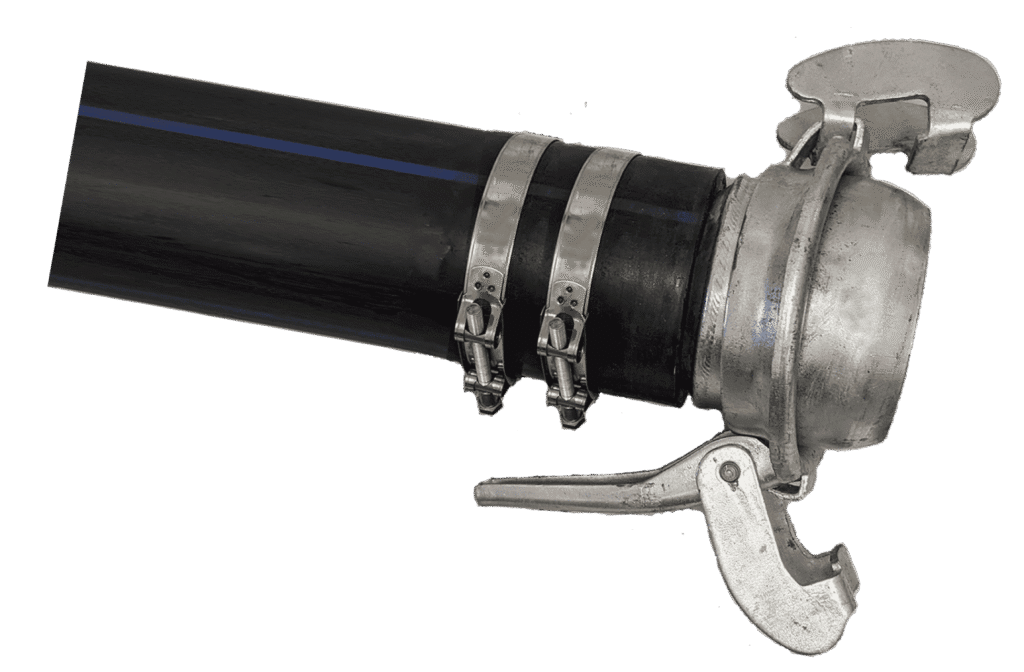

Source- Anaconda Pipe and Hose

Understanding DR11 Pipe: Composition and Core Advantages

In the world of industrial piping solutions, the DR11 pipe stands out for its unmatched combination of strength, flexibility, and chemical resistance. Designed to handle demanding conditions, the DR11 pipe—classified by its dimension ratio—offers superior performance in environments where corrosion, pressure, and chemical exposure are persistent threats.

What Is DR11 Pipe?

The term “DR11” refers to a dimension ratio (DR) of 11. This means the outside diameter of the pipe is 11 times greater than its wall thickness. As the DR number decreases, wall thickness increases, making the pipe stronger and more pressure-resistant. In practical terms, a DR11 pipe is thicker and stronger than a DR17 pipe of the same diameter.

DR11 pipe is typically made from high-density polyethylene (HDPE), a durable thermoplastic known for its corrosion resistance and long service life. HDPE DR11 pipe is frequently used in industrial settings due to its ability to maintain structural integrity under harsh conditions.

Core Advantages of DR11 HDPE Pipe:

- High pressure tolerance

- Excellent chemical resistance

- UV stability

- Flexibility in installation

- Leak-free fusion welding capabilities

DR11 Pipe Specifications and Performance Standards

When choosing piping for industrial systems, understanding the technical specifications is crucial. DR11 pipe specifications are standardized for consistency and reliability across a wide range of use cases.

Key DR11 Pipe Specifications:

- Material: High-Density Polyethylene (HDPE)

- Dimension Ratio: DR11

- Wall Thickness: 0.818 inches (for 8-inch OD pipe)

- Standard Lengths: Typically 40 ft or 50 ft, available in coils or sticks

- Joining Methods: Butt fusion, electrofusion, mechanical fittings

- Operating Temperature: Up to 140°F continuously (with derating for higher temps)

These specifications ensure that HDPE DR11 pipe can be seamlessly integrated into existing industrial systems, meeting both regulatory and operational requirements.

DR11 Pipe Pressure Rating: The pressure rating of DR11 pipe is one of its most critical performance metrics. Pressure ratings vary by pipe diameter and wall thickness, but generally:

- DR11 pipe can handle pressures up to 200 psi at 73°F (23°C)

- Pressure ratings decrease at elevated temperatures, based on derating factors

This rating makes DR11 pipe suitable for high-pressure applications, such as chemical transport, compressed air systems, and water conveyance in heavy industrial plants.

Compliance and Standards:

HDPE DR11 pipes typically comply with the following standards:

- ASTM D3035 (for pressure-rated polyethylene pipes)

- ASTM F714 (for non-pressure applications)

- NSF/ANSI 61 (for potable water)

- AWWA C906 (for municipal and industrial water systems)

Durability in Demanding Applications

The durability of polyethylene pipe, especially in DR-rated formats, is one of the reasons HDPE has replaced metal and concrete in many critical systems. DR11 pipe offers enhanced performance in the most demanding conditions, where durability is non-negotiable.

Polyethylene Pipe Durability: HDPE material boasts a long-term design life of 50 to 100 years, depending on application and exposure. DR11 pipes are particularly valued for their ability to:

- Absorb stress without cracking

- Resist long-term fatigue under cyclic pressure loads

- Maintain integrity in shifting or settling soil

Chemical-Resistant Pipe Systems: DR11 HDPE pipes excel in applications involving aggressive chemicals. Unlike metal pipes that corrode or degrade in acidic or caustic environments, HDPE offers robust chemical resistance, including:

- Acids (e.g., sulfuric, nitric)

- Alkalis (e.g., sodium hydroxide)

- Saline solutions

- Hydrocarbons (limited depending on concentration and temperature)

This makes DR11 an ideal choice for chemical manufacturing, wastewater treatment, and mining operations.

Corrosion-Resistant Pipe Performance: HDPE is inherently corrosion-resistant—unlike steel, it does not rust, pit, or scale. This eliminates internal degradation, ensuring smooth flow over time and reducing maintenance costs. DR11’s thick walls further reinforce its resistance to wear caused by particulates or abrasive slurries. To maintain this durability over decades of service, engineers often rely on advanced pipeline inspection tools to monitor structural integrity and detect potential issues early.

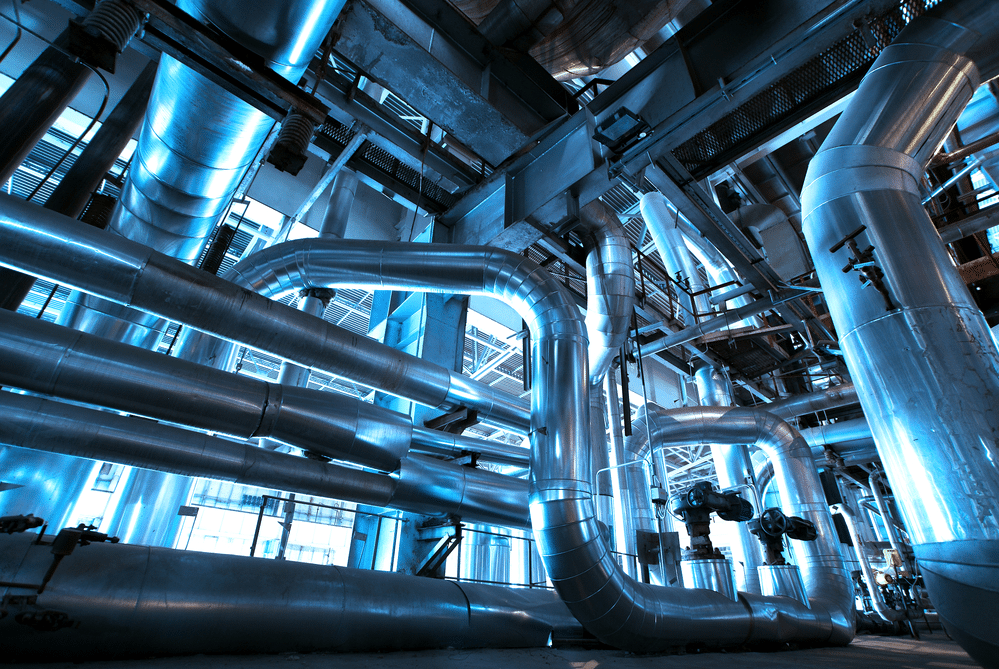

Applications in Harsh Industrial Environments

In harsh industrial environments, piping systems must withstand extreme pressures, aggressive chemicals, temperature swings, and mechanical stress. DR11 pipe is engineered to meet these demands across a broad range of industries.

Common Applications of HDPE DR11 Pipe:

- Mining Operations: For slurry transport and tailings disposal, where abrasion and chemical exposure are severe

- Chemical Processing: For transporting aggressive acids, bases, and solvents

- Oil & Gas: For water transport, chemical injection, and waste fluid management

- Power Generation: For cooling water, condensate return, and drainage systems

- Industrial Water Systems: Including raw water intake, filtration distribution, and effluent discharge

- Agricultural Irrigation: Where pressure and UV exposure are high

Environmental Challenges Addressed by DR11 Pipe:

- Elevated or fluctuating pressure

- Exposure to UV and ozone

- Soil movement and seismic activity

- High moisture or chemically aggressive environments

In each of these applications, the rugged design and flexible installation options of HDPE DR11 pipe provide an edge over rigid metal or concrete piping.

Why Choose DR-Rated HDPE Pipe for Industrial Use

Industrial systems demand high-performance materials that combine structural strength with resistance to environmental stressors. DR-rated HDPE pipe, particularly in the DR11 configuration, strikes this balance perfectly.

Key Benefits of HDPE Pipe for Industrial Use:

- Seamless Joints: Fusion-welded connections eliminate leak paths

- Flexible Installation: Can be directionally drilled, trenched, or slip-lined

- Lightweight: Easier to handle and transport than steel or ductile iron

- Low Maintenance: No corrosion means fewer replacements and less downtime

- Resilient: Can absorb ground movement and pressure surges

Why DR11 Stands Out Among DR Ratings: DR11 pipe offers one of the highest pressure ratings available in HDPE piping, making it ideal for:

- Systems with consistent high pressure

- Long-distance fluid transport

- Environments where pipe failure is costly or dangerous

Compared to DR17 or DR21, the DR11 pipe’s thicker wall provides greater peace of mind in critical applications.

DR11 vs DR17 Pipe: Which is Right for Your Project?

Selecting the right DR-rated pipe depends on several factors, including internal pressure, environmental conditions, installation method, and budget. Both DR11 and DR17 are widely used, but they serve different roles.

Comparison Table: DR11 vs DR17 Pipe

| Feature | DR11 Pipe | DR17 Pipe |

| Wall Thickness | Thicker | Thinner |

| Pressure Rating (73°F) | ~200 psi | ~125 psi |

| Weight | Heavier | Lighter |

| Flexibility | Less flexible | More flexible |

| Ideal Applications | High-pressure systems | Gravity flow, lower pressure |

| Cost | Higher | Lower |

Choosing Based on Application:

- Choose DR11 when your system operates under high pressure or involves chemical transport.

- Choose DR17 for lower pressure systems where flexibility or lower material cost is prioritized.

Ultimately, the choice comes down to balancing performance needs with project constraints.

Conclusion: Long-Term Value and Performance

When it comes to building reliable and long-lasting industrial systems, DR11 HDPE pipe sets a high standard. With superior pressure tolerance, excellent chemical resistance, and outstanding durability, DR11 pipe is purpose-built to thrive in the harshest environments.

Its combination of thick walls, corrosion resistance, and flexibility ensures minimal maintenance, long service life, and reliable operation even in extreme industrial settings. For engineers, plant operators, and project managers seeking a robust and cost-effective piping solution, DR11 pipe is a proven investment in long-term performance and operational security.

- 3shares

- Facebook0

- Pinterest0

- Twitter3

- Reddit0