I’ve seen how carbon fiber 3D printing changes what makers can build. By blending short carbon fibers into printable plastics, I can create parts that stay light but gain much greater stiffness and strength than regular filament.

Whether I print functional prototypes or end-use components, 3D printing carbon fiber opens doors to higher performance without switching to complex composite shop processes. This technology brings industrial-level properties to desktop and workshop printers, letting me push design limits while keeping production simple.

What Exactly is Carbon Fiber 3D Printing?

I use carbon fiber 3D printing when I need parts that weigh less but handle more stress. The process mixes carbon fiber with a plastic matrix so printed objects gain strength and stiffness without a big weight penalty. Carbon fiber itself is made of very thin, strong carbon filaments that reinforce the plastic much like steel rebar strengthens concrete.

There are two main ways I see carbon fiber added to prints:

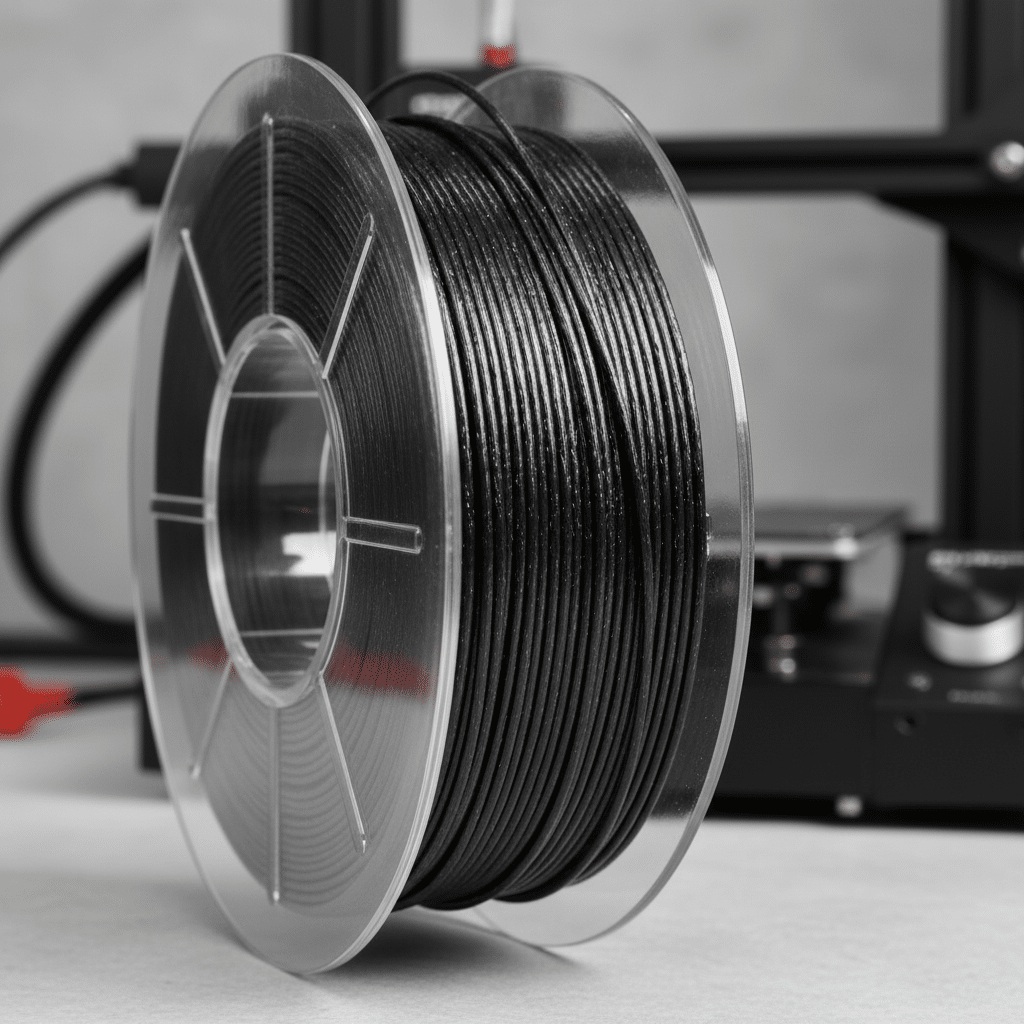

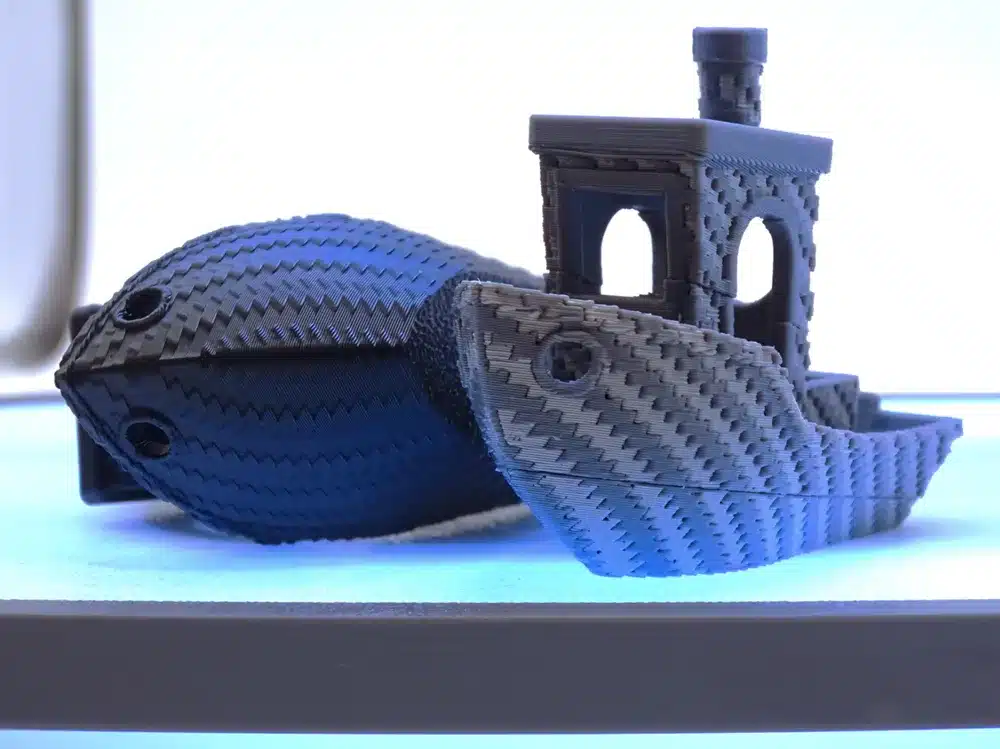

- Chopped carbon fiber: Short fibers are blended into a standard filament such as Nylon, PETG, ABS, or PLA. The tiny strands scatter through the melted plastic as it extrudes. This improves stiffness, reduces warping, and gives a matte, textured look. Chopped blends work on many desktop FDM printers and suit parts that need better mechanical properties than plain plastic.

- Continuous carbon fiber: Long, unbroken strands run through the part during printing. I can lay these fibers along load paths to make sections extremely strong and rigid—often rivaling metal in stiffness for certain shapes. Printing with continuous fiber needs specialized hardware and software, but it delivers the highest structural performance.

Key distinctions I keep in mind:

- Material: Carbon fiber adds reinforcement but the final part still depends on the polymer matrix for toughness and temperature resistance.

- Process: Chopped fiber is easy and widely available; continuous fiber is complex and optimized for high-strength uses.

- Properties: Both methods raise strength-to-weight ratio and dimensional stability, but continuous fiber gives far greater directional strength.

I often pair carbon fiber composites with design choices—like fiber orientation, wall thickness, and infill patterns—to get the best balance of weight, cost, and performance for the part’s intended function. For more background on the technology and material types, see an overview of carbon fiber 3D printing techniques (https://jlc3dp.com/blog/carbon-fiber-3d-printing).

Why Go Carbon Fiber? The Unbeatable Performance Edge

So, why bother with carbon fiber when regular plastics are so much easier to print? The answer lies in the dramatic boost in performance. Here’s why carbon fiber 3D printing is making waves:

Unmatched Strength-to-Weight Ratio

This is the holy grail for many engineers. Carbon fiber parts are incredibly strong for their weight. This means you can design lighter components that perform as well as, or even better than, heavier metal alternatives. For industries like aerospace, automotive, or drone manufacturing, every gram saved translates to improved efficiency and performance. Imagine a drone frame that’s lighter but can carry more payload, or a race car part that shaves off precious ounces without sacrificing structural integrity.

Exceptional Stiffness and Rigidity

Carbon fiber dramatically increases a part’s stiffness. While many plastics are flexible, carbon fiber composites resist bending and flexing, maintaining their shape even under significant loads. This makes them perfect for structural components, jigs, fixtures, and any application where precision and stability are critical. This rigidity helps prevent unwanted deformation, leading to more accurate assemblies and better long-term performance.

Enhanced Durability and Fatigue Resistance

Parts printed with carbon fiber are tougher. They can withstand repeated stress cycles and impacts much better than non-reinforced plastics. This durability extends the lifespan of components, especially in high-wear or high-stress environments. You’ll find these parts resisting cracks and breaks where standard plastics would fail.

Improved Temperature Resistance

Many carbon fiber reinforced filaments also boast higher heat deflection temperatures. This means your parts can perform reliably in warmer environments without deforming or softening. This is crucial for components near engines, in industrial machinery, or those exposed to direct sunlight.

Chemical Resistance

Depending on the base polymer, carbon fiber composites can offer enhanced resistance to various chemicals, oils, and solvents. This makes them suitable for use in industrial settings where exposure to harsh substances is common.

Dimensional Stability

One of the headaches with some 3D printing materials is warping or shrinking during cooling. Carbon fiber often reduces this tendency, leading to more dimensionally stable prints. The fibers help to lock the material in place, resulting in parts that are more accurate and consistent in size, which is a huge plus for tight-tolerance applications.

Technologies Bringing Carbon Fiber to Life in 3D Printing

Carbon fiber isn’t just a material; it’s an enhancement that integrates with various 3D printing processes. Understanding these technologies helps you choose the right path for your specific needs.

Fused Deposition Modeling (FDM) / Fused Filament Fabrication (FFF)

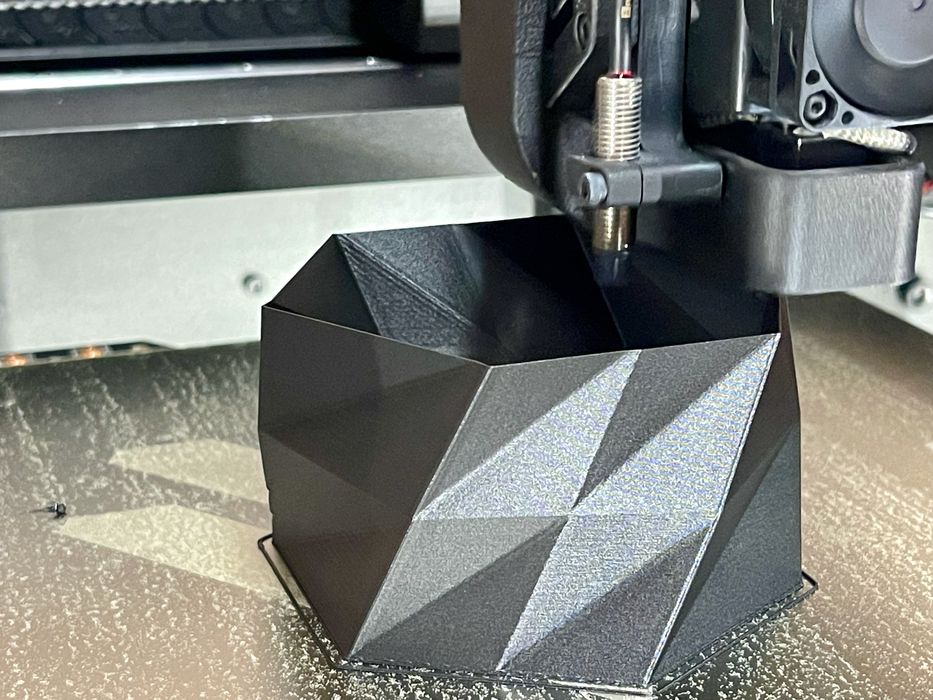

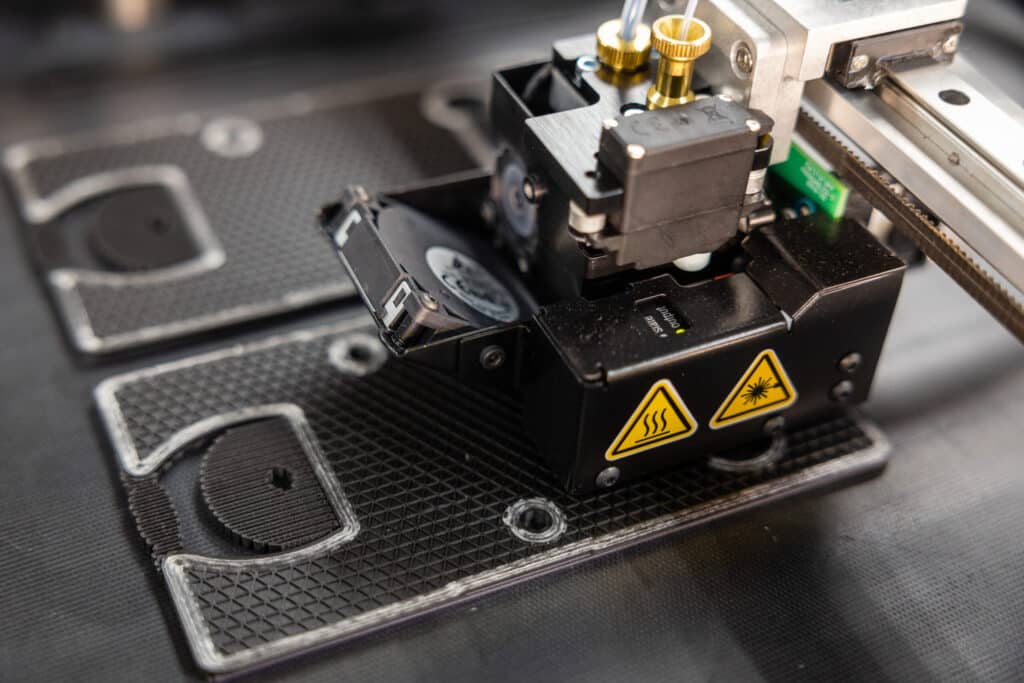

This is probably the most common type of 3D printing, and it’s where most people first encounter carbon fiber composites. FDM printers extrude molten filament layer by layer to build a part.

- Chopped Carbon Fiber (CCF) Filaments: As discussed, these are thermoplastic filaments (like Nylon, PETG, ABS) with short carbon fiber strands mixed in. They can be printed on many standard FDM printers, though with some upgrades. They offer a great balance of improved mechanical properties and relative ease of use. Brands like Markforged (Onyx series), MatterHackers (NylonX), and many others offer excellent CCF filaments. These are fantastic for making robust prototypes, custom tools, or even 3D printed cosplay props that need to withstand a bit of rough and tumble.

- Continuous Carbon Fiber (CFC) Printers: These specialized FDM machines take things to the next level. Instead of just melting plastic, they have a second nozzle (or a unique print head) that lays down continuous strands of carbon fiber alongside or within the thermoplastic matrix. This results in parts with incredible anisotropic strength – meaning they are strongest along the direction of the fiber reinforcement. Markforged is a pioneer in this space with their Industrial Series, allowing users to print parts with the strength of aluminum using composites. Anisoprint is another player with their Composite Fiber Coextrusion (CFC) technology. This is where you get truly high-performance, load-bearing parts.

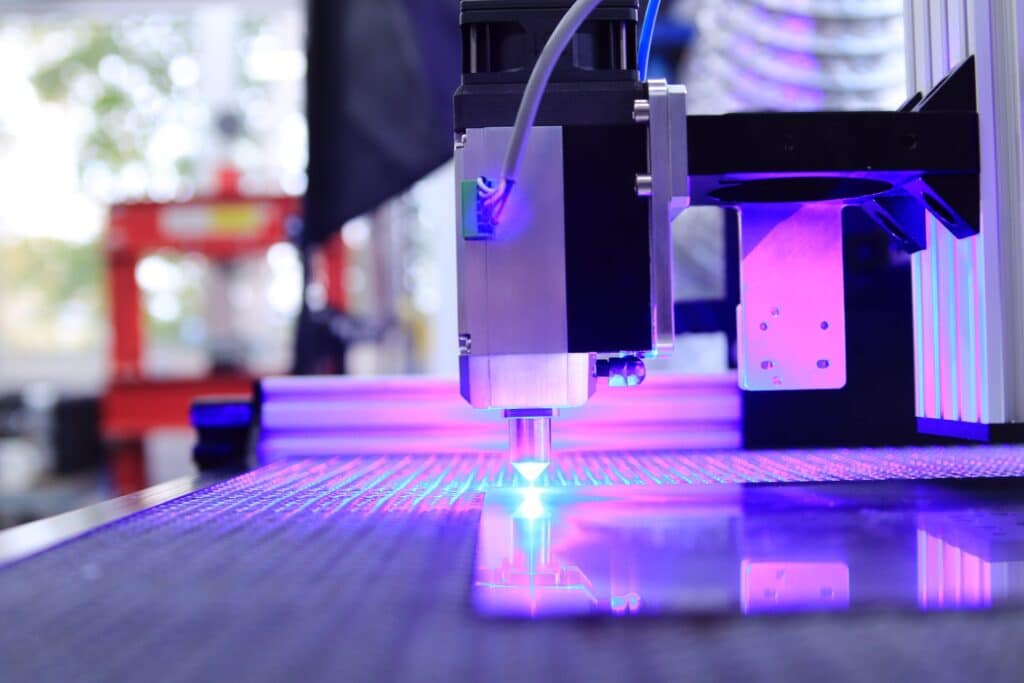

Selective Laser Sintering (SLS)

SLS printers use a laser to selectively fuse powdered material, layer by layer. For carbon fiber applications, specialized nylon powders infused with carbon fiber are used. The laser melts and sinters the carbon-filled nylon powder, creating incredibly strong, isotropic parts (meaning strength is consistent in all directions). SLS technology is known for producing parts with excellent surface finish and no need for support structures (the unfused powder acts as support), making it ideal for complex geometries.

Stereolithography (SLA) and Digital Light Processing (DLP)

While not as common for true carbon fiber reinforcement (due to the difficulty of suspending long fibers in resin and curing them with UV light), some SLA/DLP resins do incorporate ceramic or other reinforcing particles to enhance stiffness and strength. These aren’t carbon fiber in the traditional sense, but they aim for similar mechanical property improvements within the resin-based printing paradigm.

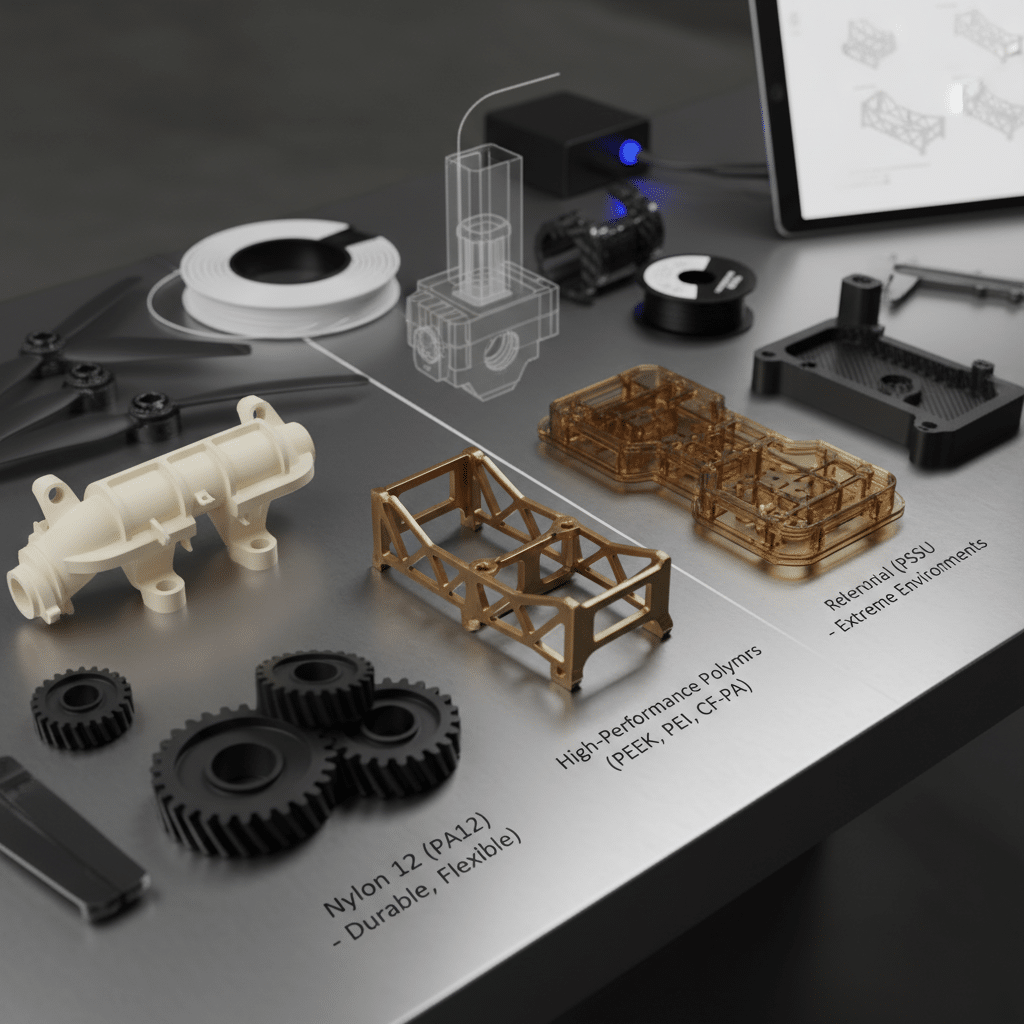

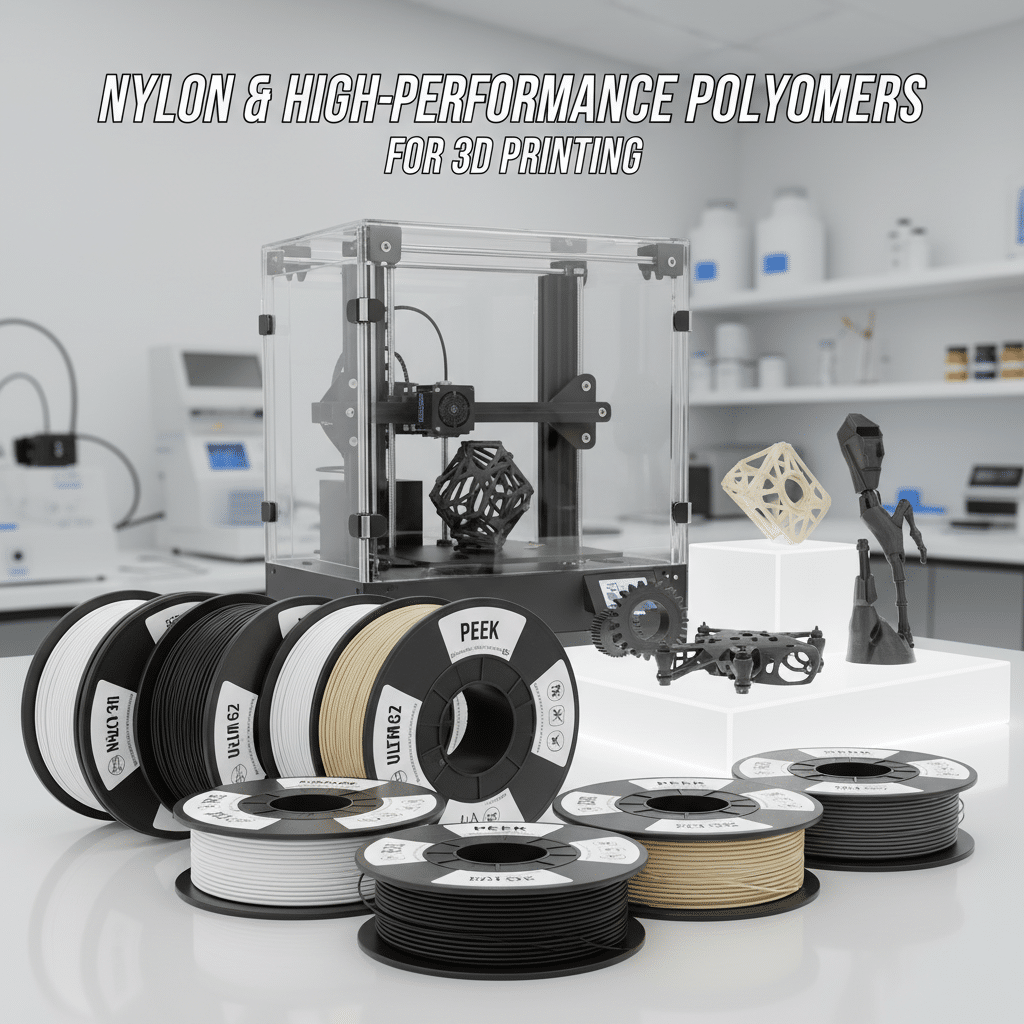

The Supporting Cast: Understanding the Polymer Matrix

I focus on the polymer matrix because it controls how chopped carbon fiber and other reinforcements behave inside a printed part. The matrix holds fibers in place, moves stress between them, and sets the part’s heat and chemical limits. Picking the right matrix material changes stiffness, strength, durability, and how easy the part is to print.

Bold polymers used with carbon fiber:

- Nylon (polyamide): I choose nylon when I need toughness and chemical resistance. Nylon carbon fiber blends (like nylon 11 CF) give high strength and stiffness while staying somewhat flexible. I watch for moisture and warping and dry filament before printing for best results.

- PETG: I use PETG-CF when I want a simple, forgiving option. It prints easier than nylon and resists warping while giving decent stiffness from the carbon filler.

- ABS: I pick ABS-CF for impact resistance and moderate heat tolerance. It works well for functional prototypes and lower-cost end-use parts.

- High-performance polymers (PEEK, PEKK, Ultem): I select these when I need extreme temperature resistance or chemical inertness. Combined with carbon fiber reinforcement, they make top-tier composite parts. They need specialized high-temperature printers and heated chambers.

Practical trade-offs I consider:

- Printability vs. performance: Filled plastics like nylon carbon fiber or nylon 11 cf often need careful drying and high nozzle temps. PETG blends ease printing but give lower max-temp performance.

- Stiffness vs. toughness: Carbon fiber reinforced matrices increase stiffness and strength but can reduce impact toughness unless the polymer remains ductile.

- Cost and equipment: High-performance polymers raise cost and demand advanced printers; ABS and PETG blends keep costs down.

Quick reference table

| Polymer family | Typical benefit | Common use |

|---|---|---|

| Nylon (CF) | Tough, chemical resistant, high strength | Drones, automotive parts |

| PETG (CF) | Easy to print, low warp | Entry-level functional parts |

| ABS (CF) | Impact resistant, heat tolerant | Prototypes, housings |

| PEEK/PEKK/Ultem (CF) | Extreme temp and chemical resistance | Aerospace, oil & gas |

I match the matrix to the application and printer capability so the carbon fiber composite performs as intended.

Where Carbon Fiber 3D Printing Truly Shines: Real-World Applications

I use carbon fiber 3D printing when I need parts that are both very strong and very light. In aerospace, I print jigs, fixtures, and lightweight brackets that cut weight without losing stiffness. I also make air ducts and small aerodynamic pieces that fit tight spaces and keep fuel use down.

In automotive work, I rely on 3D printed carbon fiber for rapid prototyping and for final parts on low-volume runs. I print custom brackets, air intakes, and trim pieces for performance cars and motorcycles. This lets me test designs fast and produce tailored carbon fiber parts without long lead times.

For robotics and drones, I choose carbon fiber parts to save weight and add strength. I print frames, arm components, and payload mounts so my robots move faster and drones fly longer. The material helps me make complex shapes that would be hard or costly with metal.

I turn to carbon fiber 3D printing for industrial tooling, especially jigs and fixtures. I can print a complex jig overnight that used to take days to machine. The result is lighter tooling that is easier for workers to handle and quick to swap during production changes. That speed matters when I need to keep lines running.

I also use 3D printed carbon fiber molds for low-volume production runs. Printing molds lets me test part geometry and make small batches without investing in expensive metal tooling. For short runs or bespoke pieces, 3D printed molds cut cost and time while still producing usable parts.

In sports gear, I print custom components like bike parts, protective gear supports, and racing drone frames. Athletes benefit from parts tuned to their size and style, and I can balance stiffness and comfort through design choices.

In medical applications, I print prosthetic sockets and orthotic supports that fit patients precisely. The lighter weight improves comfort and mobility. I also produce anatomical models for surgical planning where accuracy matters but implants aren’t involved.

For makers and high-end consumer goods, I create durable, premium-feel items that stand out. I design and print bespoke objects that combine aesthetics with performance, from custom housings to functional parts for hobbies.

Key advantages I rely on:

- Faster iteration: I can test multiple designs quickly.

- Strength-to-weight: Parts stay strong while shedding mass.

- Complex geometry: I make shapes that traditional methods struggle with.

- Cost-effective low-volume production: I avoid expensive tooling for small runs.

Bold design choices and careful print settings help me get the best from 3D printed carbon fiber. When I need jigs and fixtures, carbon fiber molds, or final carbon fiber parts in small batches, this approach often delivers the right mix of speed, strength, and savings.

For more detail on technologies and materials, I reference an industry guide to carbon fiber 3D printing that explains material blends and printer types in practical terms (https://3dspro.com/resources/blog/carbon-fiber-3d-printing-technologies-and-materials).

Getting Started: The Right Tools for Carbon Fiber 3D Printing

You’re excited, you’re convinced – now what? To jump into carbon fiber 3D printing, especially with chopped carbon fiber filaments, you’ll need a few key upgrades and considerations for your FDM printer.

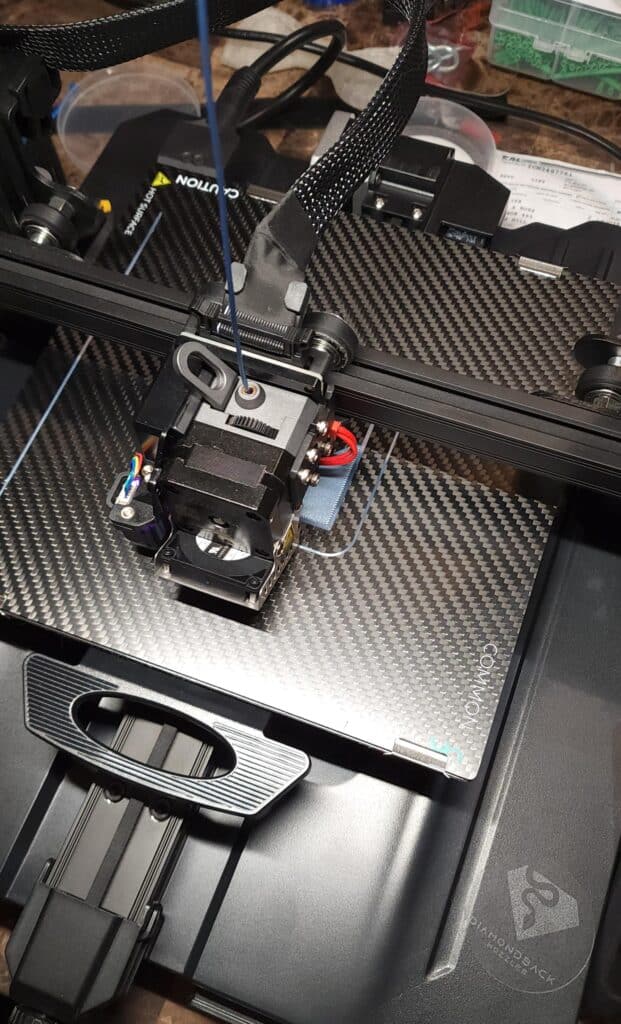

Essential Hardware Upgrades:

- Hardened Nozzle: Carbon fibers are abrasive. They will quickly wear down a standard brass nozzle, increasing the nozzle diameter and ruining print quality. You absolutely need a hardened steel nozzle, or even better, a ruby-tipped nozzle for extended life.

- Abrasion-Resistant Extruder Gears: Similar to the nozzle, the gears that drive the filament can also wear down over time. Look for hardened steel extruder gears to prevent grinding and ensure consistent filament flow.

- All-Metal Hotend: While not strictly mandatory for all CCF filaments, an all-metal hotend is highly recommended, especially if you plan to print with higher-temperature materials like Nylon-CF. It allows for higher printing temperatures without issues like PTFE degradation.

- Heated Build Plate: Most carbon fiber filaments, especially those with Nylon or ABS bases, benefit greatly from a heated bed to prevent warping and ensure good first-layer adhesion.

- Enclosed Printer: An enclosed build chamber helps maintain a stable temperature around your print, which is crucial for minimizing warping, particularly with engineering-grade filaments. If your printer isn’t enclosed, consider building a simple enclosure.

- Dry Box for Filament Storage: Carbon fiber composite filaments (especially Nylon-CF) are highly hygroscopic, meaning they absorb moisture from the air. This leads to poor print quality, weak parts, and stringing. Store your filament in a dry box and consider actively drying it before printing.

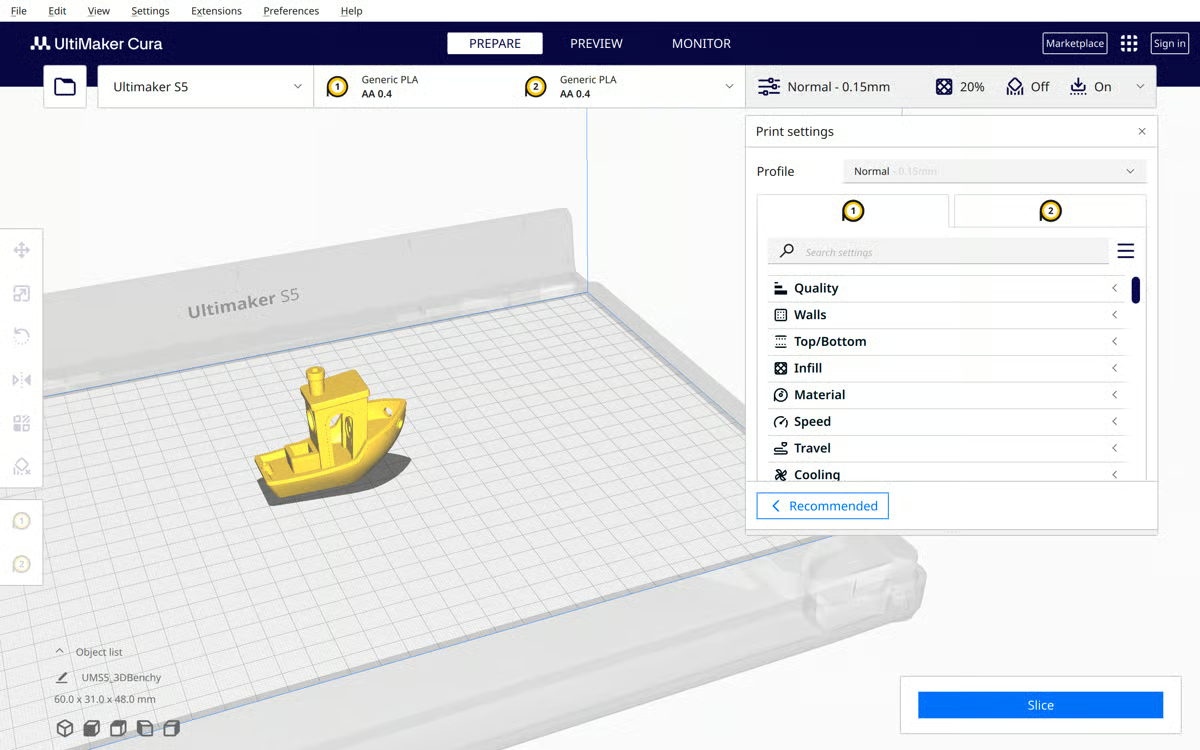

Slicer Software Settings:

Optimizing your slicer settings is just as important as having the right hardware.

- Temperature: Carbon fiber often requires slightly higher extrusion temperatures than the base plastic alone. Consult your filament manufacturer’s recommendations.

- Print Speed: While tempting to print fast, slower speeds generally yield better results and adhesion with carbon fiber, allowing the material to properly melt and bond.

- Layer Height: Finer layer heights (e.g., 0.15mm-0.2mm) can often produce stronger parts by ensuring better interlocking of the fibers between layers.

- Infill: Don’t skimp on infill. Higher infill percentages and specific patterns (like rectilinear or gyroid) can dramatically increase part strength.

- Retraction: Fine-tune retraction settings to minimize stringing, which can be more pronounced with some carbon fiber filaments.

- Support Structures: Carbon fiber parts can be stiff, making support removal sometimes challenging. Experiment with support interfaces and densities.

Navigating the Challenges of Carbon Fiber 3D Printing

While the benefits are clear, carbon fiber 3D printing isn’t without its quirks. Knowing these challenges upfront helps you prepare and overcome them.

- Abrasiveness and Wear: This is the big one. As mentioned, carbon fiber is incredibly abrasive. It will chew through brass nozzles and even standard steel components. Investing in durable hardware is non-negotiable. Regular inspection of your nozzle and extruder gears is a good practice.

- Warping and Bed Adhesion: Many carbon fiber composites, especially Nylon and ABS bases, are prone to warping, where corners lift from the build plate. A heated bed, an enclosed printer, and good bed adhesion (using adhesives like glue stick, PEI sheets, or specific adhesion sprays) are vital.

- Moisture Absorption (Hygroscopy): Filaments like Nylon-CF are like sponges for atmospheric moisture. Wet filament leads to steam bubbles during printing, resulting in weak, brittle, and aesthetically poor prints (bubbly, stringy surfaces). Proper filament drying (using a food dehydrator, filament dryer, or even a convection oven at low temps) and dry storage are absolutely essential.

- Cost: Carbon fiber filaments and the specialized printers/components for continuous fiber printing are generally more expensive than their plain plastic counterparts. Factor this into your project budget.

- Post-Processing: While carbon fiber prints often have a great matte finish, if you plan to sand or paint them, be aware that the fibers can create unique challenges. Sanding carbon fiber can release fine carbon dust, which is an irritant, so always use proper respiratory protection and ventilation.

- Safety Considerations: Printing with carbon fiber can release micro-particles and volatile organic compounds (VOCs). Always ensure your workspace is well-ventilated, and consider using an air purifier with a HEPA/carbon filter. Don’t breathe in carbon dust.

Tips for Success: Making Your Carbon Fiber Prints Shine

Ready to make some truly impressive carbon fiber prints? Here are some pro tips to help you succeed:

- Start Simple, Then Advance: Don’t jump straight to a complex, mission-critical part. Begin with smaller, less critical functional prints to dial in your settings and get a feel for the material.

- Dry Your Filament, Always: We can’t stress this enough. Even new, sealed filament can sometimes have moisture. Invest in a filament dryer or dehydrator. This one step can save you hours of troubleshooting and wasted material.

- Invest in Quality Hardware: A cheap hardened nozzle might seem like a bargain, but a high-quality one from a reputable brand will save you headaches in the long run. Good quality components ensure consistent results.

- Tune Your Retraction: Carbon fiber filaments can be prone to stringing. Spend time calibrating your retraction speed and distance to minimize this.

- Increase Nozzle Temperature Slightly: Often, carbon fiber filaments benefit from a slightly higher nozzle temperature than their non-CF counterparts. This helps the plastic flow better and ensures proper bonding between layers.

- Slow Down Your Print Speed: A slower print speed allows the material more time to heat up and bond, leading to stronger parts with better layer adhesion and fewer artifacts.

- Optimize Cooling: Too much cooling can cause warping, while too little can lead to poor overhangs. Experiment with your part cooling fan settings.

- Ensure Excellent Bed Adhesion: Don’t underestimate this. A failed first layer means a failed print. Use a reliable bed surface and appropriate adhesion aid for your chosen filament.

- Ventilate Your Workspace: Always print in a well-ventilated area. Consider an air filter. Your lungs will thank you.

- Consider Post-Processing: For aesthetic or functional finishing, remember that working with carbon fiber can be different. You might even consider using techniques like custom silicone molds to create smooth outer shells from your 3D printed masters, for instance, combining technologies for ultimate results.

- Join the Community: The 3D printing community is vast and helpful. Forums, social media groups, and online resources are great places to ask questions, share experiences, and learn from others who are also exploring carbon fiber printing.

The Future is Strong: What’s Next for Carbon Fiber 3D Printing?

The journey of carbon fiber 3D printing is just getting started, and the future looks incredibly strong and exciting. We can expect several key developments that will make this technology even more accessible and powerful:

- Material Innovations: Expect new polymer matrices that are even better suited for carbon fiber integration, offering enhanced properties like higher temperature resistance, greater flexibility where needed, or improved biodegradability. We’ll also see more specialized fibers beyond standard carbon, like basalt or aramid, opening up niche applications.

- More Accessible Continuous Fiber Printers: Currently, continuous carbon fiber 3D printers are a significant investment. As technology matures and adoption increases, we’ll likely see more affordable and compact options entering the market, democratizing access to near-metal strength 3D printing for smaller businesses and even advanced prosumers.

- Smarter Software and AI Integration: Slicer software will become even more sophisticated, with AI-driven optimization to automatically determine optimal fiber placement, print parameters, and even predict part performance. This will reduce the learning curve and allow for more efficient, robust designs.

- Broader Industrial Adoption: As the technology proves itself, more industries will integrate carbon fiber 3D printing into their supply chains for both prototyping and end-use part manufacturing. This will reduce reliance on traditional manufacturing methods for certain components, leading to faster innovation cycles. In fact, advanced manufacturing techniques, like those leveraging carbon fiber 3D printing, are becoming a key blueprint for success for many companies.

- Hybrid Manufacturing: We’ll see more integration of carbon fiber 3D printing with other manufacturing processes, such as combining it with traditional machining for critical surfaces or embedding electronics directly into printed structures.

Conclusion: Embrace the Strength of Carbon Fiber

Carbon fiber 3D printing isn’t just a trend; it’s a significant leap forward in additive manufacturing. It allows you to create parts with a level of strength, stiffness, and durability that was once reserved for expensive industrial processes. Whether you’re an engineer pushing the boundaries of design, a hobbyist looking to create truly robust functional prints, or a business seeking an edge in custom manufacturing, diving into carbon fiber printing is a rewarding endeavor.

It demands a bit more attention to detail, some specific hardware upgrades, and a willingness to learn, but the payoff is immense. You’ll gain the ability to produce lighter, stronger, and more resilient components that can withstand real-world challenges. So, if you’re ready to elevate your 3D printing game and unlock a world of high-performance possibilities, it’s time to explore what carbon fiber 3D printing can do for you. The future of strong, lightweight, and custom-made parts is here, and it’s built with carbon fiber.

FAQ

What is carbon fiber 3D printing?

Carbon fiber 3D printing involves using filaments or powders infused with tiny strands of carbon fiber, which significantly enhances the strength, stiffness, and durability of 3D printed parts by transferring the exceptional properties of carbon fiber to the components.

Why should I choose carbon fiber over regular plastics for 3D printing?

Carbon fiber provides an unmatched strength-to-weight ratio, exceptional stiffness, improved durability, higher temperature resistance, and better dimensional stability compared to standard plastics, making it ideal for high-performance applications.

What are the main forms of carbon fiber used in 3D printing?

The two main forms are chopped carbon fiber (CCF), which is short, dispersed fibers mixed into thermoplastics, and continuous carbon fiber (CFC), where long, unbroken strands are embedded within the polymer matrix during printing.

What technologies are used to incorporate carbon fiber into 3D printed parts?

Carbon fiber can be integrated into 3D printing through Fused Deposition Modeling (FDM/FFF) with CCF or CFC filaments, Selective Laser Sintering (SLS) with carbon-infused nylon powders, and resins in SLA or DLP processes with ceramic or reinforcing particles.

What hardware upgrades are necessary for 3D printing with carbon fiber filaments?

Essential hardware upgrades include a hardened steel or ruby-tipped nozzle, abrasion-resistant extruder gears, an all-metal hotend, a heated bed, an enclosed printer, and a dry box for filament storage to handle the abrasiveness and moisture absorption of carbon fiber composites.

- 0shares

- Facebook0

- Pinterest0

- Twitter0

- Reddit0