Most building renovations fall into one of two categories: the ones that make a space genuinely better to use, and the ones that just make it look different. The problem is that both can cost serious money, but only one of them pays back over time.

Walk through any recently renovated commercial building and you’ll see what this means. Fresh paint on the walls? That’s cosmetic. New flooring in the main corridor that won’t need replacing for another fifteen years? That’s functional value. Both might cost similar amounts upfront, but their impact on the building’s long-term performance couldn’t be more different.

Where Buildings Actually Break Down

The spaces that get hammered every day are the ones that determine whether a renovation was worth doing. Loading bays, stairwells, entrance areas, service corridors—these zones take more abuse in a month than a conference room sees in a year.

Here’s the thing: when these high-traffic areas start failing, they don’t just look bad. They become safety hazards, maintenance headaches, and eventual code violations. A worn-out stairway tread isn’t just ugly, it’s a liability waiting to happen. Floor surfaces that crack under constant weight create trip hazards and let moisture seep into the substructure.

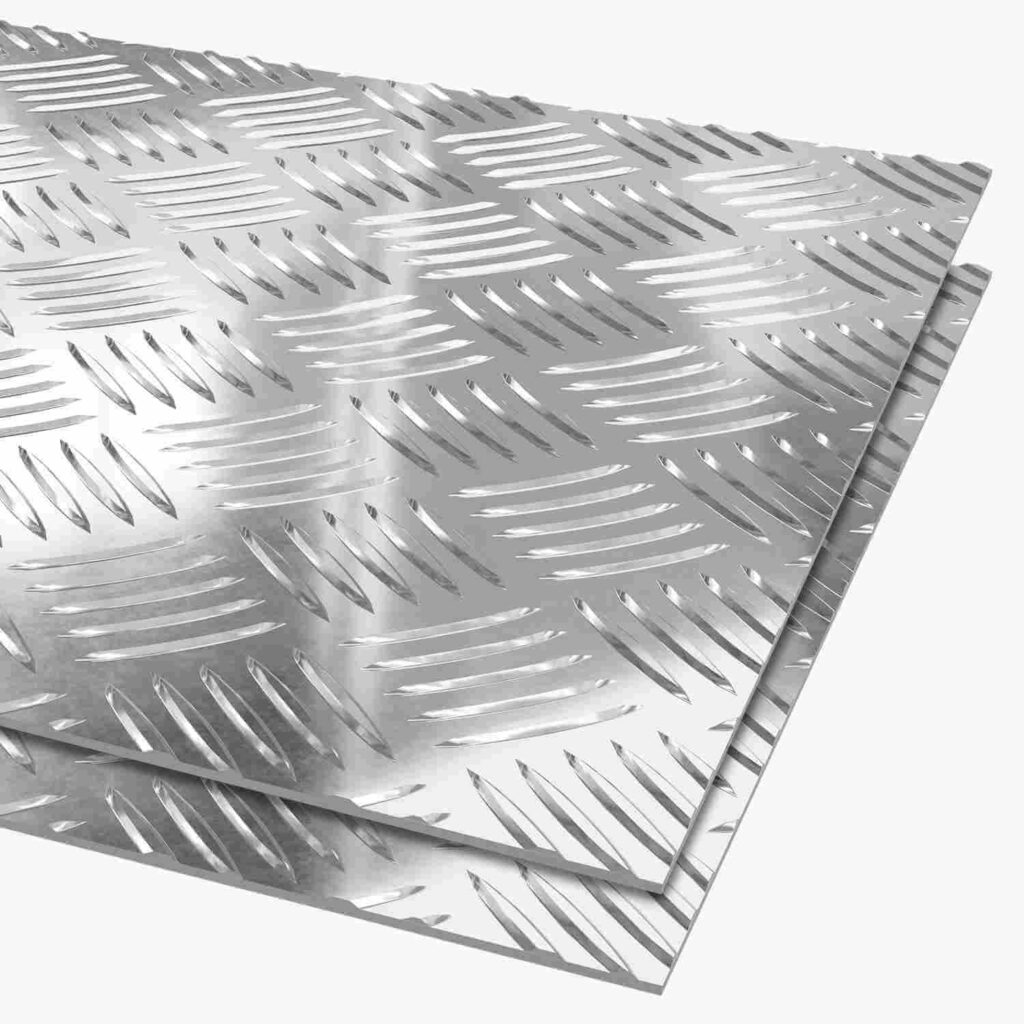

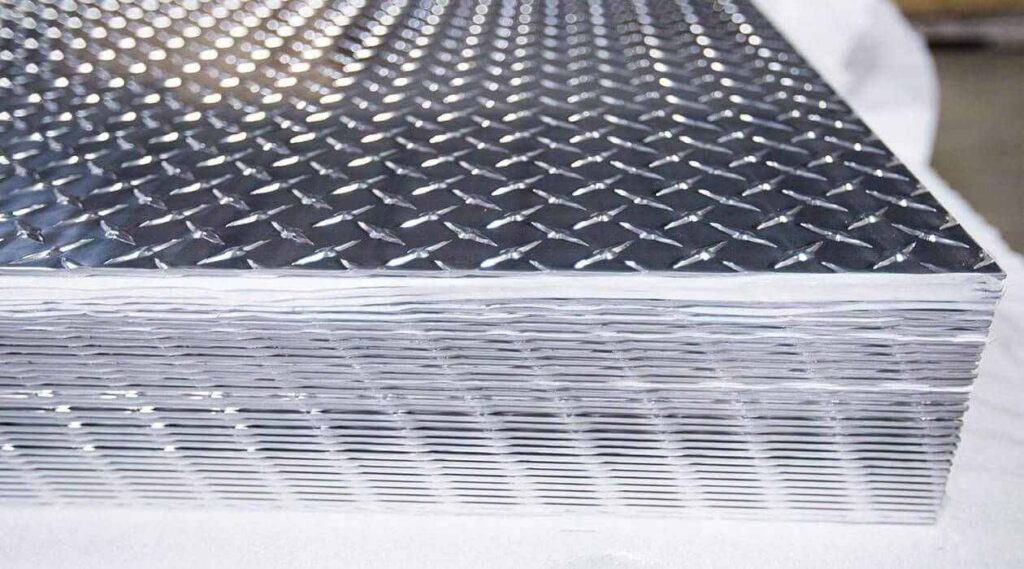

Smart renovation decisions focus on these pressure points first. Upgrading the surfaces that people walk on, work on, and move equipment across provides measurable returns. These improvements reduce slip incidents, cut down on repair callouts, and extend the time between major overhauls. When contractors choose lightweight aluminium checker plate solutions for stairs, platforms, or protective flooring, they’re making a decision that solves multiple problems at once—grip, durability, and reasonable installation weight—without the bulk of traditional steel alternatives.

Compare this to purely aesthetic changes. Replacing perfectly functional ceiling tiles with a trendier style might refresh the look of a space, but it doesn’t change how the building performs. Same goes for decorative wall panels in areas that don’t need protection, or elaborate lighting fixtures in locations where basic illumination does the job. These upgrades aren’t necessarily bad, but they don’t add the same kind of lasting value.

The Real Cost of Maintenance-Heavy Materials

Some renovation choices look great on installation day but turn into ongoing expenses within a couple of years. Materials that need regular treatment, surfaces that stain easily, finishes that chip or fade—all of these create a maintenance cycle that eats into operational budgets.

Timber cladding in outdoor or semi-exposed areas needs resealing every few years. Certain types of flooring require specialized cleaning products and techniques. Painted metal surfaces in damp or high-traffic environments start showing wear surprisingly quickly and need recoating to prevent corrosion.

The materials that hold their value are the ones that keep working without constant attention. Corrosion-resistant metals, sealed concrete, properly specified composite materials—these don’t need someone checking on them every season. They get installed, they do their job, and they’re still performing a decade later without intervention.

Accessibility and Code Compliance That Actually Matters

Building regulations exist for good reasons, and renovations that bring a structure up to current standards provide real value. The catch is knowing which compliance upgrades make a practical difference versus which ones are box-ticking exercises.

Slip-resistance improvements in wet areas, proper handrail installations, adequate lighting in exit routes—these all improve how people use a space while meeting legal requirements. They prevent accidents, reduce insurance claims, and make the building more usable for everyone who enters it.

On the other hand, some compliance work is mandatory but doesn’t change the day-to-day experience much. Fire door replacements might be required by updated codes, but they don’t necessarily improve how the building functions for its occupants. Still necessary, just not the same kind of value-add.

The renovations worth prioritizing are the ones that solve current problems while satisfying regulations. Upgrading a loading bay surface to meet modern slip-resistance standards while also increasing its load capacity? That’s a double win. Installing new emergency lighting that also improves general visibility in a previously dim corridor? Smart thinking.

When Weight Actually Matters

This doesn’t get talked about enough: the weight of renovation materials can determine whether a project is straightforward or becomes a structural engineering nightmare. Adding heavy floor protection or thick steel plating to an existing structure might require reinforcing the underlying supports, which multiplies costs and complexity.

Lighter alternatives that provide similar protection make renovations far more manageable. They reduce the load on existing structures, simplify installation logistics, and often cut down on labour time since crews aren’t wrestling with unwieldy pieces. This matters especially in multi-story buildings where getting heavy materials up flights of stairs or into service lifts creates bottlenecks.

The Longevity Factor

Buildings that still look respectable twenty years after a renovation share common characteristics. They used materials that age well, put protection where it was actually needed, and avoided trendy choices that would look dated quickly.

The trick is distinguishing between timeless function and temporary style. A well-installed metal tread on a busy staircase will still be doing its job two decades from now, probably looking much the same as it did on day one. A decorative wall treatment that seemed cutting-edge in 2025 might look embarrassingly dated by 2035.

This is where the value calculation really shows itself. Functional upgrades keep delivering their benefits year after year. Purely aesthetic choices start losing their appeal the moment design trends shift, and buildings end up getting renovated again just to update their look.

Making the Call

The best renovation decisions aren’t about choosing function over form entirely. They’re about putting the functional budget where it matters most, then adding aesthetic touches where they won’t create maintenance problems or date quickly.

Start with the areas that take punishment. Fix the surfaces that people interact with constantly. Upgrade the zones where safety is a concern. Get those right, and the building immediately becomes more valuable to own and operate.

After those priorities are covered, aesthetic improvements make more sense. But even then, choosing durable finishes and classic approaches tends to work better than chasing whatever’s trendy right now.

Buildings that get this balance right end up being pleasant to look at and cheap to maintain. The ones that prioritize appearance over function end up needing another round of renovations sooner than anyone expected, and that’s when the real costs start adding up.

- 0shares

- Facebook0

- Pinterest0

- Twitter0

- Reddit0