Green industrial design focuses on creating products and systems that reduce harm to the environment. It aims to use resources wisely while minimizing waste and pollution throughout the entire product life cycle. This approach helps companies build more sustainable products that are better for the planet and people.

The process involves using materials that are renewable or recycled and designing products that last longer and use less energy. New technologies and smart design choices make it possible to meet these goals without sacrificing quality or function. Many industries now follow rules and standards to ensure their products meet green design requirements.

This shift to greener methods can be challenging but brings benefits like cost savings and improved brand reputation. Companies that invest in green industrial design are shaping the future of manufacturing in a more responsible way.

Key Takeaways

- Green design reduces environmental impact through smart resource use.

- New tools and materials make eco-friendly products possible.

- Meeting green standards helps companies stay competitive and responsible.

Principles of Green Industrial Design

Green industrial design focuses on reducing environmental impact through careful choices in materials, energy use, and waste management. It also involves assessing the entire product lifecycle to identify areas for improvement.

Sustainable Material Selection

Sustainable material selection means choosing resources that have a low environmental footprint. Designers often prefer renewable or recycled materials to reduce the need for virgin resources. For example, using bamboo or recycled aluminum helps conserve forests and mines.

Materials that require less energy to produce or create lower pollution are also favored. Biodegradable plastics and natural fibers can break down without harming the environment. Designers avoid toxic substances that could harm workers or users.

Sustainable material choices must balance durability and impact. The goal is to extend the product’s life while minimizing waste.

Energy Efficiency in Manufacturing

Energy efficiency involves using less power during production to reduce greenhouse gas emissions. Manufacturers may switch to renewable energy sources like solar or wind power.

Efficient machines and processes can cut energy use significantly. For example, optimizing machine speed and reducing downtime help save electricity. Some factories use heat recovery systems to reuse waste heat.

Process improvements such as additive manufacturing (3D printing) reduce material waste and energy costs. The focus is on producing goods with the smallest energy footprint possible.

Lifecycle Assessment Techniques

Lifecycle assessment (LCA) evaluates the environmental impact of a product from raw material extraction to disposal. It helps identify stages with the highest impact.

An LCA looks at energy consumption, emissions, water use, and waste over the product’s life. Designers use this data to make choices that reduce overall harm to the environment.

Tools like software models help analyze supply chains and material flows. This assessment supports continuous improvement towards greener products.

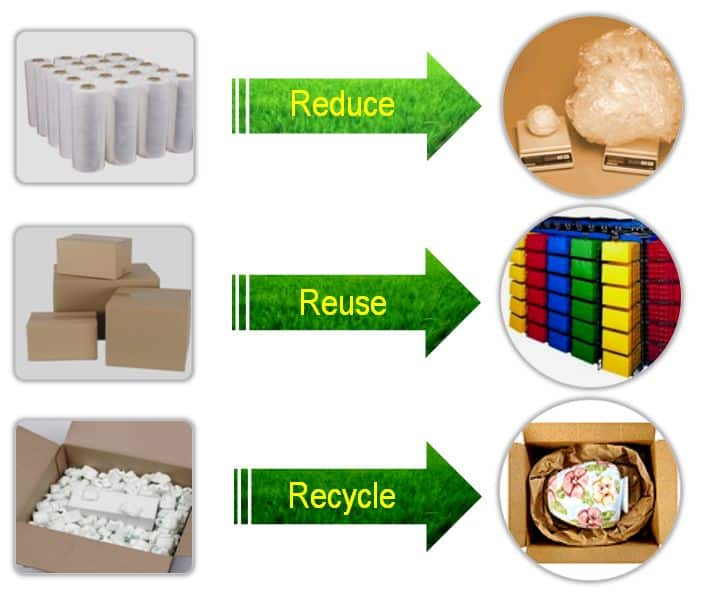

Waste Reduction Strategies

Waste reduction aims to minimize materials discarded during and after production. Strategies include designing for easy disassembly and recycling.

Manufacturers reduce scrap by improving precision in cutting and molding. Reusing by-products or defective parts lowers total waste.

Designers also avoid unnecessary packaging and select recyclable or compostable materials. Limiting waste not only protects the environment but also cuts costs.

Eco-Friendly Product Development

Developing eco-friendly products means designing them to be easier to take apart, fix, and recycle. It involves planning so that parts can be separated without waste. Using materials that can be reused or broken down helps reduce environmental impact.

Design for Disassembly

Design for disassembly focuses on making products easy to take apart. This helps when products need repair or recycling. By using screws instead of glue or welding, parts can be separated without damage.

Products designed this way support longer use. When a part breaks, it can be replaced without throwing the whole item away. This reduces waste sent to landfills.

Companies often label parts or include instructions to help users disassemble safely. This approach also makes it easier to sort materials for recycling, which saves resources.

Modular Design Approaches

Modular design splits a product into smaller, independent units or modules. Each module can work alone or be swapped out without changing the entire product.

This method allows easy upgrades or repairs. For example, a phone with modular parts lets users replace a camera or battery without buying a new device.

Modular design supports customization and reduces waste. Instead of discarding the full product, only outdated or faulty modules are replaced.

Recyclable Component Integration

Using recyclable components means choosing materials that can be reused or broken down naturally. Common choices include certain plastics, metals, and glass.

Manufacturers aim to integrate these materials to simplify processing after use. Clear labeling of components as recyclable helps recycling facilities handle them correctly.

Integrating recyclable parts reduces the need for extracting raw materials. It also lowers pollution by keeping waste out of landfills and incinerators.

Innovative Technologies in Green Industrial Design

Green industrial design uses new tools and methods to reduce waste, save energy, and use resources better. It focuses on practical ways to make manufacturing cleaner and smarter.

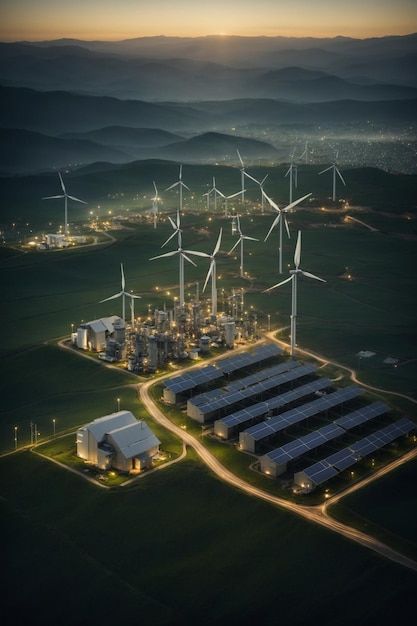

Renewable Energy Implementation

Many green designs now rely on renewable energy sources like solar, wind, and geothermal power. Factories use solar panels or wind turbines to cut down on fossil fuel use. This lowers carbon emissions significantly during production.

Some companies install solar roofs or off-grid microgrids to run machines directly with clean energy. This reduces reliance on traditional electricity grids, which often depend on coal or natural gas.

Energy storage systems like advanced batteries help store extra renewable power. This keeps production steady when sunlight or wind is low. Using renewables reduces energy costs and environmental impact.

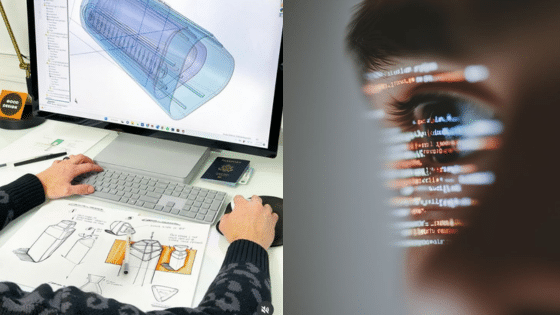

Advanced Manufacturing Methods

Advanced manufacturing focuses on cutting waste and energy use during production. Techniques like 3D printing create products layer by layer, using only the material needed. This reduces leftover scraps.

Robotics and automation improve precision, lowering errors that cause waste. Machines can reuse leftover material immediately, making processes more efficient.

Another method is additive manufacturing, which builds objects in a controlled way to reduce excess parts. This saves raw materials and energy. These technologies help companies meet environmental standards without harming productivity.

Smart Resource Management

Smart systems control water, energy, and materials in real time. Using IoT sensors, factories track resource use and detect leaks or inefficiencies quickly. This prevents waste and reduces costs.

Data analytics helps managers make better decisions about inventory and production schedules. For example, they can avoid overordering materials or using excess energy during peak hours.

Some facilities use closed-loop recycling, where waste products are collected and reused within the plant. This minimizes landfill waste and cuts raw material needs.

| Feature | Benefit |

|---|---|

| IoT Sensors | Real-time monitoring |

| Data Analytics | Improved resource use |

| Closed-loop Recycling | Waste reduction and reuse |

Regulations and Standards

Green industrial design follows specific rules and certifications to ensure products are eco-friendly. It also requires companies to follow environmental laws strictly. These measures guide designers and manufacturers to reduce harm to nature and promote sustainability.

Global Sustainability Certifications

Global certifications help show if a product meets green standards. The most known certifications include LEED, Energy Star, and Cradle to Cradle.

- LEED (Leadership in Energy and Environmental Design) focuses on buildings and materials that save energy and water.

- Energy Star rates products like appliances and electronics based on energy efficiency.

- Cradle to Cradle certifies products that are safe for human health and can be reused.

Companies use these marks to prove their commitment to sustainability. These certifications make it easier for consumers to choose greener products.

Compliance With Environmental Legislation

Green design also requires obeying laws made by governments to protect the environment. These laws control pollution, waste disposal, and resource use.

Examples include:

- REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) in Europe controls harmful chemicals.

- EPA regulations in the United States set limits on emissions and waste.

- Waste management laws require proper recycling and disposal.

Following these laws helps companies avoid fines and supports cleaner production. It also pushes innovation for safer materials and processes.

Challenges in Green Industrial Design

Green industrial design faces specific difficulties that affect its effectiveness and adoption. These challenges mostly involve managing costs while maintaining eco-friendly goals, and finding the right materials that meet environmental standards.

Balancing Cost and Sustainability

Keeping costs low while designing sustainably is a major challenge. Eco-friendly materials and processes often cost more than traditional options. This can make it harder for companies to choose green methods, especially small businesses with limited budgets.

Designers must find ways to reduce waste and energy use without raising product prices too much. They often use life cycle analysis to balance environmental benefits against expenses. This helps decide when the extra cost of green design pays off over time.

Savings in energy or materials during production can offset initial expenses. However, upfront investment remains a barrier. Incentives or regulations sometimes help make these designs more practical and appealing.

Sourcing Eco-Conscious Materials

Finding materials that are both sustainable and suitable for manufacturing is tough. Not all green materials meet the strength, durability, or safety needs of industrial products.

Designers look for recycled, biodegradable, or low-impact resources. However, supply chain issues can limit availability. Some regions have few suppliers for eco-friendly materials. Others may face delays or higher prices.

Certifications like FSC for wood or GOTS for textiles help ensure materials meet environmental standards. But verifying these claims demands extra effort and cost.

Designers must carefully test new materials to ensure performance. This can slow down production and increase development time. Balancing material quality with green credentials remains a key hurdle.

Case Studies of Sustainable Industrial Design

Sustainable industrial design focuses on reducing environmental impact through innovation and responsibility. Below are examples that show how specific products and companies apply green design principles effectively.

Industry-Leading Green Products

One example is the Fairphone, a smartphone made with recyclable materials and designed for easy repair. It uses conflict-free minerals and modular parts, which extend its life and reduce electronic waste.

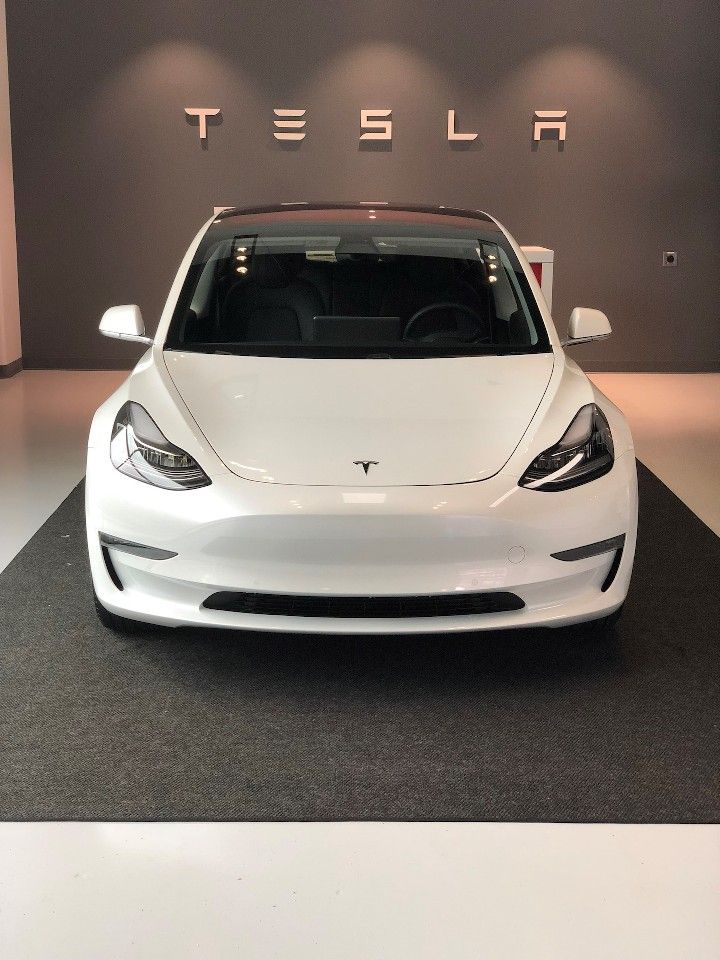

Another product is the Tesla Model 3, which uses an electric drivetrain to cut emissions. Its design emphasizes energy efficiency and recyclable components in the battery and body.

These products show how design choices like material selection and energy use can lower environmental impact.

Corporate Sustainability Initiatives

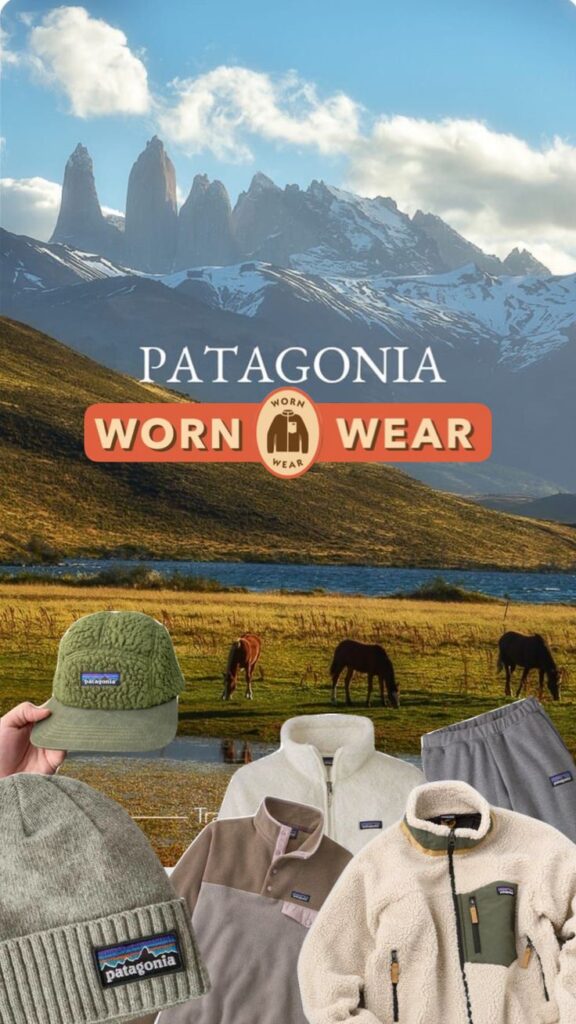

Patagonia integrates sustainability in all parts of its business. It uses recycled materials like polyester from plastic bottles. It also repairs gear to extend product life and reduce waste.

IKEA has set clear goals to use only renewable or recycled materials by 2030. It redesigns products to be easier to recycle and works on renewable energy in production.

Both companies show how long-term plans combined with design changes help meet sustainability goals.

Future Trends in Green Industrial Design

Green industrial design is evolving to focus more on sustainability and innovation. Key developments include adopting closed-loop systems and creating new technologies that reduce environmental impact.

Circular Economy Integration

This trend centers on designing products and processes so materials are reused instead of discarded. Companies aim to extend the life cycle of resources by making items easier to repair, upgrade, and recycle.

Designers prioritize modular parts that can be replaced without throwing away the whole product. They also use materials that break down naturally or can be recycled repeatedly. The goal is to reduce waste and lower production costs by keeping resources in use longer.

Many industries now track product life cycles with digital tools. These help companies collect used materials and bring them back into manufacturing, reducing the need for raw resources.

Emerging Eco-Innovations

New technologies are shaping the future of green industrial design. Innovations like bio-based plastics and energy-efficient production methods are becoming more common.

Advances in 3D printing allow companies to minimize excess material during manufacturing. Smart sensors help monitor energy and water use in real time, cutting down waste.

Some firms develop products that absorb carbon or clean air, adding environmental benefits beyond simply being sustainable. These innovations aim to reduce the overall footprint of industrial processes.

- 3shares

- Facebook0

- Pinterest0

- Twitter3

- Reddit0