Barndominiums aren’t fringe anymore. In March 2024, seven percent of U.S. single-family builders delivered at least one barndominium, according to NAHB’s Eye on Housing report. Planning to build in 2026? A pre-engineered timber-frame kit lets you combine a roomy shop with a vaulted-beam barn-style home in weeks, not months. Every beam arrives labeled and precut, slashing job-site waste while the exposed Douglas-fir or cedar frame adds instant curb appeal. Below, we rate seven national kit suppliers—cost, customization, warranty—to help you claim a production slot before next building season.

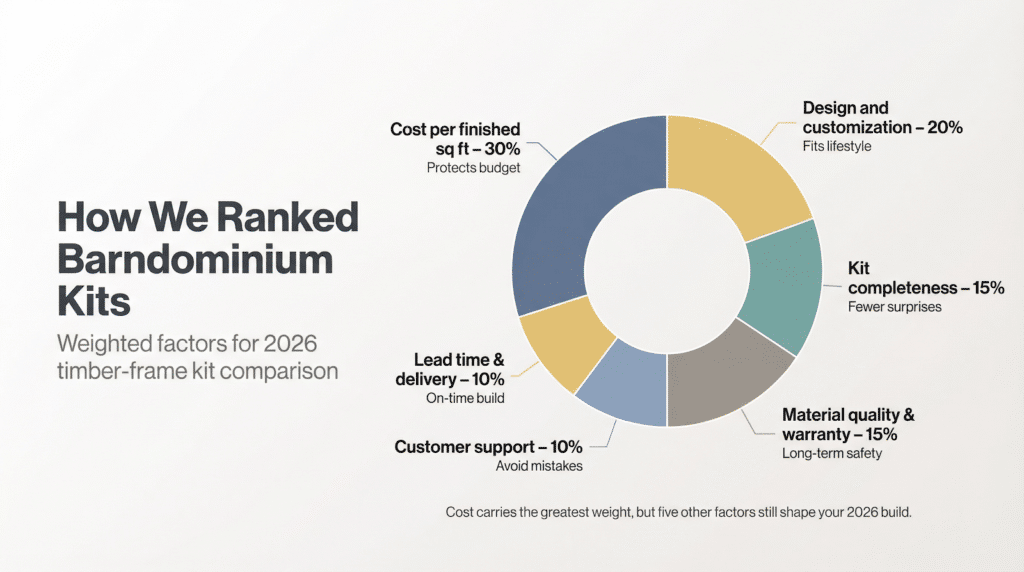

How we ranked the kits

A modern timber-frame barndominium kit combines a roomy shop with a vaulted barn-style home in one structure.

Construction costs matter most. In January 2025, the National Association of Home Builders reported that building expenses consumed 64.4 percent of a new home’s final price in 2024—the highest share on record. Price therefore carries the greatest weight in our scorecard, yet savings alone will not guarantee a smooth build. We scored each kit across six factors that directly influence your schedule, budget, and peace of mind.

Six weighted factors—led by cost per finished square foot—power the ranking of 2026 barndominium kits.

| Factor | Weight | Why it matters to you |

| Cost per finished square foot | 30 percent | Protects your budget without cutting essentials |

| Design and customization | 20 percent | Lets you match the home to your land and lifestyle |

| Kit completeness | 15 percent | Fewer supply-house runs, fewer surprises |

| Material quality & warranty | 15 percent | Safeguards the structure for the long haul |

| Customer support | 10 percent | Quick answers prevent expensive mistakes |

| Lead time & delivery | 10 percent | Keeps your project calendar on track |

To make the list, a company must ship to at least 15 states, provide engineer-stamped plans, and publish current price ranges. Any vendor that missed a requirement was removed before scoring, so you are comparing proven contenders, not question marks.

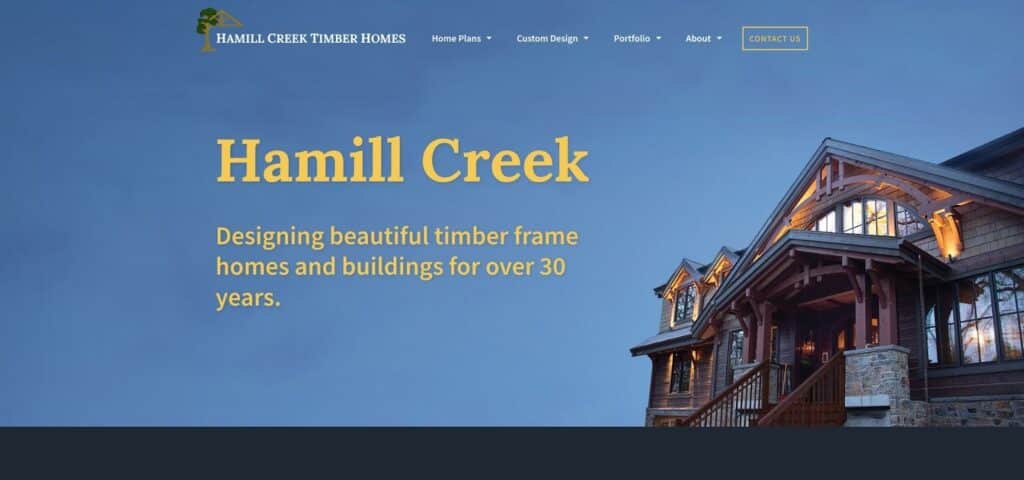

1. Hamill Creek Timber Homes: heavy-timber craft with concierge service

Picture a frame-raising where oak pegs tap into mortises and a Douglas-fir skeleton stands tall before sundown. That speed follows weeks of prep: every beam is milled, test-fitted, and numbered in Hamill Creek’s British Columbia shop, then shipped with engineer-stamped plans.

Hamill Creek Timber Homes specializes in handcrafted timber-frame houses and complete timber-frame kits.

Pricing and what’s included. The timber package runs $60–$90 per square foot for the frame, hardware, detailed drawings, and two factory coats of UV sealer. According to Hamill Creek Timber Homes’ kit and cost guides, which you can review online before you ever talk to a salesperson, that range typically covers structural engineering, 3D and 2D timber-frame drawings, pre-cut and test-fitted timbers, and labeled fasteners, so your crew shows up with an engineered assembly roadmap rather than a loose material list. Because a Hamill crew travels with the kit to raise the structure, labor for that step is already in the price, shortening your schedule while controlling quality.

Choose your depth of kit.

- Frame-only: pairs well with local siding and roofing sources.

- Lock-up shell: adds wall panels and roof to reach dry-in quickly.

- Turnkey exterior: Hamill Creek encloses the envelope so you can focus on interiors.

Why it stands out.

- In-house designers adjust dormers, window walls, or bay widths without change-order delays.

- Timbers come from responsibly managed forests, and off-cuts heat the mill, so waste stays minimal.

- Hamill Creek Timber Homes has shipped and raised custom frames across the United States since 1989, giving permit offices a track record of engineered approvals.

For a barn-style home that feels like handcrafted architecture, place Hamill Creek on your quote list.

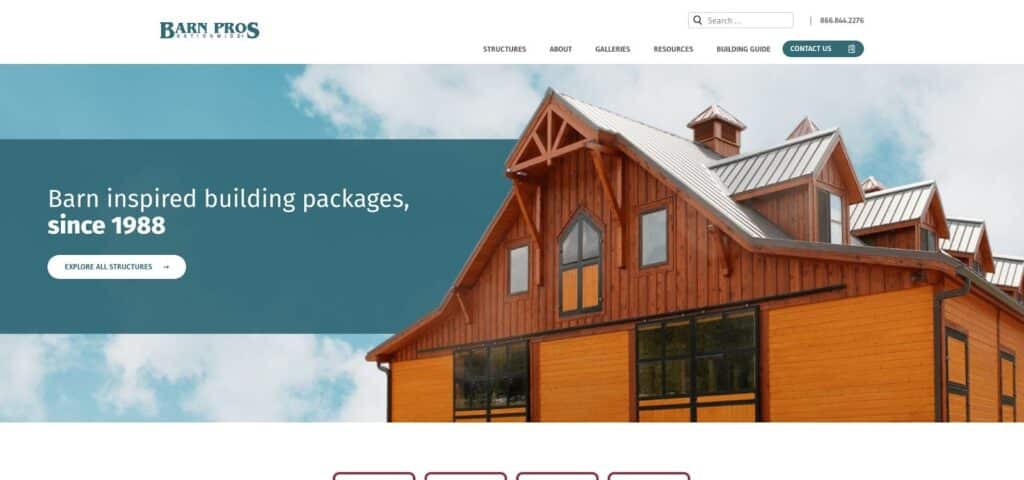

2. Barn Pros: post-and-beam style with Northwest soul

Barn Pros has shipped post-and-beam kits from its Washington facility since 1988, pairing Douglas-fir posts with classic Northwest design. Kits arrive as pre-cut timbers, trusses, siding, metal roofing, and a labeled hardware bundle. Once your permit is approved, Barn Pros estimates an eight- to twelve-week window from order to delivery.

Barn Pros offers post-and-beam barn and barn-apartment kits with seasonal savings for upcoming 2026 projects.

Cost range. A 600-square-foot backyard studio starts near $30,000, while a two-story barn apartment often reaches the low six-figure range after dormers, porches, and cupolas are added. Because you or a local contractor manage the build, labor stays local, keeping cost per square foot competitive.

Customization that stays simple. Swap pine for cedar, add a lean-to, or widen a bay without redrawing the whole plan. Your project specialist updates the blueprints, you approve, and production begins.

Seasonal savings. Orders deposited by December 31, 2025 qualify for up to twelve percent in stacked discounts on barns and shops, or nine percent on barn-apartment kits—capital you can redirect to premium windows or a polished-concrete floor.

Barn Pros suits buyers who want a proven post-and-beam kit and are comfortable coordinating a local crew for the build.

3. DC Structures: nearly turnkey timber-frame package

DC Structures ships what feels like an entire exterior “in a box.” The Meridian barn-home kit starts at $90,503 and arrives with pre-cut framing, cedar siding, windows, exterior doors, metal roofing, and labeled hardware, bundled by room for speed.

DC Structures offers pre-engineered post-and-beam and timber-frame building kits that ship nationwide.

Why it moves fast. Design and engineering take 8–10 weeks, and prefabrication another 5–8 weeks. Ordering about six months before you pour the slab keeps the schedule comfortable. Because every component is engineered to work together, crews dry-in quickly and inspectors review a single, stamped system.

Quality matters. Kiln-dried glulam posts, select-grade trusses, and powder-coated steel hardware resist shrinkage and rust, which lowers long-term maintenance costs.

Flexible but guided. Stretch a bay, vault a ceiling, or add a glass curtain wall—DC’s design staff speaks both architect and builder, turning ideas into shop drawings without stretching the timeline.

DC Structures delivers timber-frame character in one shipment, so you can focus on interior finishes instead of coordinating multiple vendors.

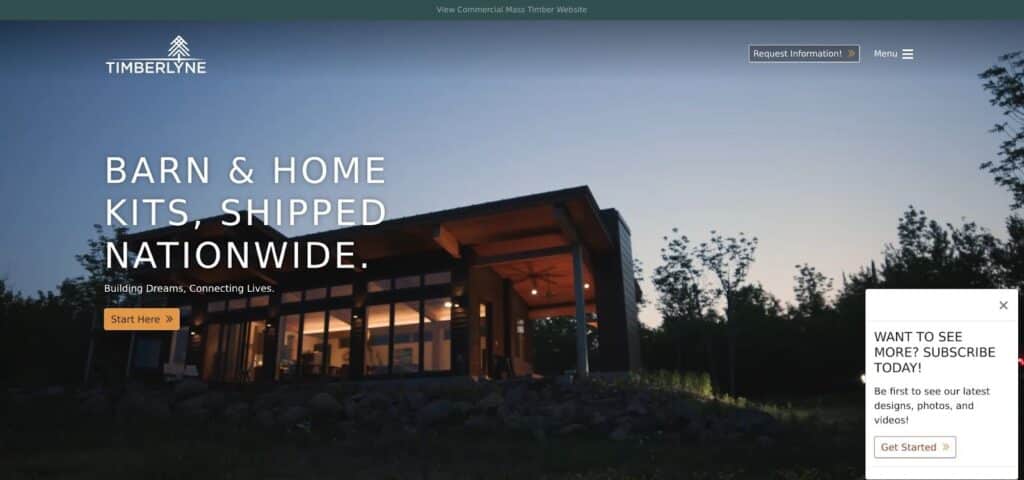

4. Timberlyne: classic barn look, coast-to-coast delivery

Formerly Sand Creek Post & Beam, Timberlyne ships CNC-cut post-and-beam kits to all 50 states. Its catalog runs from compact 480-square-foot cabins to barn homes that exceed 2,500 square feet, each built from 8×8 (or larger) timbers with steel-plate joinery.

Timberlyne ships CNC-cut post-and-beam barn home kits nationwide, from compact cabins to spacious barn homes.

Pricing sweet spot. The 480-square-foot “Poppy” kit lists at $29,879, while popular 2,600-square-foot designs like the “Gunnar” start near $87,000. Freight is rolled into the quote, so no surprise surcharges appear later.

Three-step process.

- Pick a pre-designed package.

- Join a design call to stretch bays, add porches, or swap pine siding for cedar.

- Receive a labeled kit—beams, girts, roof decking—plus plans and phone support for your crew.

Owner-led assembly. You supply the slab and telehandler; pre-drilled connections and a detailed manual keep weekend builds moving.

Timberlyne offers classic barn character, flexible layouts, and mid-tier pricing, making it a smart choice for buyers who want authentic wood aesthetics without hiring a bespoke architect.

5. Hansen Pole Buildings: budget leader for DIY enthusiasts

Hansen pioneered web-based pole-barn kits in 2002 and still runs an online configurator that returns pricing in minutes. A 40 × 60 × 12-foot shell lists at $27,062 with one overhead door, one entry door, engineering, and delivery included.

Hansen Pole Buildings lets DIY buyers start a free pole barn quote online by selecting building use and dimensions.

Why costs stay low.

- Post-frame construction uses fewer studs than stick framing, cutting lumber bills.

- You choose width, bay spacing, colors, and loft options; the CAD team then produces state-stamped plans and loads every board, screw, and closure onto one flatbed.

- Labor stays local—either your own effort or a hired crew—so no national travel surcharge inflates the budget.

Support for first-timers. The free “Pole Barn Guru” helpline answers footing depth, purlin spacing, and trim questions, often the same day.

Know the trade-offs. You pour the slab, bolt each truss, and finish the interior, yet the savings can fund better windows, HVAC, or shop tools. For buyers focused on maximum square footage per dollar, Hansen offers the quickest path to a roomy barn-style shell.

6. Worldwide Steel Buildings: wide-open interiors and a 50-year warranty

Worldwide Steel designs clear spans up to 80 ft in its open-web truss system, creating space for RV bays, basketball courts, or a full woodworking shop. Kits arrive as bolt-together trusses, factory-punched purlins, and 26-gauge panels, with no welding required. Two or three people and a scissor lift can stand the frame in a long weekend.

Worldwide Steel Buildings offers pre-engineered clear-span steel building kits with design tools and decades of experience.

Durability you can insure. Every structure carries a 50-year transferable warranty on the steel frame, and many insurers trim premiums 10–15 percent for non-combustible homes in wildfire or hurricane zones.

Cost range. A basic shell runs $25–$30 per square foot, so a 2,400-square-foot barn-home lands near $60,000 before slab and finishes. Steel pricing has remained steady through recent lumber spikes, keeping budgets predictable.

Things to plan for. You frame interior walls inside the shell and add spray-foam insulation before drywall, yet the payoff includes radiant-barrier coatings and deep overhangs that reduce long-term energy costs.

For buyers who prize space, strength, and low maintenance, Worldwide Steel belongs on the quote list.

7. Morton Buildings: turnkey expertise for stress-free builds

Morton acts as a single point of contact. One contract covers design, materials, labor, and its proprietary Morton Foundation System™ which keeps wood above grade. A local consultant visits your site, sketches the layout, and sets a timeline; Morton crews then handle everything from concrete piers to final exterior trim.

Morton Buildings offers turnkey post-frame homes, shop-houses, and hobby buildings built to last for decades.

Cost range. An insulated, lockable shell runs $75–$125 per square foot. A fully finished interior adds $75–$150 depending on selections. These figures include labor and project management, so schedules stay on track.

Built to last. Laminated wood columns mount to concrete piers, and hi-rib steel panels carry multi-decade warranties. Morton’s service team returns for any warranty touch-ups long after move-in.

Busy homeowners can hand Morton the keys and receive a weather-tight shell ready for paint and furniture on the agreed date.

Quick-compare cheat sheet

Looking for the highlights in one scan? The table below pulls pricing and lead-time data published by each provider in late 2025. Use it to match a kit to your budget, timeline, and appetite for DIY.

| Provider | Base price (2025)* | Structure type | Warranty | Core kit contents | Typical lead time | Best for |

| Hamill Creek | $60–$90 / sq ft (frame) | Heavy timber | Frame raised by Hamill crew | Frame, hardware, stamped plans, on-site raising | 10–14 weeks | Showcase timber homes |

| Barn Pros | 480-sq-ft studio ≈ $29,900; larger shells mid-$100,000s | Post-and-beam wood | Component warranties | Structure, siding, metal roof | 8–12 weeks | Rustic barn style with local GC |

| DC Structures | Meridian 2,000-sq-ft shell from $90,503 | Heavy timber | Manufacturer warranties | Frame, siding, windows, doors, roof | 12–16 weeks | Nearly turnkey exterior |

| Timberlyne | 480-sq-ft kit $29,879; 1,600-sq-ft about $100,000 | Post-and-beam wood | Per-component | Pre-cut frame, siding, roof, support line | 10–14 weeks | Classic barn look, owner build |

| Hansen Pole | $20–$30 / sq ft shell (e.g., 40 × 60 × 12 kit $27,062) | Pole-frame wood + steel | Engineering guarantee | Posts, trusses, steel, stamped plans | 6–10 weeks | DIYers maximizing square footage |

| Worldwide Steel | $25–$30 / sq ft shell | All-steel clear span | 50-year structure | Bolt-together frame, panels, drawings | 8–12 weeks | Wide-open interiors, low upkeep |

| Morton Buildings | $75–$125 / sq ft shell, labor included | Post-frame wood + steel | Multi-decade materials + workmanship | Design, materials, in-house build crew | Per contract | Turnkey, hands-off buyers |

*Base prices cover the kit or dried-in shell and delivery; slab, utilities, and interior finishes are extra.

Pick the column that matters most—price, warranty, or convenience—and request updated quotes before securing a 2026 build slot.

- 3shares

- Facebook0

- Pinterest0

- Twitter3

- Reddit0