handling automation, you create a smoother flow of materials and parts across production stages.

Welding and Packaging

Robotic welding systems help you achieve consistent weld quality, even on complex or high-volume jobs. They maintain precise heat, angle, and speed, which reduces defects and rework. This is especially useful in industries like automotive and aerospace, where weld integrity is critical.

For packaging, robots handle tasks such as sorting, labeling, and boxing. They work at high speed while maintaining accuracy, which helps you keep up with demand. Automated packaging also reduces waste by using materials more efficiently.

You gain flexibility by programming robots to handle different product sizes and packaging styles. This adaptability means you can switch between product lines without major downtime.

Quality Control and Inspection

Robots play a growing role in quality control by using vision systems, sensors, and AI-driven analysis. You can rely on them to detect defects that are too small or subtle for the human eye. This ensures that only products meeting standards move forward.

Inspection robots check dimensions, surface finishes, and assembly alignment in real time. They provide consistent measurements that reduce variability in product quality.

A typical setup might include:

- Cameras for surface inspection

- Laser scanners for dimensional checks

- Sensors for detecting material flaws

By automating inspection, you reduce human error and maintain a higher level of consistency across production batches.

Human-Robot Collaboration and Safety

When you work alongside robots in production, safety and efficiency depend on how well humans and machines share tasks. Advances in collaborative robots and structured human-robot collaboration have made it possible to combine human judgment with robotic precision in shared workspaces.

Collaborative Robots and Cobots

Collaborative robots, often called cobots, are designed to operate directly next to you without the need for physical barriers. Unlike traditional industrial robots that require cages or restricted zones, cobots use built-in sensors, force limitations, and vision systems to prevent accidents.

You can program cobots more easily than older robotic systems, often through hand-guiding or intuitive interfaces. This makes them flexible for small-batch production, assembly, and packaging. Their ability to adjust speed and force in real time helps keep your workspace safer.

A few key safety features include:

- Force and torque limits to reduce injury risk.

- Emergency stop functions within easy reach.

- Proximity and vision sensors that detect human presence.

By combining these safety mechanisms with user-friendly programming, cobots let you focus on tasks that require problem-solving while the robot handles repetitive or heavy work.

Human-Robot Collaboration in Manufacturing

Human-robot collaboration (HRC) in manufacturing focuses on shared tasks where you and a robot contribute different strengths. Robots bring consistency, endurance, and accuracy, while you provide adaptability, decision-making, and fine motor skills.

In practice, this means you might guide a robot to handle heavy lifting while you perform delicate assembly. Gesture recognition, voice commands, and wearable devices like smart gloves or exoskeletons can further improve communication and safety.

To support safe collaboration, manufacturers follow standards such as ISO/TS 15066, which outlines limits for speed, force, and contact. These guidelines help ensure that when a robot works near you, the interaction remains safe and predictable.

When implemented carefully, HRC not only improves productivity but also reduces physical strain, creating a more balanced division of labor between you and the machine.

AI and Smart Automation in Production

You can now use artificial intelligence to make production systems more adaptive, reliable, and efficient. Smarter machines help you reduce downtime, improve quality, and adjust production lines to meet changing customer needs.

Artificial Intelligence and Machine Learning

Artificial intelligence and machine learning allow production equipment to process data and adapt without constant human oversight. Instead of following fixed instructions, machines can recognize patterns and adjust operations in real time.

For example, robots equipped with AI can detect errors in assembly or adapt to different materials. This reduces waste and improves consistency.

You also gain better control of complex workflows. By analyzing thousands of data points, machine learning models can recommend adjustments that improve speed and accuracy.

A simple comparison:

| Traditional Automation | AI-Enhanced Automation |

|---|---|

| Fixed rules | Adaptive learning |

| Limited flexibility | Adjusts to new inputs |

| Manual error detection | Automated error detection |

This shift lets you use machines not just for repetitive tasks but for decision-making support as well.

AI-Driven Automation and Predictive Maintenance

AI-driven automation goes beyond moving parts on a line. It enables systems to monitor performance and make small adjustments automatically. This reduces the need for manual intervention and keeps operations running smoothly.

Predictive maintenance is one of the most practical uses. By analyzing sensor data, AI can predict when a machine part is likely to fail. You can then schedule maintenance before breakdowns occur.

This approach saves you from costly unplanned downtime. It also extends the lifespan of equipment by preventing overuse or neglect.

Key benefits include:

- Reduced downtime through early detection

- Lower maintenance costs by avoiding emergency repairs

- Higher safety since machines are less likely to fail unexpectedly

With these tools, you can focus more on production goals and less on constant troubleshooting.

Customization and Flexible Manufacturing

AI supports flexible manufacturing by letting you adjust production lines quickly. Instead of reprogramming every machine manually, AI systems adapt to new product designs or variations.

This makes mass customization possible. You can produce small batches tailored to specific customer needs without slowing down the entire operation.

For instance, AI-guided robots can switch between assembling different product models with minimal downtime. Machine learning algorithms also optimize material use, reducing waste during changeovers.

You gain the ability to respond faster to market shifts. Whether it’s adjusting packaging, modifying product features, or scaling production up or down, AI helps you stay agile without sacrificing efficiency.

Industry-Specific Applications of Robotics

Robotics in manufacturing plays a different role depending on the industry. You see robots used to improve speed, accuracy, and safety in ways that directly match the unique demands of each production environment.

Automotive Industry

You encounter robotics in the automotive industry more than almost anywhere else. Nearly a third of all industrial robots worldwide operate in car manufacturing, and they handle tasks that require both precision and consistency.

Robots perform welding, painting, assembly, and quality inspection. These jobs demand accuracy that reduces errors and ensures consistent product quality. By automating these steps, you reduce production time while keeping safety risks lower for human workers.

In final assembly, robots assist with installing parts like seats, windshields, and electronic components. You benefit from the improved throughput and reduced downtime since robots can work continuously without fatigue.

A simple breakdown looks like this:

| Task | Benefit to Production |

|---|---|

| Welding | Stronger, consistent joints |

| Painting | Even coating, less waste |

| Assembly | Faster, repeatable processes |

| Quality Control | Early error detection |

Food and Beverage Industry

In the food and beverage industry, robotics focuses on hygiene, consistency, and handling delicate products. You rely on robots to package goods, sort items, and perform palletizing in environments that demand strict cleanliness.

Robots reduce direct human contact with food, helping you meet safety standards. They also improve speed in repetitive tasks like bottling, labeling, and sealing, which cuts down on processing time.

For fragile products such as baked goods or fresh produce, robotic grippers use soft-touch technology. This allows you to move items without damage, which is critical for maintaining quality.

You also see robots increasingly used for inspection tasks. Vision systems detect defects, ensuring that only products meeting quality standards reach your customers.

Laboratory Automation

In laboratory automation, robots help you manage repetitive and precise processes such as sample preparation, testing, and data handling. These tasks often require accuracy that manual work cannot consistently deliver.

You can automate pipetting, mixing, and plate handling, which saves time and reduces the chance of human error. This improves reliability in research and diagnostic testing.

Robots also allow you to scale up laboratory operations. For example, during high-demand periods, automated systems handle large volumes of samples without delays. This is especially important in pharmaceutical production and clinical testing.

By using robotics in laboratory workflows, you gain more consistent results, faster turnaround times, and greater efficiency in environments where precision matters most.

Emerging Trends and Future Outlook

You can expect robotics in production to keep evolving as demand grows for more adaptive systems and better integration with digital manufacturing. The focus is shifting toward scalable market growth and improvements in precision that allow robots to handle complex, variable tasks with greater reliability.

Market Trends in Robotics

You’ll notice steady growth in the robotics market as industries expand automation beyond automotive and electronics. According to recent reports, global industrial robot installations now exceed $16 billion in value, reflecting both higher adoption and more diverse applications.

Manufacturers are investing in collaborative robots (cobots) that can safely work alongside people. These systems reduce the need for rigid safety barriers and make automation accessible to smaller factories with limited floor space.

Another trend is the use of robotics in logistics and supply chains. Automated guided vehicles and robotic arms now handle packaging, sorting, and palletizing, helping you meet faster delivery expectations.

Key market drivers include:

- AI integration for adaptive decision-making

- Industry 4.0 and smart factories

- Labor shortages pushing automation adoption

These forces reshape how you plan production, making robotics a central part of cost control and efficiency.

Advancements in Precision and Flexibility

You benefit from robotics that now achieve higher precision through advanced sensors, machine vision, and AI-driven calibration. Robots can align components within microns, which supports industries like electronics and medical device manufacturing where accuracy is critical.

Flexibility has also improved. Instead of being locked into one repetitive task, modern robots switch between product variants with minimal reprogramming. This reduces downtime and supports shorter production runs without sacrificing efficiency.

Examples include:

- Adaptive gripping systems that handle irregular shapes

- Real-time feedback loops for error correction

- Multi-axis arms capable of delicate assembly

These advancements allow you to integrate robotics into more stages of production, from initial assembly to quality control, while maintaining consistent output.

- 0shares

- Facebook0

- Pinterest0

- Twitter0

- Reddit0